Zinc catalyst applicable to controllable depolymerization of polyester material and catalytic method thereof

A technology of polyester material and zinc catalyst, which is applied in the field of polyester depolymerization, can solve the problem of increasing synthesis steps, and achieve the effect of simple catalyst structure, less synthesis steps and good universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

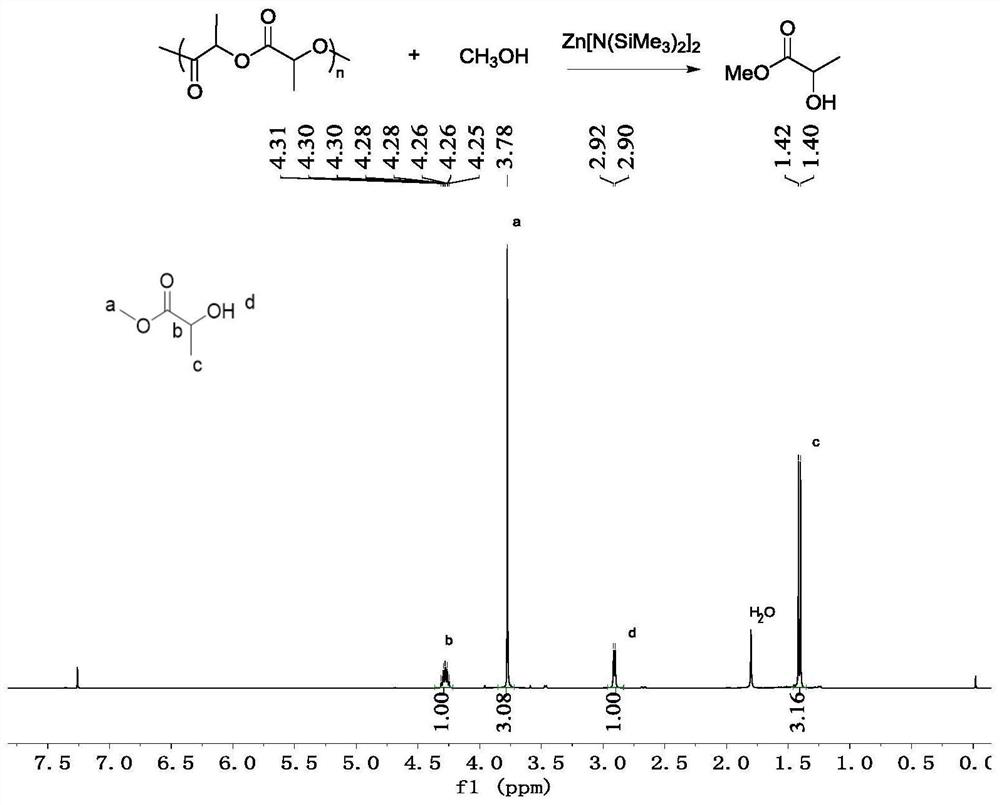

[0031] Example 1: Depolymerization of poly-β-butyrolactone. The reaction process is as follows:

[0032]

[0033] Take a 5mL Schlenk bottle, roast it and replace the argon, then add 86mg of poly-β-butyrolactone (Mn=5400g / mol, PDI=1.16) in the glove box, and then add 3.9mg of Zn[N(SiMe 3 ) 2 ] 2 Catalyst, outside the glove box, add 1mL of methanol, and stir at room temperature for reaction. After 24 hours of reaction, the reaction system was detected by NMR, and the conversion rate of the polymer was 93%, and the obtained alcoholysis product was methyl 3-hydroxybutyrate.

Embodiment 2

[0034] Example 2: Depolymerization of polylactide. The reaction process is as follows:

[0035]

[0036] Take a 5mL Schlenk bottle, smoke and roast it and replace the argon, then add 144mg of polylactide (Mn=11300g / mol, PDI=1.17) in the glove box, and then add 7.7mg of Zn[N(SiMe 3 ) 2 ] 2 Catalyst, outside the glove box, add 1mL of methanol, and stir at room temperature for reaction. After reacting for 2 hours, the NMR detection of the reaction system showed that the conversion rate of the polymer was 99%, and the obtained alcoholysis product was methyl lactate.

Embodiment 3

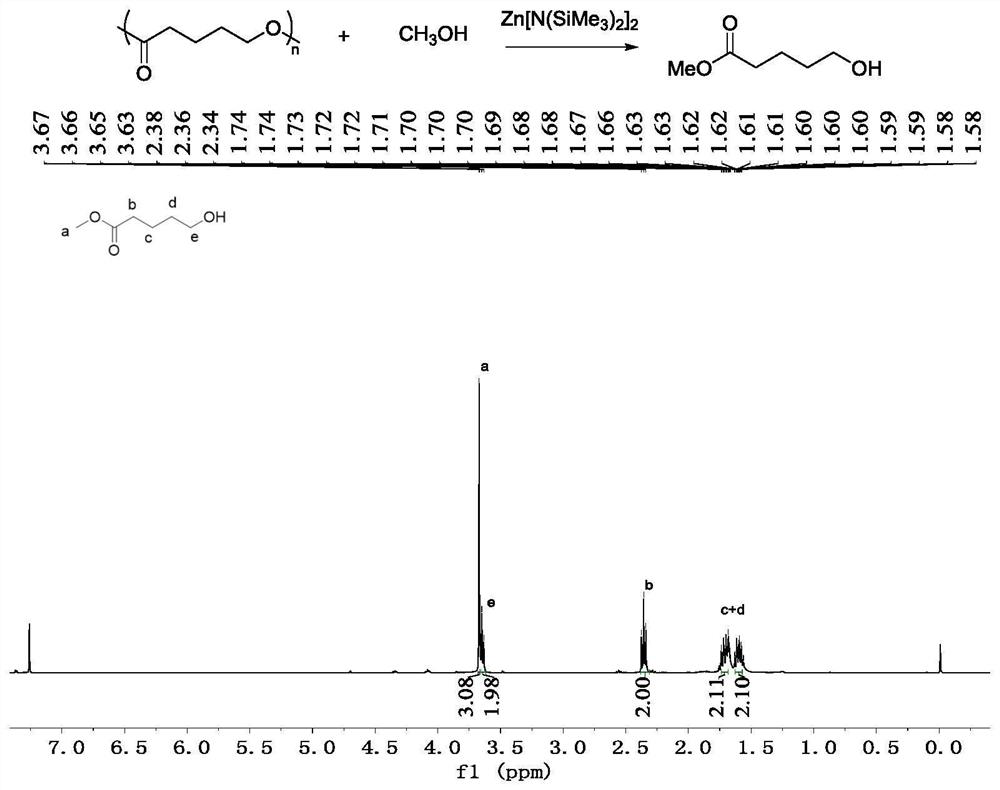

[0037] Example 3: Depolymerization of polylactide. The reaction process is as follows:

[0038]

[0039] Take a 5mL Schlenk bottle, smoke and roast it and replace the argon, then add 11.0g polylactide (Mn=49900g / mol, PDI=1.13) in the glove box, and then add 550mg of Zn[N(SiMe 3 ) 2 ] 2 Catalyst, outside the glove box, add 30mL of methanol, and stir at room temperature for reaction. After reacting for 40 minutes, the NMR detection of the reaction system showed that the polymer conversion rate was 99%, and the obtained alcoholysis product was methyl lactate. Remaining methanol was removed by distillation to obtain 14.2 g of methyl lactate with a yield of 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com