Method for preparing white carbon black and manganese fertilizer from manganese leaching residue

A technology for extracting slag and white carbon black, which is applied in the direction of silicon dioxide and silicon oxide, which can solve the problems of manganese obstacles in plants, hindering crop growth, and rising manufacturing costs, so as to increase the content of silicon dioxide and improve the degree of porosity , improve the grade effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

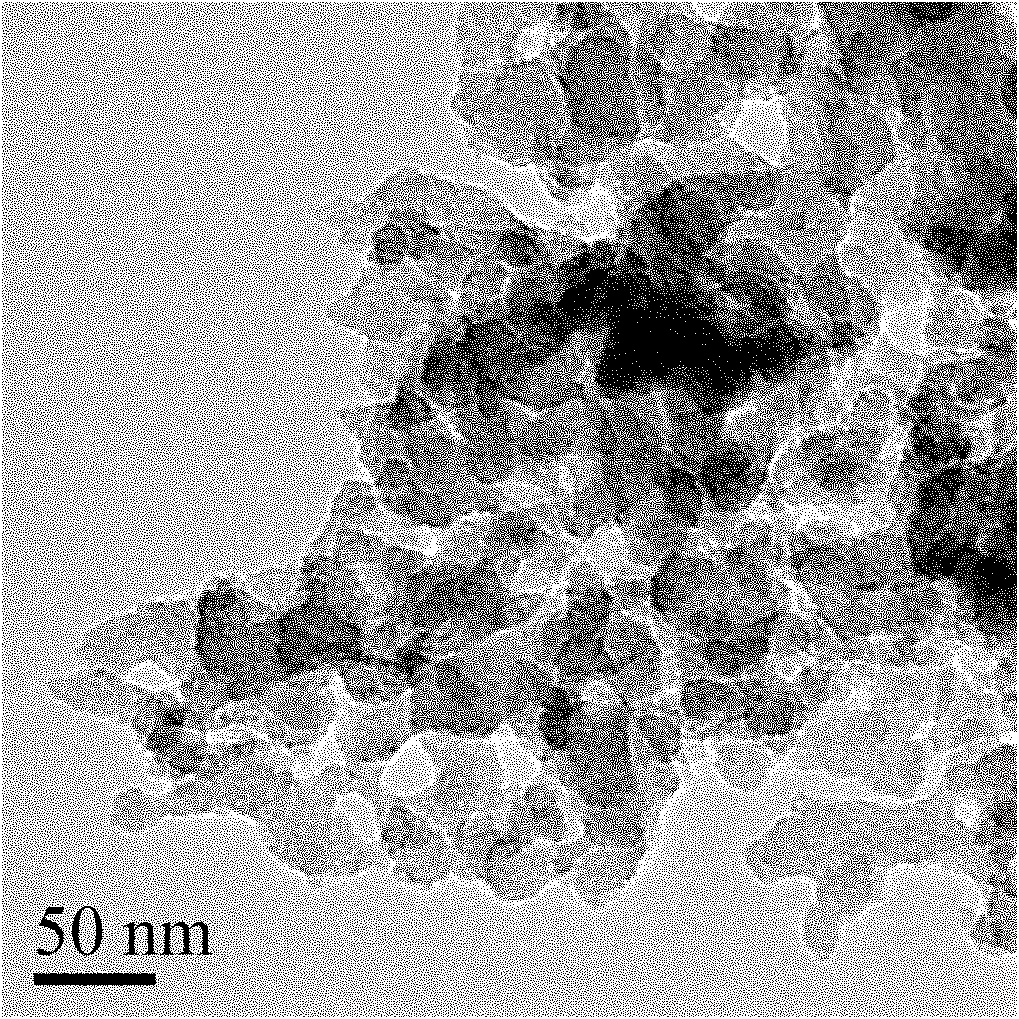

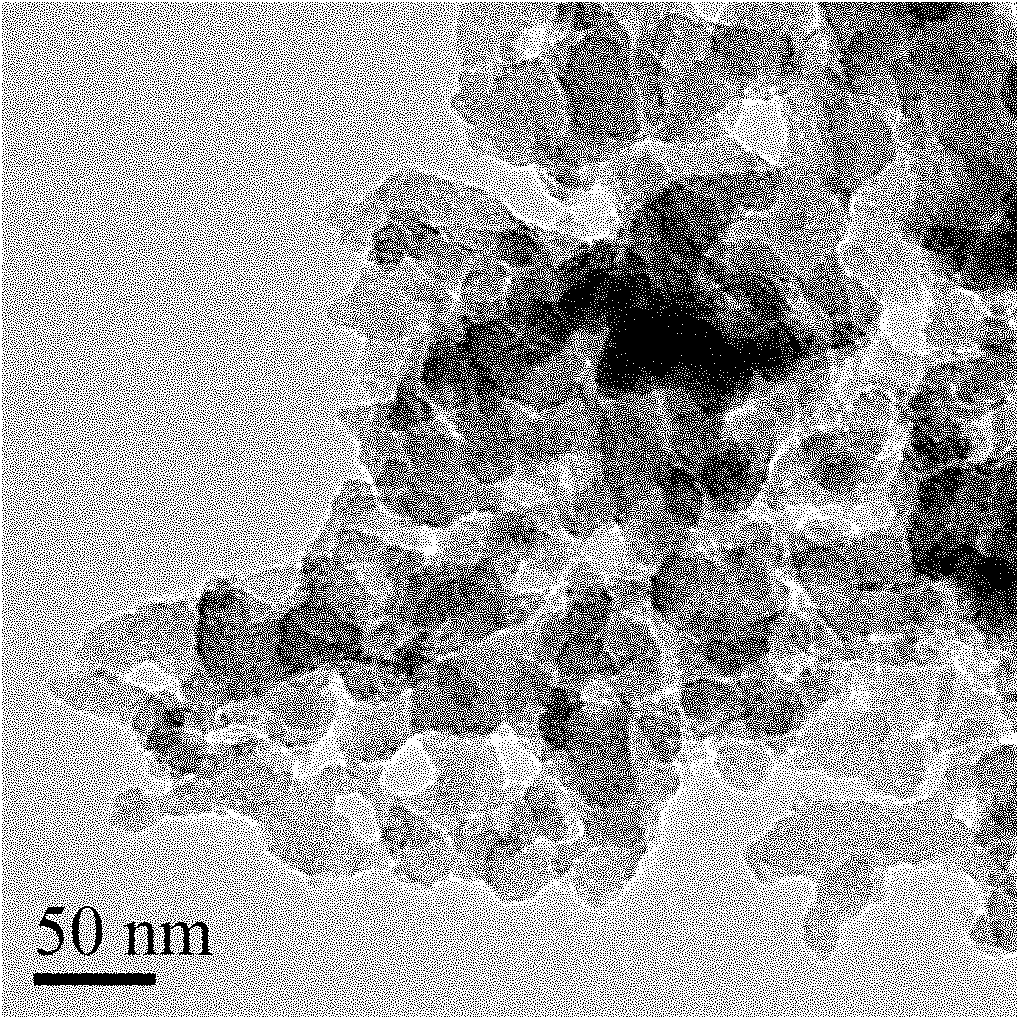

Image

Examples

Embodiment 1

[0034] A kind of method utilizing manganese leaching slag to prepare white carbon black and manganese fertilizer, the steps are as follows:

[0035](1) 100g of manganese leaching residue is washed twice with 150g of dilute sulfuric acid solution of 0.05wt%, and then washed to neutrality with tap water;

[0036] (2) filter residue and 400 g of 25 wt % sodium hydroxide solution, react at 90° C. for 5 h, filter, and wash the filter residue with distilled water to neutrality, and merge the washing solution into the filtrate, and collect the filter residue;

[0037] (3) The filtrate obtained in step (2) was successively decolorized with 0.7 g of activated carbon and 1.0 g of carboxyl-terminated hyperbranched polyester at 110° C. for 5 min to obtain a light yellow to colorless silicate aqueous solution;

[0038] (4) Add the aqueous silicate solution obtained in step (3) into the reaction kettle, add 100 g of water, slowly add 600 g of 10 wt % sulfuric acid and 0.5 g of carboxyl-term...

Embodiment 2

[0042] A kind of method utilizing manganese leaching slag to prepare white carbon black and manganese fertilizer, the steps are as follows:

[0043] (1) 100g of manganese leaching residue is washed twice with 200g of dilute sulfuric acid solution of 0.08wt%, and then washed to neutrality with tap water;

[0044] (2) React the filter residue and 500 g of 30 wt % potassium hydroxide solution at 100° C. for 4 h, filter, and wash the filter residue with distilled water to neutrality, and merge the washing liquid into the filtrate, and collect the filter residue;

[0045] (3) The filtrate obtained in step (2) was successively decolorized with 0.8 g of activated carbon and 1.0 g of carboxyl-terminated hyperbranched polyester at 120° C. for 5 minutes to obtain a light yellow to colorless silicate aqueous solution;

[0046] (4) The silicate aqueous solution that step (3) obtains is joined in the reaction kettle, add water 120g, slowly drip the sulfuric acid 400g of 20wt% and 0.7g term...

Embodiment 3

[0050] A kind of method utilizing manganese leaching slag to prepare white carbon black and manganese fertilizer, the steps are as follows:

[0051] (1) 100g of manganese leaching residue is washed twice with 250g of 1.0wt% dilute sulfuric acid aqueous solution successively, and then washed to neutrality with tap water;

[0052] (2) React the filter residue and 300 g of 40 wt % potassium hydroxide solution at 120° C. for 2 h, filter, and wash the filter residue with distilled water to neutrality, and merge the washing solution into the filtrate, and collect the filter residue;

[0053] (3) The filtrate obtained in step (2) was successively decolorized with 0.9 g of activated carbon and 0.8 g of carboxyl-terminated hyperbranched polyester at 100° C. for 5 minutes to obtain a light yellow to colorless silicate aqueous solution;

[0054] (4) Add the aqueous silicate solution obtained in step (3) into the reactor, add 150g of water, slowly add 20wt% hydrochloric acid 500g and carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com