Equipment for continuous acid leaching treatment of high silica glass fiber cloth

A technology of high-silica glass fiber and glass fiber, which is applied in the continuous processing of textile materials, the processing of textile materials, textiles and papermaking, etc., which can solve the problem that the high temperature resistance cannot be guaranteed, it is difficult to meet the needs of large-scale production, and intermittent Problems such as discontinuous pickling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

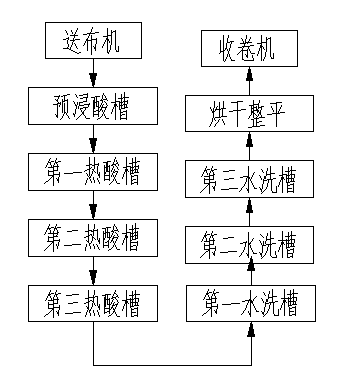

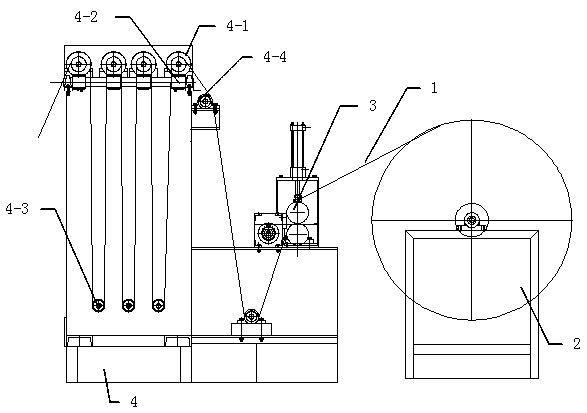

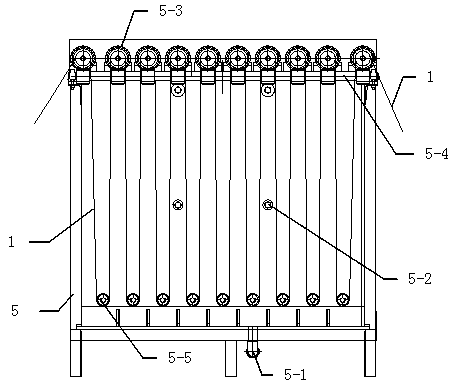

[0025] Such as Figures 1 to 5 The shown equipment for continuous acid leaching treatment of high silica glass fiber cloth includes an acid leaching tank, and the acid leaching tank includes a presoak acid tank 4, a hot acid tank 1, and a hot acid tank 2 1. Hot acid tank three, next to the hot acid tank three, there are washing tank one 6, washing tank two 7, washing tank three 8, next to the washing tank three 8, drying and leveling equipment 9 is arranged; installed in the unwinding machine The glass fiber gray cloth 1 on 2 enters the prepreg acid tank 4, hot acid tank 1, hot acid tank 2, hot acid tank 3, washing tank 1 6, washing tank 2 7, washing tank 3 8 successively through the cloth feeder 3, Pickling and water washing are completed, and then drying and leveling is carried out by the drying and leveling equipment 9, and then winding is carried out by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com