Iron tailings roller compacted concrete for pavement

A technology of roller compacted concrete and iron tailings, applied in the field of concrete materials, can solve the problems of high silica content and achieve the effects of fine particle size, low price and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Using PO42.5 Portland cement, the ratio of each raw material is:

[0023] Water cement ratio raw material water cement Admixture Anshan type iron tailings aggregate Superplasticizer 0.38 Kg / m 3 152 275 333 392 1030 0.55

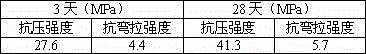

[0024] Mix well and put it into the test mold. After the mold is installed, place it on the upper surface of the vibration table and apply 300Kg / m 2 The pressure is formed by the pressure vibration method; after forming, it is kept under standard maintenance conditions, and the technical indicators of the corresponding age are as follows:

[0025]

Embodiment 2

[0027] Using PO52.5 Portland cement, the ratio of each raw material is:

[0028] Water cement ratio raw material water cement Admixture Iron tailings Anshan type aggregate Superplasticizer 0.38 Kg / m 3 152 275 298 405 1052 0.55

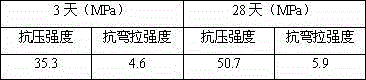

[0029] Mix well and put it into the test mold. After the mold is installed, place it on the upper surface of the vibration table and apply 300Kg / m 2 The pressure is formed by the pressure vibration method; after forming, it is kept under standard maintenance conditions, and the technical indicators of the corresponding age are as follows:

[0030]

Embodiment 3

[0032] Using PO52.5 Portland cement, the ratio of each raw material is:

[0033] Water cement ratio raw material water cement Admixture Anshan type iron tailings aggregate Superplasticizer 0.40 Kg / m 3 160 225 405 392 1000 0.55

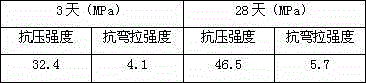

[0034] Mix well and put it into the test mold. After the mold is installed, place it on the upper surface of the vibration table and apply 300Kg / m 2 The pressure is formed by the pressure vibration method; after forming, it is kept under standard maintenance conditions, and the technical indicators of the corresponding age are as follows:

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com