Refining process of glyceride type fish oil

A technology of glyceride type and processing technology, which is applied in the field of glyceride type fish oil refining and processing technology, can solve the problems of difficulty in obtaining high-content products, difficulty in realizing large-scale production, reducing production costs, etc., so as to reduce production costs and equipment investment. , Overcome the effect of poor lye dispersion and prevent waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

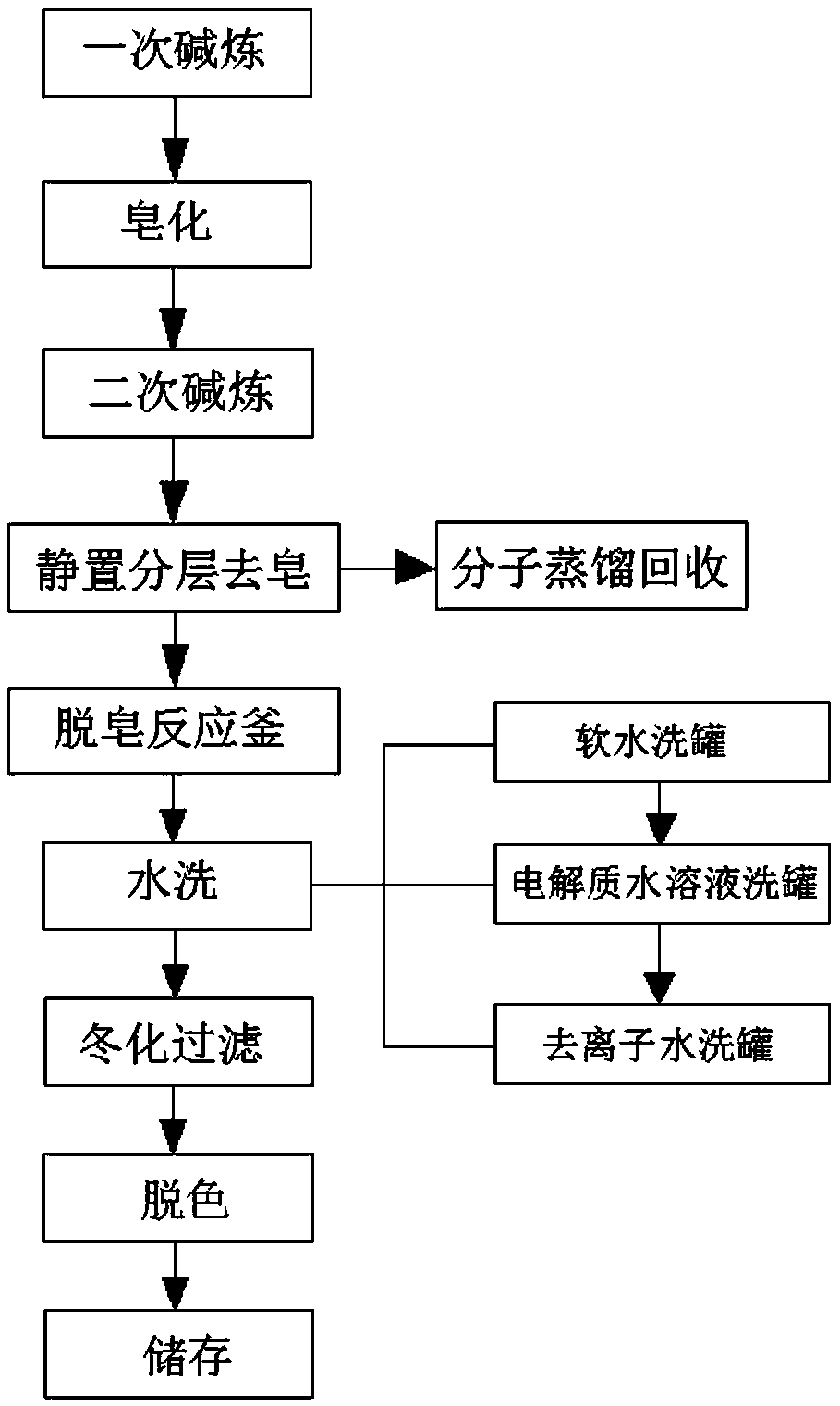

[0040] see figure 1 , a kind of glyceride type fish oil refining process, specifically comprises the following steps:

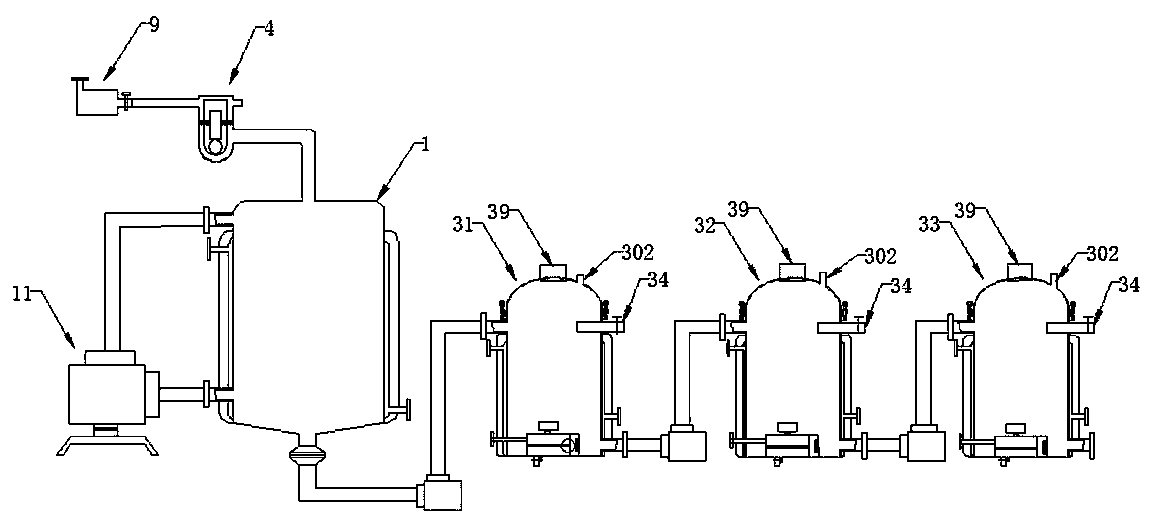

[0041] S1. Transport the crude fish oil with a weight of 1.5t after being metered by the metering pump to the alkali refining tank 1 through the feed pipe, and simultaneously open the static mixer 11 connected to the alkali refining tank 1 and the heating device arranged outside the alkali refining tank 11 , the heating device can be heated by steam, and the hair fish oil is heated and circulated and stirred (not shown in the figure);

[0042] S2. Prepare the light lye containing sodium hydroxide with a mass fraction of 4% and heat the light lye synchronously with the hairy fish oil. When the hairy fish oil and the light lye are heated to 38°C at the same time, slowly add the light lye to the alkali refining In tank 1, the amount of alkali added for the first alkali refining is calculated according to the acid value of the crude fish oil minus 1.5, so that t...

Embodiment 2

[0053] see figure 1 , a kind of glyceride type fish oil refining process, specifically comprises the following steps:

[0054] S1. Transport the crude fish oil with a weight of 2.5t after being metered by the metering pump to the alkali refining tank 1 through the feed pipe, and simultaneously turn on the static mixer 11 connected to the alkali refining tank 1 and the heating device arranged outside the alkali refining tank 11 (not shown in the figure), the heating device can be heated by steam; the hair fish oil is heated and circulated;

[0055] S2. Prepare the light lye containing sodium hydroxide with a mass fraction of 6% and heat the light lye synchronously with the hairy fish oil. When the hairy fish oil and the light lye are heated to 42°C at the same time, slowly add the light lye to the alkali refining In tank 1, the amount of alkali added for the first alkali refining is calculated according to the acid value of the crude fish oil minus 1.5, so that the light lye a...

Embodiment 3

[0066] see figure 1 , a kind of glyceride type fish oil refining process, specifically comprises the following steps:

[0067] S1, transport the crude fish oil weighing 2t after metering by the metering pump to the alkali refining tank 1 through the feed pipe, and simultaneously open the static mixer 11 connected to the alkali refining tank 1 and the heating device arranged outside the alkali refining tank 11, The heating device is steam heating, and the hair fish oil is heated and circulated for stirring;

[0068] S2. Prepare the light lye containing sodium hydroxide with a mass fraction of 5% and heat the light lye synchronously with the hairy fish oil. When the hairy fish oil and the light lye are heated to 40°C at the same time, slowly add the light lye to the alkali refining In tank 1, the amount of alkali added for the first alkali refining is calculated according to the acid value of the crude fish oil minus 1.5, so that the light lye and the crude fish oil are fully m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com