Method for preparing oil at low temperature

A low-temperature, oil-based technology, applied in the field of low-temperature production of oil and oil, and oil extraction from oil plants, can solve the problems of long processing time, no method for low-temperature production and refining of oil, and high cost, and achieves low protein denaturation and effective amino acids. The effect of low loss and reduced fiber content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

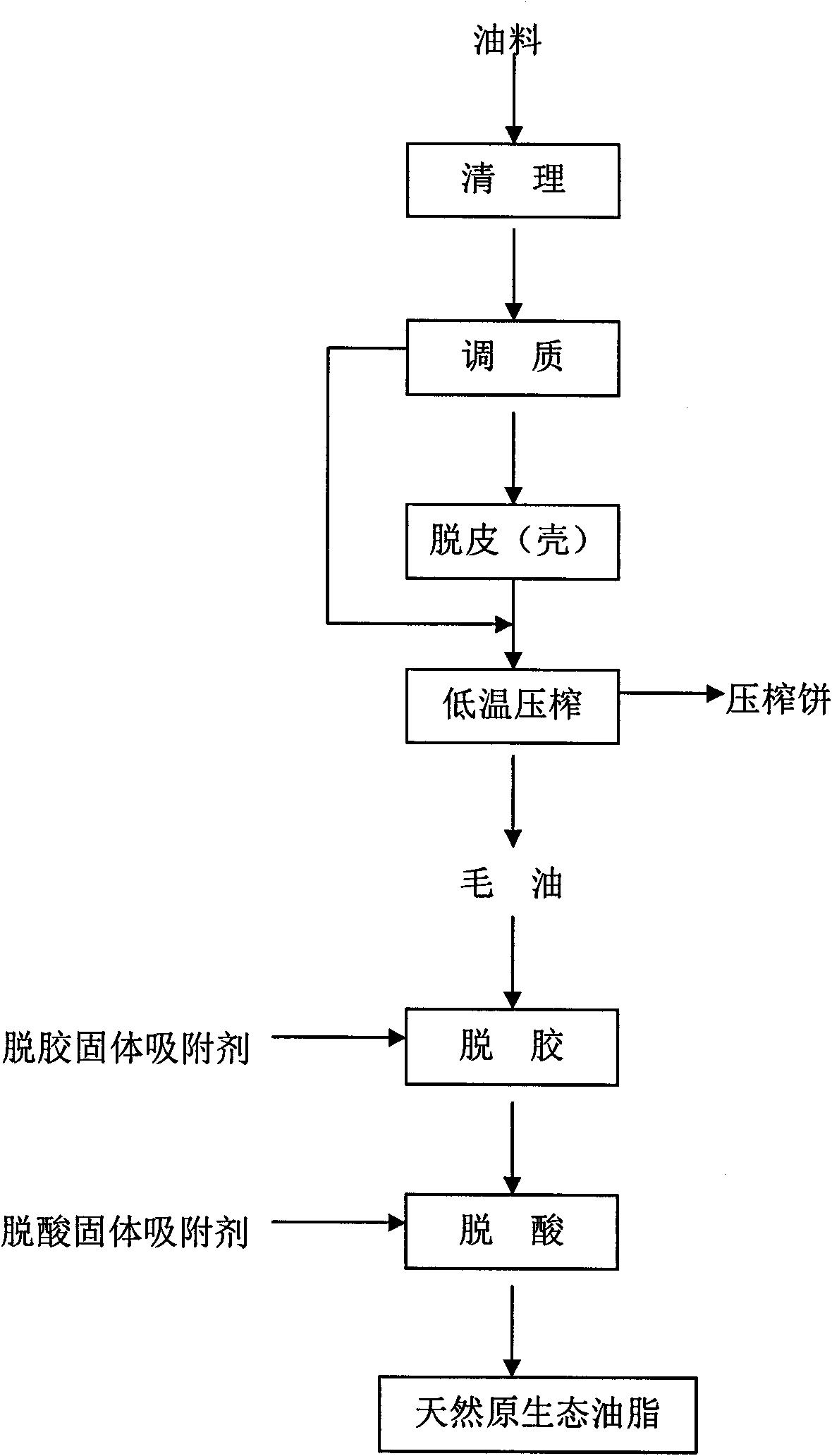

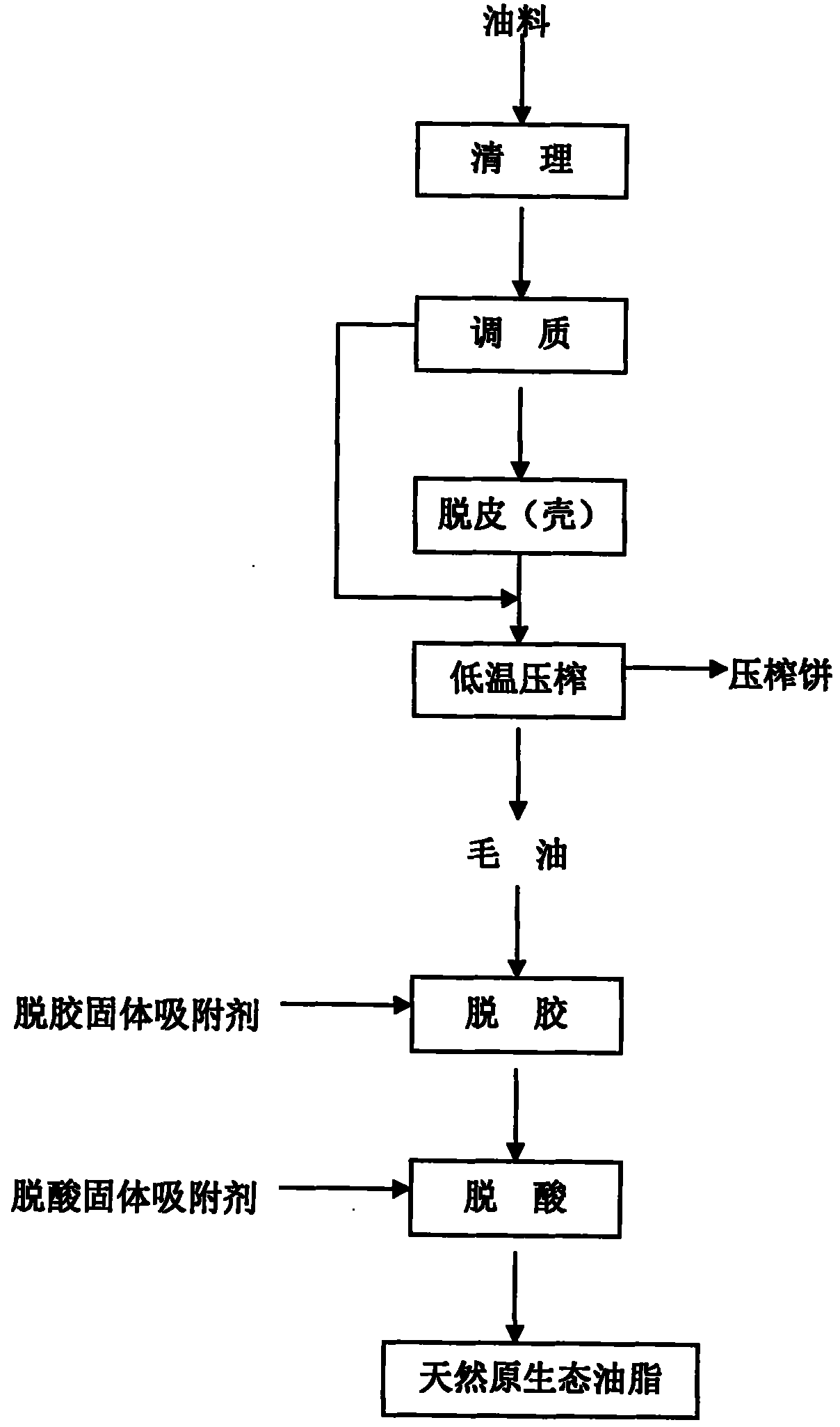

[0049] Such as figure 1 Shown, a kind of method for grease low temperature preparation, it comprises the steps:

[0050] 1) cleaning: use rapeseed as raw material to clean and remove impurities;

[0051] 2) conditioning: then drying the moisture of the rapeseed to 7wt%, and cooling the rapeseed to 50°C;

[0052] 3) Low-temperature pressing: use a rapeseed shelling separator to peel and separate the conditioned rapeseed, measure the peeling rate to 95%, and obtain rapeseed kernels; collect the rapeseed kernels, and use a screw press to squeeze them, and the temperature for pressing is 35 DEG C, the moisture content of the rapeseed kernel that goes into the press is 8wt%; Obtain rapeseed crude oil;

[0053] 4) Degumming: Centrifuge the crude rapeseed oil to remove the sediment, measure the acid value to 1.56mgKOH / g, then keep the temperature of the crude rapeseed oil at 30°C, add 0.5% of the crude rapeseed oil to the degummed solid for adsorption agent, the degumming time is ...

Embodiment 2

[0065] Such as figure 1 Shown, a kind of method for grease low temperature preparation, it comprises the steps:

[0066] 1) cleaning: using soybeans as raw materials to clean and remove impurities;

[0067] 2) conditioning: then dry the moisture of soybeans to 9wt%, and cool soybeans to 45°C;

[0068] 3) Low-temperature pressing: direct pressing with a screw press, the pressing temperature is 45°C, and the moisture content of soybeans is 9wt%; crude soybean oil is obtained;

[0069] 4) Degumming: Centrifuge the crude soybean oil to remove the sediment, measure the acid value to 2.05mgKOH / g, then keep the temperature of the crude soybean oil at 40°C, add a degumming solid adsorbent with a mass of 1.5% of the crude soybean oil, and process The time is 0.6h, followed by centrifugation to obtain degummed soybean oil, which is analyzed by heating test. The analysis result shows that there is no precipitate, and the yellow value and red value remain unchanged;

[0070] 5) Deacidi...

Embodiment 3

[0081] Such as figure 1 Shown, a kind of method for grease low temperature preparation, it comprises the steps:

[0082] 1) Cleaning: use camellia oleifera seed as raw material to clean and remove impurities,

[0083] 2) conditioning: then drying the moisture of the camellia oleifera seed to 7.5wt%, and cooling the camellia oleifera seed to 35°C;

[0084] 3) Low-temperature pressing: the camellia oleifera seed is shelled and separated by a camellia seed shelling separator, and the shelling rate is determined to be 90%; the camellia oleifera seed kernel is collected and pressed by a screw press. The temperature for pressing is 30° C., and the moisture content is 7.5wt%; Obtain tea seed crude oil;

[0085] 4) Degumming: Centrifuge the crude tea seed oil to remove the sediment, measure the acid value to 1.80mgKOH / g, then keep the temperature of the crude camellia seed oil at 30°C, add 1% degummed solid of the crude camellia seed oil for adsorption agent, the treatment time is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com