Silicon-carbon negative electrode material as well as preparation method thereof and electrode comprising silicon-carbon negative electrode material

A negative electrode material, silicon carbon technology, applied in the direction of negative electrode, battery electrode, active material electrode, etc., can solve the problems of battery electrochemical performance decline, porous silicon method is cumbersome, irreversible capacity loss, etc., to improve cycle performance and shorten production Cycle time, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] One aspect of the present invention provides a method for preparing a silicon-carbon negative electrode material, comprising the following steps:

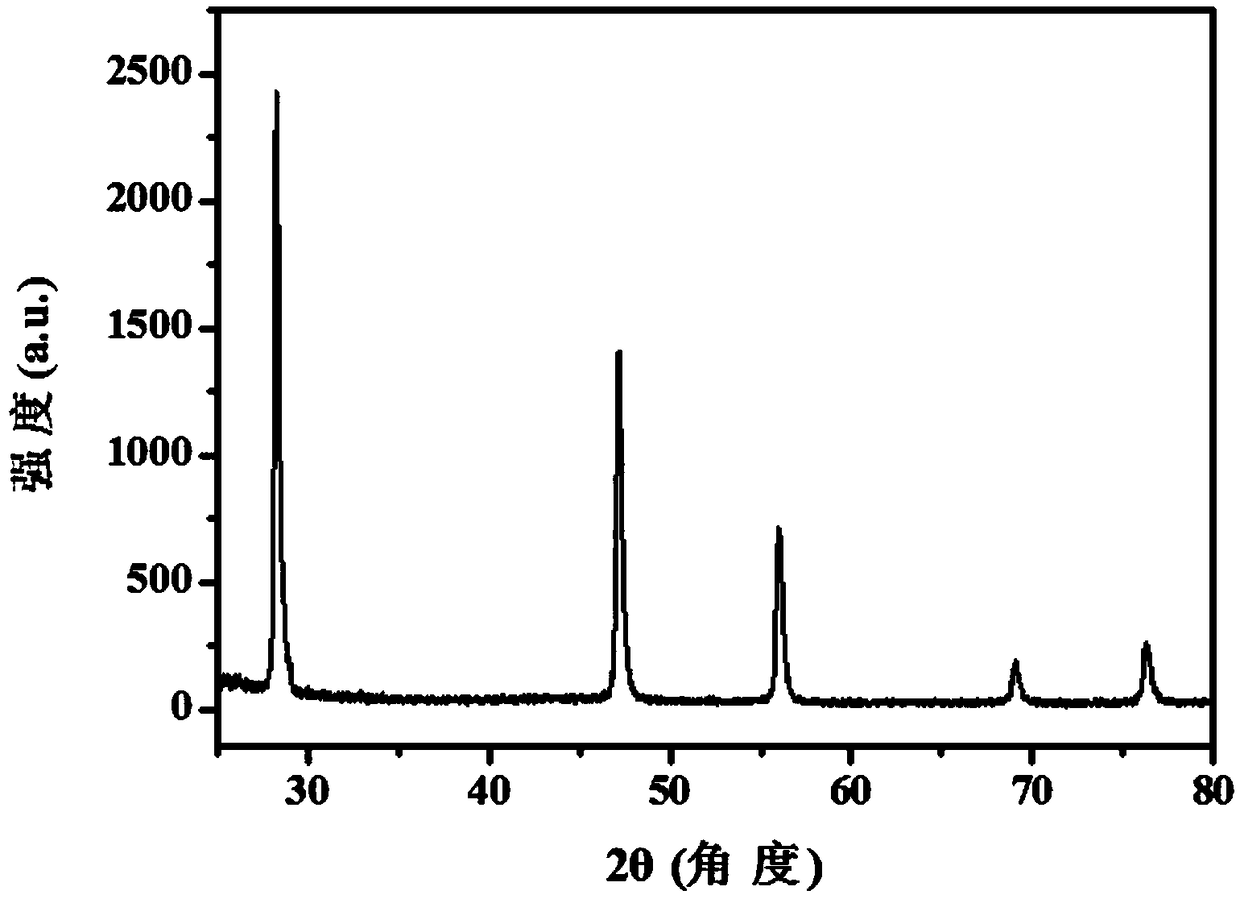

[0034] a) providing zeolite powder, the zeolite powder is sequentially subjected to reduction treatment and purification treatment to obtain porous silicon;

[0035] b) After carbon-coating the porous silicon with a pyrolytic carbon source and graphite, a silicon-carbon anode material is obtained.

[0036] In the preparation method of the silicon-carbon negative electrode material of the present invention, zeolite powder is used as the raw material for the preparation of porous silicon. The zeolite is not only low in cost, but also has a higher silica content and higher quality than other low-cost silicon sources such as rice husks. The fraction is about 65%. At the same time, using zeolite powder as the silicon source material can also reduce the steps of ashing when rice husk is used as the silicon source, simplify the pre...

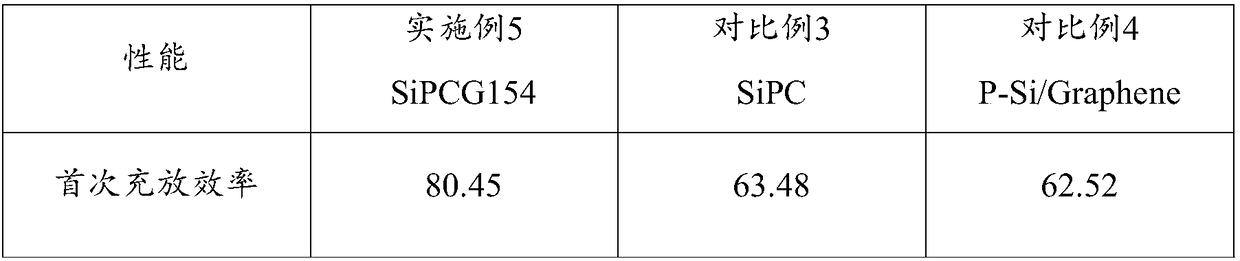

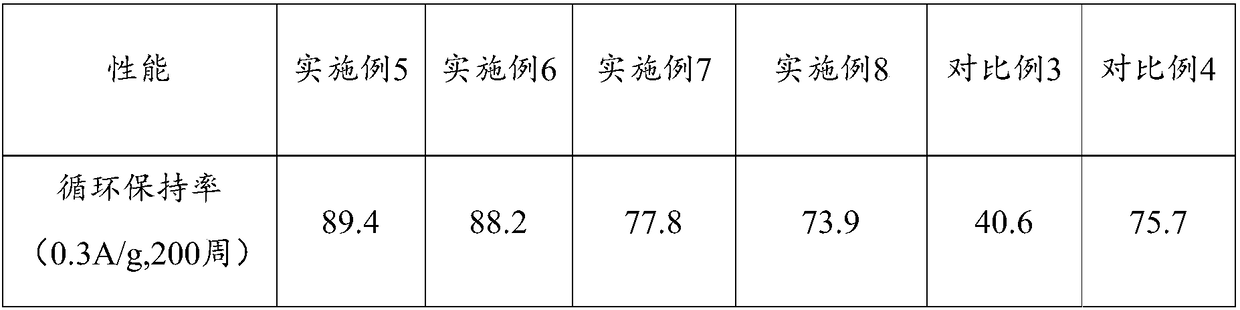

Embodiment 1

[0058] This embodiment is a method for preparing a silicon-carbon negative electrode material, comprising the following steps:

[0059] a) Take a certain amount of 300-mesh natural zeolite powder (silicon dioxide content is 65wt%), add dilute hydrochloric acid with a mass fraction of 5wt%, repeatedly wash and suction filter three times, then wash with water until neutral and dry;

[0060] b) get dried zeolite powder 60g and mix with 32.76g magnesium powder (the molar ratio is Mg / SiO 2 =2.1), the mixture of zeolite powder and magnesium powder is placed in a tube furnace and calcined at a high temperature of 650°C for 4h, so that the magnesium powder can fully reduce the silicon dioxide in the zeolite powder;

[0061] c) washing the calcined product with HCl with a mass fraction of 5 wt% to remove MgO generated by the magnesia thermal reduction reaction and other impurities in the zeolite powder, then repeatedly washing with water and drying; then using an ethanol solution of HF...

Embodiment 2

[0066] This embodiment is a method for preparing a silicon-carbon negative electrode material. The difference from Example 1 is that the weight ratio of porous silicon, glucose and graphite is 2:5:3, that is, in step d), 20g of porous silicon is weighed The material is dispersed in an ethanol solution, 50g of glucose is weighed, 30g of graphite is added to the ethanol solution of porous silicon, ball milled at 500rpm for 5h under a vacuum atmosphere, and then spray-dried to obtain the precursor of the silicon-carbon composite material. The preparation process of other steps The same as in Example 1, the finally obtained silicon carbon negative electrode material is denoted as SiPCG253.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com