Vegetable insulating oil refining process taking rapeseed oil as raw material

A technology of vegetable insulating oil and rapeseed oil, applied in organic insulators, fat oil/fat refining, organic liquid insulators, etc., can solve the problem of inability to prepare high-quality insulating oil at one time, rise of acid value in rapeseed oil, complicated filtration procedures, etc. problems, to achieve the effect of reducing saponification, improving transesterification rate, good physical and chemical properties and electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

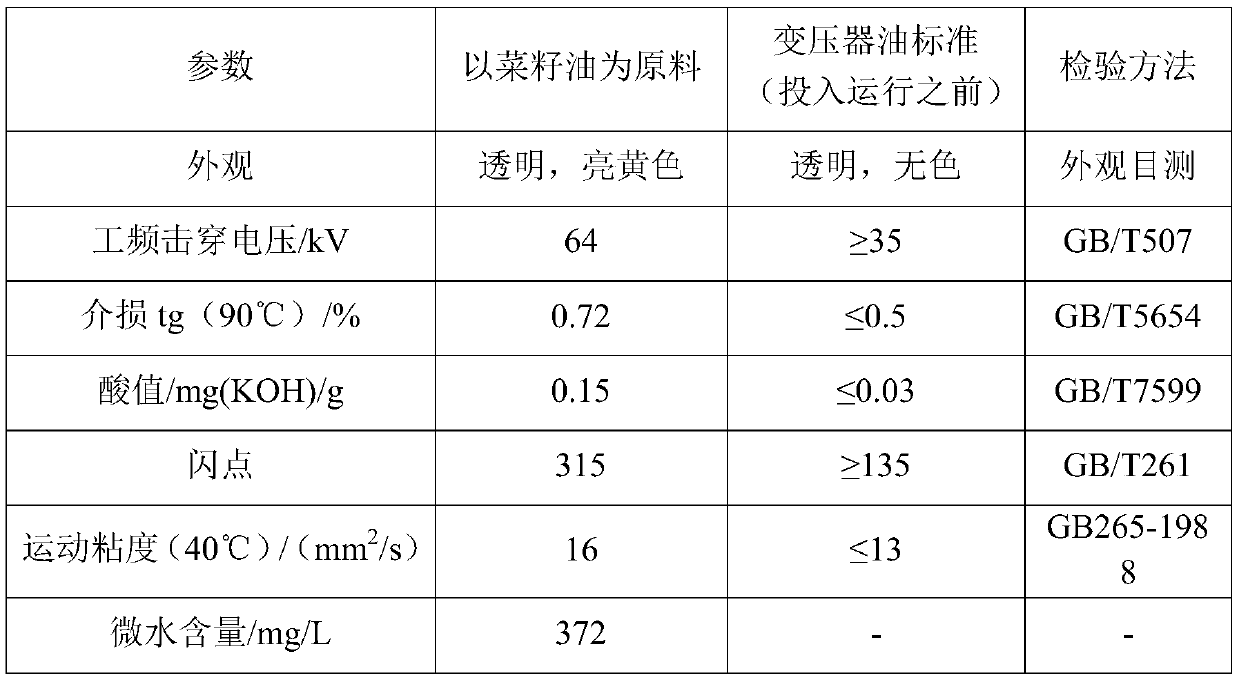

Embodiment 1

[0043] A vegetable insulating oil refining process using rapeseed oil as raw material, said method comprising the following steps:

[0044] (1) Degumming, washing, preliminary deacidification, vacuum distillation, atmospheric decolorization and deodorization are carried out after methyl esterification of rapeseed oil to obtain refined rapeseed oil;

[0045] (2) Carry out secondary alkali refining treatment to the refined rapeseed oil; Carry out vacuum distillation afterwards, remove unnecessary moisture in the oil;

[0046] (3) Put the oil after vacuum distillation into the stirring tank to cool, then add antioxidant and anticoagulant respectively when the stirring tank is stirred to 50-60r / min, and continue stirring for 4-6 hours to obtain the modified dish seed oil.

[0047] Preferably, in said step (1), the following steps are included:

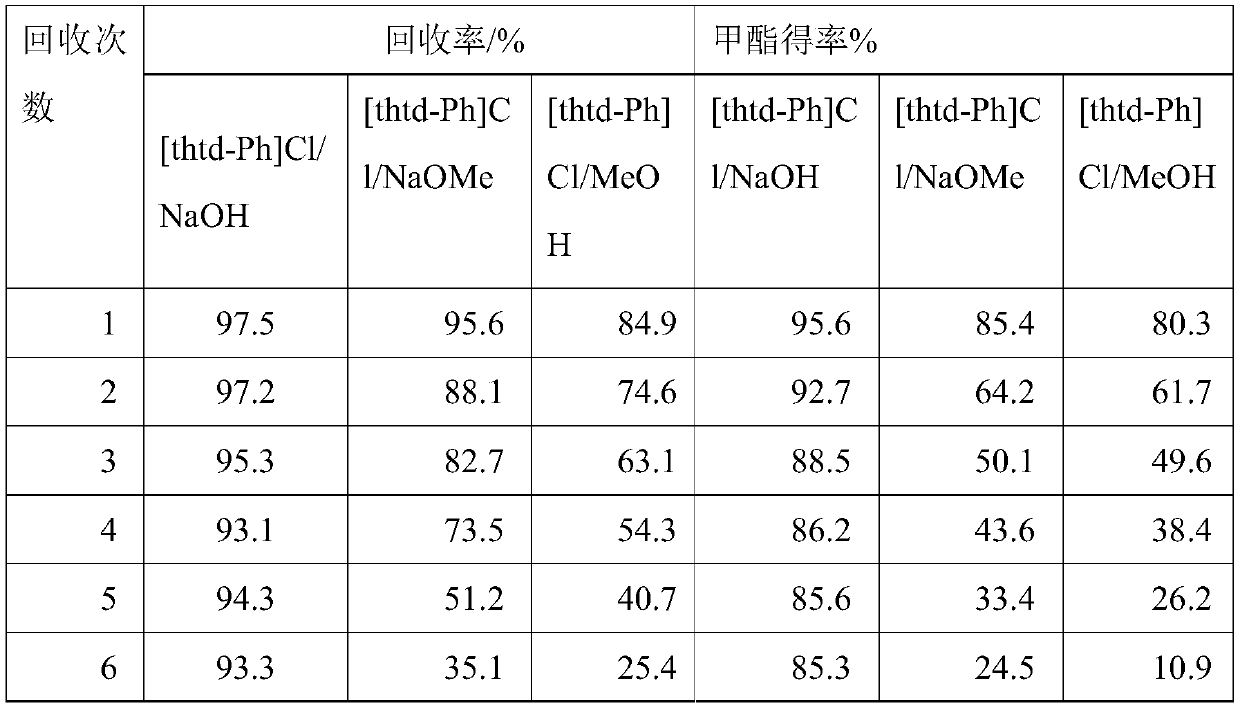

[0048] (1.1) Using rapeseed oil as raw material, add catalyst (NaOH), ionic liquid [thtd-Ph]Cl, methanol, carry out transesterification...

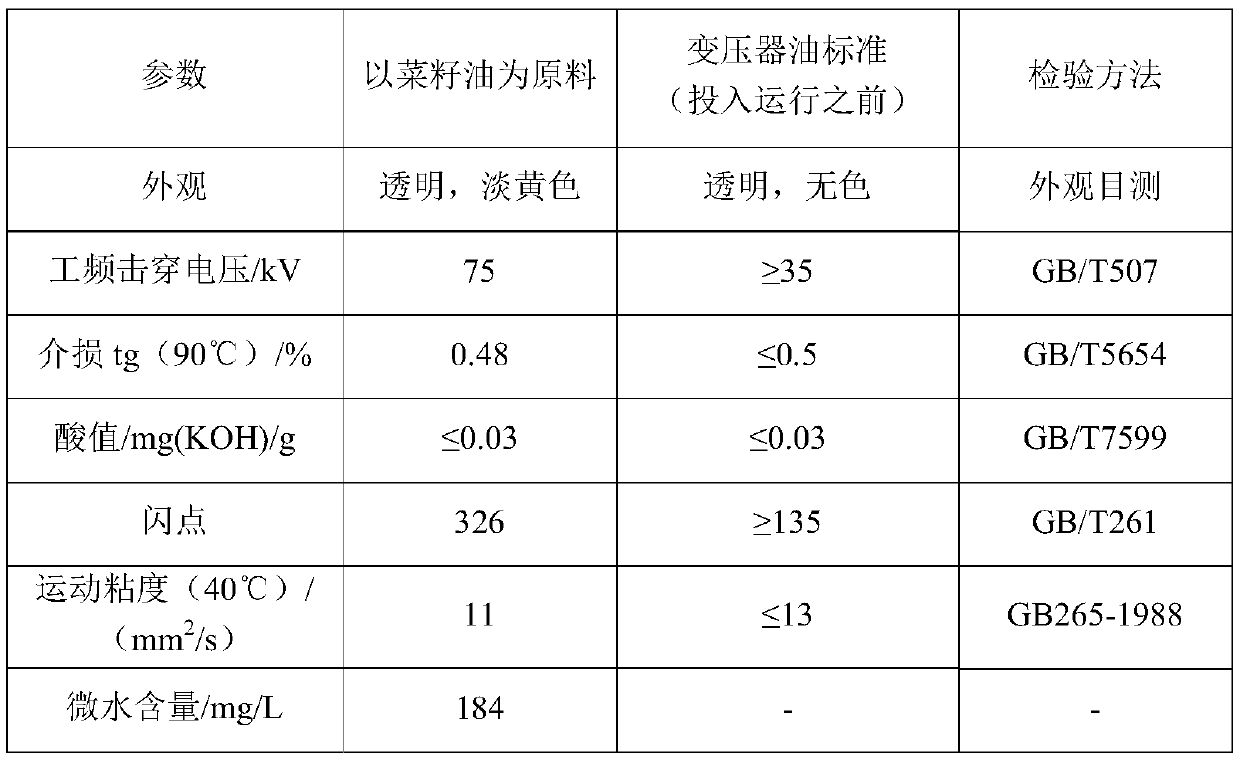

Embodiment 2

[0069] A vegetable insulating oil refining process using rapeseed oil as raw material, said method comprising the following steps:

[0070] (1) Degumming, washing, preliminary deacidification, vacuum distillation, atmospheric decolorization and deodorization are carried out after methyl esterification of rapeseed oil to obtain refined rapeseed oil;

[0071] (2) Carry out secondary alkali refining treatment to the refined rapeseed oil; Carry out vacuum distillation afterwards, remove unnecessary moisture in the oil;

[0072] (3) Put the oil after vacuum distillation into the stirring tank to cool, then add antioxidant and anticoagulant respectively when the stirring tank is stirred to 50-60r / min, and continue stirring for 4-6 hours to obtain the modified dish seed oil.

[0073] Preferably, in said step (1), the following steps are included:

[0074] (1.1) Using rapeseed oil as raw material, add catalyst (NaOH), ionic liquid [thtd-Ph]Cl, methanol, carry out transesterification...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com