Fly ash non-burned high-strength ceramsite and preparation method thereof

A technology of high-strength ceramsite and fly ash, which is applied in the field of fly ash-free high-strength ceramsite and its preparation, can solve problems such as environmental pollution, energy waste, and increased production costs, and achieve simple equipment, good recycling, and easy-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

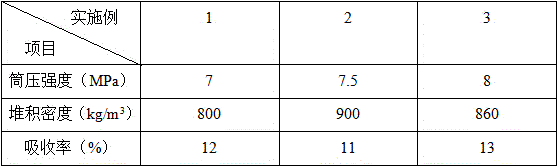

Embodiment 1

[0016] 1. A fly ash non-burning high-strength ceramsite, comprising the following components in parts by weight: 93.5 parts of fly ash, 2.95 parts of sodium silicate and 2.95 parts of calcium chloride.

[0017] Two, the preparation method of above-mentioned fly ash unburned high-strength ceramsite, comprises the steps:

[0018] 1) Weigh the raw materials according to the above formula, mix the binder and the reinforcing agent with water respectively, and prepare the bonding solution and reinforcing solution for later use; wherein, the mass volume ratio of the binder and reinforcing agent to water Both are 1:100;

[0019] 2) Pour the weighed fly ash into the ball plate, open the ball plate, spray the bonding liquid prepared in step 1) into the fly ash, turn it into a ball plate and roll it into a ball, and at the same time put the step 1) The prepared reinforcing liquid was sprayed on the surface of the sphere to prepare ceramsite with a diameter of 5 mm; among them, the diame...

Embodiment 2

[0022] 1. A fly ash non-burning high-strength ceramsite, comprising the following components in parts by weight: 94 parts of fly ash, 3 parts of sodium silicate and 3 parts of aluminum sulfate.

[0023] Two, the preparation method of above-mentioned fly ash unburned high-strength ceramsite, comprises the steps:

[0024] 1) Weigh the raw materials according to the above formula, mix the binder and the reinforcing agent with water respectively, and prepare the bonding solution and reinforcing solution for later use; wherein, the mass volume ratio of the binder and reinforcing agent to water Both are 1:105;

[0025] 2) Pour the weighed fly ash into the ball plate, open the ball plate, spray the bonding liquid prepared in step 1) into the fly ash, turn it into a ball plate and roll it into a ball, and at the same time put the step 1) The prepared reinforcing liquid was sprayed on the surface of the sphere to prepare ceramsite with a diameter of 20 mm; among them, the diameter of ...

Embodiment 3

[0028] 1. A fly ash non-burning high-strength ceramsite, comprising the following components in parts by weight: 94.5 parts of fly ash, 3.05 parts of sodium silicate and 3.05 parts of calcium nitrite.

[0029] Two, the preparation method of above-mentioned fly ash unburned high-strength ceramsite, comprises the steps:

[0030] 1) Weigh the raw materials according to the above formula, mix the binder and the reinforcing agent with water respectively, and prepare the bonding solution and reinforcing solution for later use; wherein, the mass volume ratio of the binder and reinforcing agent to water Both are 1:110;

[0031] 2) Pour the weighed fly ash into the ball plate, open the ball plate, spray the bonding liquid prepared in step 1) into the fly ash, turn it into a ball plate and roll it into a ball, and at the same time put the step 1) The prepared reinforcing liquid was sprayed on the surface of the sphere to prepare ceramsite with a diameter of 30 mm; among them, the diame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com