Mining high-strength anti-shrinkage water plugging material and preparation method thereof

A high-strength, anti-shrinkage technology, applied in the field of mining materials, can solve the problems of low compressive strength, low strength, large shrinkage, etc., and achieve the effect of improving the compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

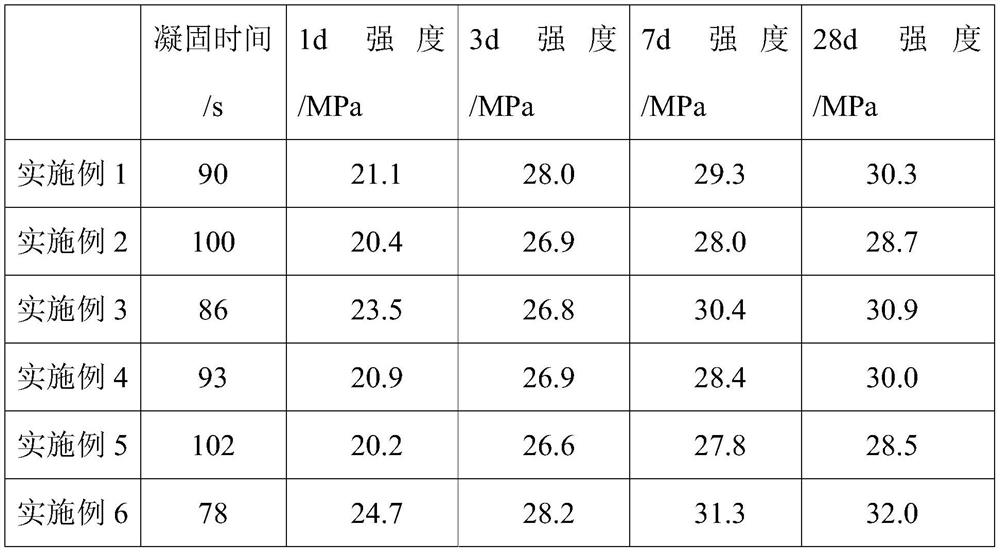

Examples

preparation example Construction

[0020]A method for preparing a high-strength anti-shrinkage water plugging material for mines includes the following steps:

[0021]Step 1. Weigh polyvinyl alcohol, sulphoaluminate cement, quartz powder, slag powder, gypsum powder, quicklime, retarder, crosslinker, accelerator and stabilizer according to the mass ratio;

[0022]Step 2. Add the polyvinyl alcohol, sulfoaluminate cement, quartz powder, slag powder, gypsum powder, and quicklime weighed in step 1 to the ball mill to grind to particles with an average particle size of 2mm, and then mix with the crosslinking agent. The coagulant and the stabilizer are put into the mixer and mixed evenly, and the high-strength water blocking material of the present invention is prepared.

Embodiment 1

[0025]Weigh 300g of polyvinyl alcohol, 5820g of sulphoaluminate cement, 500g of quartz powder, 1500g of slag powder, 600g of dihydrate gypsum, and 480g of quicklime, and mix them with a ball mill to an average particle size of 2mm. Then add 100g of sodium gluconate. , Sodium sulfate 200, sodium nitrate 200g, hydroxypropyl methylcellulose 300g, use a mixer to stir for 30min to get.

Embodiment 2

[0027]Weigh 500g of polyvinyl alcohol, 6610g of sulfoaluminate cement, 1000g of quartz powder, 550g of slag powder, 240g of hemihydrate, and 400g of quicklime and mix them with a ball mill to a particle with an average particle size of 2mm, and then add 100g of citric acid. 100g boric acid, 200g lithium carbonate, 300g carboxymethyl hydroxyethyl cellulose, use a blender to stir for 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com