Lithium ion battery anode material manganese lithium phosphate and preparation method thereof

A lithium ion battery, lithium manganese phosphate technology, applied in electrode manufacturing, battery electrodes, chemical instruments and methods, etc., can solve the problems of low purity of synthetic products, poor electrochemical performance, high production cost, and achieve excellent cycle stability, Low production cost and low environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

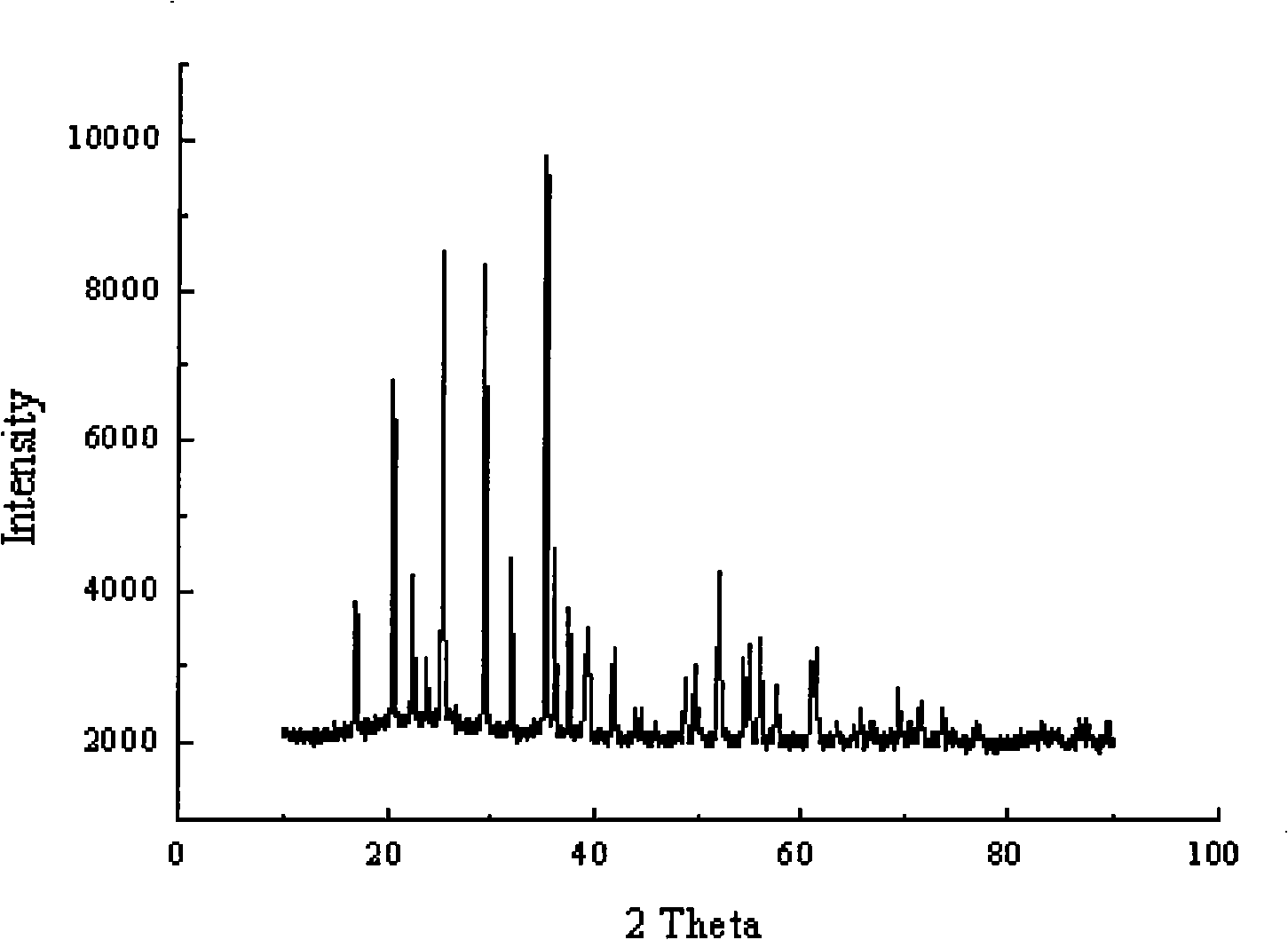

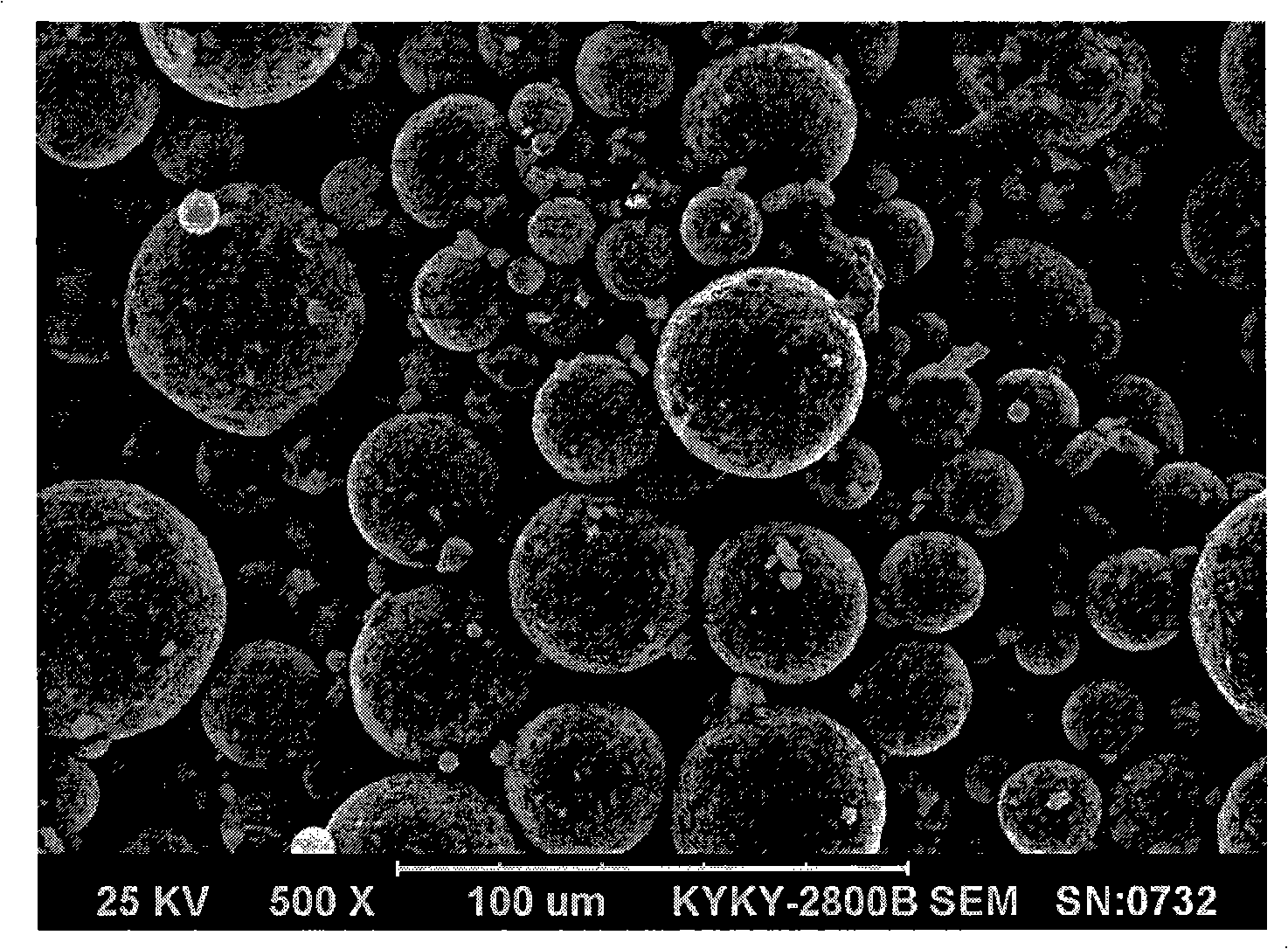

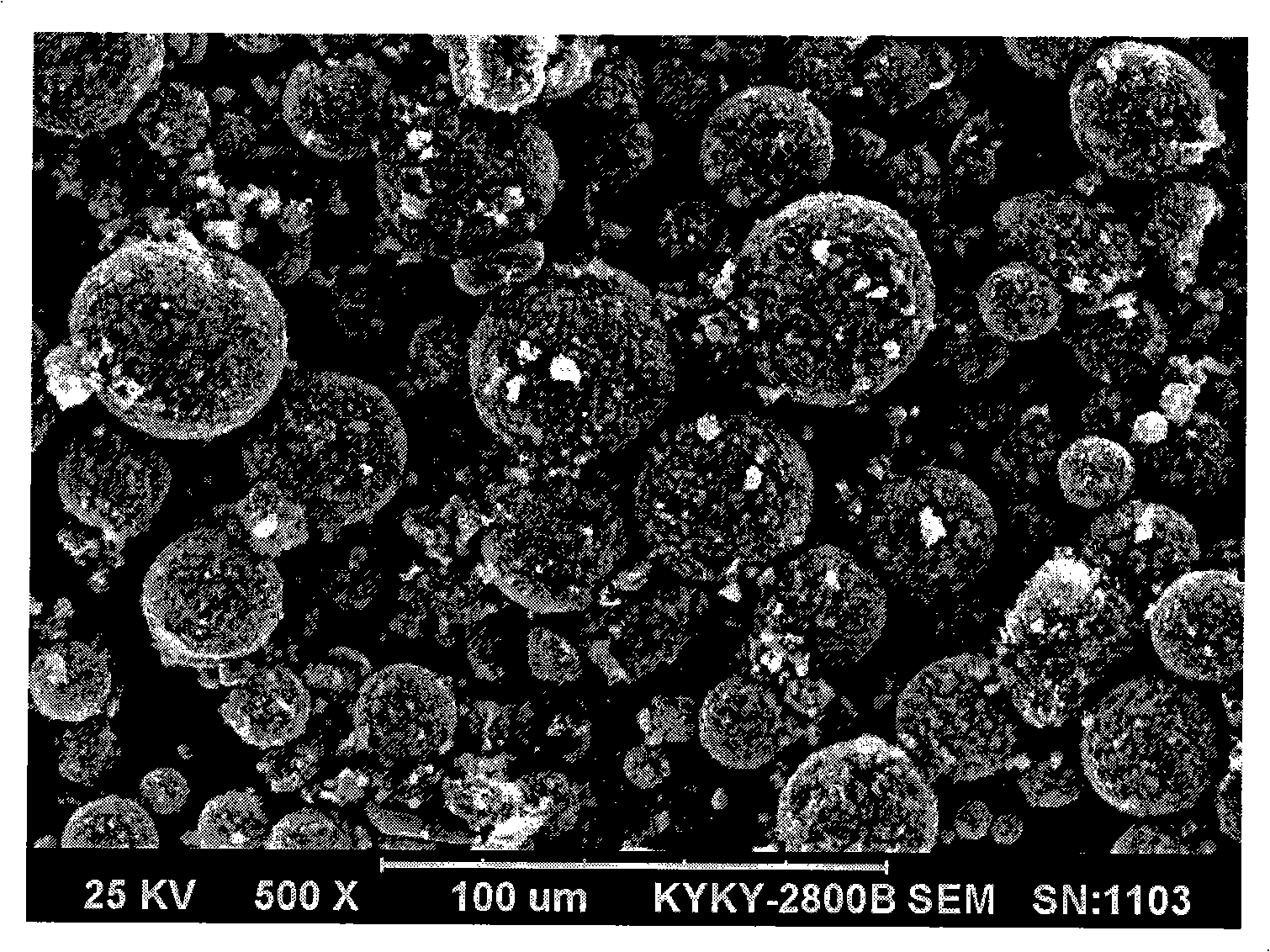

Image

Examples

preparation example Construction

[0038] The preparation method of lithium manganese phosphate lithium ion battery cathode material of the present invention adopts the following steps:

[0039] 1. Preparation of nanoparticles: Lithium source compounds, manganese source compounds, phosphorus source compounds and carbon materials are processed by wet ultra-fine ball milling into submicron or nanoscale particles, which are one-time molding particles, water-soluble manganese source compounds and Carbon materials do not need to be processed in this step. The wet ultra-fine ball mill adopts the SX-2 circulation stirring ball mill of Wuxi Xinguang Powder Processing Technology Co., Ltd., and other ball milling or crushing equipment can also be used: stirring ball mill, sand mill, colloid mill, jet mill, Impact micro-powder ball mill, airflow vortex micro-powder machine, impact pulverizer or rod mechanical pulverizer. Lithium source compounds are lithium hydroxide LiOH, lithium carbonate Li 2 CO 3 , lithium acetate ...

Embodiment 1

[0051] Example 1, the raw materials lithium hydroxide, manganese dioxide, ammonium dihydrogen phosphate and conductive acetylene carbon black were respectively pulverized to a particle size of nanometer order, and 401.3 grams of lithium hydroxide, 811.5 grams of manganese dioxide, and 1099.8 grams of ammonium dihydrogen phosphate were accurately weighed. gram and 114.8 grams of conductive acetylene carbon black were added successively to 1500 milliliters of 20° C. deionized water, and stirred at constant temperature for 3 hours.

[0052] After adding 0.1wt.% CuO to the above sample, ball mill at a speed of 500r / min for 0.5 hours, spray dry and granulate at 100°C, and perform fusion treatment at a speed of 200r / min for 2 hours, and then place the product under argon Under protection, in a box furnace, pretreatment at 300°C for 4 hours at a heating rate of 8°C / min, and natural cooling to obtain the pretreated powder, which is the precursor of lithium manganese phosphate.

[0053...

Embodiment 2

[0056] Example 2, the raw materials lithium hydroxide and manganese acetate were ball milled to submicron size, and 88.29 grams of lithium hydroxide, 468.8 grams of manganese acetate, 220.52 grams of phosphoric acid and 126.4 grams of glucose were accurately weighed. Glucose was dissolved in 1500 ml of deionized water at 90°C, and stirred at constant temperature for 0.5 hours; lithium hydroxide and manganese acetate were added to the above solution in turn, and finally phosphoric acid was added, and stirred at a speed of 150 r / min for 2 hours.

[0057] The above sample was mixed with 2wt.% Al 2 o 3 After mixing, ball mill at a speed of 400r / min for 1 hour, spray dry and granulate at 360°C, and perform fusion treatment at a speed of 600r / min for 1 hour, then place the product in a tube furnace under the protection of argon, Pretreatment was performed at 350°C for 4 hours at a heating rate of 1°C / min, and pretreated powder was obtained after natural cooling.

[0058] The obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com