Formaldehyde-free soybean meal based artificial board adhesive and preparation method thereof

An aldehyde-soybean meal-based, wood-based panel technology is applied in the preparation of adhesives, animal glue or gelatin, and the types of adhesives. performance, saving production costs, increasing the effect of crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

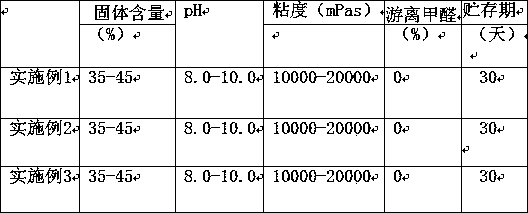

Examples

Embodiment 1

[0041] A formaldehyde-free soybean meal-based wood-based panel adhesive is prepared from the following raw materials in parts by weight:

[0042] 68 parts of demineralized water

[0043] Sodium hydroxide 2 parts

[0044] 35 servings of defatted soy protein powder

[0045] Bisulfite with 1 part

[0046] 3 parts of cross-linking enhancer

[0047] Polyethylene glycol 7 parts

[0048] 1 part sodium benzoate

[0049] A preparation method of the above-mentioned aldehyde-free soy-based self-based wood-based panel adhesive, comprising the following steps:

[0050] 1) Weigh each raw material according to the above weight ratio.

[0051] 2) In a reaction kettle equipped with a stirrer, a thermometer and a condensing device, add all the demineralized water, cross-linking enhancer, soybean protein powder and stir well, add sodium hydroxide, sodium bisulfite, polyethylene glycol and stir well .

[0052] 3) Heat in a water bath to 40-45°C, and keep it warm for 3 hours.

[0053] 4) ...

Embodiment 2

[0058] A formaldehyde-free soybean meal-based wood-based panel adhesive is prepared from the following raw materials in parts by weight:

[0059] 64 parts of demineralized water

[0060]4 parts sodium hydroxide

[0061] 33 servings of defatted soy protein powder

[0062] Hydrogen sulfite and 1.5 parts

[0063] Enhancer 3 parts

[0064] Polyethylene glycol 12 parts

[0065] Sodium Benzoate 15 parts

[0066] A kind of preparation method of formaldehyde-free soya-bean self-based wood-based panel adhesive, comprises the following steps:

[0067] 1) Weigh each raw material according to the above weight ratio.

[0068] 2) Add all the demineralized water, cross-linking enhancer and soybean protein powder into a reaction kettle equipped with a stirrer, thermometer and condensing device and stir evenly, add sodium hydroxide, sodium bisulfite and polyethylene glycol and stir evenly.

[0069] 3) Heating to 40-45° C. in a water bath, and reacting for 6 hours.

[0070] 4) The react...

Embodiment 3

[0075] A kind of aldehyde-free soy-based wood-based panel adhesive is prepared from the following raw materials in parts by weight:

[0076] 62 parts of demineralized water

[0077] Sodium hydroxide 8 parts

[0078] 35 servings of defatted soy protein powder

[0079] Sodium bisulfite 0.2 part

[0080] Enhancer 15 parts

[0081] Polyethylene glycol 9 parts

[0082] Sodium toformate 5 parts

[0083] A kind of preparation method of aldehyde-free bean-based self-based wood-based panel adhesive, comprising the following steps:

[0084] 1) Weigh each raw material according to the above weight ratio.

[0085] 2) In a reaction kettle equipped with a stirrer, thermometer and condensing device, add all the demineralized water, cross-linking enhancer, soybean protein powder and stir well, add hydroxide, hydrogen sulfite, polyethylene glycol and stir well .

[0086] 3) Heating to 40-45° C. in a water bath, and reacting for 6 hours.

[0087] 4) The temperature of the reactant was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com