Patents

Literature

96results about How to "High in silica" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods for producing pulp and treating black liquor

InactiveUS20060201641A1Maintaining output qualityRaise the reaction temperaturePretreatment with water/steamPulp liquors combustionCalcium silicateOrganic content

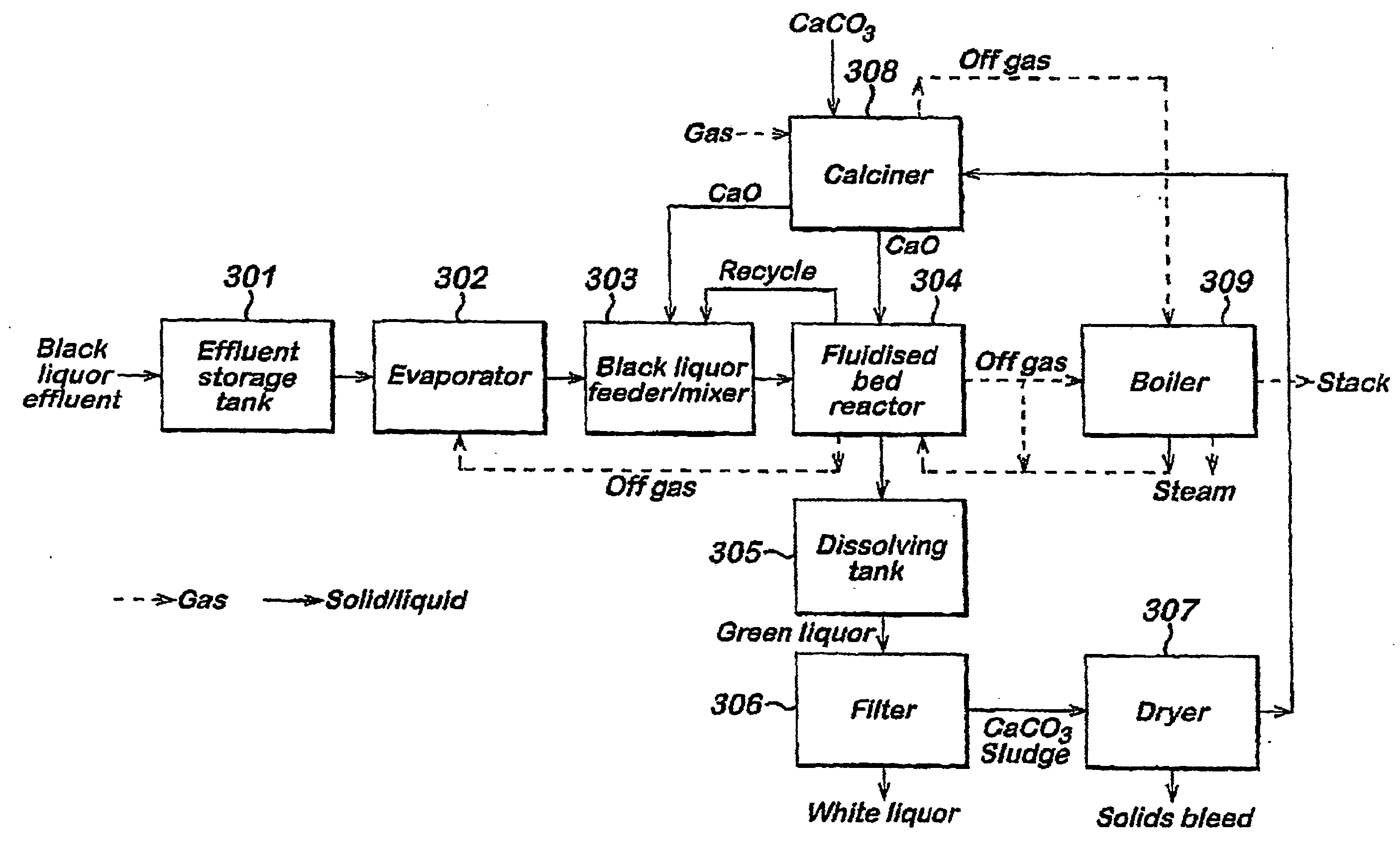

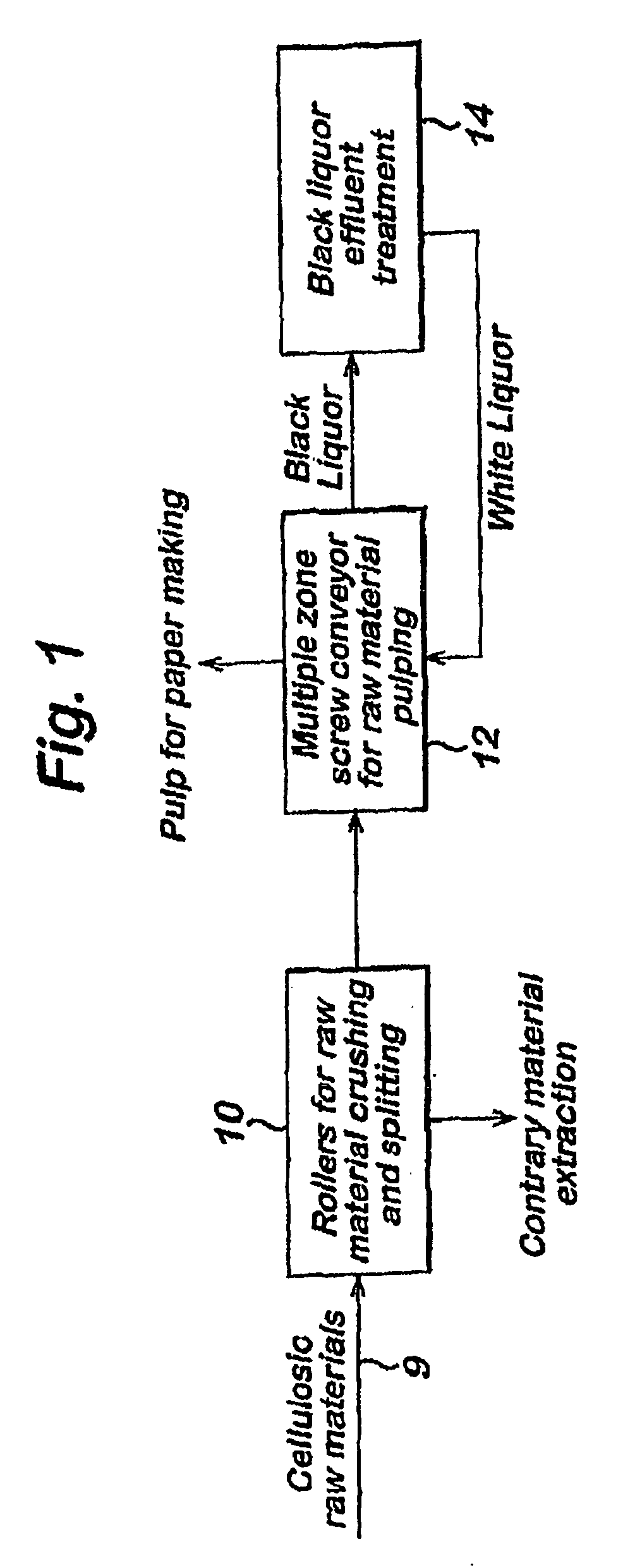

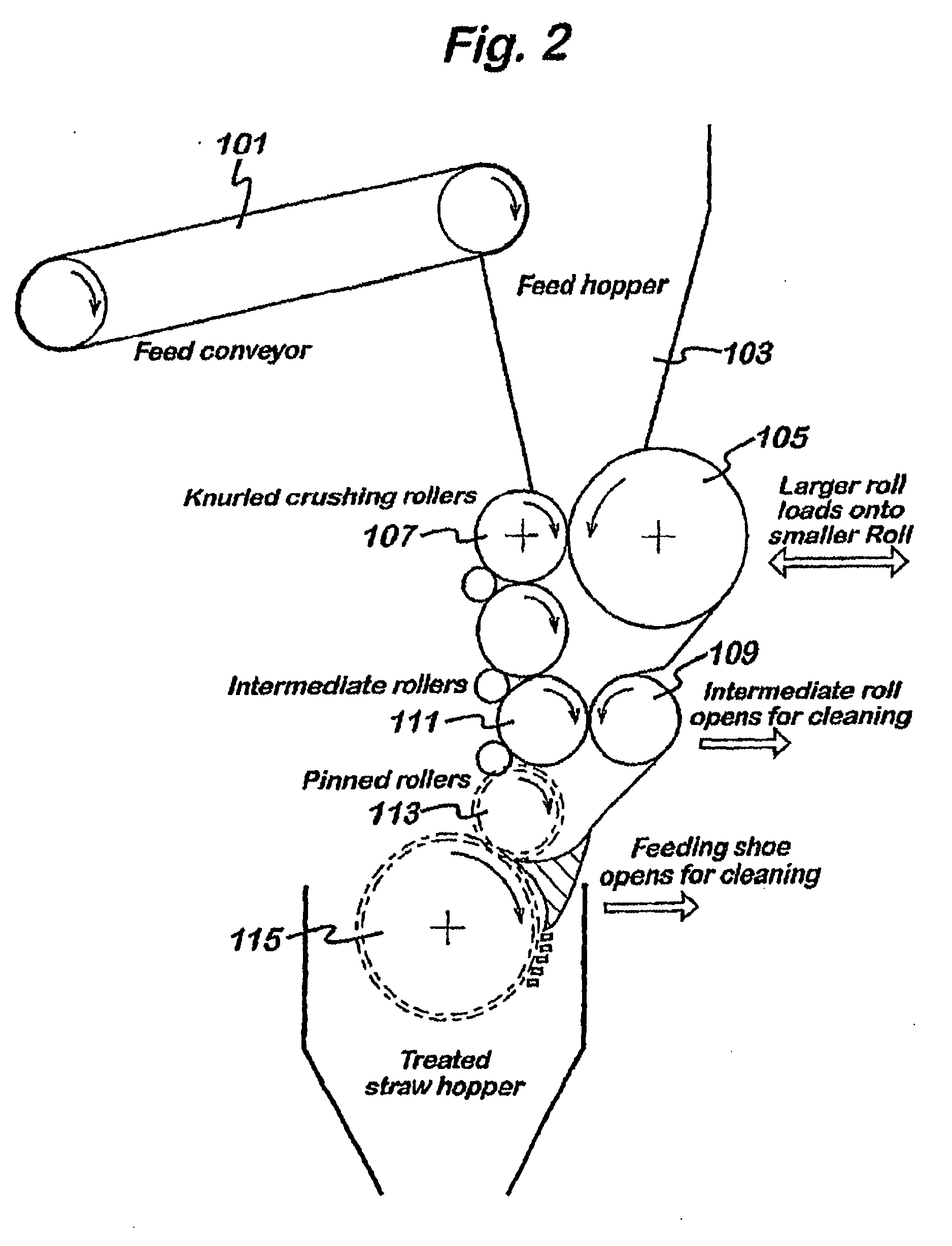

A method is provided for treating black liquor particularly derived from non-wood pulp, by heating with an alkaline earth metal oxide in a toroidal fluidised bed reactor at a temperature of above 650° C. The method may be used alone or as part of a method of converting graminaceous raw material to pulp for paper or board, said method comprising (a) digesting said raw material with a white liquor based on sodium hydroxide and further comprising calcium hydroxide in an amount effective to substantially convert silica of said raw material to calcium silicate; (b) recovering pulp and black liquor substantially free of uncombined silica; (c) heating the black liquor in a fluidized bed reactor containing calcium oxide for catalysing conversion of organic content of said black liquor to gas and for providing recovered solids including sodium values of said white liquor and calcium oxide; and regenerating said white liquor using said recovered solids. The use of the above mentioned white liquor permits treatment of wheat straw, rice straw and other high-silica materials without resulting in a black liquor that is difficult to treat.

Owner:BIOREGIONAL MINIMILLS UK

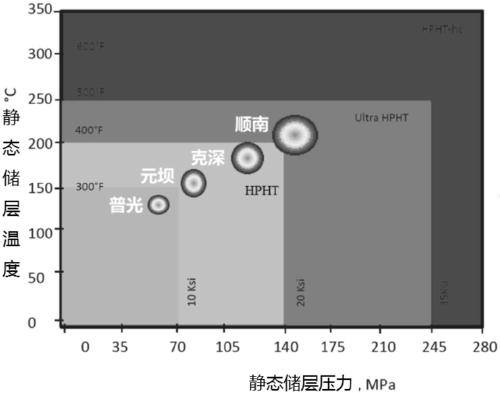

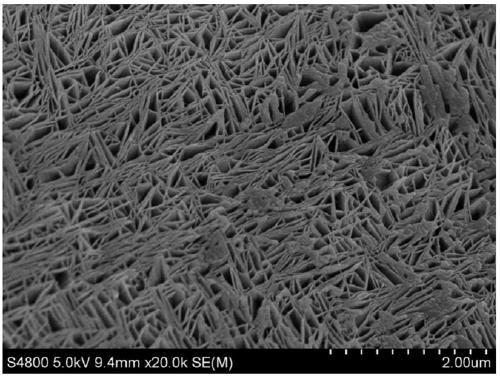

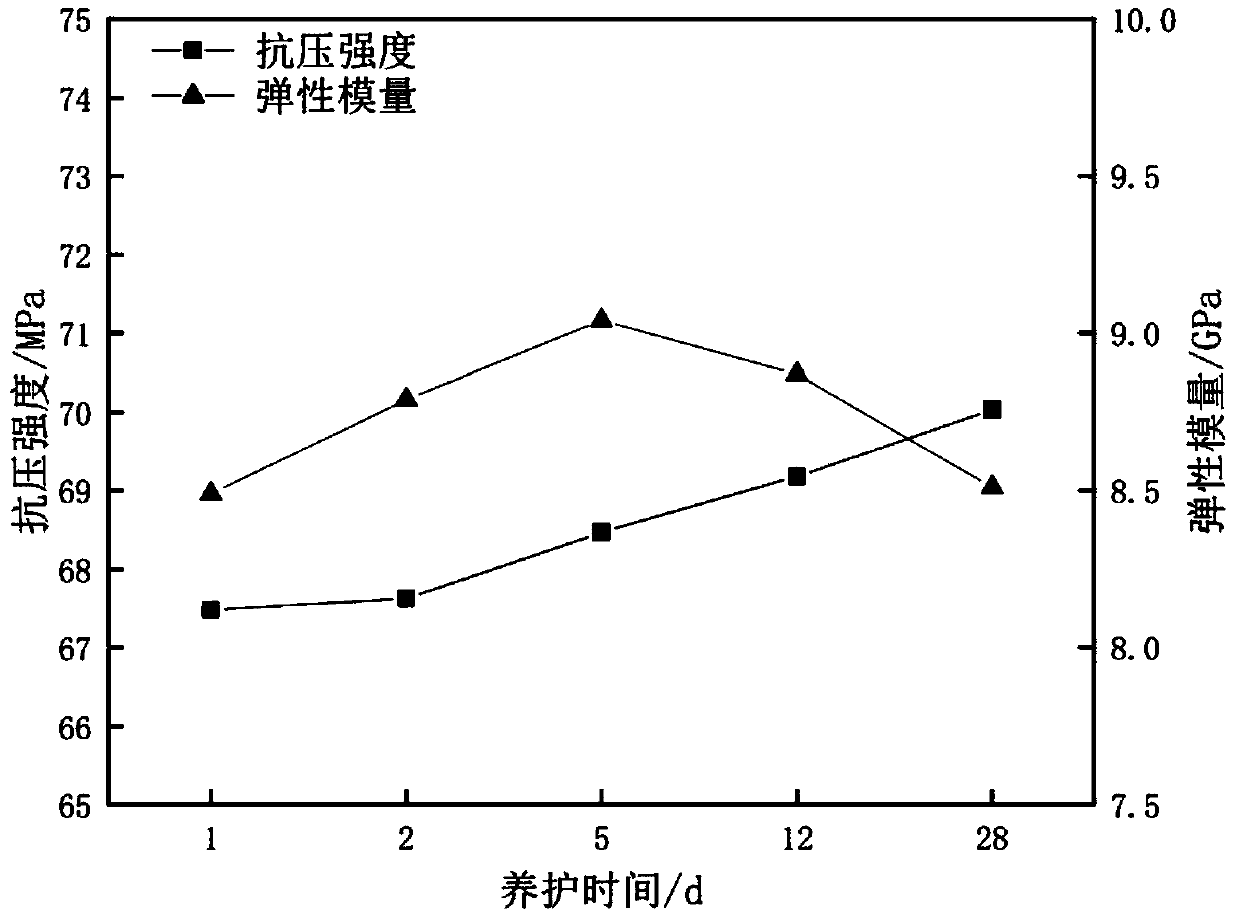

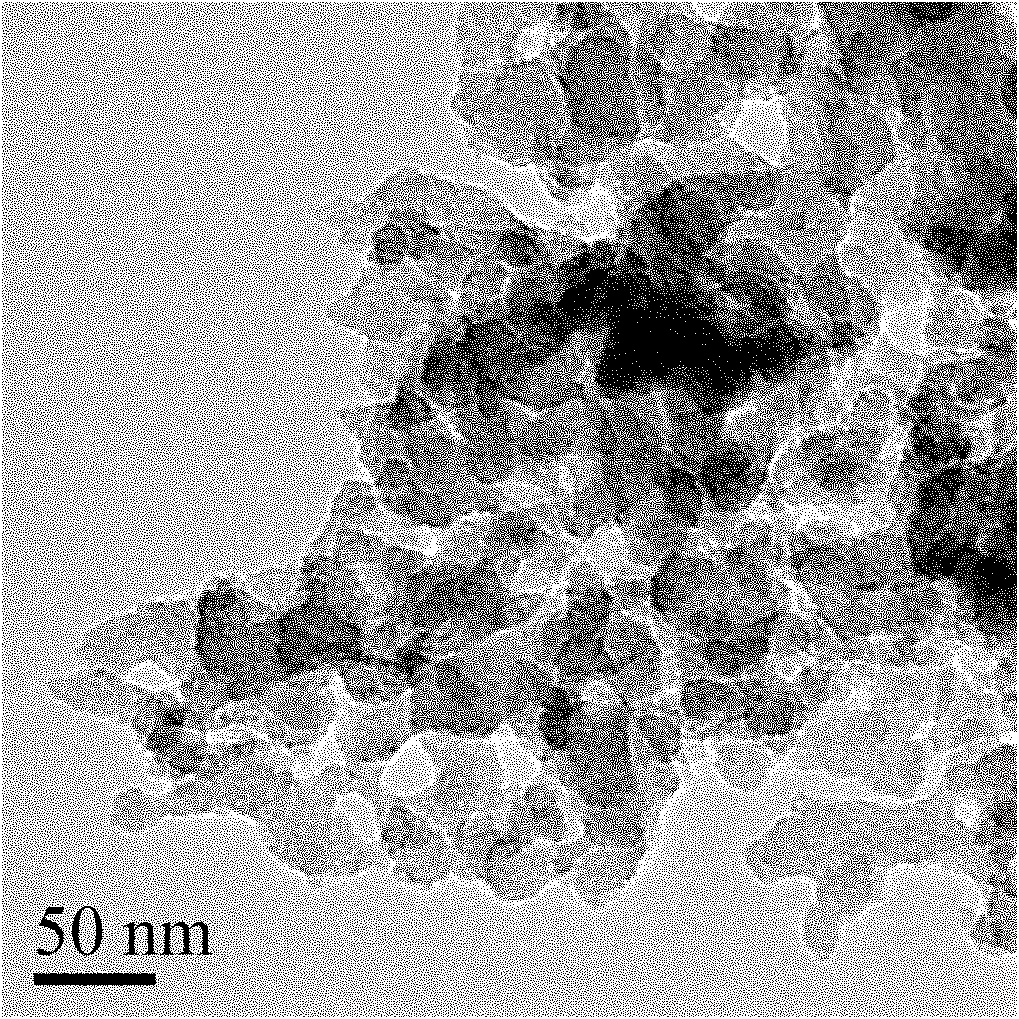

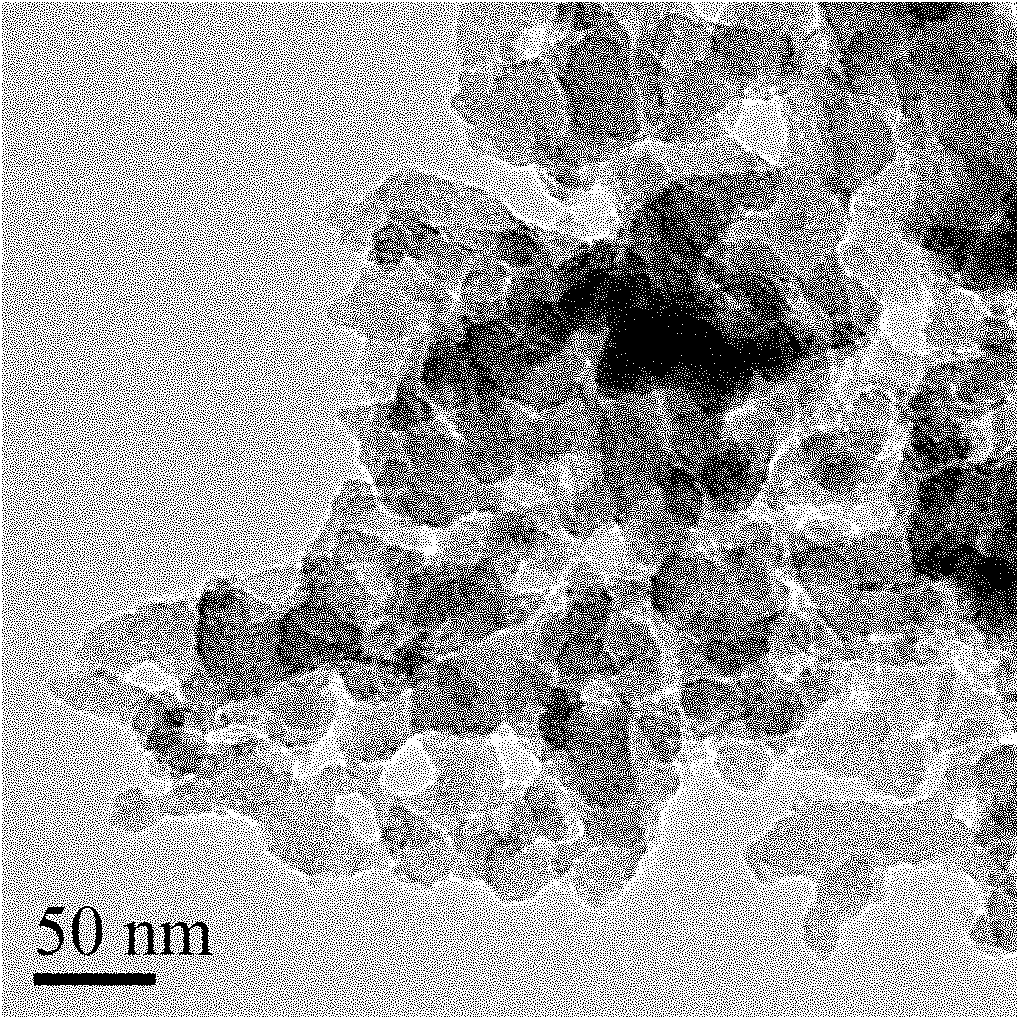

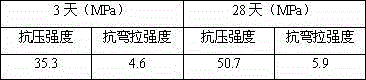

Nano-material mixed modified superhigh-temperature high-performance well cementing slurry system and preparation method thereof

The invention relates to a nano-material mixed modified superhigh-temperature high-performance well cementing slurry system and a preparation method thereof. The slurry system comprises the followingingredients in parts by weight: 100 parts of oil well cement, 15-25 parts of coarse silica sand, 15-20 parts of fine silica sand, 1-10 parts of nano-silicon dioxide, 1-10 parts of nano-calcium carbonate, 0.2-1 part of a defoaming agent, 4-10 parts of a fluid loss agent, 0-3 parts of a drag reduction agent, 0.5-4 parts of a retarder and 30-100 parts of water. In the slurry system, set cement has excellent compressive strength and toughness under superhigh temperature, and the compressive strength and the elasticity modulus cannot be obviously changed as the maintenance time is prolonged. The slurry system has good rheological property, lower water loss and proper thickening time, and the comprehensive properties of the slurry system can completely meet the related requirements of site wellcementing construction, so that the technical support is provided for well cementing under high temperature. A nano-material obtained by mixing the nano-silicon dioxide and the nano-calcium carbonateis added, and micropores of the set cement can be effectively filled, so that the system becomes denser. Therefore, the volume shrinkage of the set cement is relieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for obtaining LSX zeolite bodies

InactiveUS6264881B1High in silicaThe process is simple and fastOther chemical processesCeramic shaping apparatusSorbentPotassium hydroxide

A process for the production of faujasite X agglomerates containing at least 95% of faujasite LSX, that is to say with an Si / Al ratio equal to 1, constituting the active adsorbent. The agglomerate is formed from zeolite LSX and from a binder which can be converted to zeolite, the conversion of which to active zeolite is obtained by conversion to zeolite in a sodium hydroxide / potassium hydroxide or sodium hydroxide liquor.

Owner:ELF ATOCHEM SA

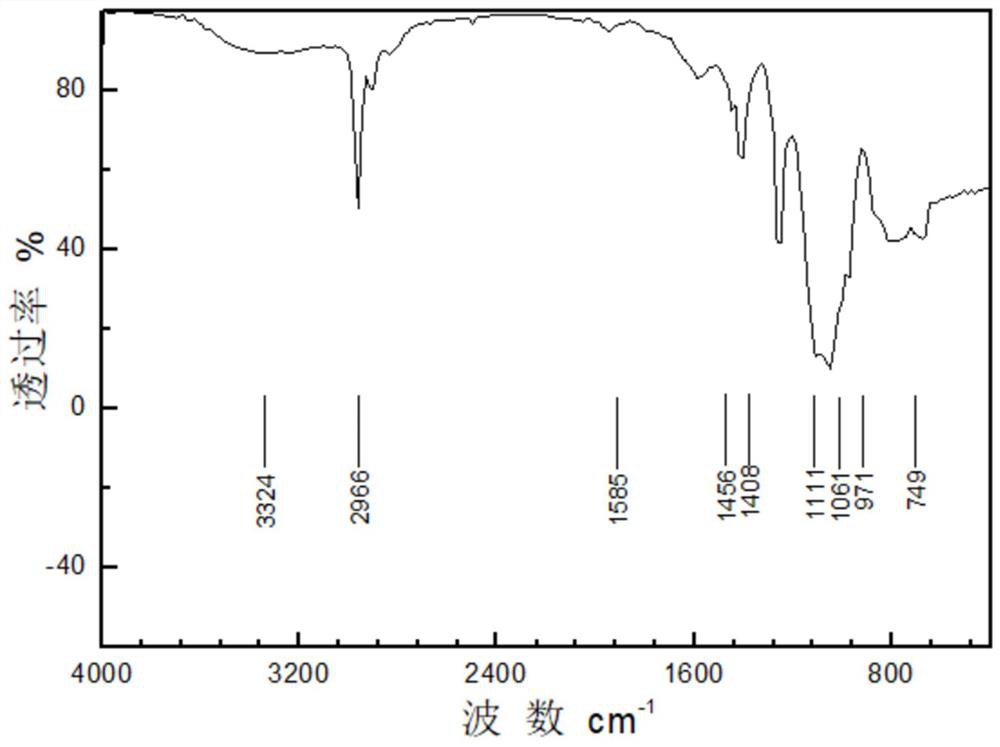

Method for preparing white carbon black and manganese fertilizer from manganese leaching residue

The invention discloses a method for preparing white carbon black and manganese fertilizer from manganese leaching residue. The method comprises the following steps: 1, washing the manganese leaching residue with dilute sulphuric acid solution and running water in turn to obtain the residue; 2, conducting reaction between the residue and 25 to 40% strong base solution by mass at 90 to 120 DEG C for 2 to 5 h, and filtering to obtain filtrate; 3, decoloring the filtrate with active carbon and then carboxyl-terminated hyperbranched polyester at 100 to 120 DEG C to obtain the aqueous solution of silicate; 4, adding water and then inorganic acid and carboxyl-terminated hyperbranched polyester for reaction at 40 to 90 DEG C for 0.5 to 2 h to obtain the white carbon black; and 5, drying and dehydrating the residue obtained in step 2 and adding into a high-speed mixer, adding phosphoric acid, anticaking agent and manganese sulfate into the high-speed mixer, and mixing at room temperature for 10 to 20 min to obtain the manganese fertilizer. The method is simple in process and low in cost and is suitable for industrial production; and the silicon dioxide content of the prepared white carbonblack is more than 95% by mass, the specific area is more than 270 m<2> / g and the particle size is less than 50 nm.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

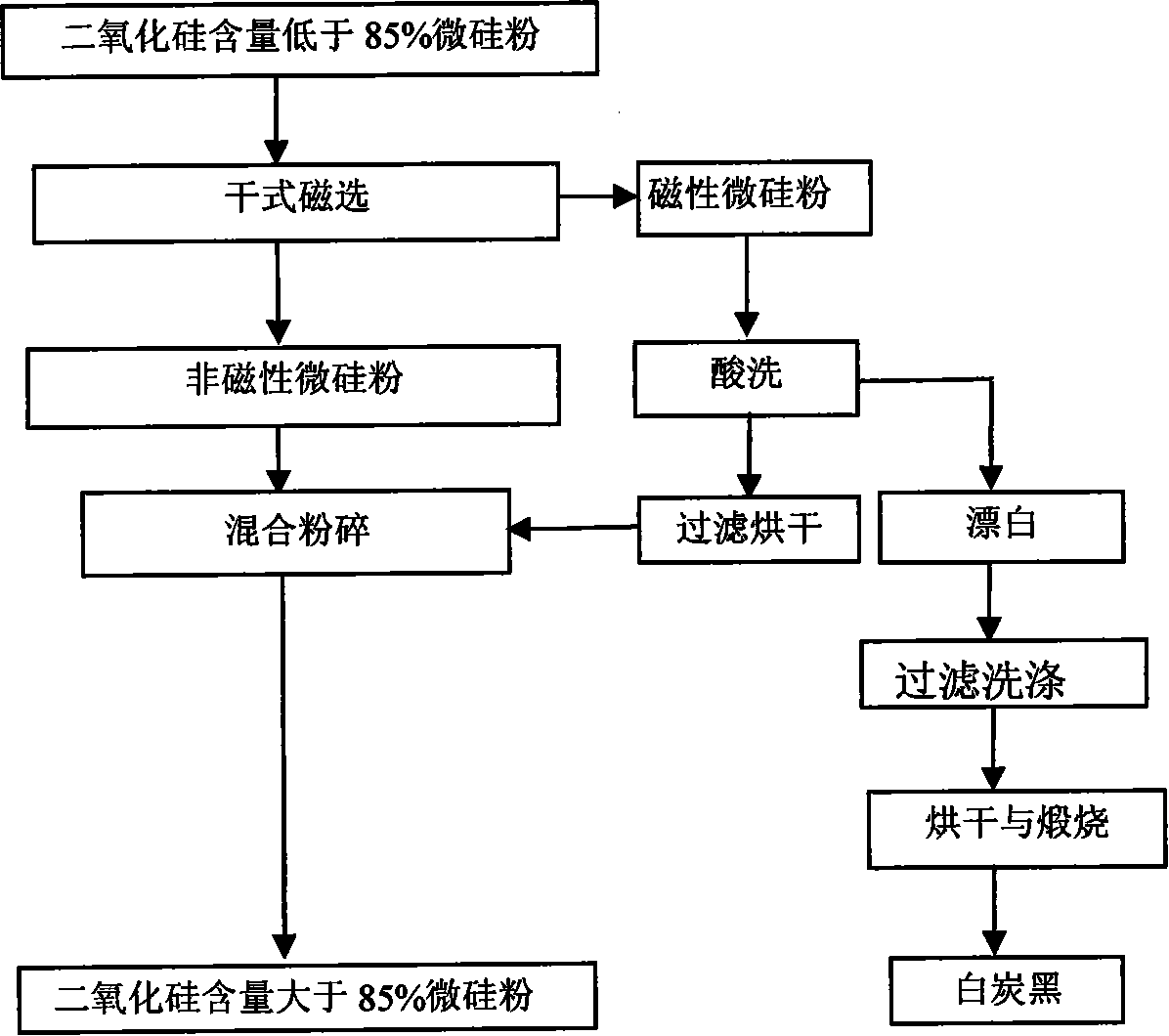

Method for increasing content of silicon dioxide in silicon ash and producing white carbon black

The present invention discloses method of raising silica content in silica fume and process of producing carbon white. Through dry magnetic dressing on fine silica fume with silica content lower than 85 % to separate magnetic fine silica fume and non-magnetic fine silica fume, pickling treatment on the magnetic fine silica fume, and mixing the dried magnetic fine silica fume and non-magnetic fine silica fume, fine silica fume with silica content higher than 85 % is produced. The magnetic fine silica fume after being pickled may be further bleached, stoved and calcined to obtain carbon white. The present invention provides low cost method of raising silica content in silica fume and new process of producing carbon, and has low production cost, utilization of waste resource and wide application in metal silicon works and ferrosilicon alloy works.

Owner:CHANGAN UNIV

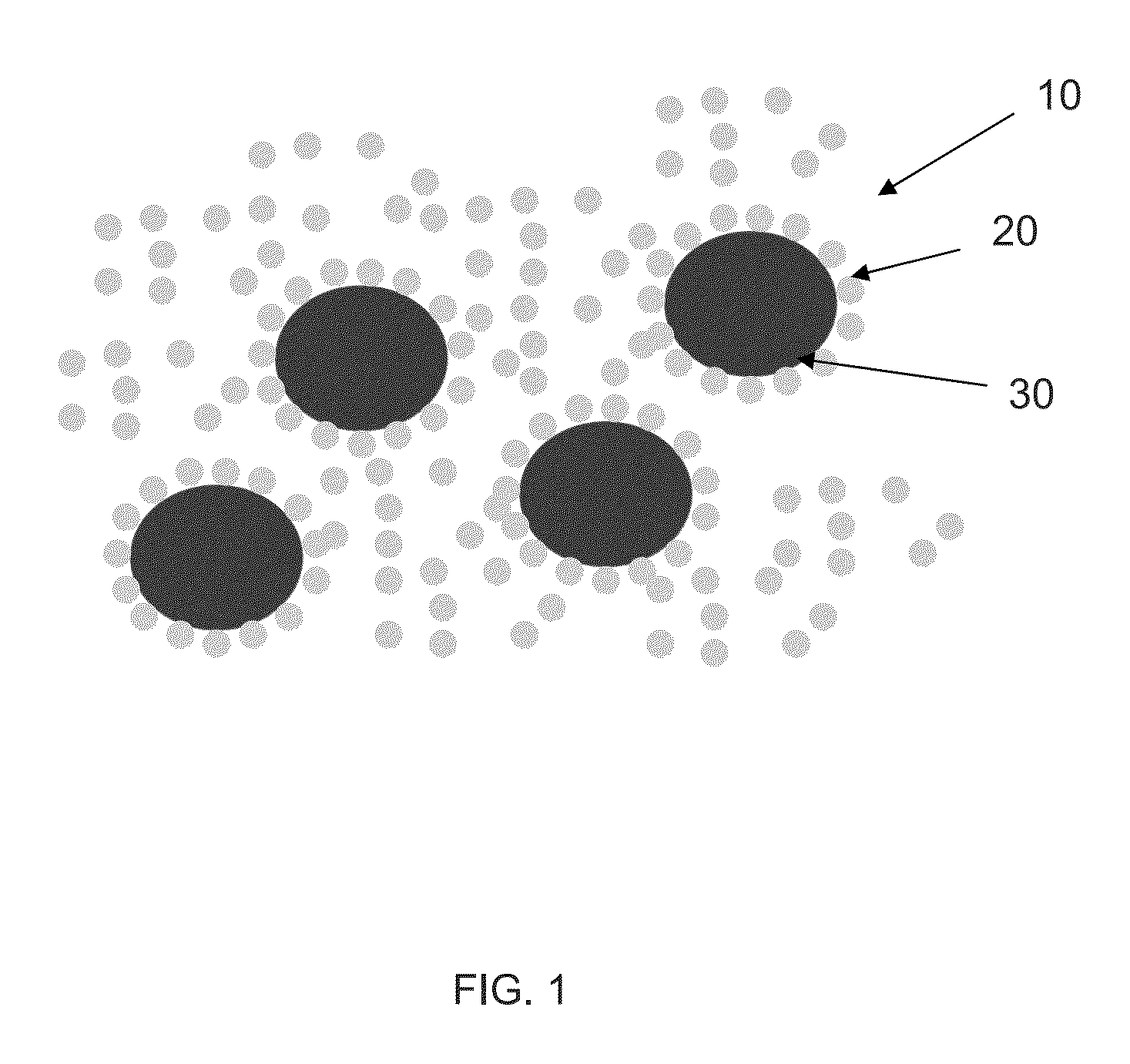

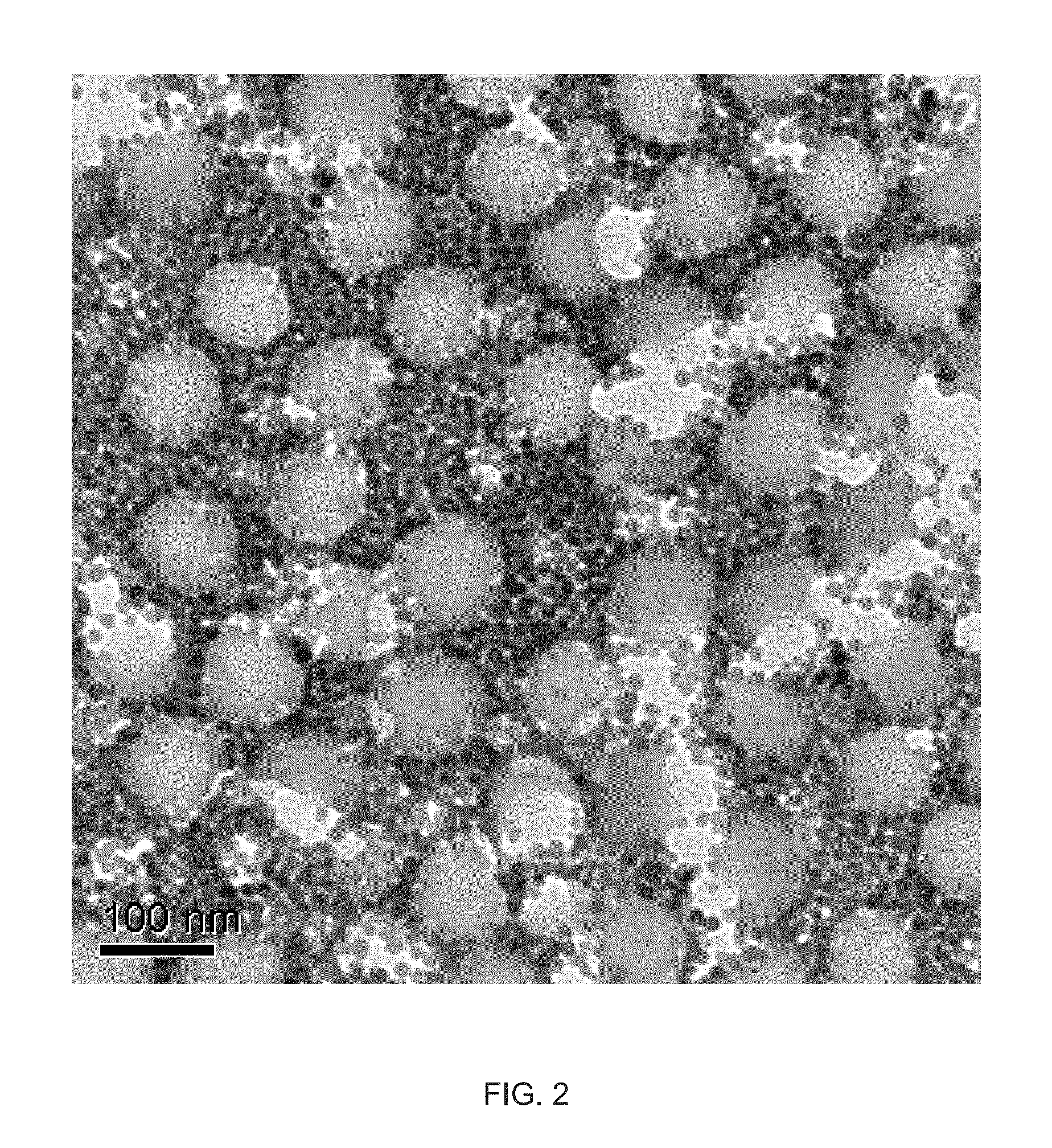

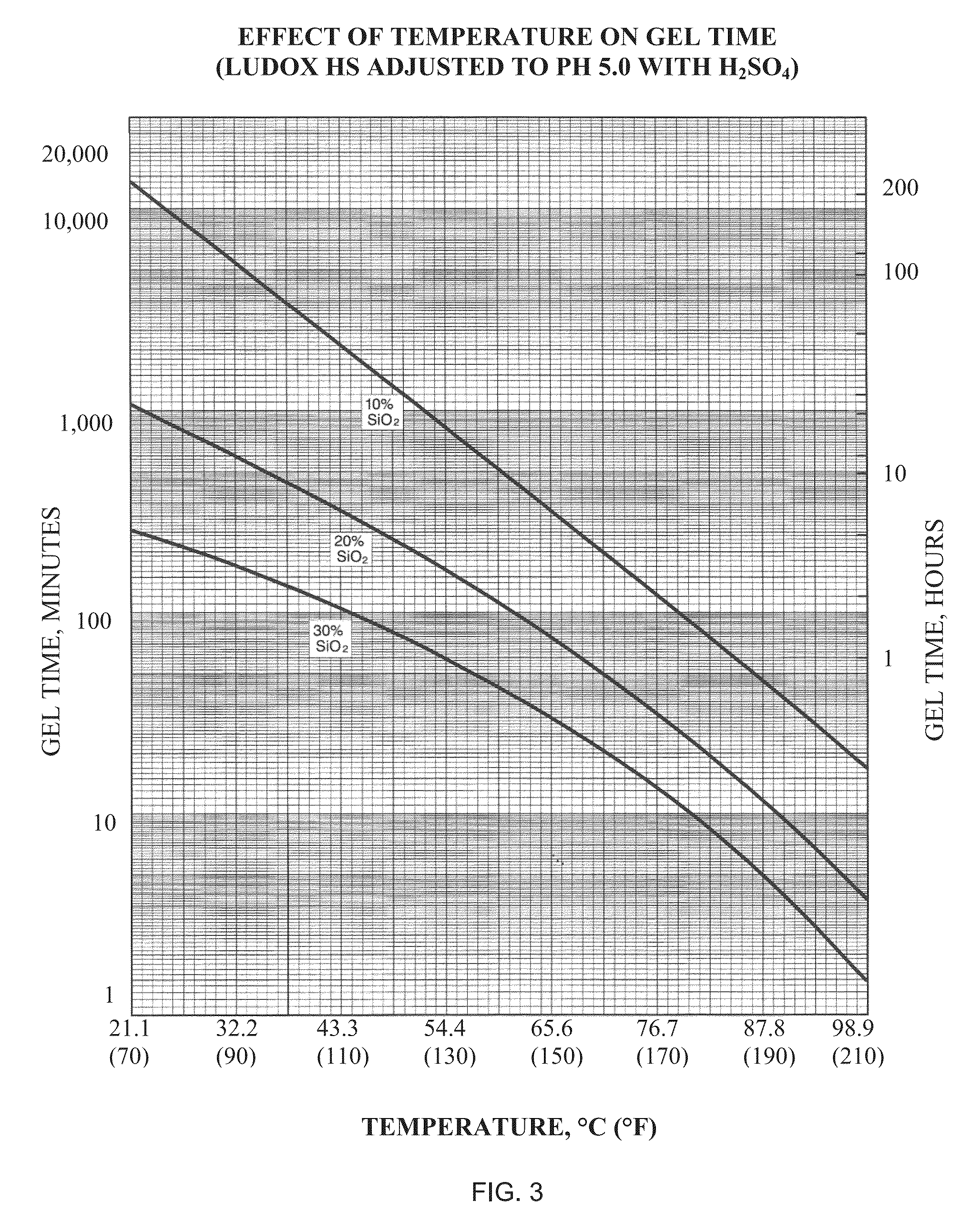

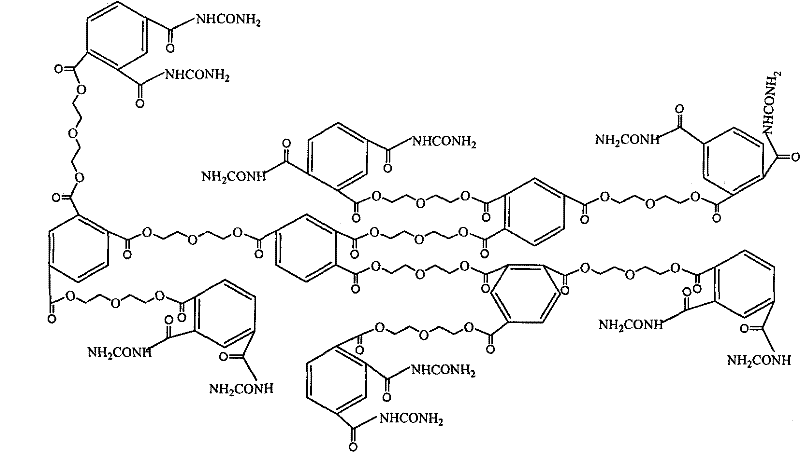

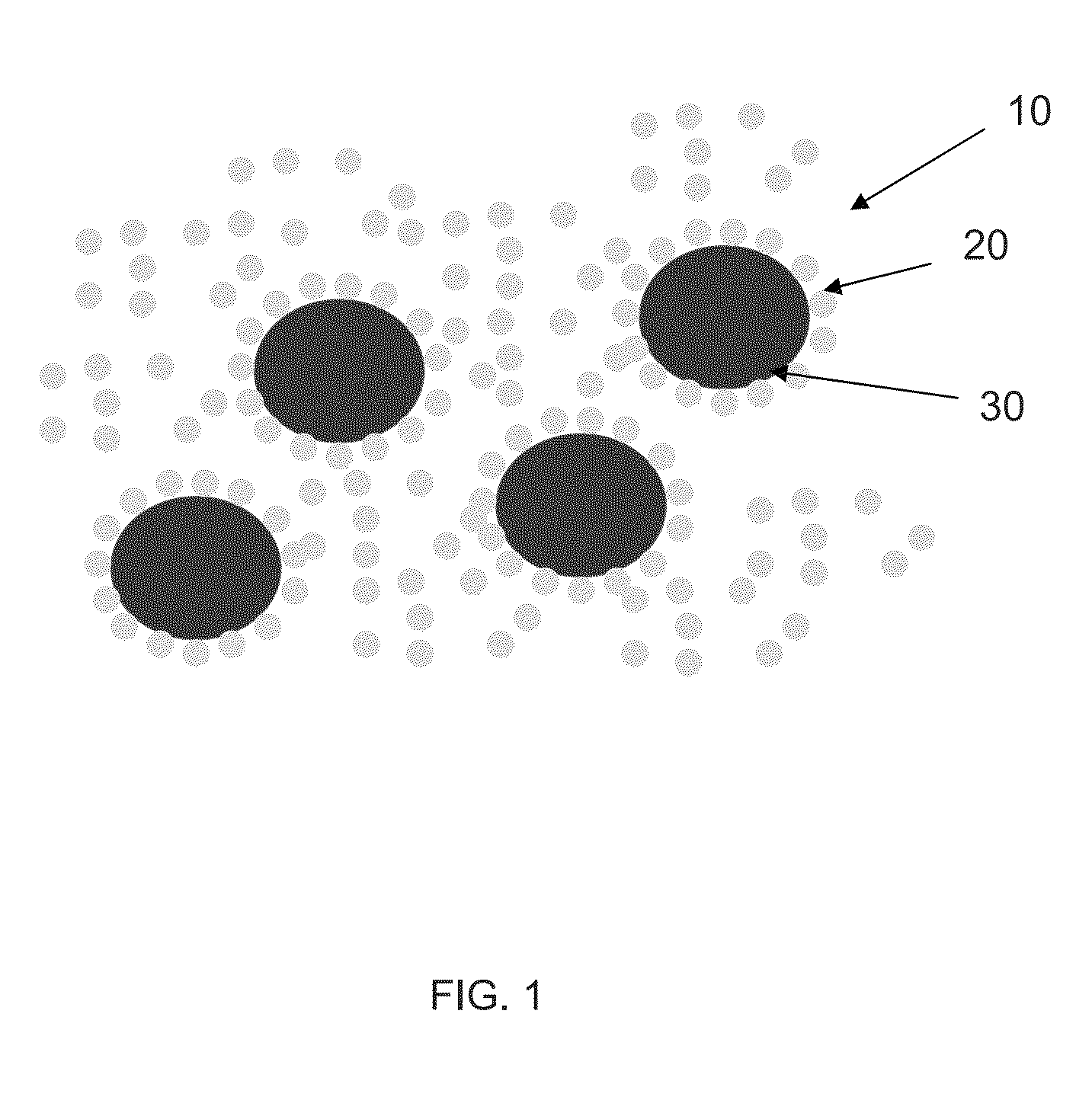

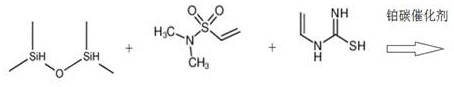

Hybrid Organic-Inorganic Nanocomposites

ActiveUS20130005881A1Improvement in performance of paintHigh solid contentSilicon organic compoundsMaterial nanotechnologySilica nanoparticlesSilicon dioxide

The present invention relates to a dispersion of hybrid organic-inorganic nanocomposite molecules comprising discrete inorganic silica nanoparticles that are covalently bonded to organic polymers, wherein the dispersion has a high solid content (>30% wt.) and high silica content (>35% wt.) with low coagulum (about 100-400 ppm or about 0.05% wt or less). The hybrid organic-inorganic nanocomposite is prepared by (1) hydrolyzing silane monomers at acidic conditions; (2) surface treating inorganic silica nanoparticles with silane monomers; (3) stabilizing the surface-treated inorganic silica nanoparticles with an amine stabilizer; and (4) reacting organic monomers with surface-treated inorganic silica nanoparticles.

Owner:COLUMBIA INSURANCE CO

Method for preparing alcohol-dispersed silica sol

The invention relates to the technical field of silica sol, and in particular relates to a method for preparing alcohol-dispersed silica sol. The method comprises the following steps of: adding alcohol into acidic aqueous silica sol, concentrating by adopting an ultrafiltration concentration process till the solid content of the aqueous silica sol meets the requirement, adjusting the pH (potential of Hydrogen) to 4-5, heating to 40-50 DEG C and adding silane to carry out hydrolysis reaction. The method has the advantages that the silicon dioxide content of the obtained product is up to 20-40%; the particle size is 10-120nm; the water content is less than 1%; the stable period is greater than 6 months; the normal silica sol is adopted as the main raw material, so that the cost is low; and the ultrafiltration membrane process and the normal-pressure hydrolysis reaction are adopted, so that the production process is simple.

Owner:山东百特新材料有限公司

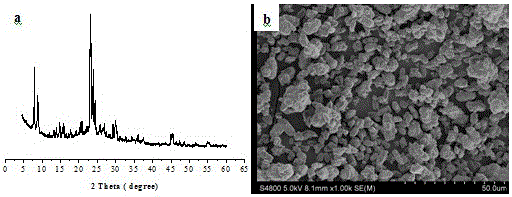

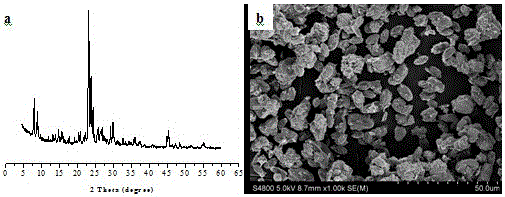

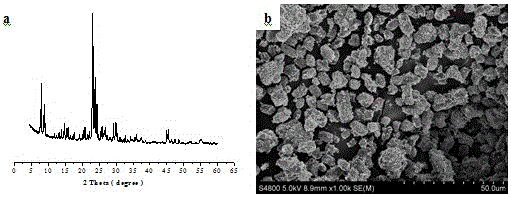

Method for low-cost synthesis of ZSM-5 molecular sieve

InactiveCN105776246AHigh in silicaHigh reactivityPentasil aluminosilicate zeoliteCrystallinityNatural mineral

The invention belongs to the technical fields of molecular sieve and preparation method thereof, and specifically relates to a process for synthesis of a ZSM-5 molecular sieve by using a hydrothermal method and taking natural minerals diatomite and kaolin as raw materials for providing all aluminum sources and silicon sources required for synthesis of the ZSM-5, and particularly, relates to a method for low-cost synthesis of the ZSM-5-5 molecular sieve. The natural minerals diatomite and kaolin as the raw materials provide all the silicon sources and aluminum sources required for synthesis of the ZSM-5 molecular sieve, the use of any chemical silicon or aluminum products are not required, the ways of diatomite low temperature liquid alkali dissolving and kaolin low temperature solid alkali melting are provided for achieving low temperature high-efficiency activation of natural mineral silicon and aluminum 'nutrients', at the same time, inert impurities in the raw materials are removed, and crystallinity and purity of a crystallized product are improved. The method has obvious advantages in aspects of expanding the range of molecular sieve synthetic raw materials, increasing the added value of the natural mineral products, reducing the production cost of molecular sieve, reducing the environmental pollution and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for manufacturing high temperature resisting and high pressure resisting oil well cementation briquette through silicon bauxite ceramic microbeads

InactiveCN104478418AChange the dependence of floating beadsLow densityWell cementingPulverized fuel ash

A method for manufacturing a high temperature resisting and high pressure resisting oil well cementation briquette through silicon bauxite ceramic microbeads comprises the steps that the silicon bauxite closed-hole hollow ceramic microbeads are manufactured, burdening, mixing, stirring and size mixing are carried out, 55-65wt percent of G-class oil well cement, 25-35wt percent of the silicon bauxite closed-hole hollow ceramic microbeads with the grain size of five microns to 50 microns, five to seven wt percent of pulverized fuel ash with the loss on ignition of 1.1 percent and the grain size of 20 microns to 50 microns, 1.5 to two wt percent of calcium oxide with the purity of 99.9 percent, 0.5-1.0wt percent of sodium sulfate and one to three wt percent of micro-silicon with the grain size of five microns to 20 microns are mixed, size mixing is carried out according to the water cement ratio of 0.5 to 0.7, the mixtures are poured into a set of two briquette molds with the length of 53 mm, the width of 53 mm and the height of 53 mm, are maintained in a water bath maintenance box for 24 hours and 48 hours respectively at the constant temperature of 52 DEG C, and are soaked in cold water for one hour after demolding, and a performance index test is carried out.

Owner:SHANDONG UNIV OF TECH

Method for preparing ultra-fine active white carbon black by using manganese leached slag and manganese electrolysis waste acid

The invention relates to a method for preparing ultra-fine active white carbon black by using manganese leached slag and manganese electrolysis waste acid. According to the invention, first, manganese leached slag is washed and neutralized by diluted acid and alkaline aqueous solution; the obtained filter residue strong alkaline solution is reacted and filtered, such that a filtrate is obtained; the filtrate is sequentially decolorized by using amino-terminated hyperbranched polyester and polyacrylamide with a number-average molar mass above 1000000 g / mol, such that a decolorized silicate aqueous solution is obtained; a particle activator is added to the solution, then decolorized manganese electrolysis waste acid is dropped to the solution; the obtained solution is reheated, reacted, filtered, washed, and dried, such that white carbon black is obtained. According to the present invention, white carbon black with a high added value can be produced by using waste slag and waste liquid discharged from a manganese mine enterprise, such that environment protection and comprehensive utilization of resources can be realized. The method also has advantages of simple technology, low cost,high added value, and is suitability for industrialized productions.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND +1

Method for preparing oil well cementing test block resistant to high temperatures and high pressures from aluminum diatomite ceramic microspheres

InactiveCN104592963AChange the dependence of floating beadsLow densityDrilling compositionCeramicwareMicrosphereSlurry

The invention provides a method for preparing an oil well cementing test block resistant to high temperatures and high pressures from aluminum diatomite ceramic microspheres. The method comprises the preparation of aluminum diatomite closed-pore hollow ceramic microspheres, burdening, blending and stirring for slurry mixing. Specifically, the method comprises the steps that 55-65wt% of G-grade oil-well cement, 25-35wt% of aluminum diatomite closed-pore hollow ceramic microspheres having the particle size of 10-50 microns, 5-7wt% of coal ash having the ignition loss of 1.1% and the particle size of 20-50 microns, 1.5-2wt% of calcium oxide having the purity of 99.9%, 0.5-1.0wt% of sodium sulfate, and 1-3wt% of micro-silicon having the particle size of 5-20 microns are mixed to obtain a mixture; the mixture is mixed with water in the water cement ratio of 0.5-0.7 to obtain the slurry; one part of the slurry is poured into a group of two test molds which are 53mm long, 53mm wide and 53mm high, and maintained in a constant-temperature water bath curing box at 52 DEG C for 24 hours and 48 hours, respectively; next, the stripped product is soaked in cold water for 1 hour, and then a performance index test is performed.

Owner:SHANDONG UNIV OF TECH

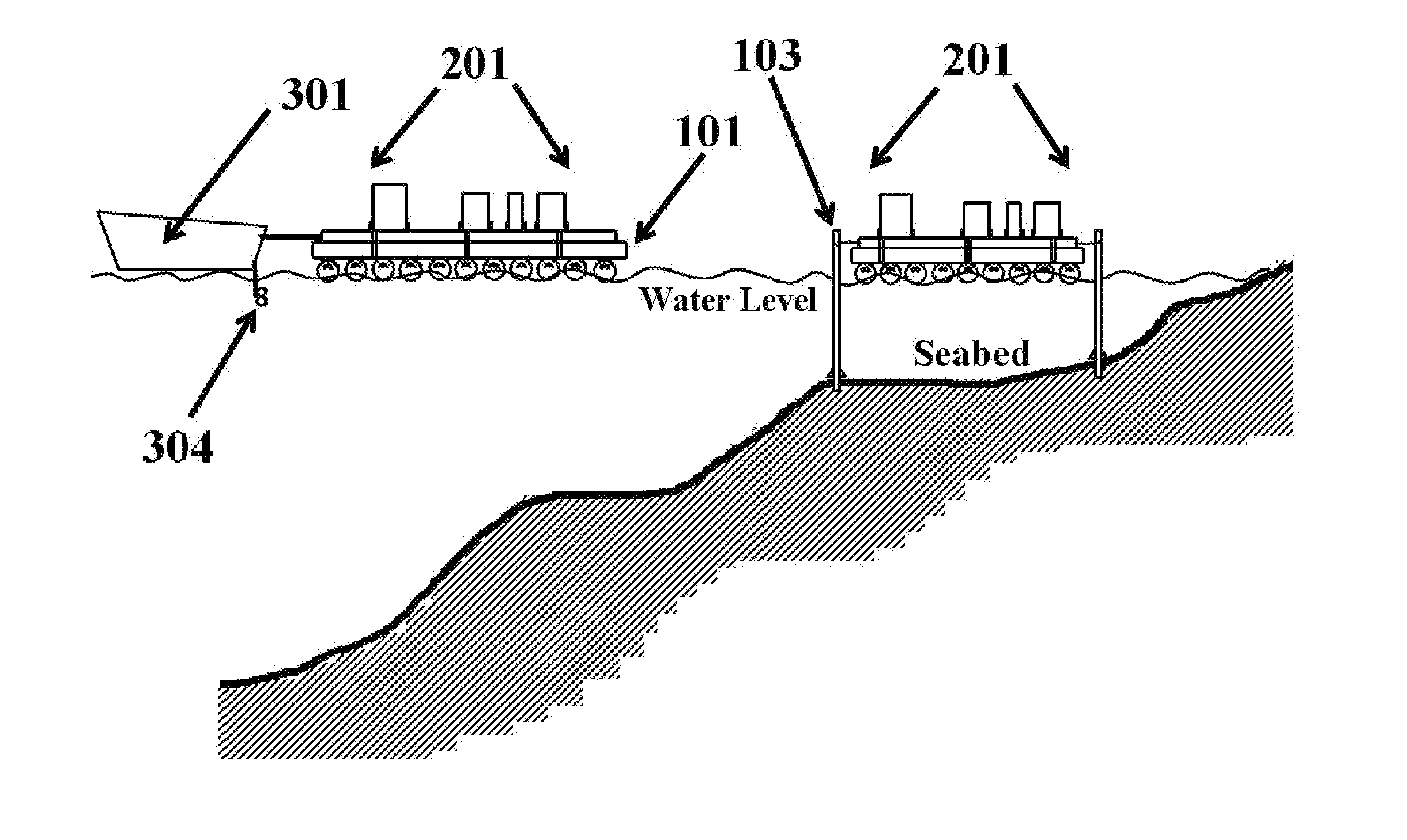

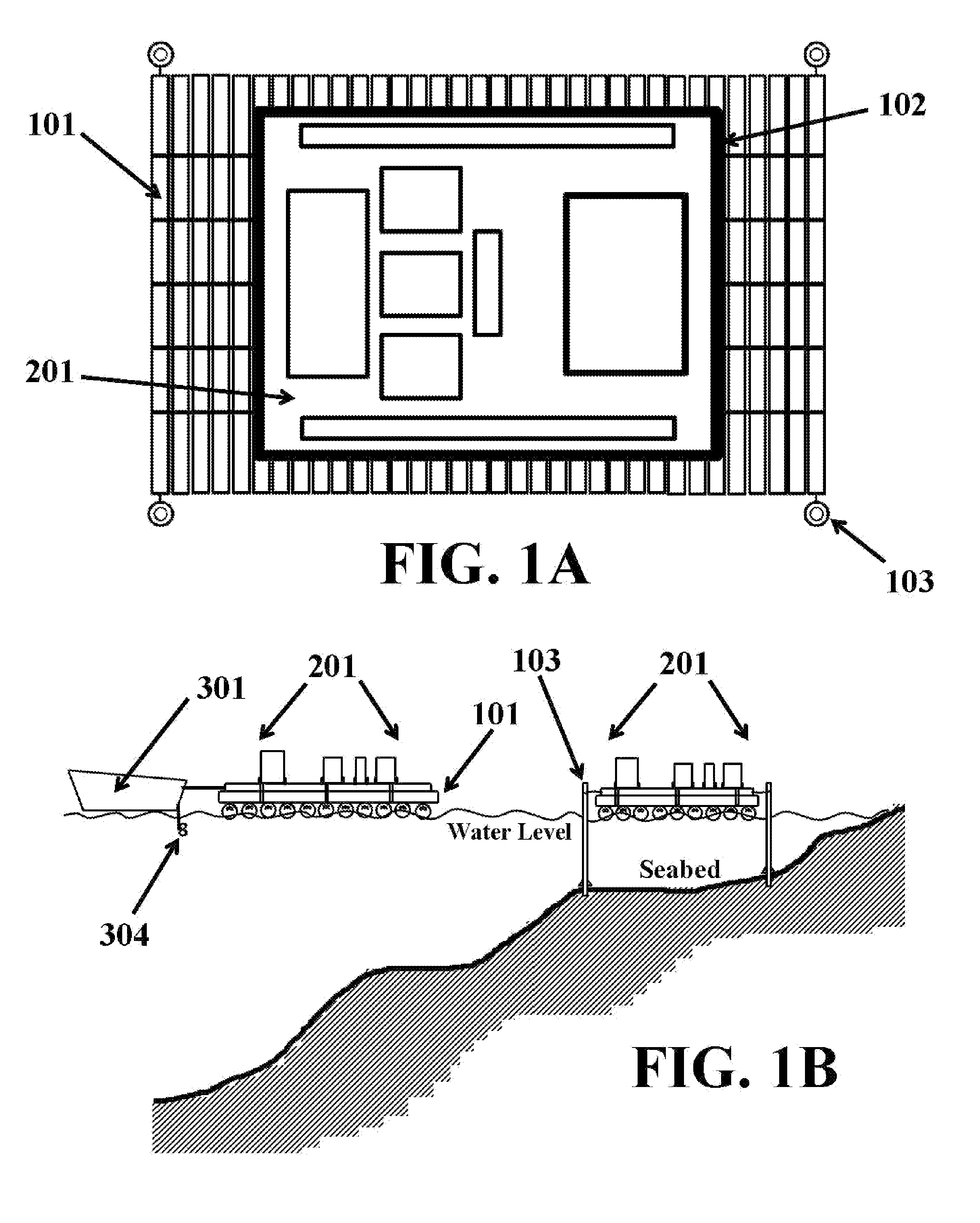

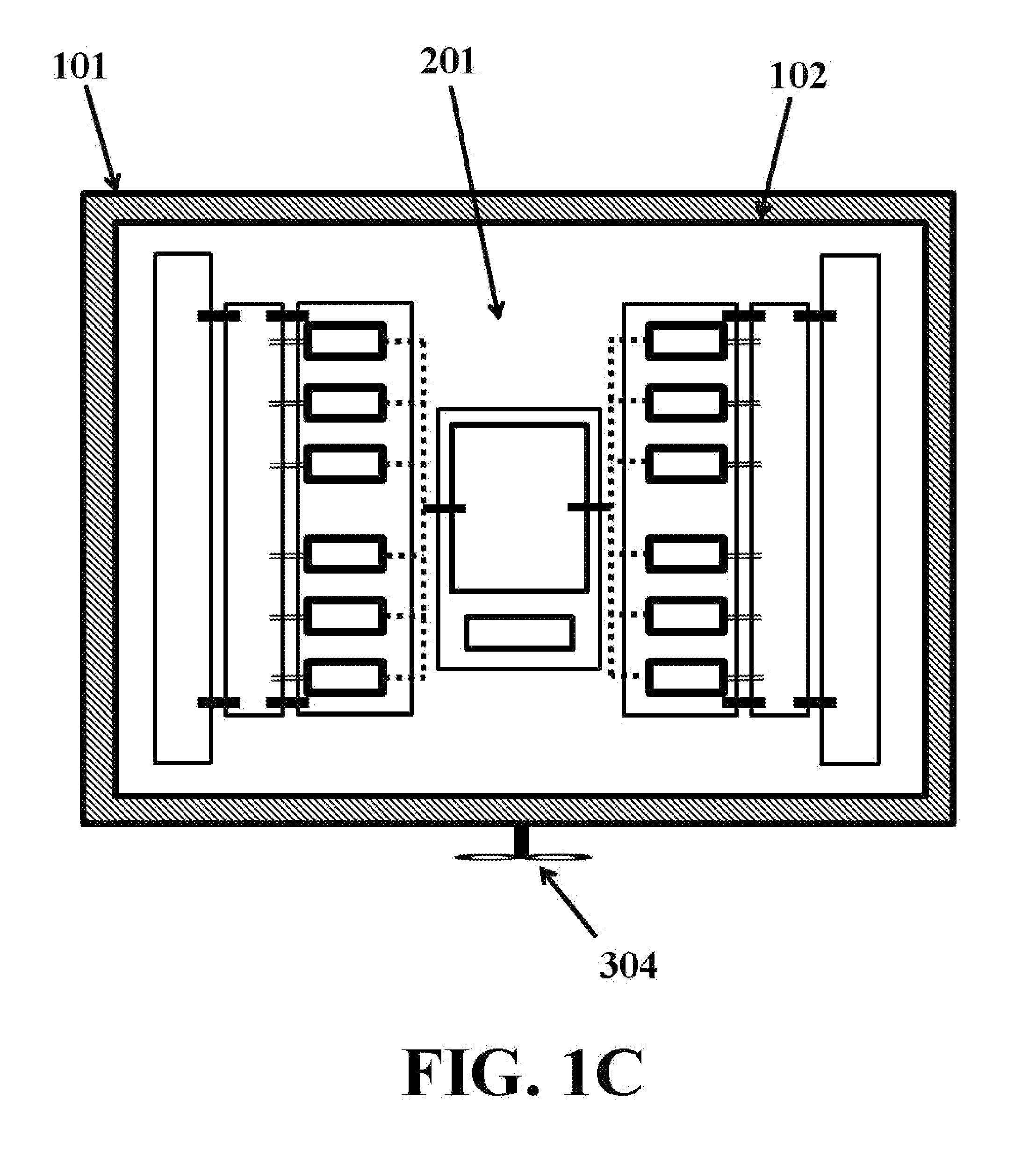

Applications of the bittern produced using the evaporation process of the floating salt farm

InactiveUS20130318870A1High salinityReduce salinityOther chemical processesRotary clutchesSaline waterElectricity

A Floating Salt Farm is an offshore system in which its purpose is to produce crystallized salt and bittern using the evaporation process. This present application is regarding three different applications of the bittern produced using the Floating Salt Farm: (1) An osmotic power (or salinity gradient power) plant is used jointly with the Floating Salt Farm to generate electricity at offshore locations by using produced bittern and extracted seawater; (2) The bittern and / or crystallized salt to be used to melt ice and snow are produced with the Floating Salt Farm by using seawater, in which has been affected by volcanic activities and has substantial silica content (silicon dioxide); (3) In a halophyte farm, where there may not be saline water readily available, the bittern produced using the Floating Salt Farm is applied to the saline soil to adjust its salinity level to maintain proper conditions for halophytes.

Owner:LIM JAE HYUN

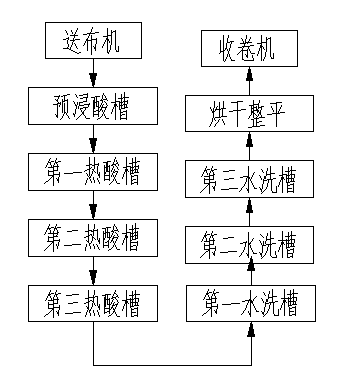

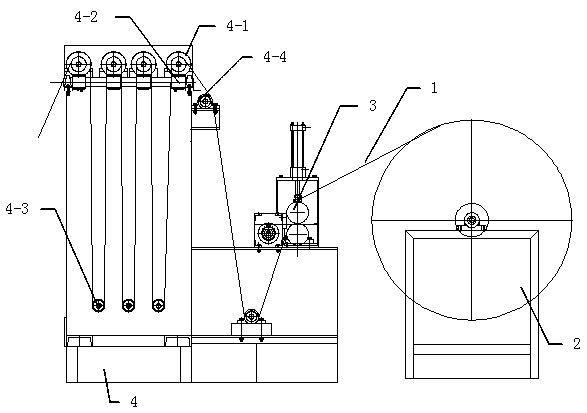

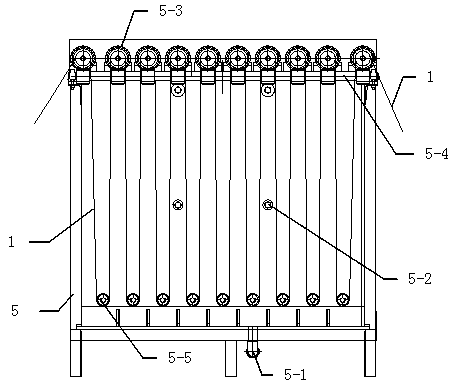

Equipment for continuous acid leaching treatment of high silica glass fiber cloth

ActiveCN104250898AHigh in silicaSilica content is stableSucessive textile treatmentsProduction lineWinding machine

The invention discloses equipment for continuous acid leaching treatment of high silica glass fiber cloth. The equipment comprises an acid leaching slot; the acid leaching slot comprises a presoaking acid slot, a thermal acid slot I, a thermal acid slot II and a thermal acid slot III; the glass fiber cloth arranged on an unwinding machine enters the presoaking acid slot, the thermal acid slot I, the thermal acid slot II, the thermal acid slot III, a water washing slot I, a water washing slot II and a water washing slot III in sequence by a cloth feeding machine, pickling and washing are finished, the glass fiber cloth is dried and flattened by drying and flattening equipment, and is wound by a winding machine beside the drying and flattening equipment, and the production line operation is finished. The equipment is a piece of production line equipment, the content of SiO2 in the glass fiber cloth can be improved from 70% to be over 96% by controlling the process parameters through the process steps, the temperature resistance performance of grey cloth is improved to 100 DEG C, the continuous production line acid leaching production efficiency is high, the SiO2 content of obtained grey cloth is stable, the comprehensive performance of the product is greatly improved, and benefits are increased for an enterprise.

Owner:JIANGSU HENGZHOU SPECIAL GLASS FIBER MATERIAL

Granite waste rock powder ceramsite and preparation method thereof

InactiveCN107445646AHigh in silicaHigh hardnessCeramic materials productionCeramicwareExpanded clay aggregateCoal

The invention discloses granite waste rock powder ceramsite, which is prepared from the following ingredients in percentage by mass: 50.0 to 80.0 percent of granite waste rock powder, 4.0 to 15.0 percent of clay tailings, 10.0 to 20.0 percent of waste porcelain powder, 5.0 to 10.0 percent of clay and 1.0 to 5.0 percent of pulverized coal. The invention also discloses a preparation method of the granite waste rock powder ceramsite. The process is simple; the cost is low; a large amount of granite waste rock powder is consumed; the waste utilization rate is high; the performance of the prepared granite waste rock powder ceramsite is excellent; the application prospects are wide. By the process, the raw materials are directly mixed and pelletized, and are then put into a high-temperature furnace to be calcined to be prepared into the granite waste rock powder ceramsite; the formation process is simplified; the work efficiency is improved; meanwhile, the preparation method is suitable for mass production.

Owner:UNIV OF JINAN

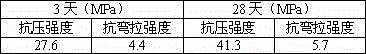

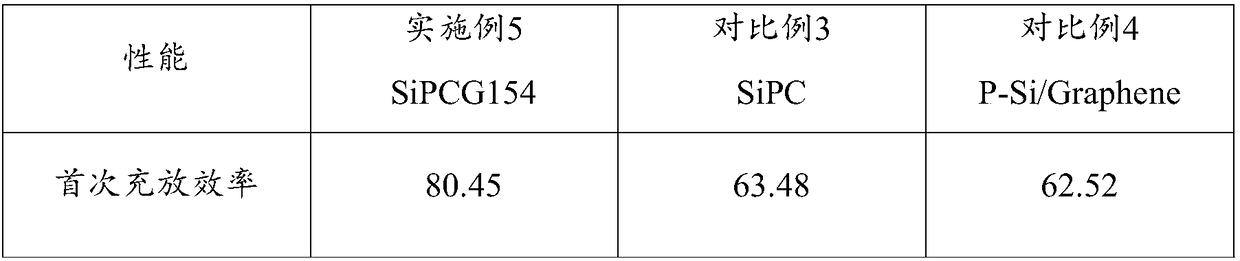

Iron tailings roller compacted concrete for pavement

InactiveCN104529322AWide variety of sourcesHigh in silicaSolid waste managementRoller-compacted concreteSlag

The present invention relates to iron tailings roller compacted concrete for pavement. The iron tailings roller compacted concrete is characterized in that the iron tailings roller compacted concrete is prepared from 218-327 Kg / m<3> of a silicate cement, 283-436 Kg / m<3> of an admixture, 349-436 Kg / m<3> of iron tailings, 873-1091 Kg / m<3> of an aggregate, 0.44-0.88 Kg / m<3> of an additive and 150-174 Kg / m<3> of water, wherein the admixture is a mixture of iron tailings, blast furnace slag and fly ash, the aggregate is formed by crushing iron mine waste rock, and the additive is a polycarboxylic acid water reducing agent. According to the present invention, the iron tailings roller compacted concrete of the present invention is mixed and is loaded into a mold, and then is placed onto the upper surface of the vibrating table, and 300 Kg / m<2> of the pressure is applied, the pressing-vibrating method is utilized to mold, and the flexural strength after 28 days achieves more than or equal to 5.7 MPa.

Owner:ANSTEEL GRP MINING CO LTD

Granite waste rock powder ceramsite pervious concrete and preparation method thereof

InactiveCN107445556AHigh in silicaHigh hardnessCeramicwareExpanded clay aggregatePulverized fuel ash

The invention provides granite waste rock powder ceramsite pervious concrete and a preparation method thereof. The granite waste rock powder ceramsite pervious concrete is prepared from the following ingredients in percentage by weight: 60 to 75 percent of granite waste rock powder ceramsite, 10 to 25 percent of cement, 6 to 20 percent of pulverized fuel ash, 0.1 to 0.5 percent of water reducing agents and 7 to 8 percent of water, wherein the granite waste rock powder ceramsite has the grain diameter being 10 to 20mm, and is prepared from the following ingredients in percentage by weight: 50 to 80 percent of granite waste rock powder, 4 to 15 percent of clay tailings, 10 to 20 percent of waste porcelain powder, 5 to 10 percent of clay and 1 to 5 percent of coal dust. A large amount of granite waste rock powder ceramsite is used for replacing natural aggregate; the surface of the granite waste rock powder ceramsite is hard; fine and fine honeycomb micropores are formed at the inside; the characteristics of small density, low heat conductivity, high strength and good water permeability are realized. Meanwhile, the fireproof performance of the ceramsite sintered through high temperature is excellent; the consistency with the concrete is good; the performance of the pervious concrete can be obviously improved.

Owner:UNIV OF JINAN

Aroma type spirit distiller grain comprehensive utilization method

ActiveCN101565187BQuality improvementThe size of granuleSilicaFood processingCombustionProcess engineering

The invention belong to wine brewing waste material comprehensive utilization field and aims at providing an efficiency method for applying the aroma type spirit distiller grains. The method comprisesfollowing steps: a. cleaning the aroma type spirit distiller grains, and smashing the mass in a machine; b. drying the products in step a in a drier to control the water content of 6-15%; c. grindingthe products in step b on a mill and peeling the rice hulls and the other components; d. feeding the grinded aroma type spirit distiller grains in a sieving machine for separation. The products on the sieve contain a lot of rice hulls for fuel. The burned rice hulls are used for producing carbon white. The sieved products are used for preparing feeds. The method has little equipment investment, low production cost, high feed quality, high rice hull combustion rate and stable rice hull dusts and can adequately use the aroma type spirit distiller grains.

Owner:SICHUAN YIBIN WULIANGYE GROUP +1

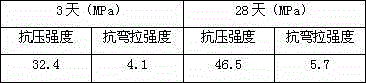

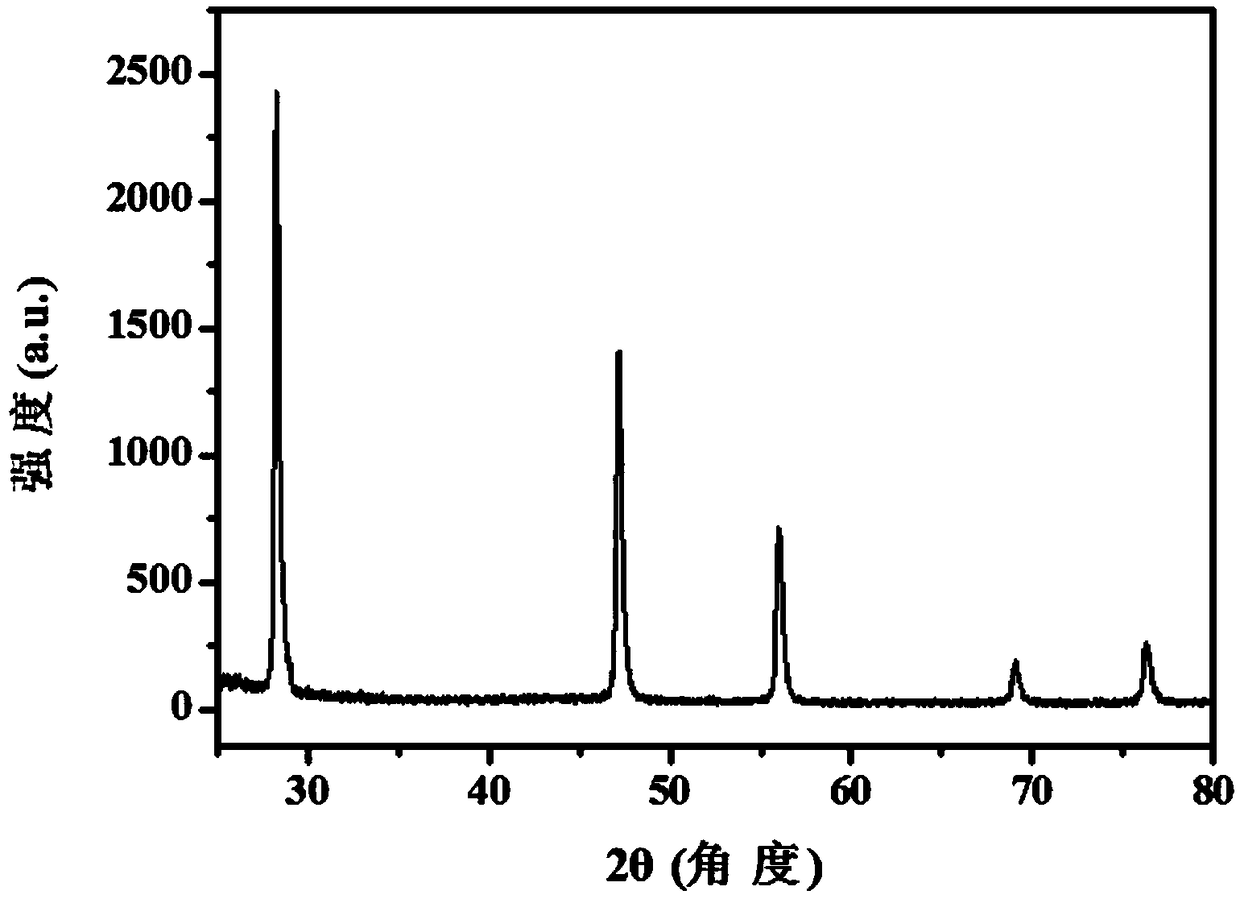

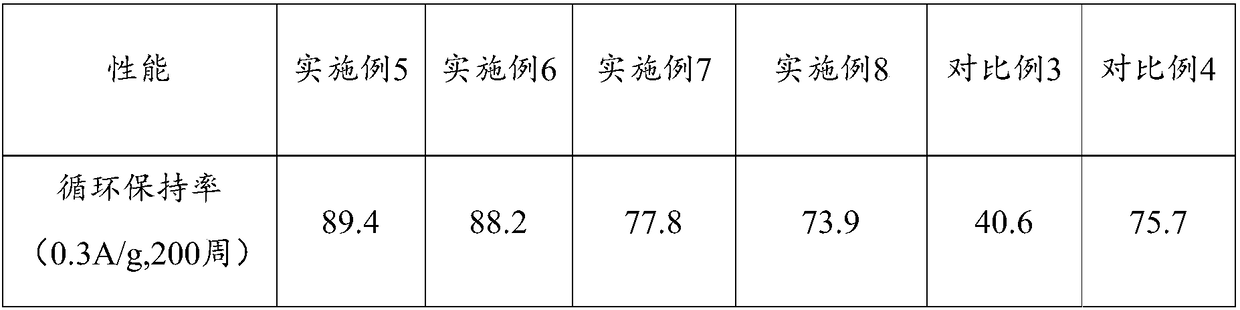

Silicon-carbon negative electrode material as well as preparation method thereof and electrode comprising silicon-carbon negative electrode material

ActiveCN108417816ALow costHigh in silicaSecondary cellsNegative electrodesCapacity lossReduction treatment

The invention provides a silicon-carbon negative electrode material as well as a preparation method thereof and an electrode comprising the silicon-carbon negative electrode material, and relates to the technical field of battery materials. The preparation method of the silicon-carbon negative electrode material comprises the following steps: a) providing zeolite powder which is sequentially subjected to reduction treatment and purifying treatment to obtain porous silicon; and b) using a pyrolysis carbon source and graphite to coat porous silicon to obtain the silicon-carbon negative electrodematerial. The preparation method can be utilized for solving the technical problems that an existing silicon-carbon negative electrode material is high in cost, is low in content of silicon dioxide in the raw material, and is complex in a method for preparing the porous silicon, especially can be used for solving the technical problem that an existing silicon-carbon negative electrode material has irreversible capacity loss, and is used for obtaining the silicon-carbon negative electrode material with excellent electrochemical performance.

Owner:SOUNDON NEW ENERGY TECH CO LTD

Red-base golden-dot ceramic glaze and preparation method thereof

The invention relates to a red-base golden-dot ceramic glaze and a preparation method thereof, belonging to the technical field of ceramics. The red-base golden-dot ceramic glaze comprises the following raw materials in percentage by mass: 30-35.5% of fusion cake, 21.5-27% of potassium feldspar powder, 14.5-19% of silicon dioxide, 6.6-7% of lithium carbonate and 21.9-27.4% of ferric oxide. The fusion cake comprises the following raw materials in percentage by mass: 1.5-2% of potassium oxide, 15.5-17.5% of sodium oxide, 6.9-8% of calcium oxide, 2.1-3.1% of barium oxide, 2.4-3.4% of aluminum oxide and 66-71.6% of silicon dioxide. The red-base golden-dot ceramic glaze can also contain 1% of manganese peroxide. The glaze color of the red-base golden-dot ceramic glaze has the artistic effects of the particular ceramic glaze material, and the red-base golden-dot ceramic glaze has the golden or orange metal bright dot grains on the dark red ceramic glaze surface. After a long-time experiment under the temperature condition of -30 DEG C, cracking or shedding does not appear on the glaze surface, and the glaze can resist corrosion of common acids and alkalis.

Owner:SHENYANG JIANZHU UNIVERSITY

Method for manufacturing high temperature and high pressure resisting oil well cementing test block through silicon kaolin ceramic microbeads

InactiveCN104531111AChange the dependence of floating beadsLow densityDrilling compositionCeramicwareKaolin clayMixed materials

Disclosed is a method for manufacturing a high temperature and high pressure resisting oil well cementing test block through silicon kaolin ceramic microbeads. The method comprises the steps of the silicon kaolin blind hole hollow ceramic microbeads are prepared, batched, mixed and stirred for size mixing, 55 wt% to 65 wt% of G-level oil well cement, 25 wt% to 35 wt% of the silicon kaolin ceramic microbeads with the particle size of five microns to 50 microns, 5 wt% to 7 wt% of coal ash with the ignition loss of 1.1 percent and the particle size of 20 microns to 50 microns, 1.5 wt% to 2 wt% of calcium oxide with the purity of 99.9 percent, 0.5 wt% to 1.0 wt% of sodium sulfate and 1 wt% to 3 wt% of micro-silicon with the particle size of five microns to 20 microns are mixed, size mixing is carried out on the mixed materials according to the water cement ratio of 0.5-0.7, the mixed materials are poured into a set of two test molds with the length of 53 mm, the width of 53 mm and the height of 53 mm, the test molds are maintained in water bath maintenance boxes at the constant temperature of 52 DEG C for 24 hours and 48 hours respectively, the mixed materials are soaked in cold water for one hour after demolding, and a performance index test is carried out.

Owner:SHANDONG UNIV OF TECH

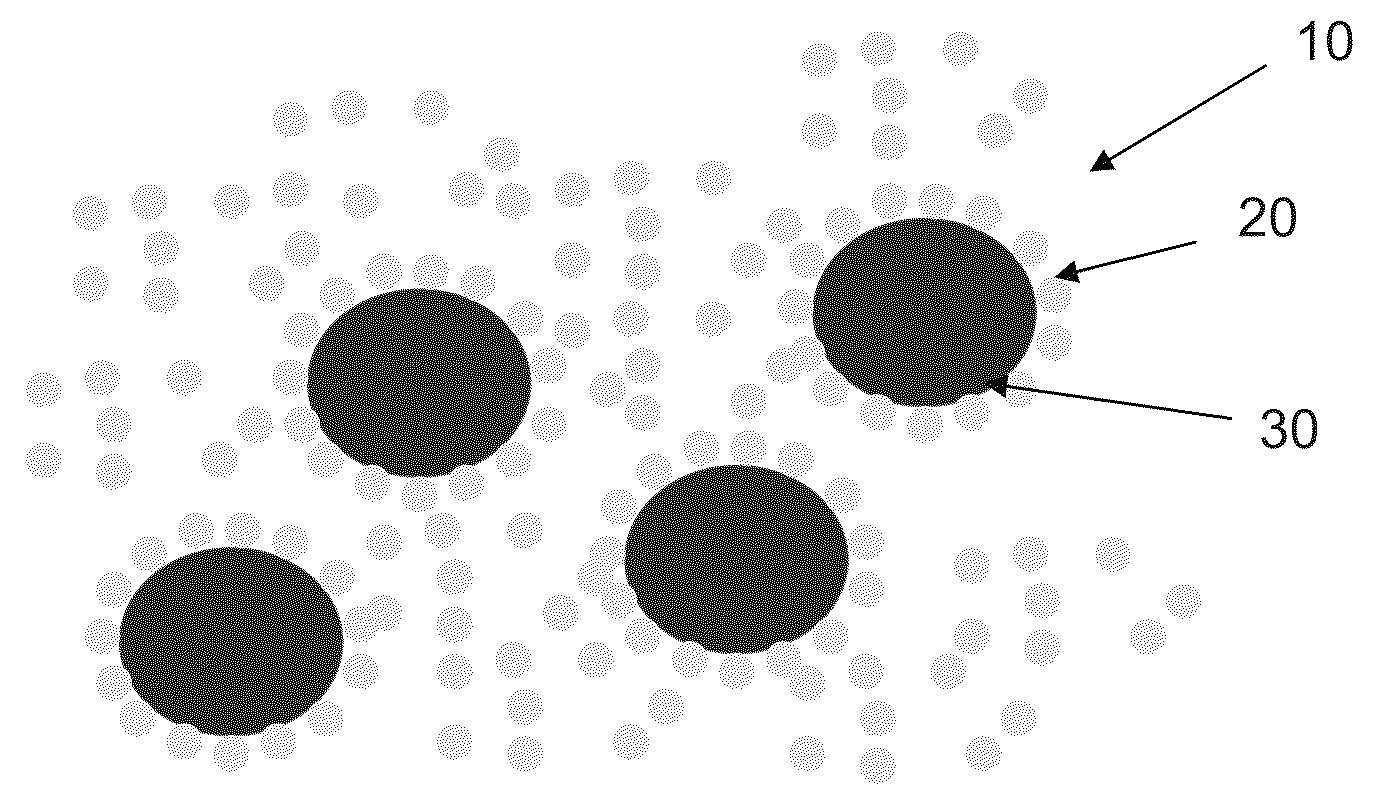

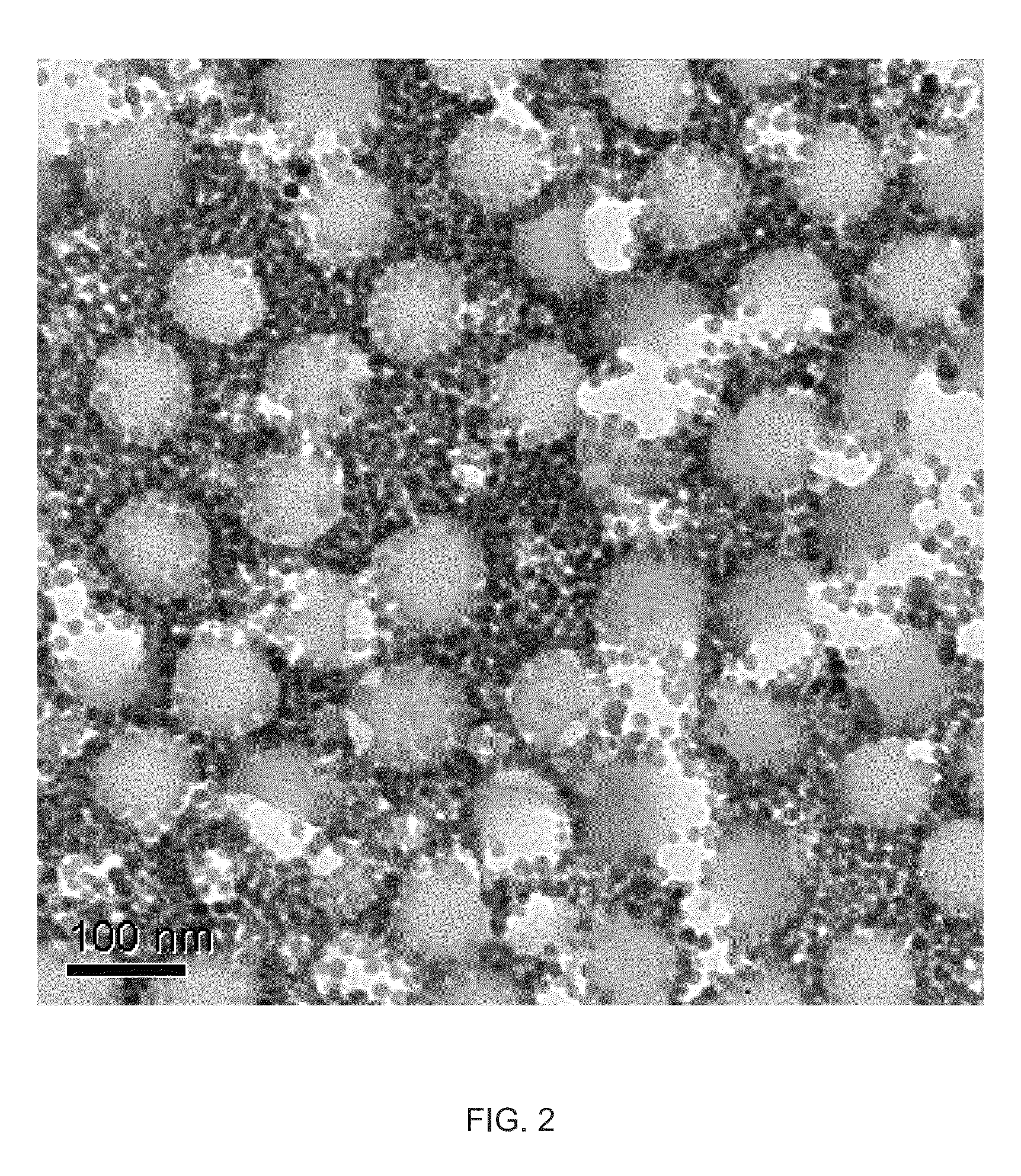

Hybrid organic-inorganic nanocomposites

ActiveUS8815981B2Improve performanceHigh solid contentSpecial tyresCoatingsSilica nanoparticlesSilicon dioxide

The present invention relates to a dispersion of hybrid organic-inorganic nanocomposite molecules comprising discrete inorganic silica nanoparticles that are covalently bonded to organic polymers, wherein the dispersion has a high solid content (>30% wt.) and high silica content (>35% wt.) with low coagulum (about 100-400 ppm or about 0.05% wt or less). The hybrid organic-inorganic nanocomposite is prepared by (1) hydrolyzing silane monomers at acidic conditions; (2) surface treating inorganic silica nanoparticles with silane monomers; (3) stabilizing the surface-treated inorganic silica nanoparticles with an amine stabilizer; and (4) reacting organic monomers with surface-treated inorganic silica nanoparticles.

Owner:COLUMBIA INSURANCE CO

Te-hua scallion-root-white porcelain and preparation process thereof

InactiveCN107129268AHigh in silicaIncrease warmthCeramic materials productionClaywaresTransmittanceAbsorption rate

The invention belongs to the field of porcelain products, and particularly relates to Te-hua scallion-root-white porcelain and a preparation method thereof. A whiteness degree of the prepared Te-hua scallion-root-white porcelain is between 83 and 85 degrees, a water absorption rate is 0, the light transmittance is greater than 15 percent (1 mm), the Te-hua scallion-root-white porcelain is white and pure, and a glaze surface is moisturized. According to the Te-hua scallion-root-white porcelain, local raw materials of Te-hua are selected as raw materials for burning the scallion-root-white porcelain, chemical components of the raw materials are strictly controlled, rose quartz are introduced into the raw materials of a green body and glaze, so that not only can the content of silicon dioxide in the raw materials be increased, but also natural and trace Mn and Ti of the rose crystals can improve the moisturizing degree of the green body and the glaze surface, the color is moisturized, the glaze surface is soft, and an artistic effect closest to traditional Te-hua scallion-root-white porcelain can be achieved.

Owner:CERAMICS SCI & TECH RES INST QUANZHOU +1

Nickel oxide high-temperature purple silk-gloss ceramic glaze and preparation method thereof

The invention provides nickel oxide high-temperature purple silk-gloss ceramic glaze and a preparation method thereof, and belongs to the field of ceramic. The nickel oxide high-temperature purple silk-gloss ceramic glaze is obtained by firstly preparing a nickel oxide high-temperature purple silk-gloss ceramic glaze material, and then glazing and sintering at high temperature, wherein the nickeloxide high-temperature purple silk-gloss ceramic glaze material is prepared from the following raw materials according to the mass percent of each raw material: 45 percent to 35 percent of potassium feldspar powder, 4.5 percent to 6 percent of silicon dioxide, 4.5 percent to 10 percent of kaolin, 10 percent to 20 percent of zinc oxide, 30 percent to 40 percent of a frit and 1 percent to 2 percentof nickel oxide. The frit is prepared from the following raw materials according to the mass percent of each raw material: 1 percent to 3 percent of potassium oxide, 12 percent to 20 percent of sodiumoxide, 2 percent to 8 percent of calcium oxide, 10 percent to 35 percent of barium carbonate and 40 percent to 60 percent of silicon dioxide. By adopting the method provided by the invention, a phenomenon in a firing process of a traditional glaze material that a lot of poisonous heavy metal is volatilized is overcome; meanwhile, phenomena that needle holes and cracks are formed in the surface ofa fired product are effectively prevented.

Owner:SHENYANG JIANZHU UNIVERSITY

Melting method and apparatus

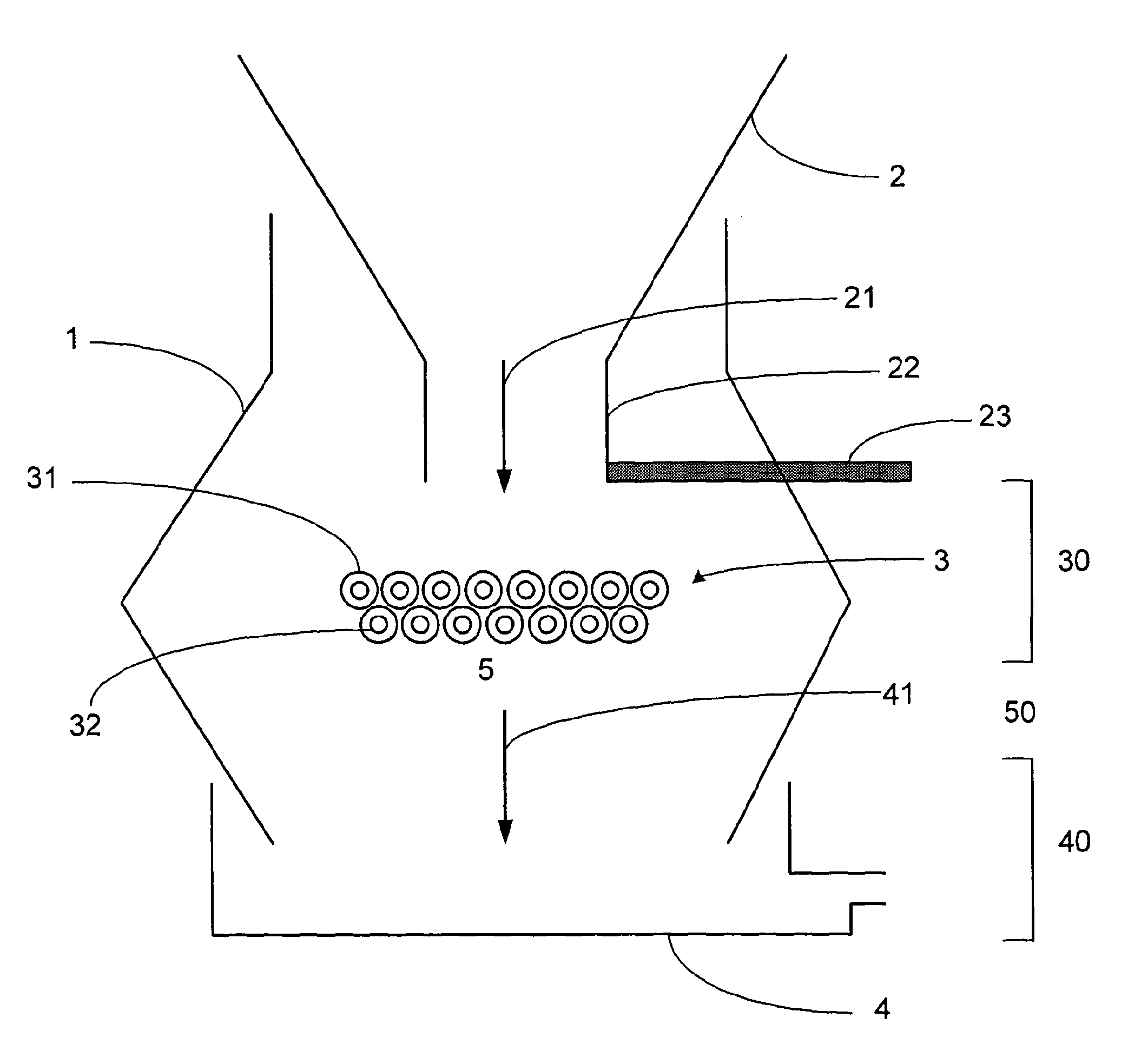

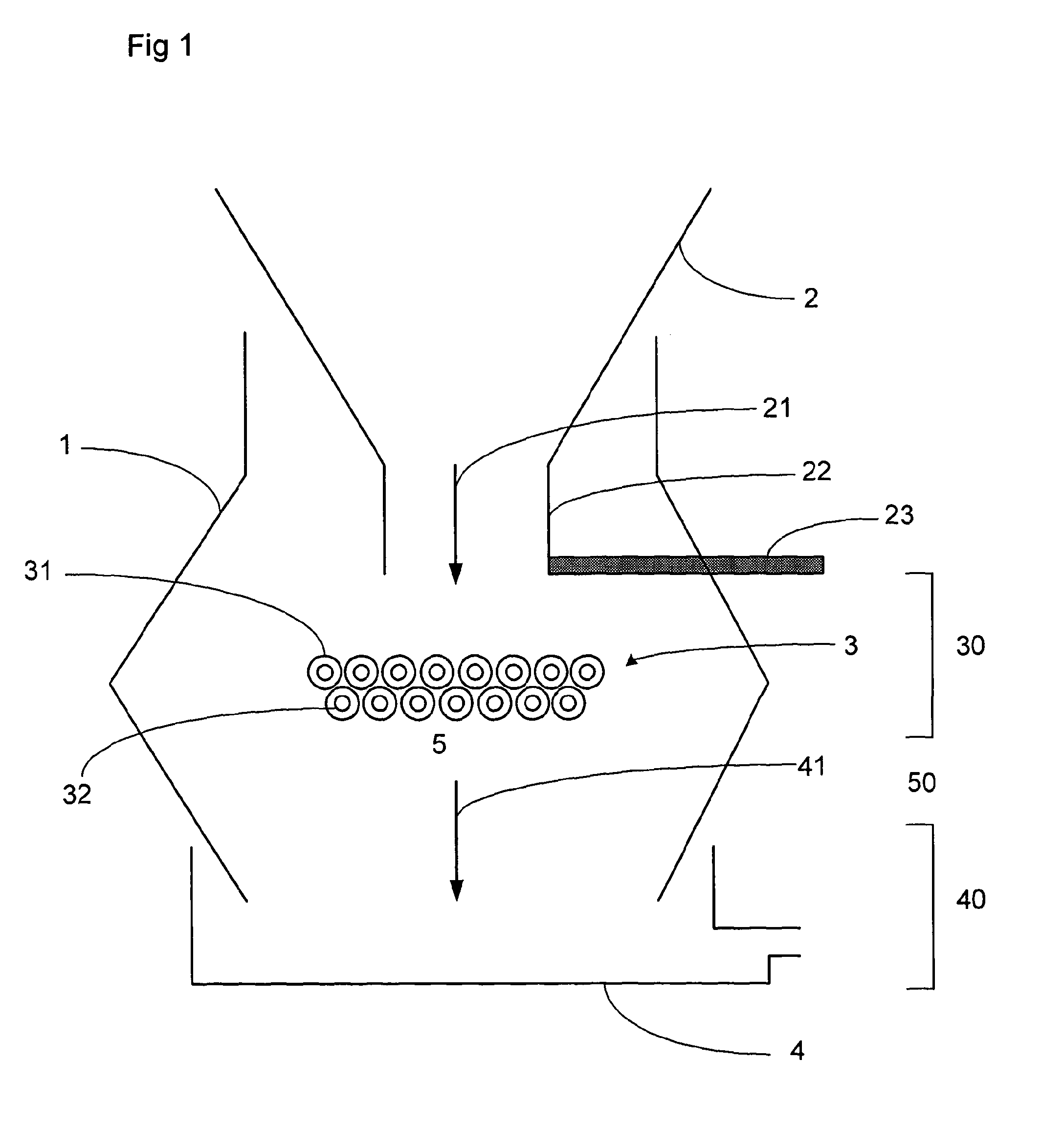

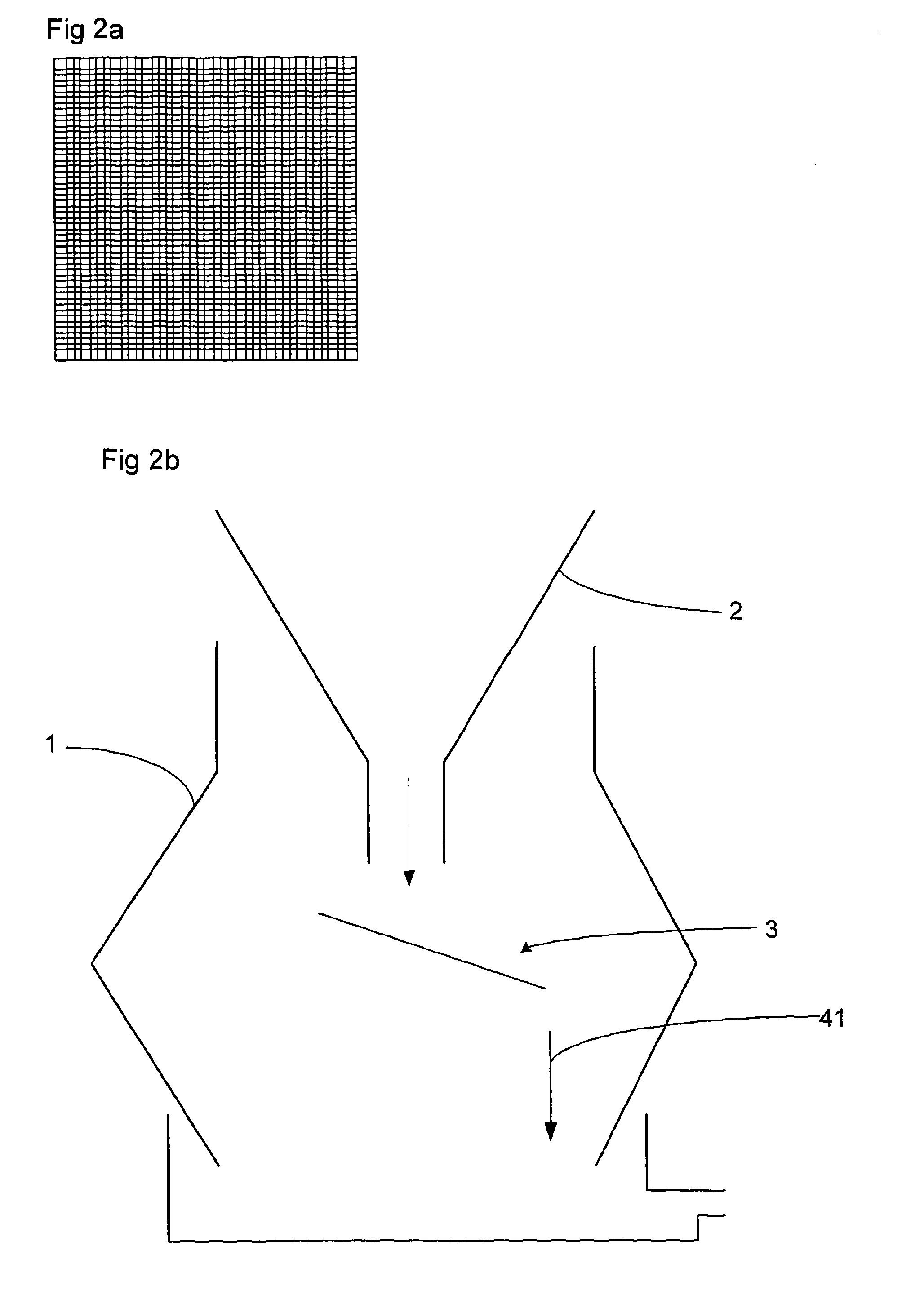

InactiveUS20120272685A1Reduce risk of contaminationMinimize contactCharging furnaceTank furnacesSolid phasesChemistry

A method and apparatus for melting a raw material such as glass. The method comprises a creating a flow of raw material interrupted by a heated phase separation barrier (3,31,32), wherein melting is achieved by transfer of heat from the phase separation barrier to the raw material. The process comprises: providing solid raw material to the phase separation barrier, wherein the phase separation barrier supports the solid raw material; heating the phase separation barrier to a temperature which is (a) at least 700° C. and (b) sufficient to cause melting of the solid raw material which contacts the barrier, wherein any melted raw material formed on contact with the phase separation barrier flows off or through the phase separation barrier; and collecting the melted raw material; wherein the phase separation barrier causes separation of the solid and melted phases within the flow of the raw material. Two or more melters may be used in parallel and the resultant melted raw materials mixed together in the melted state. In addition, there is provided a method and apparatus for producing a melt comprising a mixture of melted raw materials. The apparatus comprises two melting chambers connected via outlets to a homogeniser.

Owner:PAULI ROGER

Water glass wet production method

The invention discloses a water glass wet production method. The method comprises mixing water glass having a baume concentration of 50Be and a liquid base having purity of 50% according to a ratio of 1: 1, cooling the mixture along with continuous stirring to precipitate sodium metasilicate pentahydrate crystals, introducing the crystals into a centrifugal machine when the temperature is reduced to 40 DEG C, carrying out dehydration treatment, exporting a sodium metasilicate pentahydrate mother liquor, mixing the sodium metasilicate pentahydrate mother liquor and quartz sand having silicon content of 98% and fineness of 150 to 200 meshes according to a weight ratio of 60: 40, feeding the mixture into a reactor, filling the reactor with steam under pressure of 0.6 MPa, and carrying out a reaction process for 6h to obtain high silica content water glass. The method solves the technical problem that the silica content does not satisfy the standard. The silica obtained by the method has the content of 32% and modulus of about 2.5, is in an excellent shape and is worthy of promotion.

Owner:江西省欧陶科技有限公司

Green background sliver crackle high-temperature crystal glaze and preparation method thereof

The invention discloses green background sliver crackle high-temperature crystal glaze and a preparation method thereof, and belongs to the field of ceramic. The green background sliver crackle high-temperature crystal glaze is formed by firstly preparing a green background sliver crackle high-temperature crystal glaze material and then performing glazing and high temperature sintering. The greenbackground sliver crackle high-temperature crystal glaze comprises the following raw materials in mass percent: 33 to 43 percent of frits, 23 to 33 percent of calcined zinc oxide, 13 to 23 percent ofsilicon dioxide, 1 to 5 percent of kaolin, 2 to 8 percent of titanium dioxide, 1 to 4 percent of bentonite, 1 to 6 percent of chalk powder, and 1 to 5 percent of copper carbonate. The frit comprises the following raw materials in mass percent: 1 to 3 percent of potassium oxide, 10 to 20 percent of sodium oxide, 4 to 10 percent of calcium oxide, 1 to 5 percent of diboron trioxide, and 65 to 75 percent of silicon dioxide. The method ensures that ceramic enamel produces sliver flaky crystals during the production of green ceramic glaze, the crystals are uniformly distributed, and a special artistic effect is realized.

Owner:SHENYANG JIANZHU UNIVERSITY

Copper carbonate high-temperature purple ceramic glaze and preparation method thereof

The invention belongs to a copper carbonate high-temperature purple ceramic glaze and a preparation method thereof, which belong to the field of ceramics. The copper carbonate high-temperature purpleceramic glaze is prepared by the steps of firstly preparing a copper carbonate high-temperature purple ceramic glaze material, glazing and sintering at high temperature. The copper carbonate high-temperature purple ceramic glaze material is prepared from the raw materials in percentage by mass: 42 percent to 52 percent of potassium feldspar, 6 percent to 10 percent of chalk powder, 15 percent to 25 percent of silicon dioxide, 1 percent to 4 percent of kaolin, 4 percent to 8 percent of sodium pyroborate, 4 percent to 10 percent of dolomite, 2 percent to 6 percent of zinc oxide, 1 percent to 4 percent of stannic oxide, 0.5 percent to 2 percent of copper carbonate, and 2 percent to 5 percent of titanium dioxide. The glaze formula is subjected to long-time adjustment and multiple experiments,a ceramic glaze surface has a uniform color and wide sintering temperature, and meanwhile, the stability of physical and chemical properties of the ceramic glaze is achieved.

Owner:SHENYANG JIANZHU UNIVERSITY

Cement kiln co-processing fly ash solidification method

The invention relates to the field of environmental protection, in particular to a cement kiln co-processing fly ash solidification method. The cement kiln co-processing fly ash solidification methodcomprises the steps of material mixing, pulping, dehydration, calcination and the like. The invention provides a method for co-processing solidified fly ash by using a cement kiln. According to the method, soluble chloride in the fly ash is washed away in a pulping manner; meanwhile, under the action of the heavy metal chelating agent, soluble heavy metal salt is chelated and precipitated and is fixed in dry slurry, and meanwhile, the heavy metal salt dissolved in the slurry is further cured by utilizing carbon dioxide gas contained in cement kiln flue tail gas so that the obtained waste liquid does not need to be subjected to secondary treatment; according to the method, the flue tail gas of the cement kiln and the high temperature of the rotary kiln are comprehensively utilized, and thepurpose of volume reduction and weight reduction comprehensive utilization in waste treatment is achieved.

Owner:浙江红狮环保股份有限公司

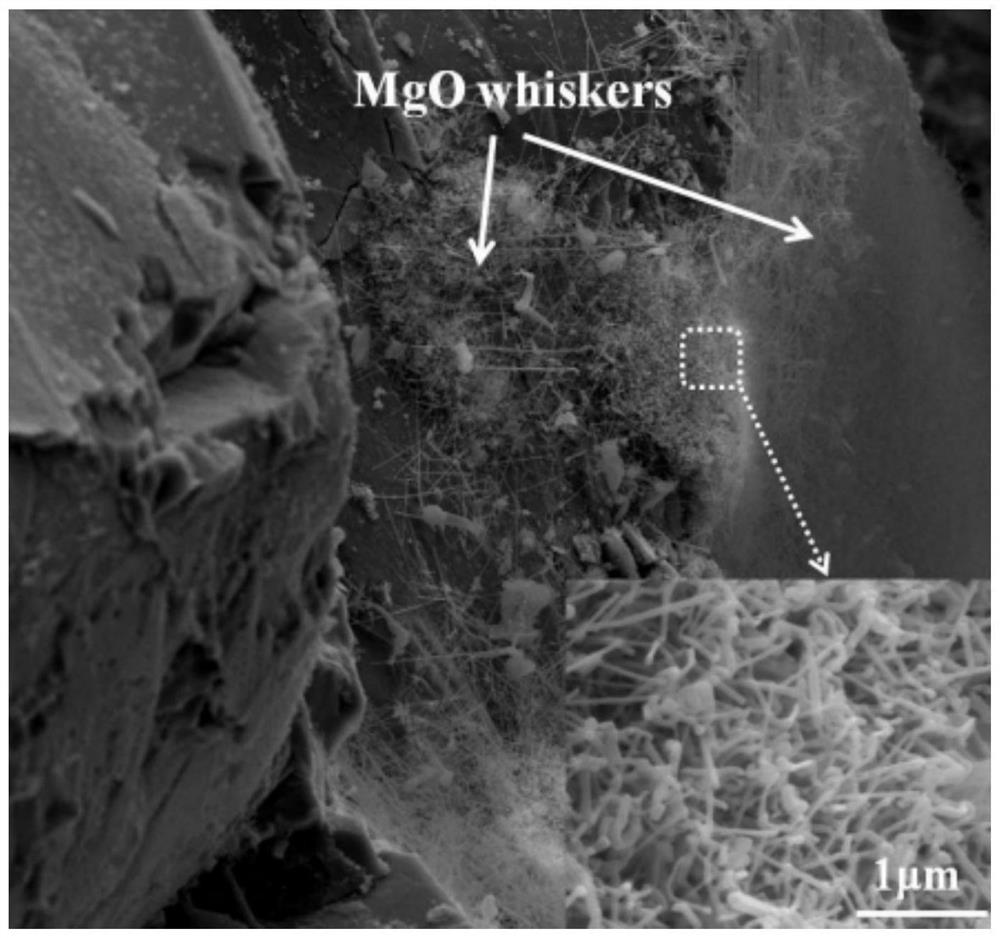

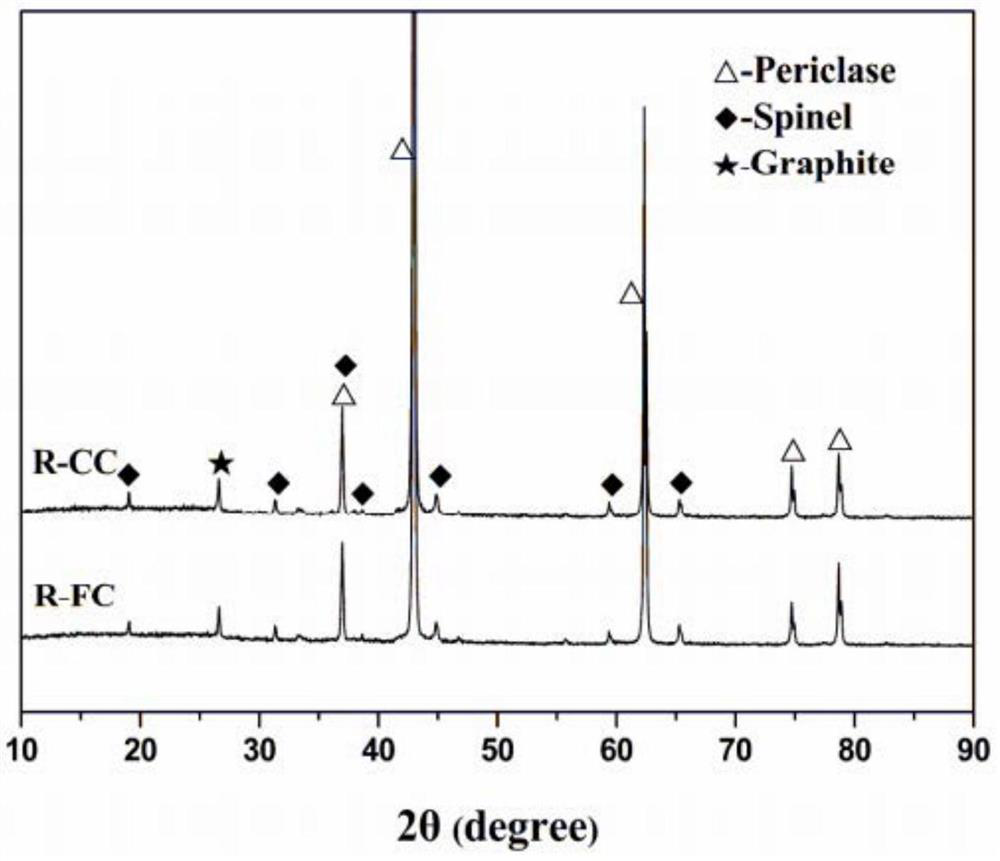

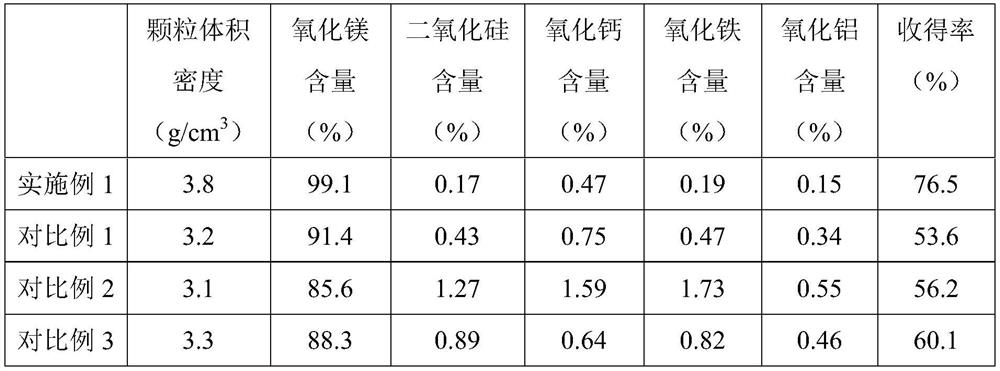

Preparation method of macrocrystalline magnesia with low silicon dioxide content

InactiveCN112094106AObvious performance advantageHigh in silicaFlotationElectric arc furnaceMacrocrystalline

The invention discloses a preparation method of macrocrystalline magnesia with low silicon dioxide content, and belongs to the technical field of mineral resource processing. The method comprises thefollowing steps: (1) fine selection: taking low-grade magnesite as a raw material, and finely selecting magnesite with the magnesium oxide content of 40%-45%; (2) cleaning: cleaning magnesite; (3) refining: refining the magnesite; (4) roasting: feeding the concentrate powder into a rotary kiln or a fluidized bed furnace for roasting, and cooling to room temperature to obtain light calcined magnesia; (5) dry pressing: feeding the light calcined magnesia into a ball press machine for dry pressing to obtain balls; and (6) electric melting: feeding the spheres prepared in the step (5) into an electric arc furnace for electric melting, and carrying out heat preservation, cooling and crystallization. The prepared macrocrystalline magnesia has good performance advantages, the test parameters suchas the particle volume density, the magnesium oxide content, the silicon dioxide content, the calcium oxide content, the iron oxide content, the aluminum oxide content and the yield show significantdifferences, and the macrocrystalline magnesia is high-quality macrocrystalline magnesia.

Owner:LIAONING DONGHE NEW MATERIAL CO LTD

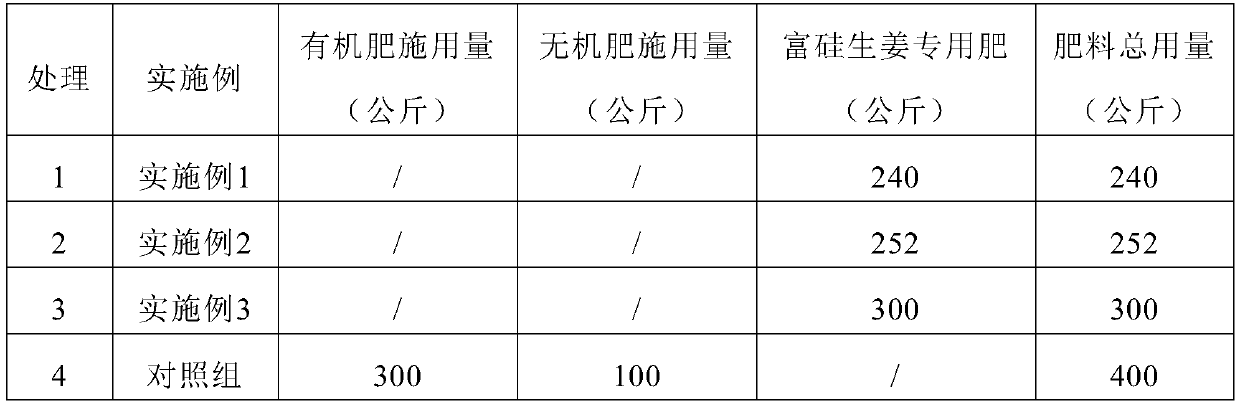

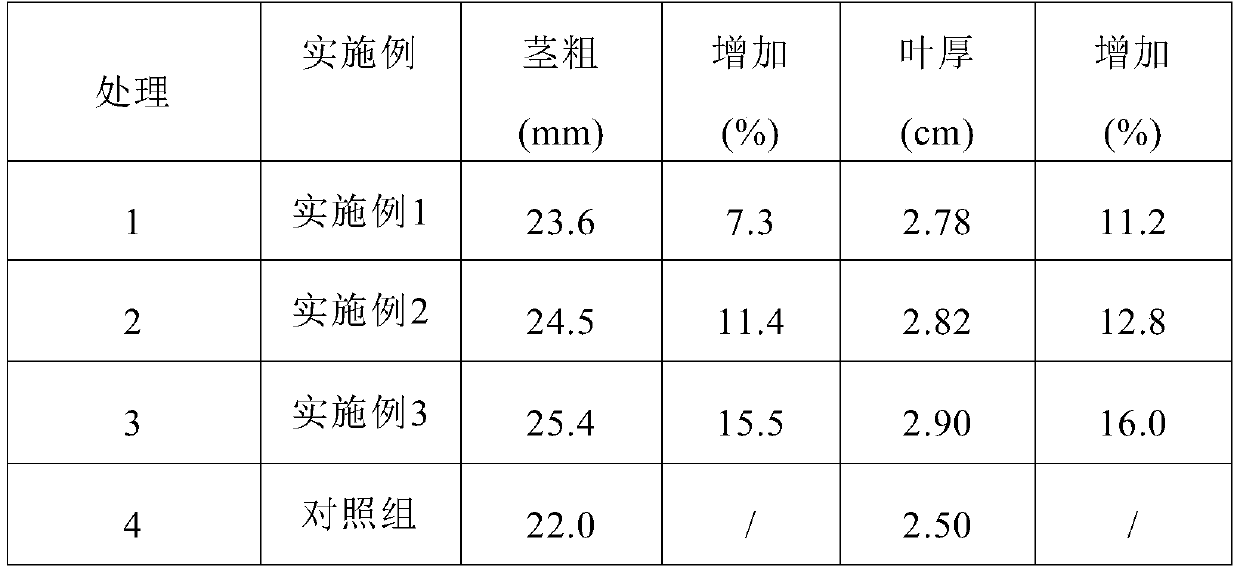

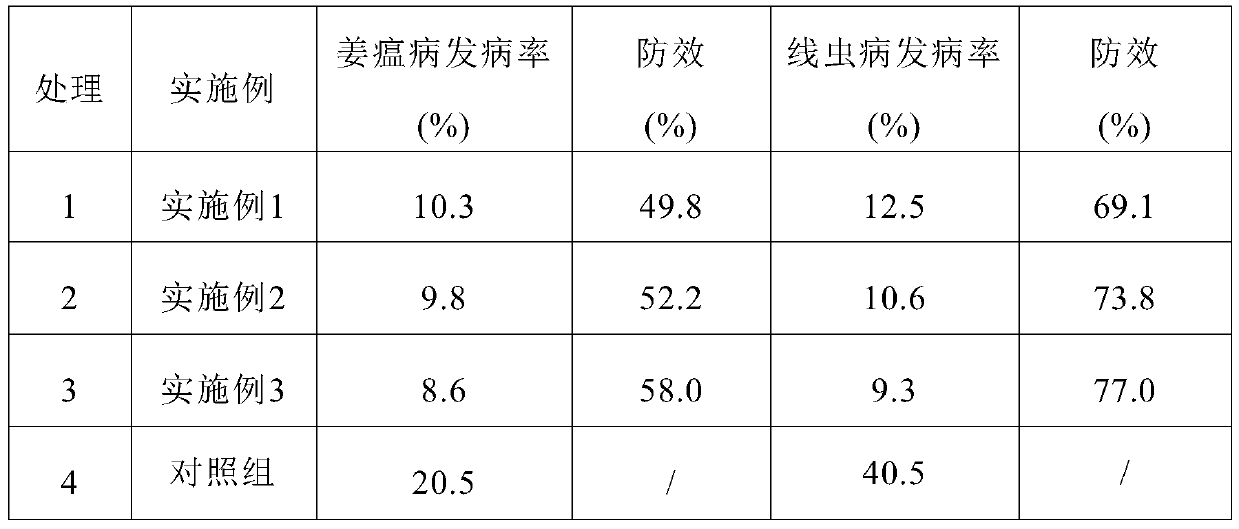

Silicon-rich fertilizer special for ginger and preparation method thereof

ActiveCN110950706AReduce pests and diseasesSolve pollutionAmmonium nitrate fertilisersFertilizer mixturesAgricultural engineeringInsect pest

The invention discloses a silicon-rich fertilizer special for ginger. The technical scheme of the invention discloses a silicon-rich fertilizer special for ginger, the silicon-rich fertilizer specialfor ginger is composed of a rice husk silicon ginger straw organic fertilizer and a slow-release blended fertilizer in a mass ratio of (3-4): 1. According to the silicon-rich fertilizer special for ginger, ginger straw and rice husk are turned into wealth, waste resources in the crop planting process are fully utilized, local materials are used, the fertilizer cost is reduced, plant diseases and insect pests of ginger can be obviously reduced after the fertilizer is applied to ginger for a long time, organic matters can be supplemented to soil, and the yield of ginger is increased. And the pollution problem of straw can be solved.

Owner:上海永通生态工程股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com