Method for preparing ultra-fine active white carbon black by using manganese leached slag and manganese electrolysis waste acid

A technology for leaching slag and electrolytic manganese, which is applied in the direction of silicon dioxide and silicon oxide, can solve the problems of low yield, small particle size and low tensile strength requirements, and improve quality and added value. The effect of reducing the diameter, improving the crosslink density and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

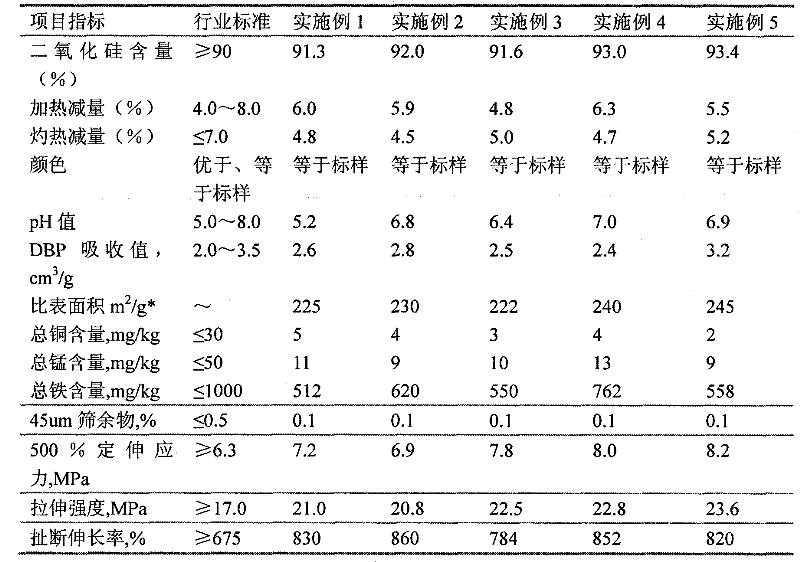

Examples

Embodiment 1

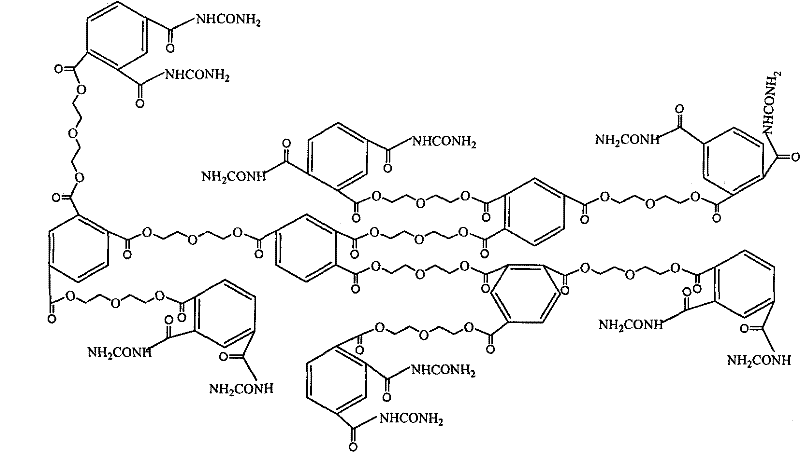

[0027] The preparation of particle active agent: (following examples are the same)

[0028] 1.2 mol of carbon disulfide, 1.2 mol of 20% sodium hydroxide aqueous solution and 0.1 mol of amino-terminated hyperbranched polyester (300 g) powder are uniformly mixed, stirred and reacted at 40° C. for 6 hours, then cooled for crystallization and filtered. Obtain sodium dithiocarbamate solid powder 336g, similar way can obtain potassium dithiocarbamate solid powder.

[0029] Preparation of ultrafine activated white carbon black:

[0030] (1) Wash 100 g of manganese leaching residue with 350 g of 0.10 wt % dilute sulfuric acid aqueous solution and 300 g of 0.10 wt % sodium hydroxide aqueous solution, and then wash with tap water until neutral;

[0031] (2) React the filter residue and 300 g of 41wt% sodium hydroxide solution at about 121° C. for 5 hours, filter, and wash the filter residue with distilled water to neutrality, and merge the washing solution into the filtrate, and collec...

Embodiment 2

[0036] (1) Wash 100 g of manganese leaching residue with 320 g of 0.12 wt % dilute sulfuric acid aqueous solution and 350 g of 0.07 wt % sodium hydroxide aqueous solution in turn, and then wash with tap water until neutral;

[0037] (2) React the filter residue and 200 g of 55 wt% sodium hydroxide solution at about 130° C. for 3 h, filter, and wash the filter residue with distilled water until neutral, and merge the washing liquid into the filtrate, and collect the filtrate;

[0038] (3) The filtrate obtained in step (2) was decolorized with 0.8 g of amino-terminated hyperbranched polyester and 1.0 g of polyacrylamide with a number average molecular weight of 1,000,000 g / mol or more at about 60°C for 5 minutes to obtain a light yellow to colored silicate aqueous solution;

[0039] (4) Take 1,000g of electrolytic manganese waste acid solution, decolorize it with 1.0g of activated carbon at about 95°C for 5 minutes, then use 0.15g of amino-terminated hyperbranched polyester at a...

Embodiment 3

[0042] (1) Wash 100 g of manganese leaching residue with 300 g of 0.15 wt % dilute sulfuric acid aqueous solution and 330 g of 0.05 wt % sodium hydroxide aqueous solution, and then wash with tap water until neutral;

[0043] (2) React the filter residue and 250 g of 45 wt % potassium hydroxide solution at about 125° C. for 2 h, filter, and wash the filter residue with distilled water until neutral, and merge the washing liquid into the filtrate, and collect the filtrate;

[0044] (3) The filtrate obtained in step (2) is decolorized with 1.0 g of amino-terminated hyperbranched polyester and 0.8 g of polyacrylamide with a number-average molecular weight of 1,000,000 g / mol or more at about 80 ° C for 5 min, respectively, to obtain light yellow to colored silicate aqueous solution;

[0045] (4) Take 1000g of electrolytic manganese waste acid solution, decolorize it with 1.5g of activated carbon at about 100°C for 5min, then use 0.10g of amino-terminated hyperbranched polyester at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com