Smelting method of ultralow manganese steel

A smelting method, ultra-low manganese steel technology, applied in the field of steelmaking, can solve the problems of high Mn content, difficulty in making, and inability to produce ultra-low manganese steel, etc., and achieve the effect of improving the smelting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Taking the 260t converter as an example, the dual production process route of molten iron pretreatment-converter-LF furnace-RH-continuous casting is adopted, including the following steps:

[0038] Step 1. Preparation

[0039] Before the production of this steel type, it is necessary to produce one pour (6 cans) of ultra-low carbon steel, and the steel ladle of these 6 cans of steel is used for the next pour of ultra-low manganese steel to ensure the cleanliness of the steel ladle.

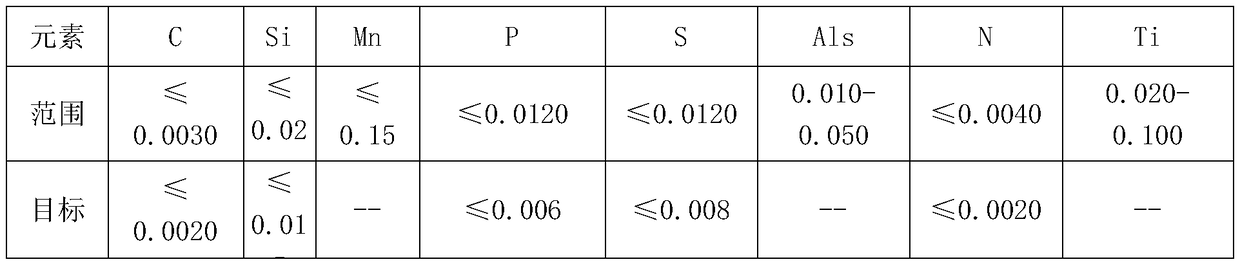

[0040] Before the production of this steel type, one pour (6 cans) of ultra-low carbon steel should be produced. The composition requirements of ultra-low carbon steel are shown in Table 1:

[0041] Table 1 Ultra-low carbon steel composition table Unit: mass percentage content

[0042]

[0043] Step 2. Hot metal pretreatment

[0044] 1. Iron selection target: molten iron temperature 1350°C, molten iron Si mass percentage content 0.45%, molten iron Mn mass percentage content 0.15%, molt...

Embodiment 2

[0066] Taking the 260t converter as an example, the dual production process route of molten iron pretreatment-converter-LF furnace-RH-continuous casting is adopted, including the following steps:

[0067] Step 1. Preparation

[0068] Before the production of this steel type, it is necessary to produce one pour (6 cans) of ultra-low carbon steel, and the steel ladle of these 6 cans of steel is used for the next pour of ultra-low manganese steel to ensure the cleanliness of the steel ladle.

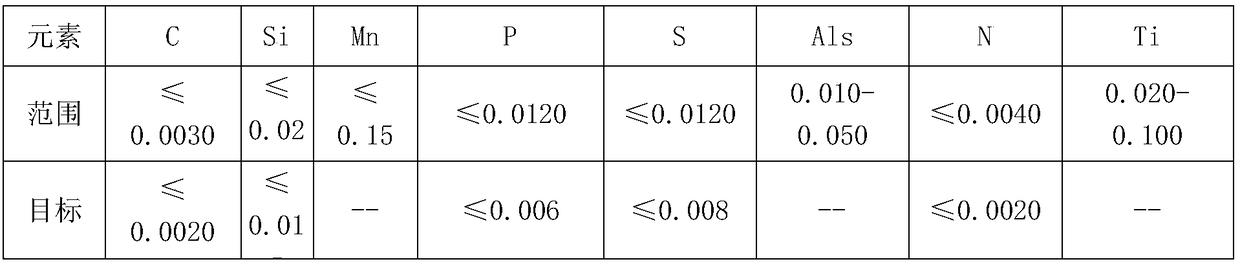

[0069] Before the production of this steel type, one pour (6 cans) of ultra-low carbon steel should be produced. The composition requirements of ultra-low carbon steel are shown in Table 1:

[0070] Table 2 Ultra-low carbon steel composition table Unit: mass percentage content

[0071]

[0072] Step 2. Hot metal pretreatment

[0073] 1. Iron selection target: molten iron temperature 1350°C, molten iron Si mass percentage content 0.45%, molten iron Mn mass percentage content 0.15%, molten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com