Production method of graphene-modified fiber core-spun elastic yarn and graphene-modified fiber core-spun elastic fabric

A graphene modification, graphene technology, applied in the field of spinning and weaving, to achieve good development prospects, promote microcirculation, and improve the effect of shrink resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

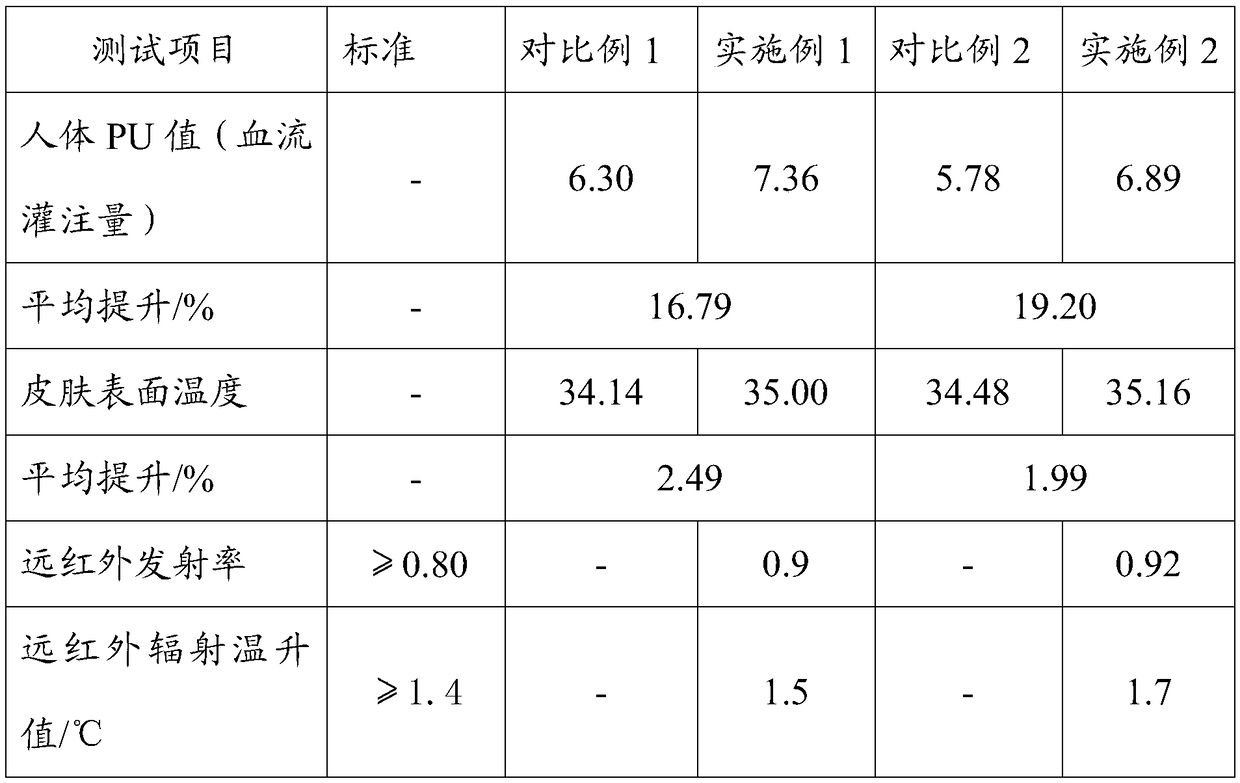

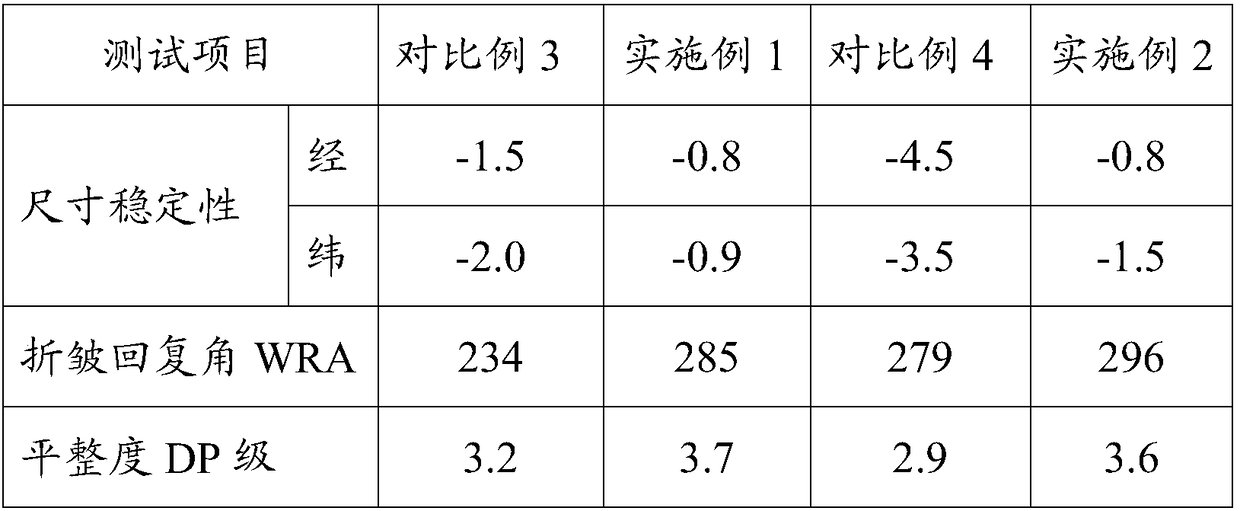

Examples

Embodiment 1

[0028] The graphene modified fiber core-spun elastic woven garment fabric of the present invention has a specification of 32 combed cotton yarns for the warp yarn and 32 combed graphene modified fiber blended yarns for the core-spun 40D spandex yarn. The composite yarn count of the core yarn is 29.6, wherein the weight ratio of the graphene-modified polyester fiber of the graphene-modified fiber blended yarn is 50%, and the weight ratio of the cotton fiber is 50%. The warp yarn density is 130 yarns / inch and the weft yarn density is 78 yarns / inch. The used weave is twill weave. The graphene modified fiber is a graphene polyester modified fiber, the graphene content is 1%, the graphene modified fiber linear density is 1.2D, and the length of the fiber is 38mm. Graphene modified fiber was purchased from Jinan Shengquan Group Co., Ltd.

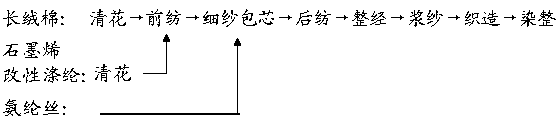

[0029] The process route is as shown in the attached drawing of the manual figure 1 As shown, the specific steps include:

[0030] 1. Cleanin...

Embodiment 2

[0050] In the graphene modified fiber core-spun elastic knitted fabric of the present invention, the yarn adopts 40 counts of combed graphene modified fiber core-spun 30D spandex yarn, 40 counts of combed pure cotton yarn, 75D low elastic yarn, and a combination of core-spun yarn The yarn count is 37.4, wherein in the graphene-modified fiber blended yarn, the weight ratio of the graphene-modified polyester fiber is 50%, and the weight ratio of the cotton fiber is 50%. Weight 340g / m 2 , the tissue used is a sandwich double-sided tissue.

[0051] The difference between this embodiment and embodiment 1 is:

[0052] Spinning process: The main difference between Example 1 and Example 2 is that the total draft ratio of the spun yarn is changed from 33.86 times to 42.26 times, the twist is adjusted from 92 twists / 10cm to 115 twists / 10cm, the model of the spun yarn traveler is 6903 10 / 0, and the spun yarn The jaws are 2.75 ordinary jaws, and the pre-drawing ratio is 3.0 times.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com