Method for increasing content of silicon dioxide in silicon ash and producing white carbon black

A technology of silica and white carbon black, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as waste of resources, impact on environmental pollution, poor economy, etc., and achieve low production costs , simple process, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

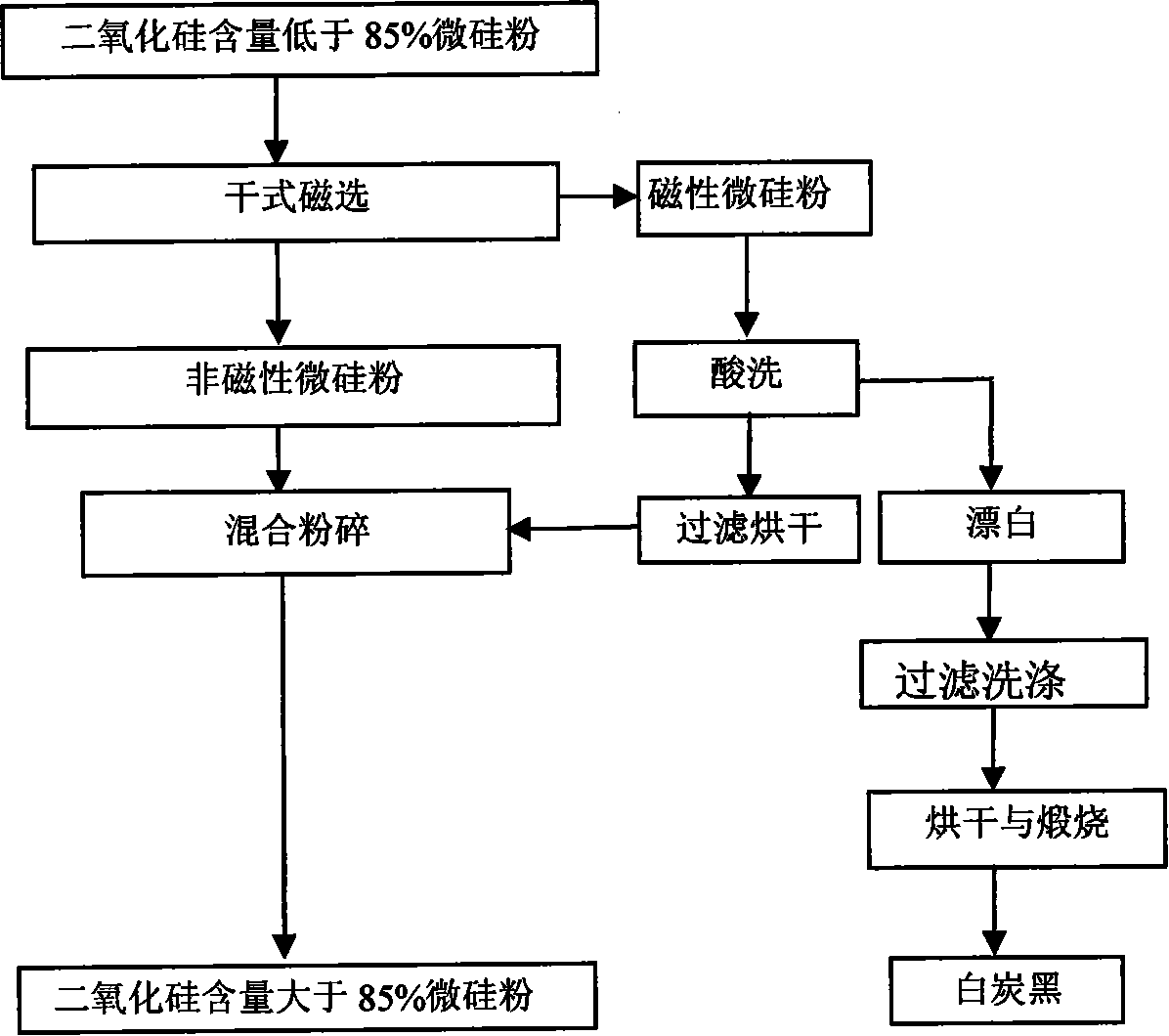

Image

Examples

Embodiment 1

[0015] A method for increasing silicon dioxide content and preparing white carbon black from silica fume, carried out according to the following steps:

[0016] a. Carry out dry-type magnetic separation of micro-silicon powder with a silicon dioxide content lower than 85% by weight by adjusting the magnetic field strength. After dry magnetic separation, non-magnetic micro-silicon powder and magnetic micro-silicon powder can be formed. After magnetic separation The non-magnetic micro-silica powder is stored for use;

[0017] b. Pickling the magnetic silica powder with nitric acid, hydrochloric acid or sulfuric acid, the pickling temperature is 20°C-90°C, the pickling time is 1-4 hours, the pH value during pickling is less than 2, and the pickling time is solid The liquid ratio is controlled within the range of 1:2 to 1:6, and washed 1-3 times;

[0018] c. Filter the pickling solution, and dry the filtered solid at a temperature of 95°C to 110°C. After drying, the product is mi...

Embodiment 2

[0028] Using micro-silicon powder with a silicon dioxide content of 78% by weight as raw material, using magnetic separation technology to control magnetic separation parameters, so that 40% of magnetic micro-silicon powder and 60% of non-magnetic micro-silicon powder are selected.

[0029] Add 40% of the selected magnetic silica fume into 15% sulfuric acid aqueous solution according to the solid-to-liquid ratio of 1:5, react at a temperature of 80°C for 3 hours, then filter, wash twice, dry and pulverize, and measure the carbon dioxide The silicon content is 93%.

[0030] According to the ratio of 4:6, the micro-silicon powder with a silicon dioxide content of 93% after pickling and the micro-silicon powder with a silicon dioxide content of 80% after magnetic separation are mixed to obtain a silicon dioxide content of 85.2%. Microsilica fume meets the requirements for use.

[0031] For the production of white carbon black, bleach the silica fume with a silicon dioxide conten...

Embodiment 3

[0033] Using micro-silicon powder with a silicon dioxide content of 80% by weight as raw material, using magnetic separation technology to control magnetic separation parameters, so that 30% of magnetic micro-silicon powder and 70% of non-magnetic micro-silicon powder are selected.

[0034] Add 30% of the selected magnetic silica powder to 20% sulfuric acid aqueous solution according to the solid-to-liquid ratio of 1:4, react at a temperature of 90°C for 4 hours, then filter, wash twice, dry and pulverize, and measure the carbon dioxide The silicon content is 97%.

[0035] According to the ratio of 3:7, the micro-silicon powder with a silicon dioxide content of 97% after pickling and the micro-silicon powder with a silicon dioxide content of 82% after magnetic separation are mixed to obtain a silicon dioxide content of 86.5%. Microsilica fume meets the requirements for use.

[0036] For the production of white carbon black, bleach the micro-silica powder with a silica content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com