Thermal circulation system cooled by liquefied natural gas and flow

A technology of thermal cycle system and power cycle, applied in liquefaction, charging system, refrigeration and liquefaction, etc., can solve the problems of insufficient cold utilization of LNG, decreased system efficiency, and yet to achieve zero CO2 emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0110] Referring to Table 2-2 for the thermal performance of the cycle of the first embodiment, the main thermal performance parameters of the cycle of the first embodiment are given under the equilibrium conditions shown in Table 2-1.

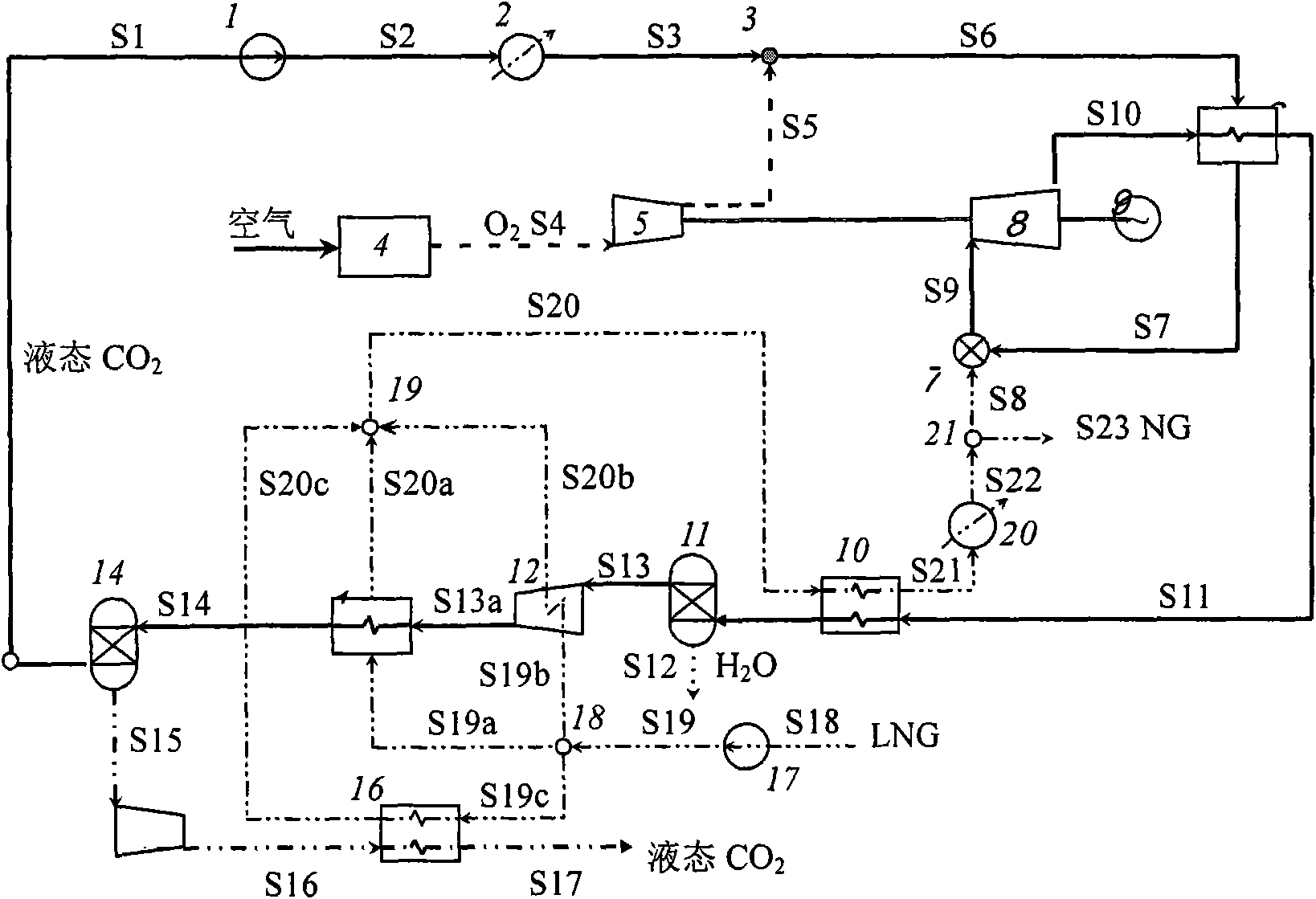

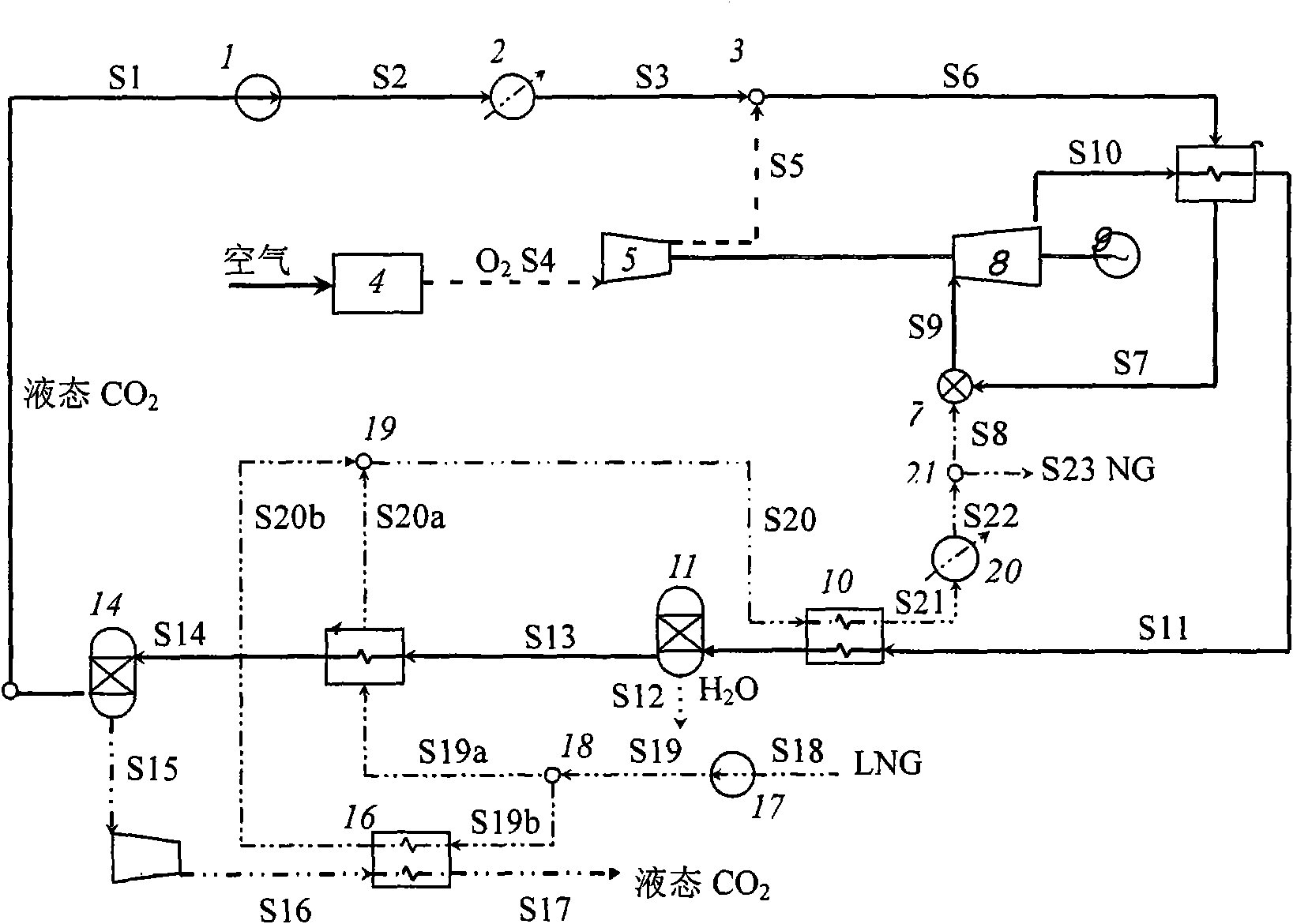

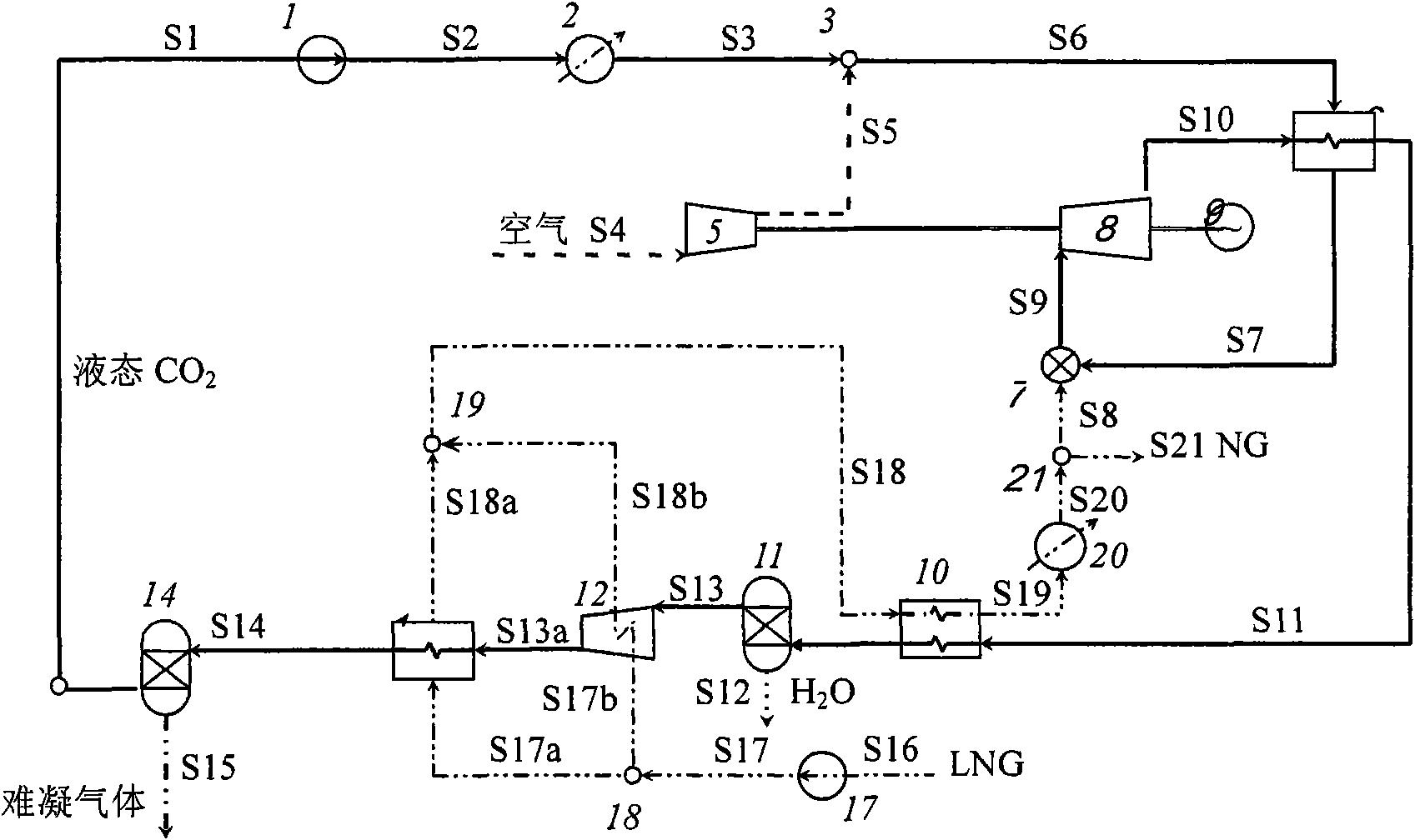

[0111] See the second embodiment figure 2 , the main part of the present invention is based on CO 2 It is a regenerative Brayton-Rankine composite power cycle and a liquefied natural gas (LNG) gasification unit as the main circulating working fluid. Where: 1-Liquid CO 2 Booster pump; 2-evaporator; 3-working medium mixer; 4-air separation unit; 5-compressor; 6-regenerator; 7-combustion chamber; 8-gas turbine; 9-generator; 10 -LNG vaporizer; 11-water separator; 13-CO 2 Condenser; 14-CO 2 Separator; 15-Tail gas compressor; 16-Tail gas heat exchanger; 17-LNG booster pump; 18-LNG splitter; 19-LNG mixer;

[0112] The connection in the above system is a known technology, and the present invention will not be described in detail here.

[0113] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com