Soybean-meal-based wood adhesive and preparing method thereof

A wood adhesive and adhesive technology, applied in the preparation of adhesives, animal glue or gelatin, adhesive types, etc., can solve problems such as formaldehyde pollution, achieve the effect of saving production costs, comprehensively utilizing resources, and meeting water resistance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides an adhesive for wood-based panels, and the adhesive is prepared according to the following weight ratio:

[0039] Demineralized water 73 kg

[0040] Defatted Soy Protein Powder 27 kg

[0041] Denaturant 1.0kg

[0042] Viscosity reducer 0.001kg

[0043] Emulsifier 0.5kg

[0044] Enhancer 7kg

[0045] Among them, the protein content of defatted soybean protein powder is more than 43% (purchased from Huifu Grain and Oil Co., Ltd.); the denaturant is commercially available common guanidine hydrochloride, the viscosity reducer is papain, and the emulsifier is polyvinyl alcohol (purchased from Beijing Chemical Reagent Co., Ltd. Co., Ltd., content 99%); the reinforcing agent is self-made tannin-resorcinol-glutaraldehyde prepolymer (solid content 60%, viscosity 2400mPa.s).

[0046] This embodiment provides the preparation method of above-mentioned adhesive simultaneously, and specific preparation steps are as follows:

[0047] 1) In a mixer equipped...

Embodiment 2

[0052] This embodiment provides an adhesive for wood-based panels, and the adhesive is prepared according to the following weight ratio

[0053] Tap water 71 kg

[0054] Defatted Soy Protein Powder 29 kg

[0055] Denaturant 1.5kg

[0056] Viscosity reducer 0.002kg

[0057] Emulsifier 1.0kg

[0058] Enhancer 12kg

[0059] Among them, the protein content of defatted soybean protein powder is more than 43% (purchased from Huifu Grain and Oil Co., Ltd.); the denaturant is commercially available urea, the viscosity reducing agent is bromelain, and the emulsifier is polyacrylamide (purchased from Beijing Chemical Reagent Co., Ltd. , content 99%); the enhancer is self-made tannin-resorcinol-glutaraldehyde prepolymer (solid content 60%, viscosity 2400mPa.s).

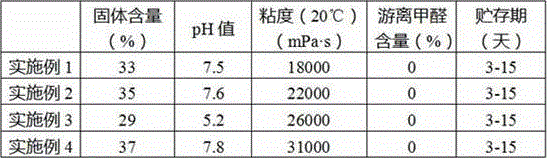

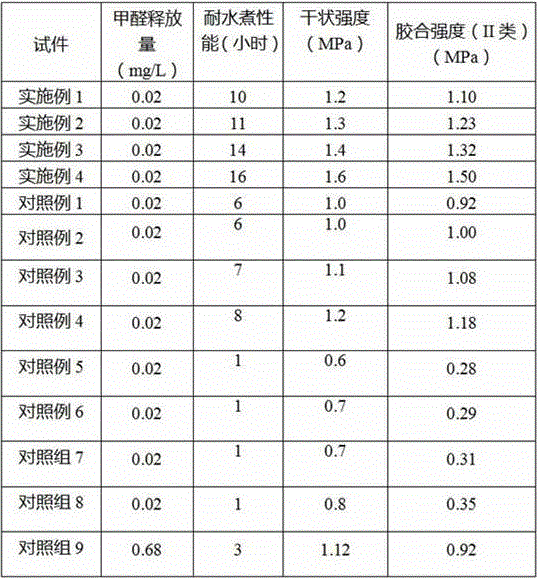

[0060] The preparation method of the adhesive described in this example is the same as in Example 1, and the performance and quality indicators of the obtained adhesive are shown in Table 1.

Embodiment 3

[0062] This embodiment provides an adhesive for wood-based panels, and the adhesive is prepared according to the following weight ratio:

[0063] Demineralized water 69 kg

[0064] Defatted Peanut Protein Powder 31 kg

[0065] Denaturant 1.0kg

[0066] Viscosity reducer 0.002kg

[0067] Emulsifier 1.5kg

[0068] Enhancer 18kg

[0069] Among them, the protein content of defatted soybean protein powder is more than 43% (purchased from Huifu Grain and Oil Co., Ltd.); the denaturant is commercially available urea, the viscosity reducing agent is neutral protease, and the emulsifier is polyetherimide (purchased from Beijing Chemical Industry Co., Ltd. Reagent Co., Ltd., content 99%); the enhancer is self-made tannin-resorcinol-glutaraldehyde prepolymer (solid content 60%, viscosity 2400mPa.s).

[0070] The preparation method of the adhesive described in this example is the same as in Example 1, and the performance and quality indicators of the obtained adhesive are shown in Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com