Method for low-cost synthesis of ZSM-5 molecular sieve

A technology of ZSM-5 and molecular sieve, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of high energy consumption, environmental pollution, low efficiency, etc., and reduce energy consumption , Improve activation efficiency and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

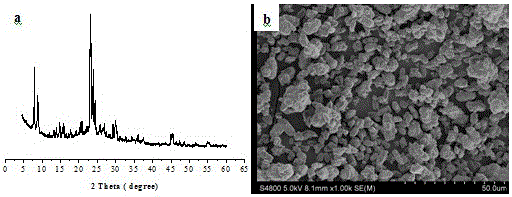

[0037] First, mix the diatomite raw material with a 10% sodium hydroxide solution according to a solid-to-liquid ratio of 1:5 (g / ml), stir evenly, dissolve in alkali at 150°C for 4 hours, and filter with suction to obtain diatomite Alkali-soluble supernatant. Then, kaolin and sodium hydroxide solid were mixed at a ratio of 1:2, and solid-phase alkali fusion was carried out at 200° C. for 60 minutes to obtain activated kaolin. Secondly, take diatomite to activate the supernatant, and add the activated kaolin at a ratio of 1 / 30 of kaolin / diatomite mass ratio, then add n-butylamine and water, and prepare the composition as n(H 2 O) / (SiO 2 )=50, n-butylamine / SiO 2 =0.2, the initial gel system with a pH value of 11 (adjusted by sulfuric acid), was stirred uniformly and then crystallized at 170° C. for 36 hours. Finally, cooling, suction filtration, washing, drying, and calcination at 550° C. for 6 hours to obtain a crystallized product. According to XRD analysis, the crystalliz...

Embodiment 2

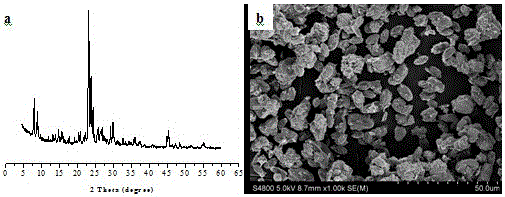

[0039] First, mix the diatomite raw material with 20% sodium hydroxide solution according to the solid-to-liquid ratio of 1:3 (g / ml), stir evenly and dissolve in alkali at 100°C for 6 hours, and filter with suction to obtain diatom Soil alkali dissolved supernatant. Then, kaolin and sodium hydroxide solid were mixed at a ratio of 1:1.5, and solid-phase alkali fusion was carried out at 250° C. for 30 minutes to obtain activated kaolin. Secondly, take diatomite to activate the supernatant, and add activated kaolin, ZSM-5 seed crystals and water according to the ratio of kaolin / diatomite mass ratio of 1 / 50, and the preparation composition is n(H 2 O) / (SiO 2 )=50, ZSM-5 molecular sieve seed crystal / SiO 2 =6% (mass ratio), the initial gel system with a pH value of 9.5 (adjusted by sulfuric acid), stirred evenly and crystallized at 170° C. for 36 hours. Finally, cooling, suction filtration, washing, drying, and calcination at 550° C. for 6 hours to obtain a crystallized product. ...

Embodiment 3

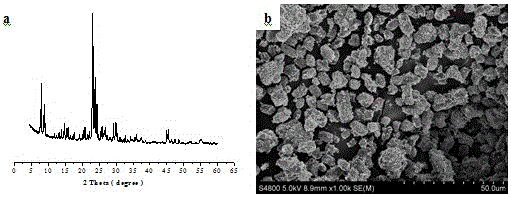

[0041] First, mix the diatomite raw material with a 20% sodium hydroxide solution according to a solid-to-liquid ratio of 1:4 (g / ml), stir evenly, dissolve in alkali at 100°C for 6 hours, and filter with suction to obtain diatomite Alkali-soluble supernatant. Then, kaolin and sodium hydroxide solid were mixed at a ratio of 1:2, and solid-phase alkali fusion was carried out at 250° C. for 30 minutes to obtain activated kaolin. Secondly, take diatomite to activate the supernatant, and add activated kaolin, ZSM-5 seed crystals and water according to the ratio of kaolin / diatomite mass ratio of 1.5 / 50, and the preparation composition is n(H 2 O) / (SiO 2 )=50, ZSM-5 molecular sieve seed crystal / SiO 2 =6% (mass ratio), the initial gel system with a pH value of 9.5 (adjusted by sulfuric acid), stirred evenly and crystallized at 170° C. for 36 hours. Finally, cooling, suction filtration, washing, drying, and roasting at 550° C. for 6 hours to obtain a crystallized product. According...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com