Cement kiln co-processing fly ash solidification method

A co-processing and cement kiln technology, applied in cement production and other fields, can solve secondary pollution control and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for co-processing solidified fly ash in a cement kiln, the main scheme of which is:

[0030] A, mixing, 150kg fly ash, 5kg heavy metal chelating agent, 5kg glass slag powder, 5kg scrap iron slag and 10kg water are added in the pre-mixer, stirred and mixed for 10 minutes;

[0031] B. Pulping, continue to add 60kg of water to the material, and transport the material to the pulping machine for mixing and stirring for 20 minutes, then feed the cement kiln flue gas into the slurry, and mix for 5 minutes;

[0032] C, dehydration, the obtained material slurry is dehydrated, and in obtaining the dry slurry, add 0.5kg flux;

[0033] D. Calcination. The obtained dry slurry is mixed with cement raw meal at a ratio of 10%, and then entered into a rotary kiln as a raw material for the production of cement clinker, and calcined at 1200°C.

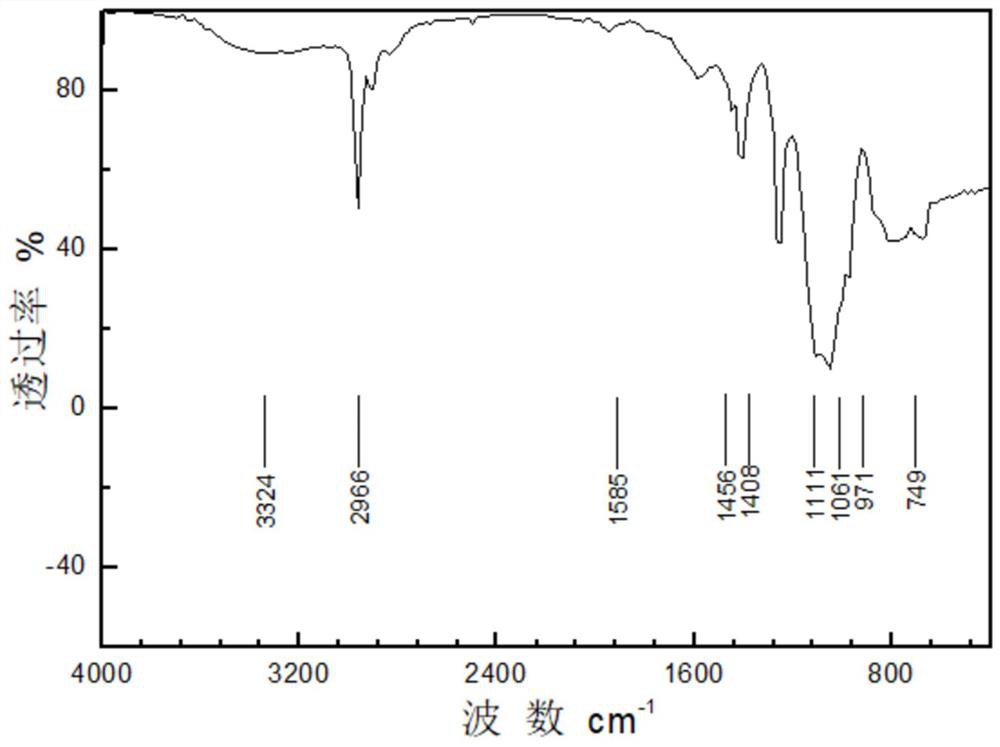

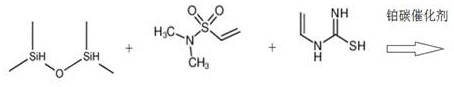

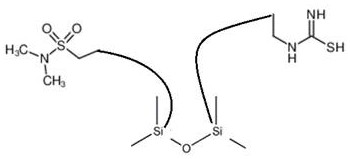

[0034] Described heavy metal chelating agent, its preparation method is as follows:

[0035] Add 60kg of tetramethyl (hydrogen) disilo...

Embodiment 2

[0043] A method for co-processing solidified fly ash in a cement kiln, the main scheme of which is:

[0044] A, mixing materials, 180kg fly ash, 7kg heavy metal chelating agent, 12kg glass slag powder, 8kg scrap iron slag and 20kg water are added in the pre-mixer, stirred and mixed for 20min;

[0045] B. Pulping, continue to add 65kg of water to the material, and transport the material to the pulper for mixing and stirring for 25 minutes, then feed the cement kiln flue gas into the slurry, and mix for 8 minutes;

[0046] C, dehydration, the obtained material slurry is dehydrated, and in obtaining the dry slurry, add 0.8kg flux;

[0047] D. Calcination. The obtained dry slurry is mixed with cement raw meal according to the ratio of 12%, and it is used as a raw material for the production of cement clinker into a rotary kiln, and calcined at 1300°C.

[0048] Described heavy metal chelating agent, its preparation method is as follows:

[0049] 80kg of tetramethyl (hydrogen) disil...

Embodiment 3

[0057] A method for co-processing solidified fly ash in a cement kiln, the main scheme of which is:

[0058] A, mixing materials, 200kg fly ash, 10kg heavy metal chelating agent, 23kg glass slag powder, 12kg scrap iron slag and 30kg water are added in the pre-mixer, stirred and mixed for 30min;

[0059] B. Pulping, continue to add 70kg of water to the material, and transport the material to the pulping machine for mixing and stirring for 30 minutes, then feed the cement kiln flue gas into the slurry, and mix for 10 minutes;

[0060] C, dehydration, the obtained material slurry is dehydrated, and in obtaining the dry slurry, add 1kg flux;

[0061] D. Calcination. The obtained dry slurry is mixed with cement raw meal at a ratio of 15%, and then entered into a rotary kiln as a raw material for the production of cement clinker, and calcined at 1400°C.

[0062] Described heavy metal chelating agent, its preparation method is as follows:

[0063] 100kg of tetramethyl (hydrogen) di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com