Nigre removal process and equipment for vegetable oil and vegetable oil production process

A production process and vegetable oil technology, which is applied in the dry soap removal process of vegetable oil, and can solve the problems of high difficulty in wastewater treatment, large water resources, and environmental pollution by wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

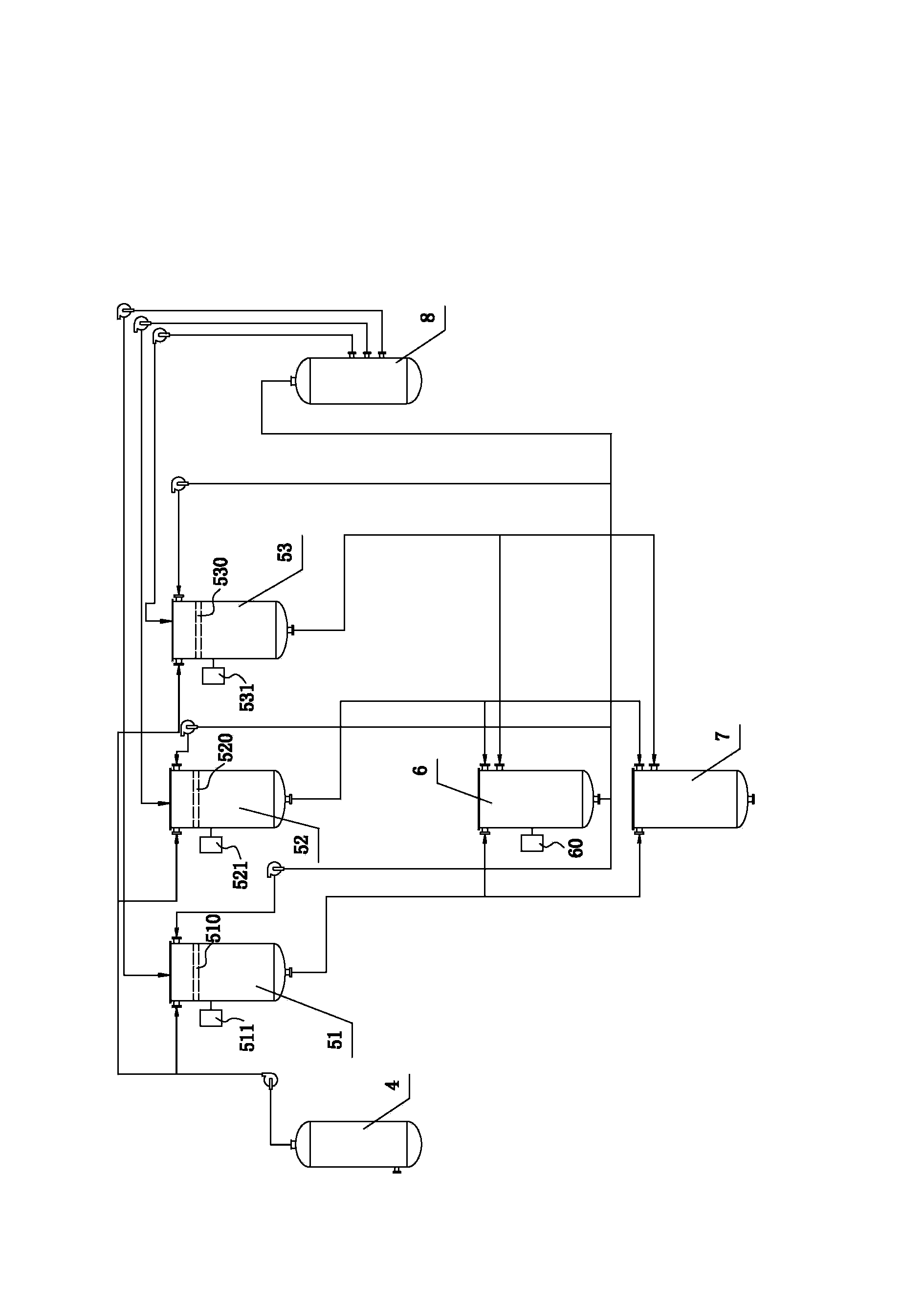

[0055] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

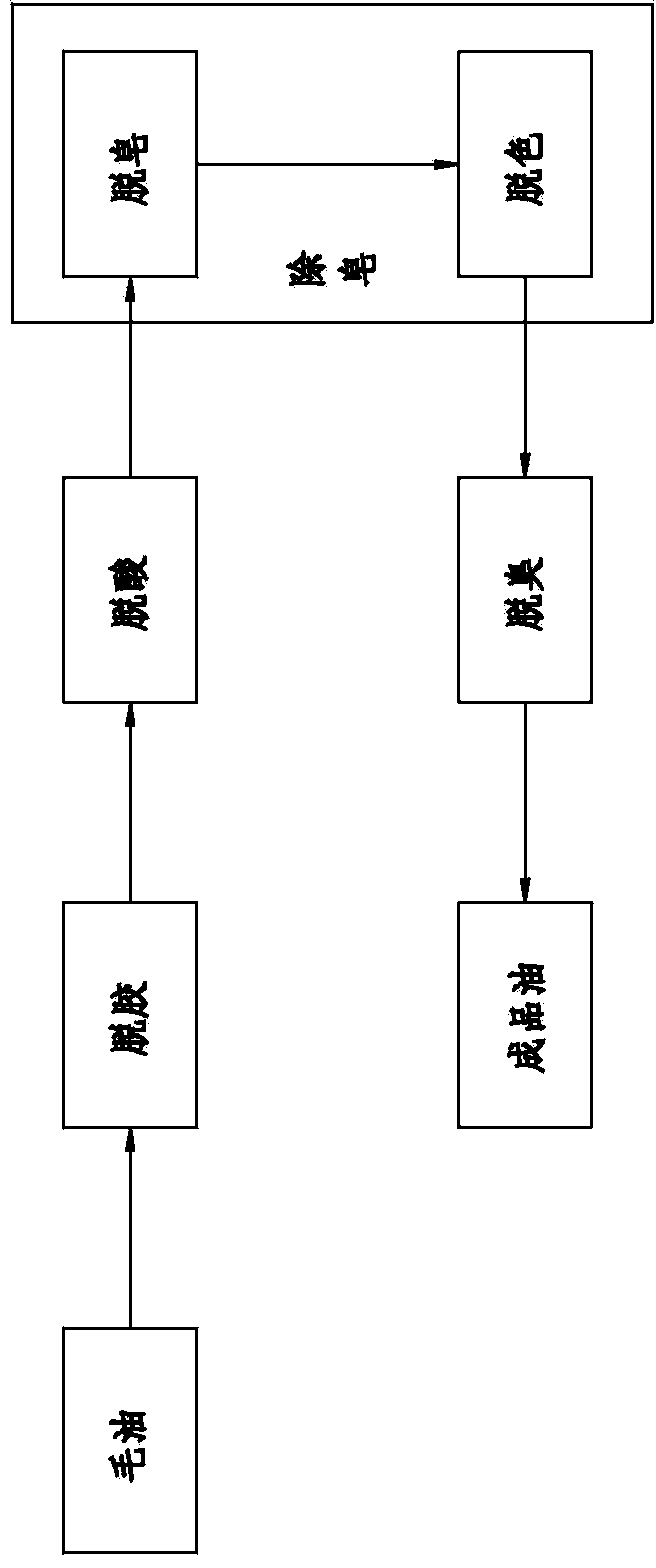

[0056] figure 1 A flow chart showing a vegetable oil production process. Crude oil needs to go through four processes of degumming, deacidification, soap removal and deodorization in sequence before it can be processed into finished oil. The soap removal process can be divided into desoaping process and decolorization process. In the degumming process, phosphoric acid needs to be added to the crude oil, mixed thoroughly and then filtered to remove protein and phospholipids in the crude oil. In the deacidification process, it is necessary to add alkali to the vegetable oil after the degumming process for neutralization reaction to remove free fatty acids in the vegetable oil. The deodorization process includes the following steps: distilling the vegetable oil after the soap removal process at a temperature of 230° C. to 290° C. to remove phenolic compoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com