Low-dosage high-early-strength alkali-free liquid accelerator and preparation method thereof

An early-strength and accelerator technology, which is applied in the preparation of low-volume, high-early-strength, alkali-free liquid accelerators, and in the field of low-volume, high-early-strength, alkali-free liquid accelerators, can solve the problem of alkali-free liquids Low dosage of accelerator, high dosage, good stability and other problems, to achieve the effect of low cost, low dosage and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

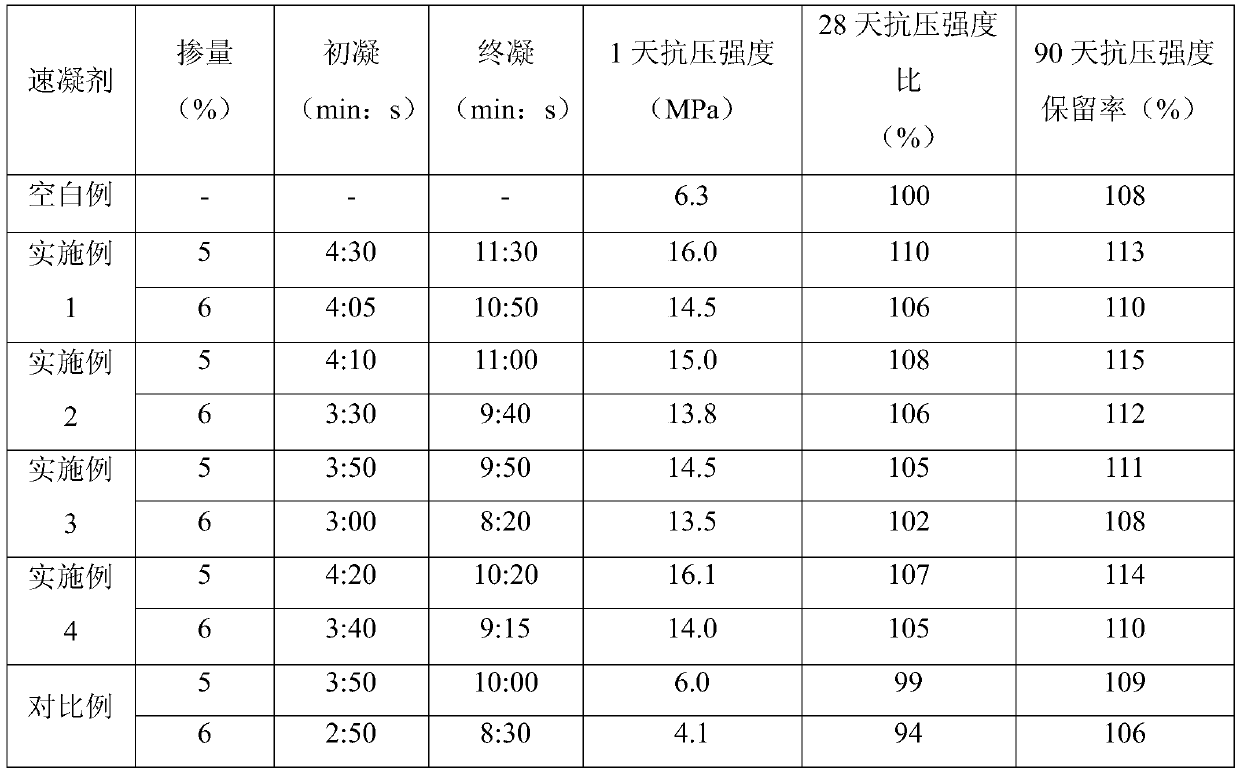

Embodiment 1

[0018] Embodiment 1: The low-dosage high-early-strength type alkali-free liquid quick-setting agent of the present invention is made of the raw materials of the following components and mass percentages: modified aluminum sulfate 50%, fluoroaluminum complex solution 4%, organic co-solvent 3%, pH regulator 1%, inorganic stabilizer 0.5%, viscosity modifier 0.5%, composite early strength agent 6%, water 35%, the sum of the mass percentages of the above components is 100% . The modified aluminum sulfate is made by mixing and grinding industrial aluminum sulfate and pseudo-boehmite with aluminum oxide content ≥ 16.0%, and the mass ratio of the two is: industrial aluminum sulfate: pseudo-boehmite= 9:1; Fluoroaluminum complex solution is made of water: fluorosilicic acid: industrial aluminum hydroxide according to the mass ratio of 1.5:2.5:1, stirred at room temperature for 30 minutes; organic co-solvent is made of diethanolamine and glycerol It is mixed according to the mass ratio ...

Embodiment 2

[0019] Embodiment 2: The low-dosage high-early-strength type alkali-free liquid quick-setting agent of the present invention is made of the raw materials of the following components and mass percentages: modified aluminum sulfate 55%, fluoroaluminum complex solution 3%, organic co-solvent 4%, pH regulator 1.5%, inorganic stabilizer 1.0%, viscosity modifier 0.5%, composite early strength agent 5%, water 30%, the sum of the mass percentages of the above components is 100% . The modified aluminum sulfate is made by mixing and grinding industrial aluminum sulfate and pseudo-boehmite with aluminum oxide content ≥ 16.0%, and the mass ratio of the two is: industrial aluminum sulfate: pseudo-boehmite= 9:1; Fluoroaluminum complex solution is made of water: fluorosilicic acid: industrial aluminum hydroxide according to the mass ratio of 1.5:2.5:1, stirred at room temperature for 20min; organic co-solvent is made of triethanolamine and glycerin It is mixed according to the mass ratio of...

Embodiment 3

[0020] Embodiment 3: The low-dosage high-early-strength type alkali-free liquid quick-setting agent of the present invention is made of the raw materials of the following components and mass percentages: modified aluminum sulfate 60%, fluoroaluminum complex solution 3%, organic co-solvent 6%, pH regulator 2%, inorganic stabilizer 0.7%, viscosity regulator 0.3%, composite early strength agent 5%, water 23%, the sum of the mass percentages of the above components is 100% . The modified aluminum sulfate is made by mixing and grinding industrial aluminum sulfate and pseudo-boehmite with aluminum oxide content ≥ 16.0%, and the mass ratio of the two is: industrial aluminum sulfate: pseudo-boehmite= 9:1; Fluoroaluminum complex solution is made of water: fluorosilicic acid: industrial aluminum hydroxide according to the mass ratio of 1.5:2.5:1, stirred at room temperature for 30 minutes; organic co-solvent is made of diethanolamine and glycerol It is mixed according to the mass ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com