Patents

Literature

116results about How to "Improve environmental protection requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Weather resistant halogen-free flame retardant ABS resin and preparation process thereof

The present invention discloses a weather-proof anti-flaming ABS resinoid. The compositions and the weight percentage thereof are as follows: 45 to 75 percent of ABS resinoid, 5 to 30 percent of polyester, 10 to 20 percent of fire retardant, 1 to 10 percent of plasticizer, 0.3 to 5 percent of photo-thermal stabilizer, 0.2 to 5 percent of nucleating agent, and 1 to 5 percent of processing accessory ingredient. The weather-proof anti-flaming ABS resinoid obtains largely improved fire retardancy and weatherability because polyester components are added, can be applied to the occasions such as electric switches, transformer cases, control panels of various electric appliances, and the like which directly contact light ray, have higher requirement on appearance and environment, can not use PVC alloy, and have strict requirement on the fire retardancy of the material. The resinoid has wide application prospect. In addition, the adopted twin-screw extrusion preparation process has the advantages of simple flow, high production efficiency, stable product quality, low cost, environment protection, easy industrial implementation, and the like.

Owner:SHANGHAI KINGFA SCI & TECH +1

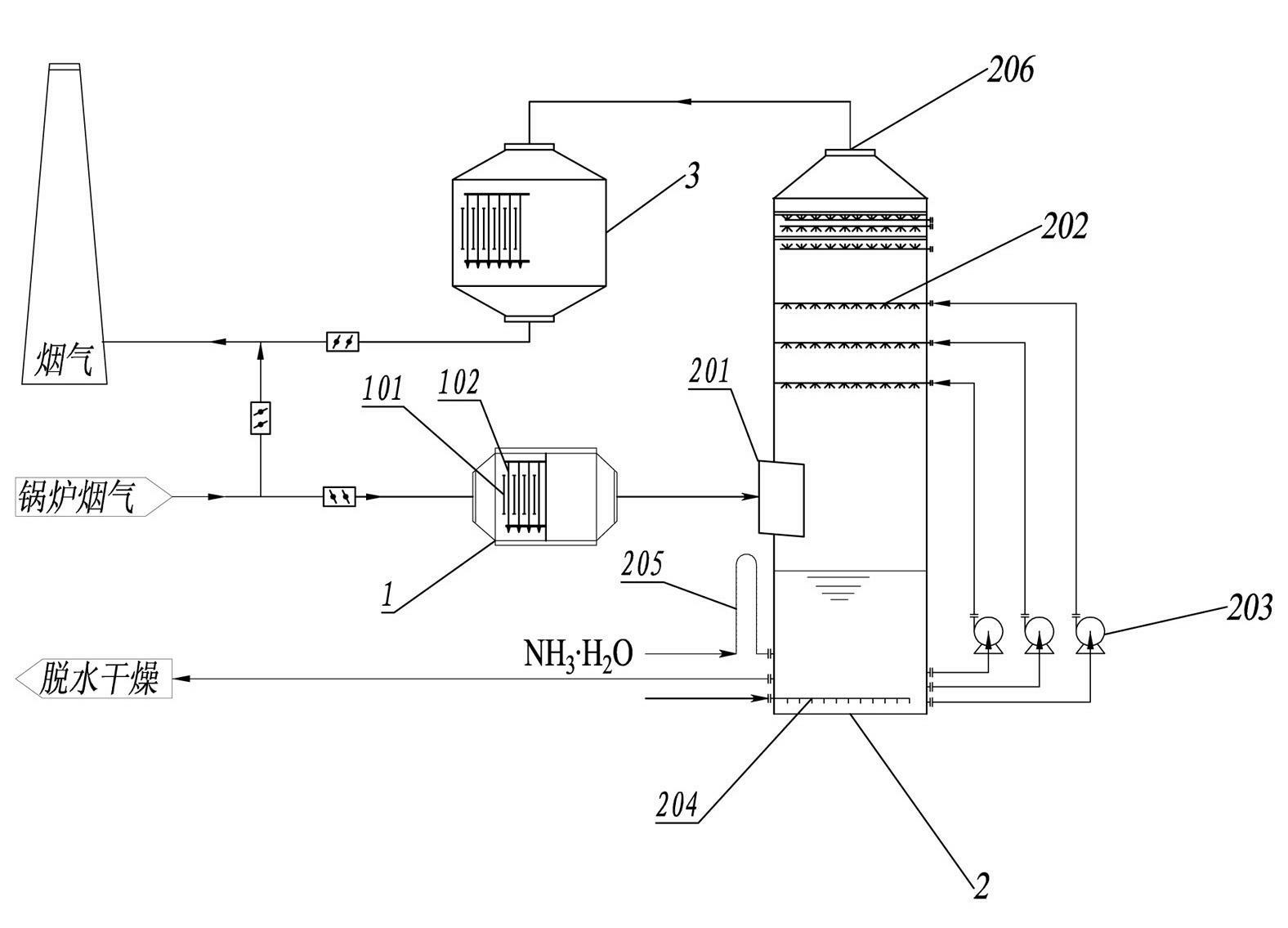

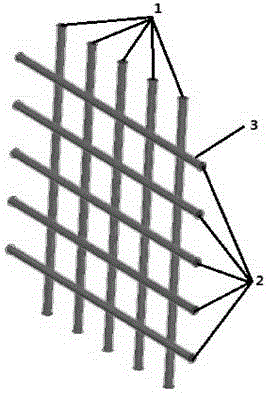

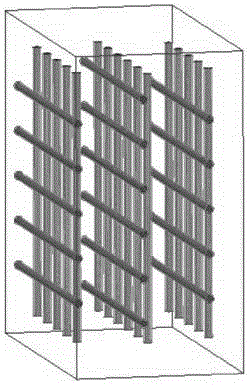

Method and device for integrally desulfurizing, denitrating and dust-removing by plasma

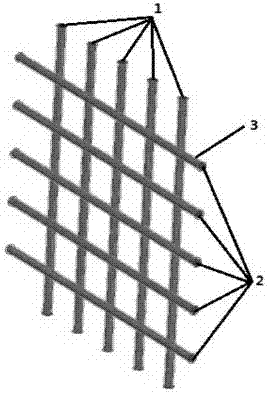

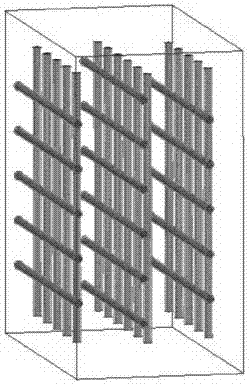

ActiveCN103566722AIncrease the number ofReduce electric field strengthDispersed particle separationElectrode constructionsChemical reactionAdditive ingredient

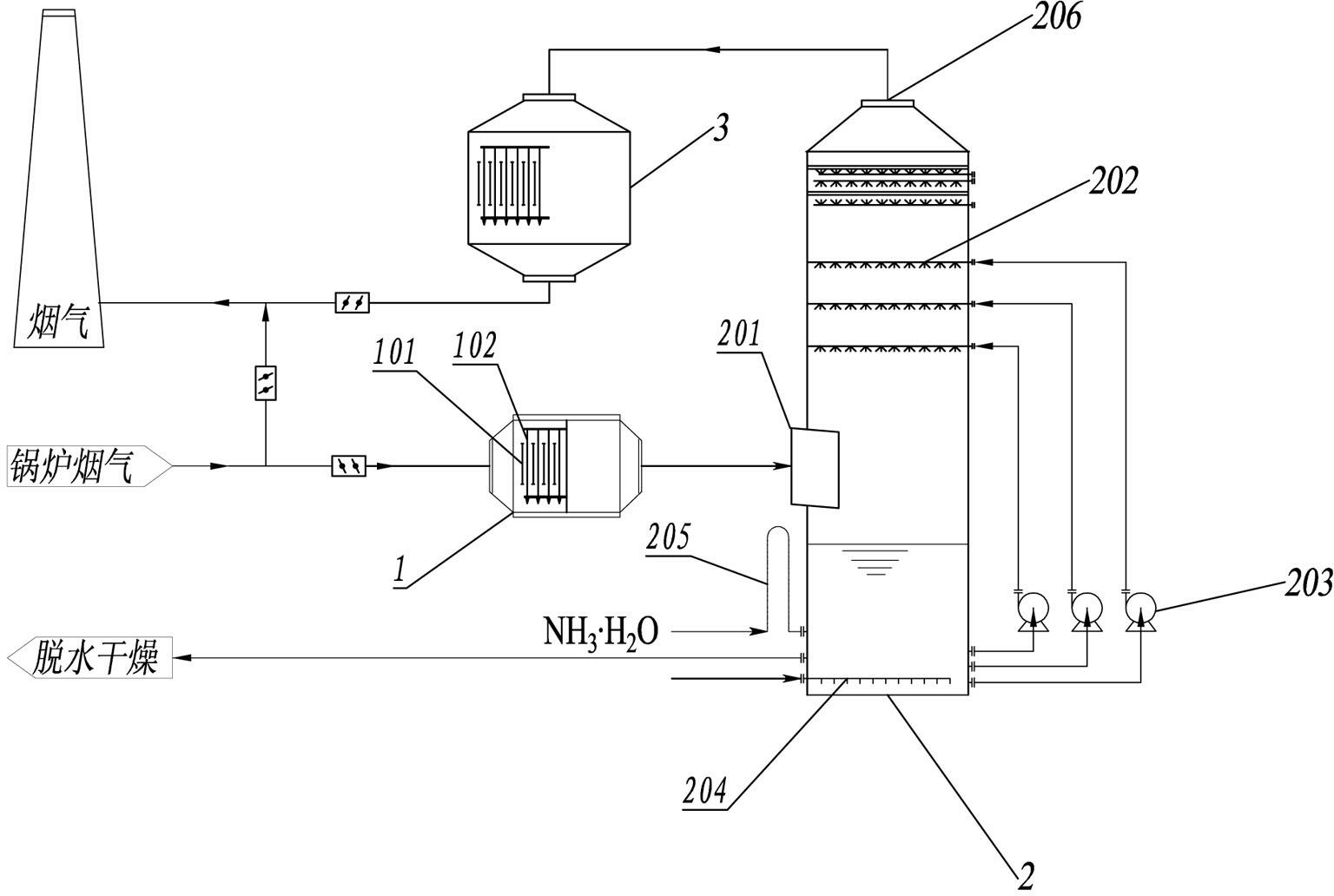

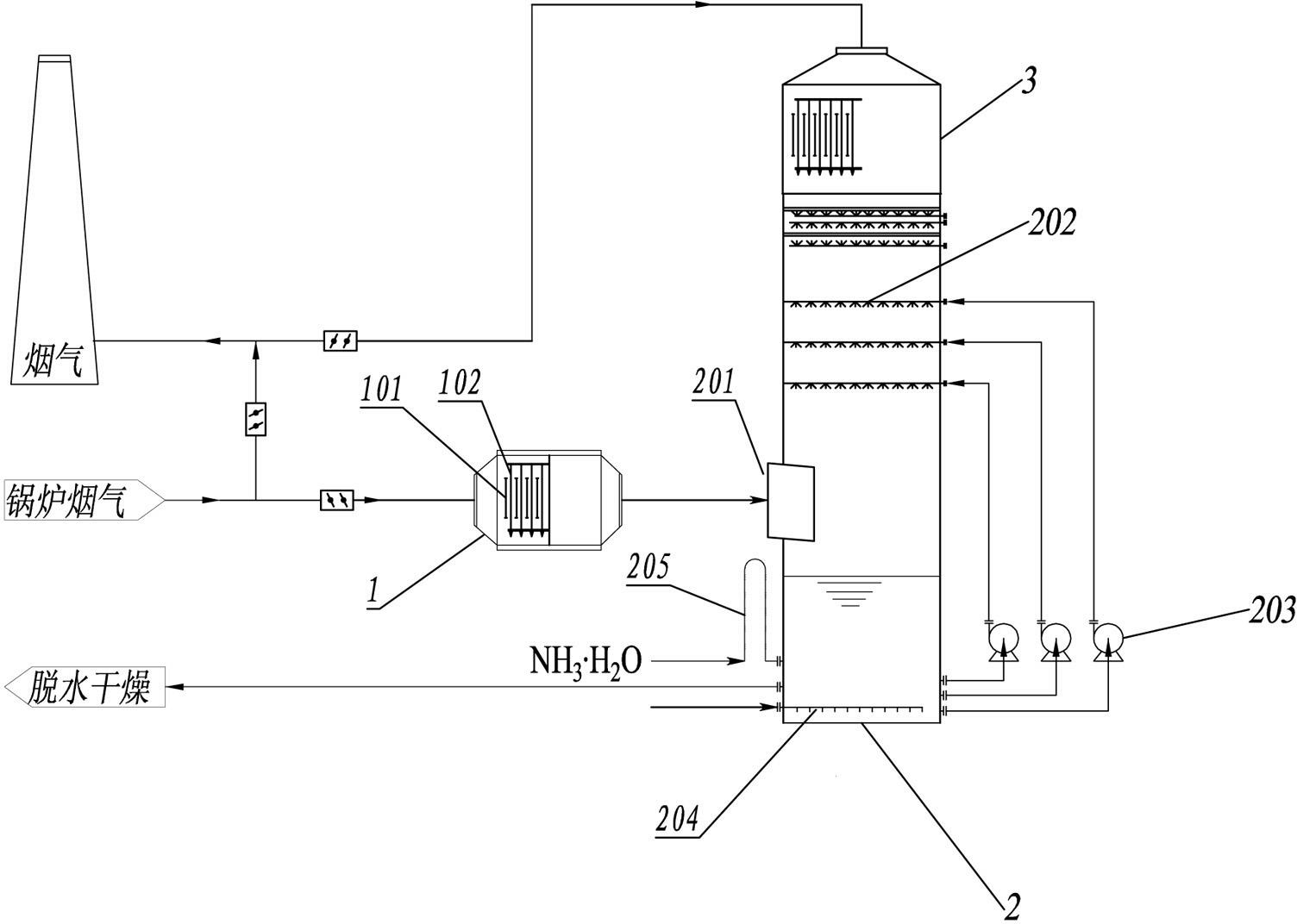

The invention discloses an integrated treatment method capable of desulfurizing, denitrating and dust-removing at the same time, and provides a device which adopts the treatment method. Smoke formed after the combustion in a boiler contains the main ingredients of SO2, NOX and dust, and passes through a plasma generation electrode; generated plasmas contain a large amount of high-energy electronics and act on O2 and H2O to generate a large quantity of active particles, such as H, O, OH and O3. The SO2 and the NOX can perform chemical reaction to generate high-valence state sulfur oxides and nitrogen oxides under the effect of the active particles, and then the sulfur oxides and the nitrogen oxides are combined with introduced ammonia gas to generate ammonium salts; the ammonium salts are recovered and serve as secondary products; and therefore, the desulfurizing and the denitrating are realized. In the process, charged particles in the plasmas can electrify dust particles, so that the charged particles can move directionally under the effect of an additional direct-current bias electric field; and therefore, the function of removing the dust is realized. According to the method and the device, the static electricity dust removal and the plasma desulfurizing and denitrating are integrated, so that the number of power supplies is reduced, the efficiency of a discharge power supply is improved, the energy consumption can be reduced, the investment is saved, the occupied area is reduced, and the cost is reduced.

Owner:BEIJING RUIYUDA TECH

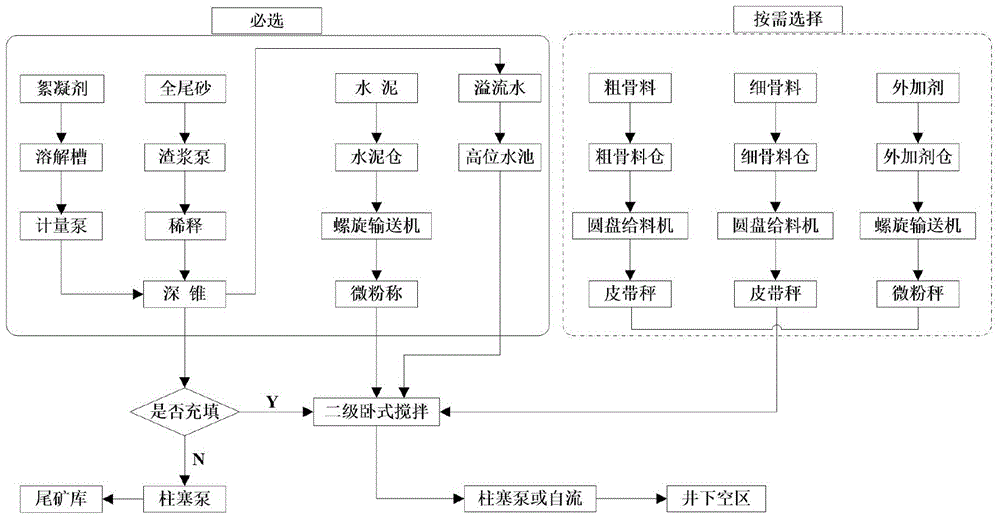

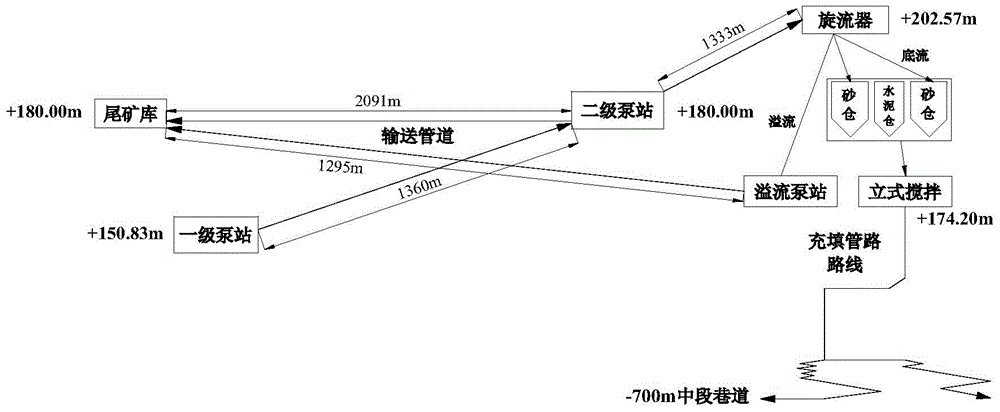

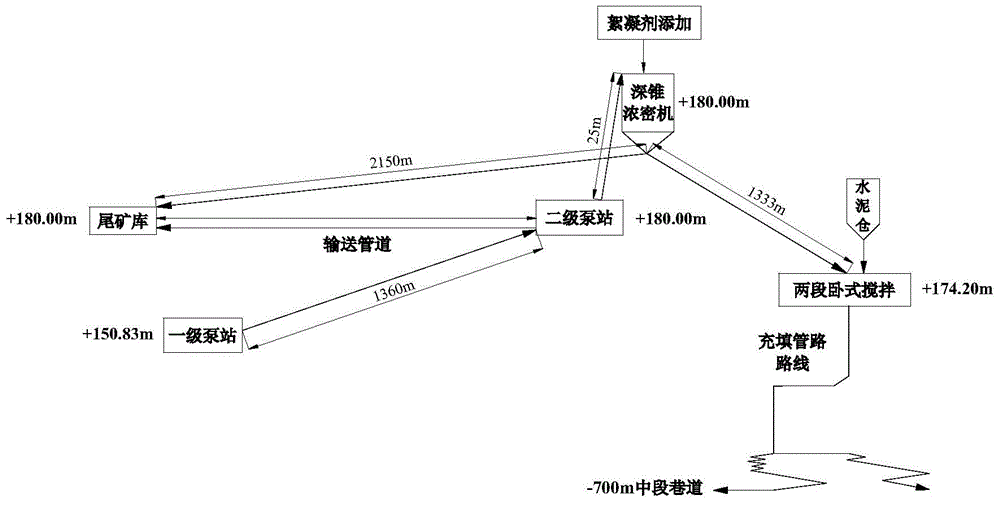

Total-tailings paste filling and stockpiling combined treatment method based on deep-cone thickener

ActiveCN104929683AHigh emission concentrationImprove security levelMaterial fill-upMining engineeringCombined treatment

The invention relates to a total-tailings paste filling and stockpiling combined treatment method based on a deep-cone thickener. A combined treatment system is composed of a one-stage or multi-stage pump station, the deep-cone thickener and a two-segment horizontal stirring device. The deep-cone thickener is arranged near the multi-stage pump station. A continuous feeding and discharging mode is adopted for achieving the continuous concentration process, and the two functions of filling and tailings stockpiling are both taken into consideration. In the running process of a filling system, total tailings of a concentration plant are completely thrown into the deep-cone thickener through the one-stage or multi-stage pump station. When filling is needed, deep-cone bottom flow is pumped to the two-segment stirrer through a mortar pump and is mixed with cement, and qualified paste is prepared and flows to or is pumped to a stope. When filling is not needed, the bottom flow is pumped by a plunger pump to a tailings pond by means of the pump station, and stockpiling of paste is performed. The method can well solve the filling problem of a gob and the stockpiling problem of tailings at the same time, filling cost is greatly reduced, the strength of filling bodies is improved, discharge of the tailings is reduced to the maximum extent, and meanwhile tailings paste is discharged.

Owner:UNIV OF SCI & TECH BEIJING +1

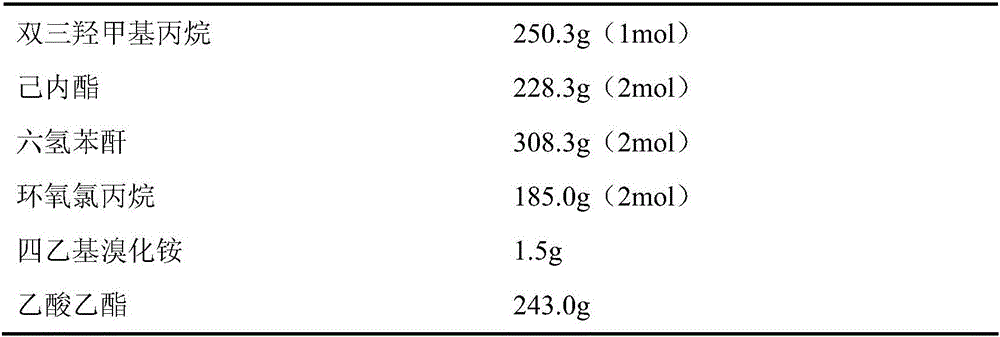

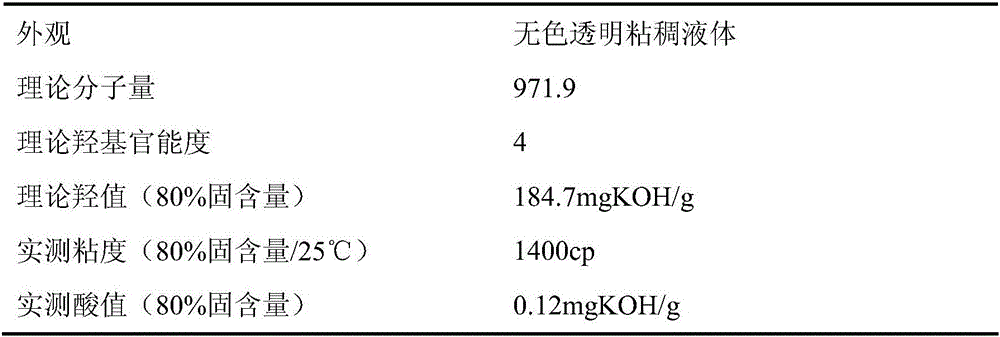

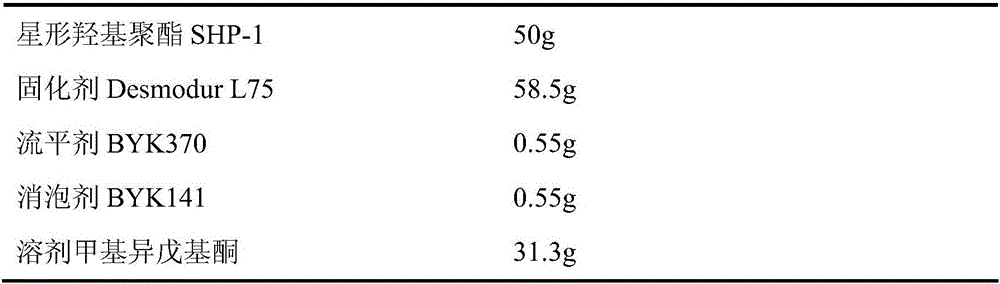

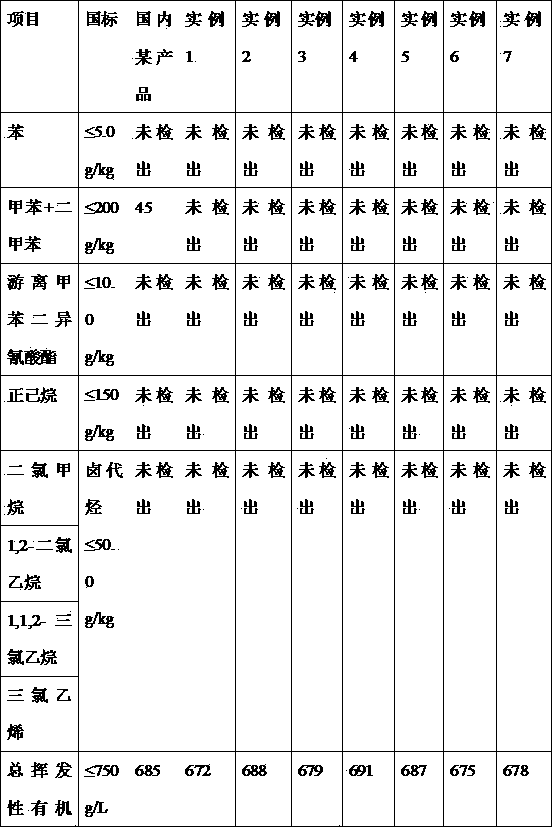

Star-shaped hydroxyl polyester adopting polyhydric alcohol as nucleus and preparation method and application of star-shaped hydroxyl polyester

ActiveCN106279659AAffect activation periodImprove catalytic abilityPolyurea/polyurethane coatingsPolyesterSolvent

The invention discloses star-shaped hydroxyl polyester adopting polyhydric alcoho as a nucleus and a preparation method and an application of the star-shaped hydroxyl polyester. The preparation method comprises the following steps: enabling 1 to 8 molar caprolactone and 1 to 4 molar anhydride to react for 6 to 10 h at 80 to 140 DEG C by adopting 1 molar small molecular polylasic alcohol as a core molecule to obtain a matrix star-shaped polyester, then reacting with 1 to 4 molar monoglycidyl ether at 90 to 150 DEG C to obtain star-shaped hydroxyl polyester. The prepared star-shaped hydroxyl polyester has the advantages of simple synthesis process, high solid content and low viscosity, a hydroxyl value is 140 to 250 mg KOH / g (80 percent of solid content), the viscosity at 25 DEG C when the solid content is 80 percent is 300 to 3000cp, the star-shaped hydroxyl polyester can be cross-linked with a polyurethane curing agent containing an isocyanate group and can be used for preparing a coating with a high solid content, the VOC content at the construction viscosity is smaller than 380 g / L, and the film performance can satisfy the national standard of the solvent-type dual-component polyurethane wood coatings.

Owner:SOUTH CHINA UNIV OF TECH +1

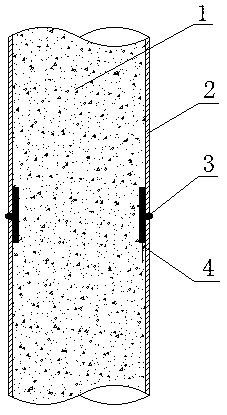

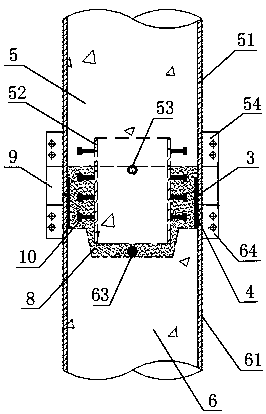

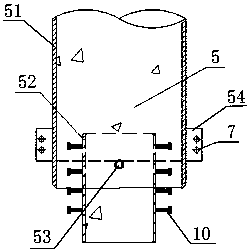

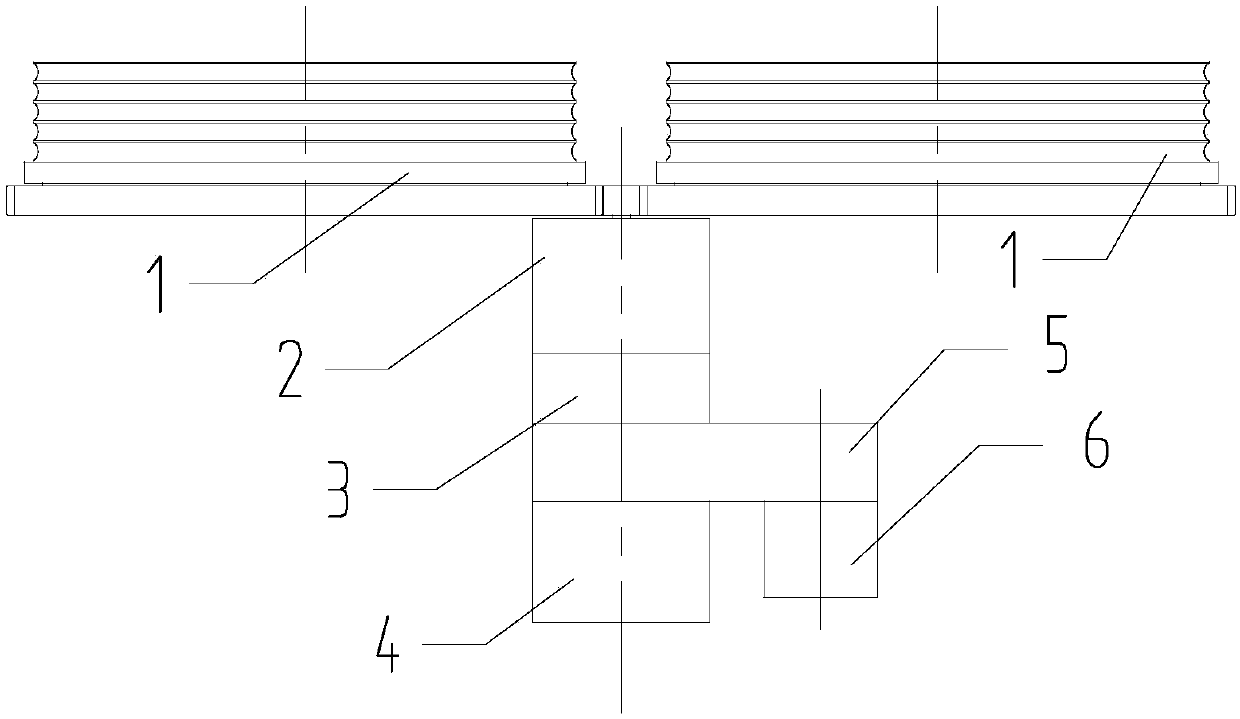

Connecting structure of fabricated concrete-filled steel tubular column body

The invention discloses a connecting structure of a fabricated concrete-filled steel tubular column body. The connecting structure comprises a first steel tubular column section and a second steel tubular column section; the first steel tubular column section is in butt joint with the second steel tubular column section, an inner steel tube is inserted into an inserting groove in a second outer steel tube, and a liner tube is arranged at the connecting position of a first outer steel tube and the second outer steel tube; the first outer steel tube, the second outer steel tube and the liner tube are welded into one through V-shaped groove welding; cementing materials are poured into gap areas in the first outer steel tube and the second outer steel tube, and air in the gap areas is exhausted though exhaust vents; and connecting plates are mounted on a first lug plate and a second lug plate through bolts. The connecting structure has the advantages that the shear-bearing ability of the connecting parts is improved, so that the column body reaches the normal section compression-bending bearing force and the shear-bearing ability which are not less than those of cast-in-place concrete,mounting is easy and convenient, the production and construction efficiency is improved, dust and noise pollution is further reduced, and the environmental-friendly requirements of green buildings are met.

Owner:重庆大学建筑规划设计研究总院有限公司

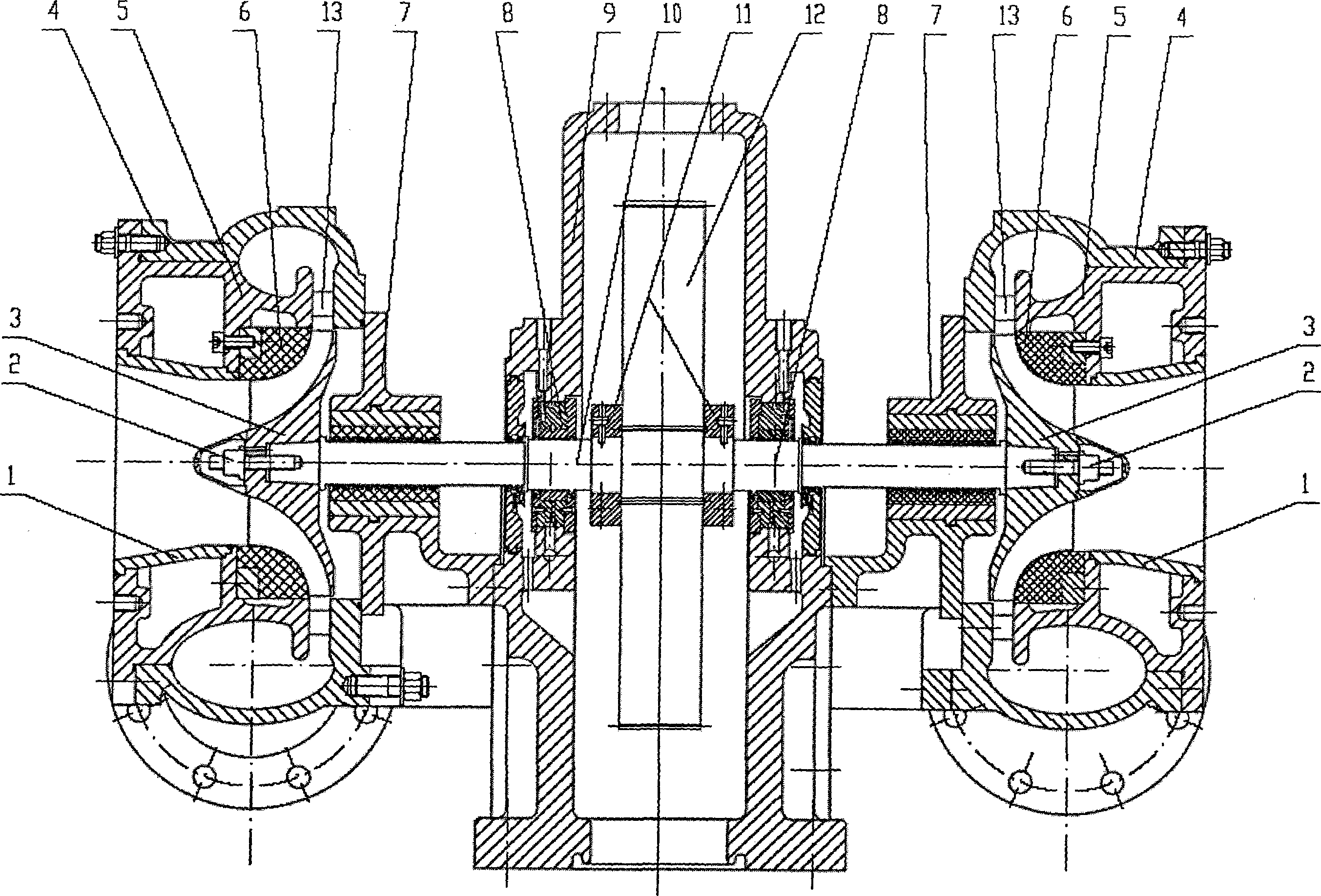

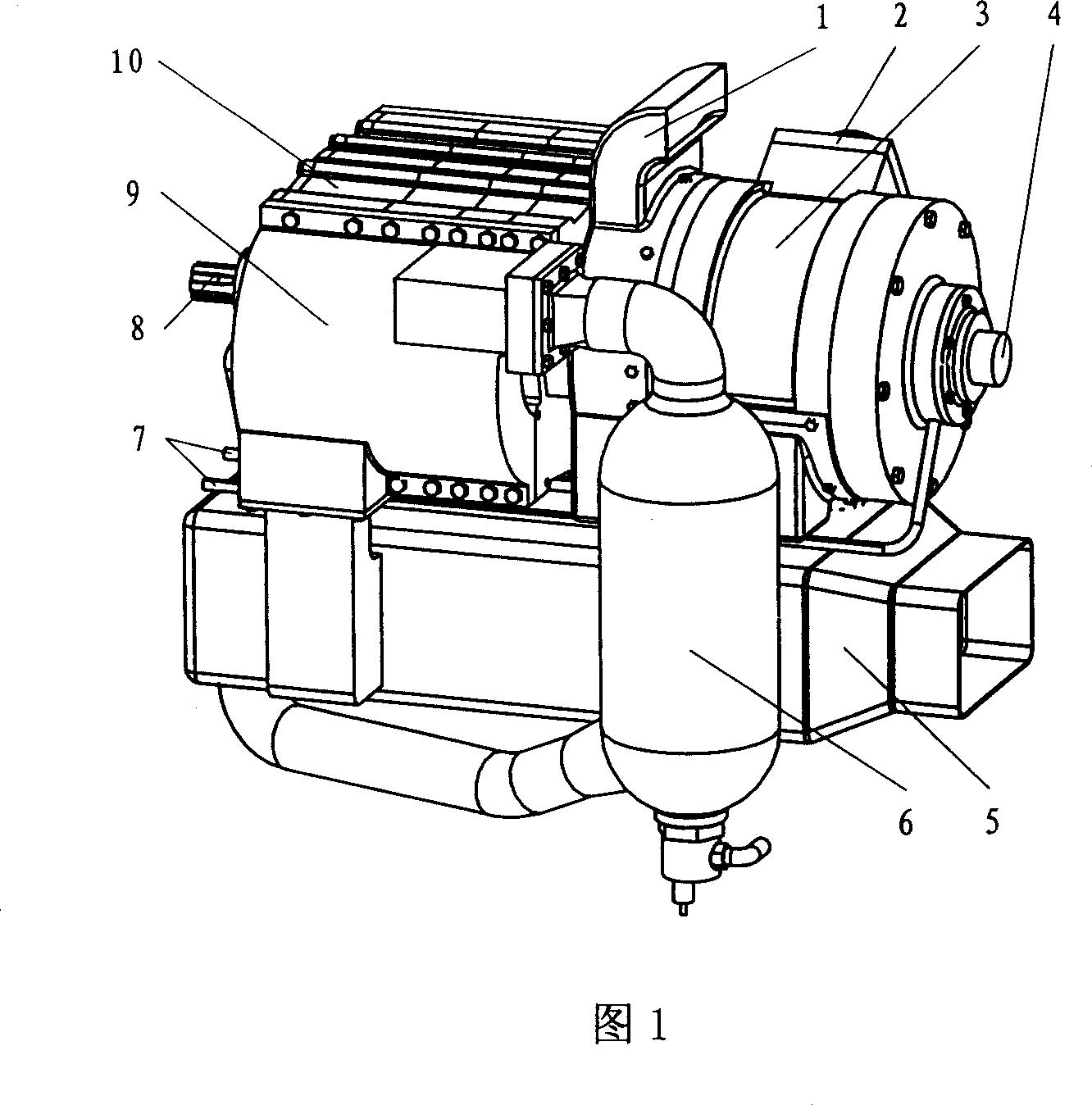

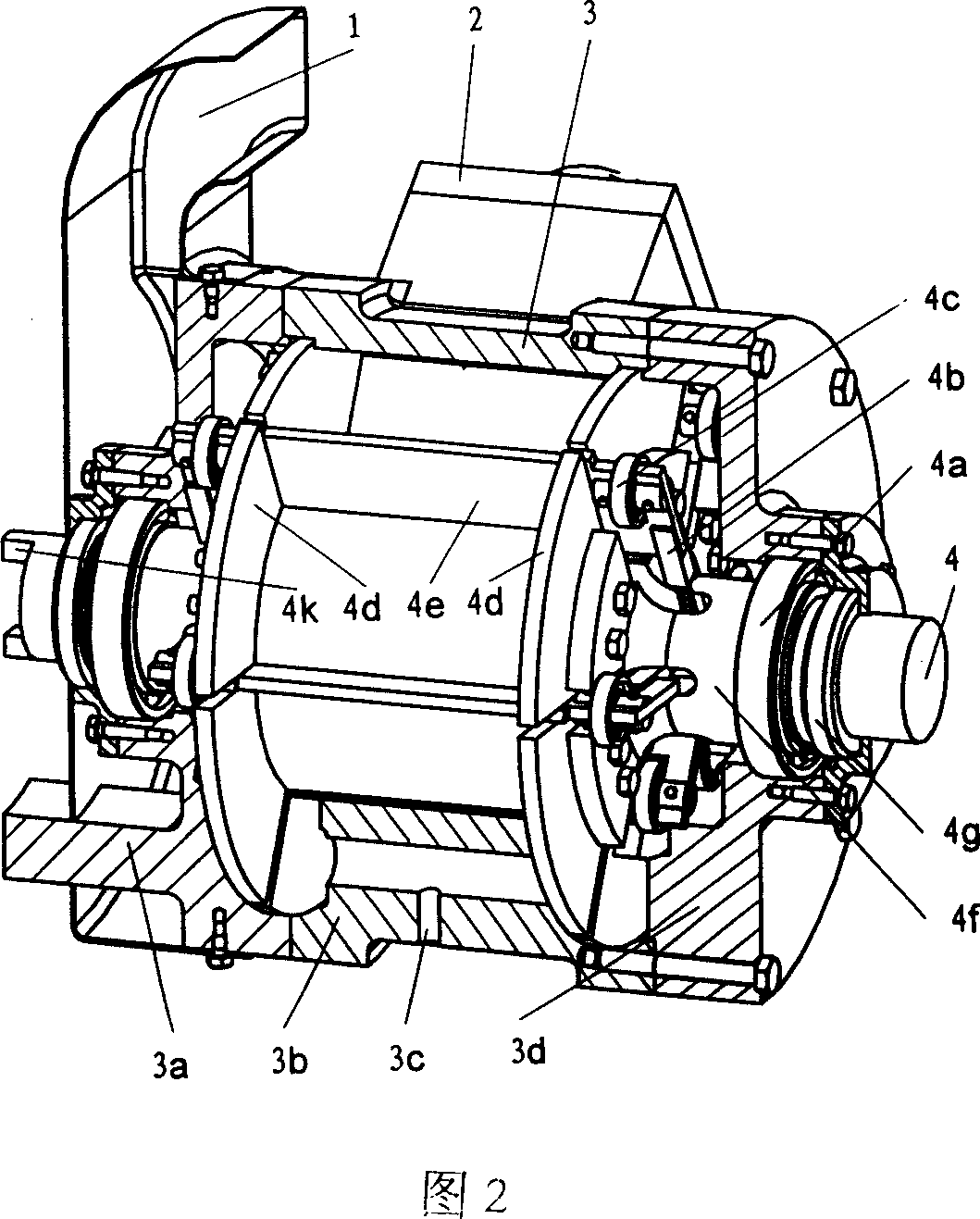

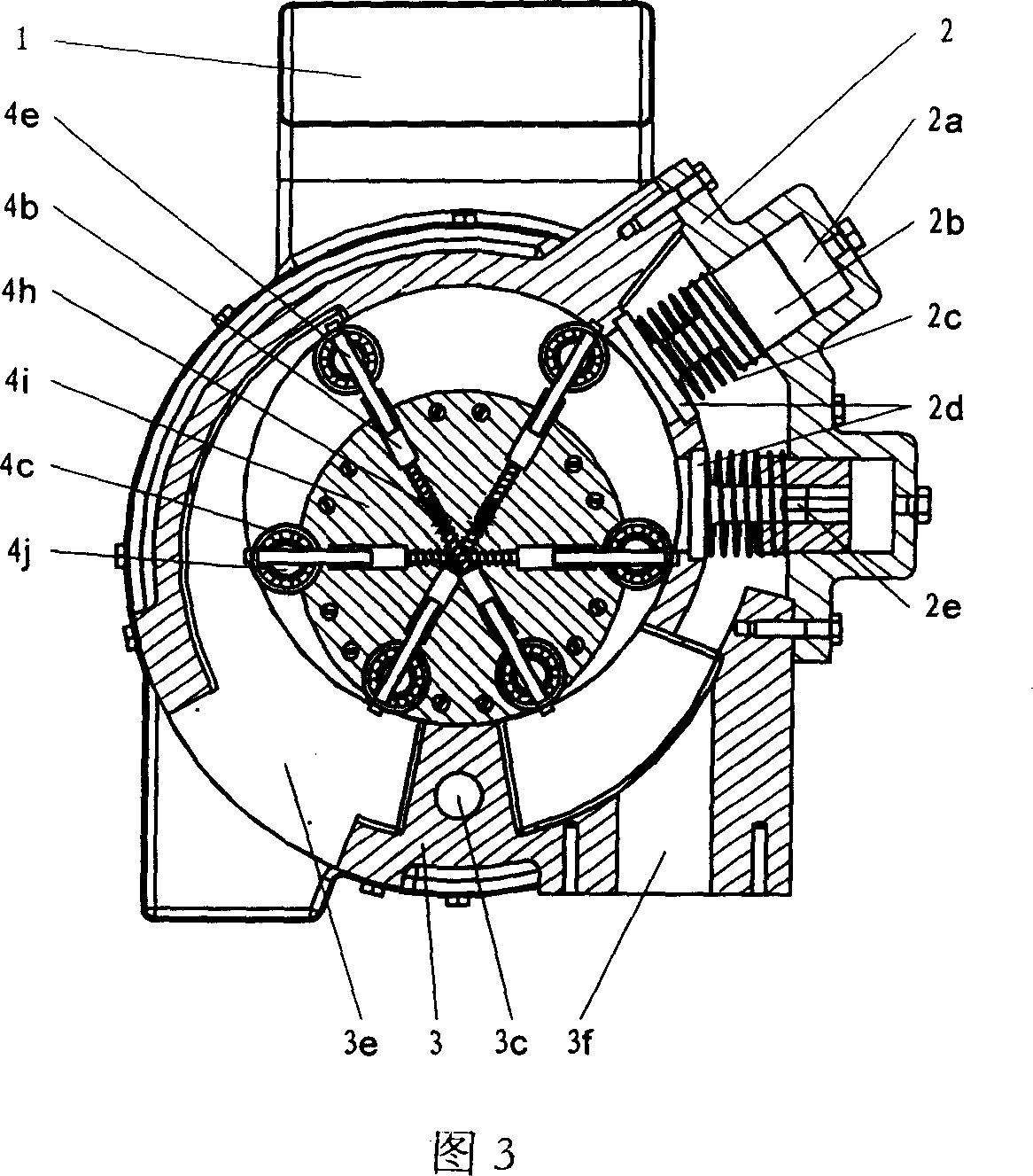

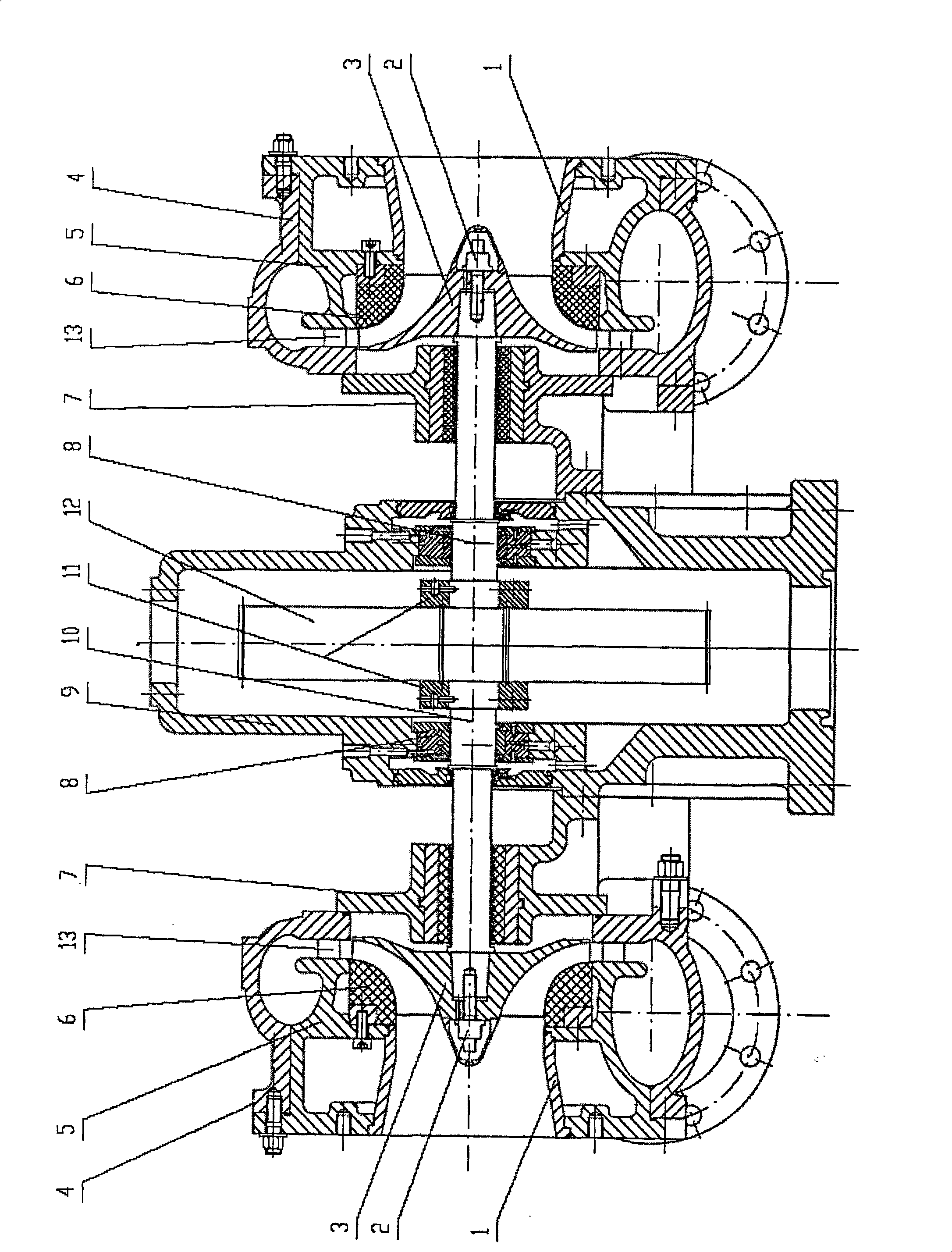

Cantilever type high rate turbine vacuum pump and its evacuation method

ActiveCN101122294AEfficient extractionReduce energy consumptionPump componentsPump installationsRevolutions per minuteChemical industry

The invention discloses a cantilever-type high-speed vacuum turbine pump and the vacuum pumping method. A high-speed eccentric impeller of 10000 revolutions per minute to 30000 revolutions per minute is used to realize the pumping of vacuum with minus 30kPa to minus 70kPa. The pump comprises a gear increase box, independent pump heads and a high-speed rotor. A large gear of the gear increase box is connected with a prime motor. Independent pump heads stand separately at both sides or a single side of the gear increase box. The pump heads adopt a split structure and comprise a suction inlet, an internal volute body, an impeller stopping cover, a volute shell and an air seal. The high-speed rotor comprises a high-speed gear shaft, a thrust collar, an impeller, and a fastening bolt, and is supported by a sliding bearing on the gear increase box. An impeller cantilever is arranged on the tail end of the high-speed gear shaft. The invention uses a high-speed turbine to realize the rapid vacuum pumping with a large flow. Moreover, a multi-pump head structure can make a single pump realize the multi-position, multi-vacuum degree and simultaneous pumping in the fields of paper making, chlor-alkali chemical industry, and so on and greatly reduce the vacuum system energy consumption. Meanwhile, the pump is provided with the advantage that the pump is concise in the structure, highly reliable, widely applicable, and environment-friendly, and does not need a liquid working ring, and so on.

Owner:ZHEJIANG UNIV +1

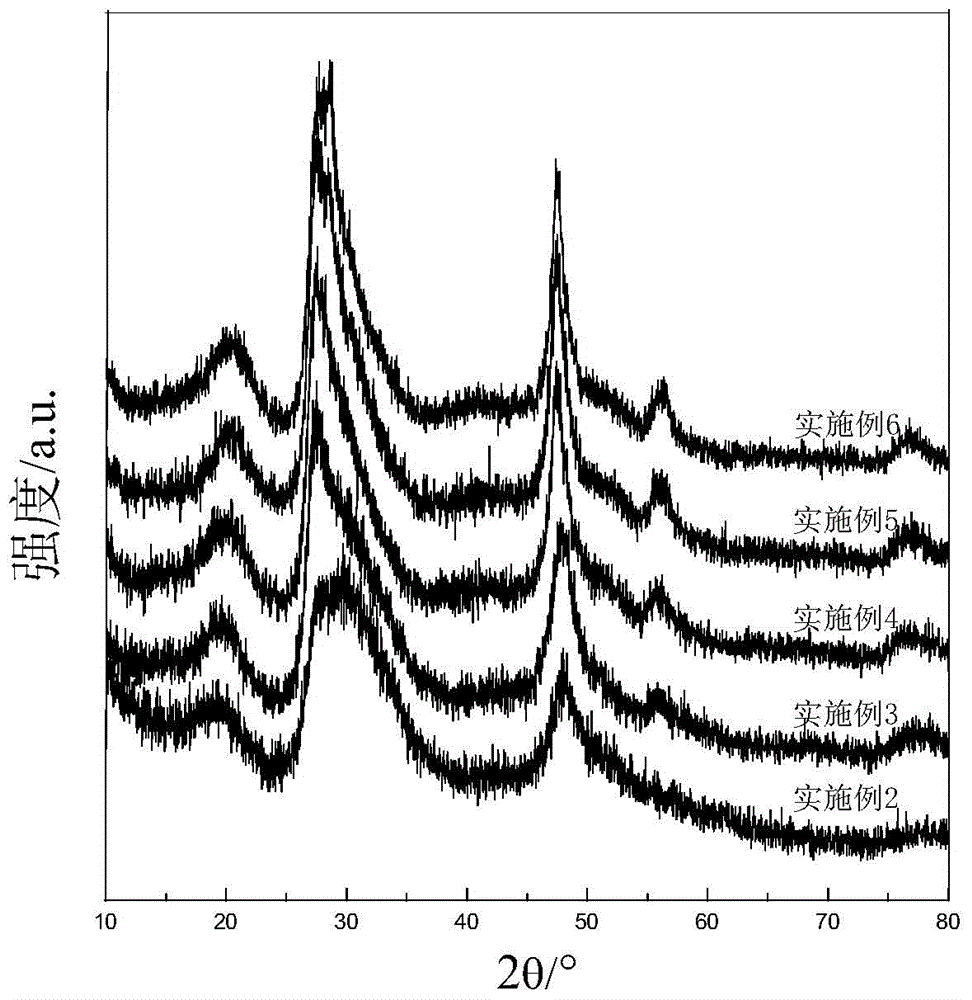

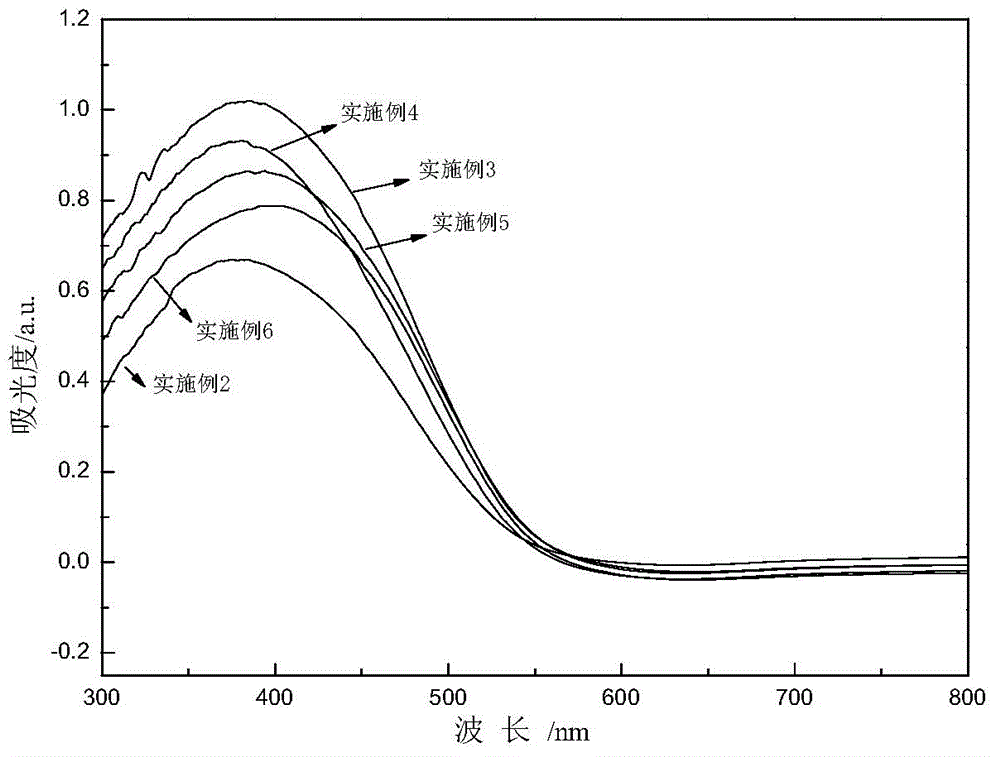

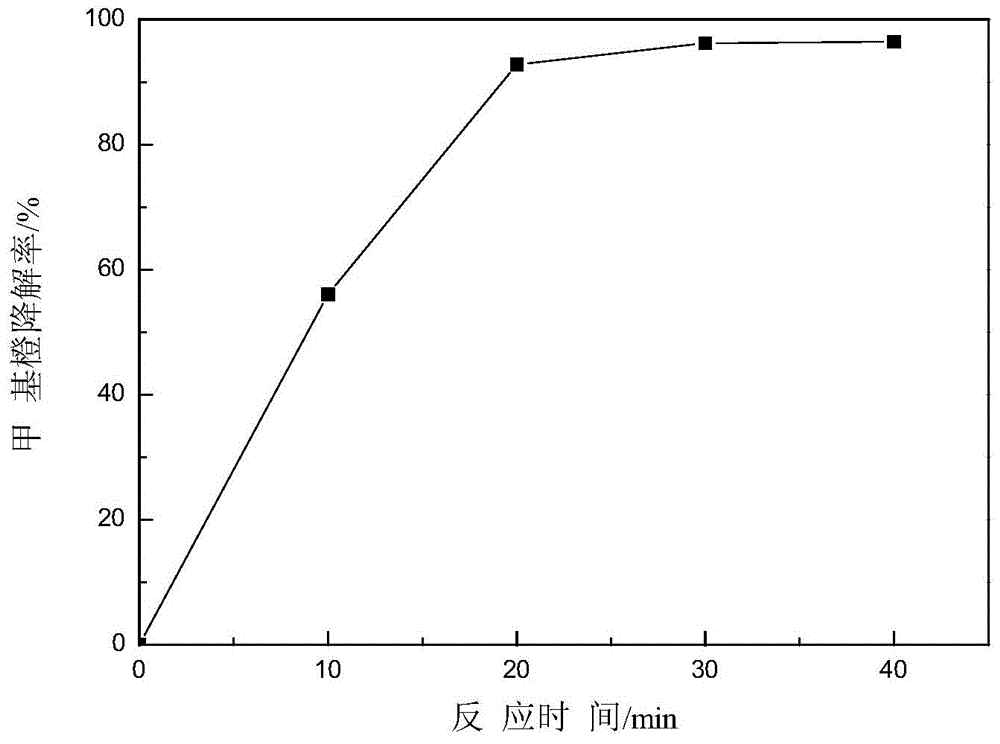

ZnIn2S4 photocatalyst obtained by hydrothermal synthesis of ionic liquid microemulsion and preparation method of ZnIn2S4 photocatalyst

InactiveCN104477972ALarger than surfaceUniform shapePhysical/chemical process catalystsGallium/indium/thallium compoundsIndiumIonic liquid

The invention discloses a preparation method of a ZnIn2S4 photocatalyst by hydrothermal synthesis of ionic liquid microemulsion. The preparation method comprises the following steps: (1) adding a sulfur source into the ionic liquid and a surfactant, heating, and stirring until the sulfur source is dissolved to obtain a mixture A; (2) fully dissolving a divalent zinc salt and a trivalent indium salt in deionized water to obtain a mixture B; (3) transferring and mixing the mixture A and the mixture B in an autoclave having polytetrafluoroethylene lining and uniformly stirring; (4) closing the autoclave, placing the autoclave at 50-90 DEG C and reacting for 4-24 hours and naturally cooling at room temperature to obtain a yellow precipitate; and (5) respectively washing the yellow precipitate with deionized water and anhydrous ethanol, transferring to a drying oven and drying overnight at 40-90 DEG C to obtain the final product. The preparation process is simple, rich in raw materials and low in cost, and the product has the advantages of large specific surface area, high catalytic activity and high hydrogen generation efficiency.

Owner:SOUTH CHINA UNIV OF TECH

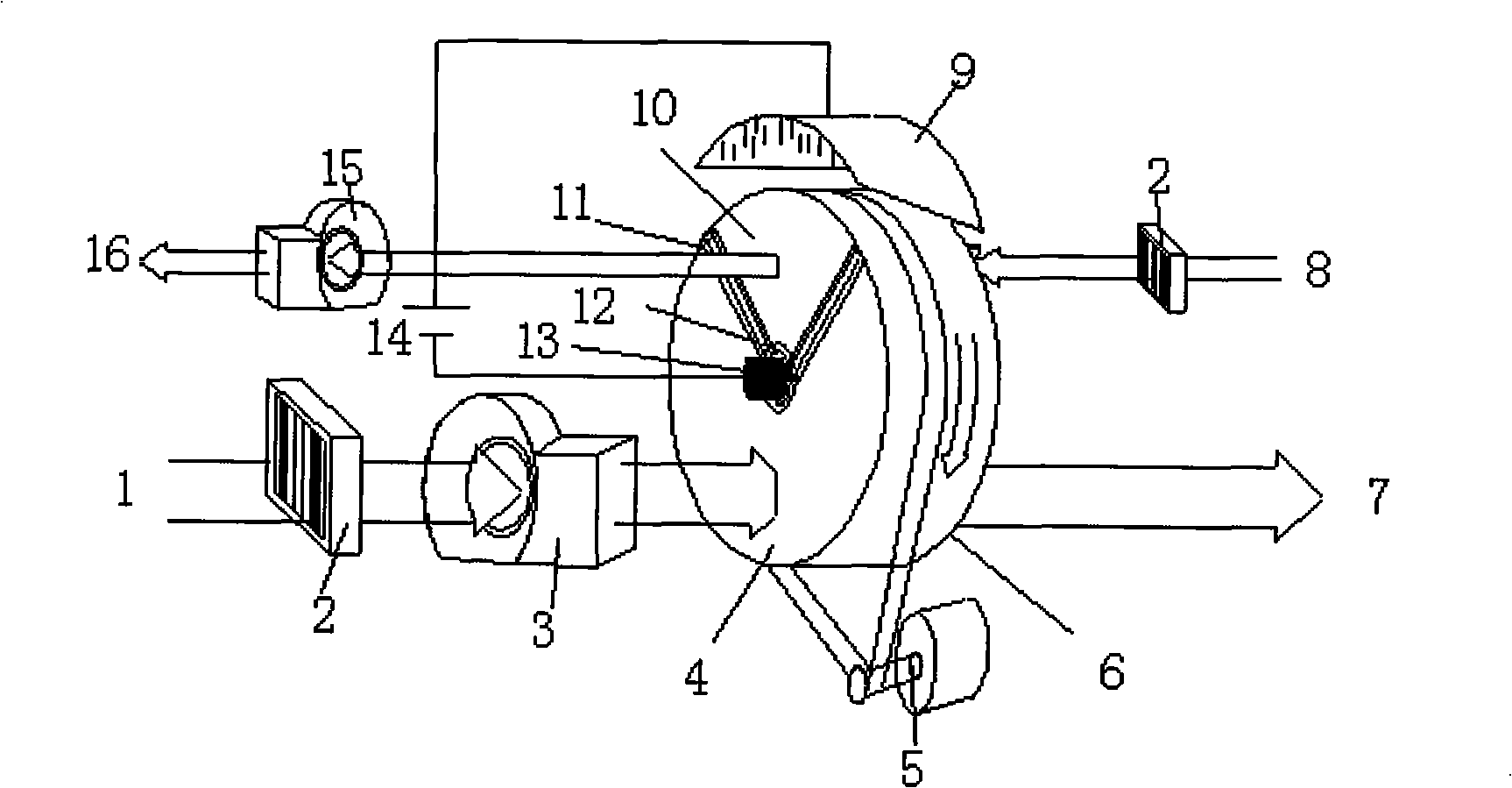

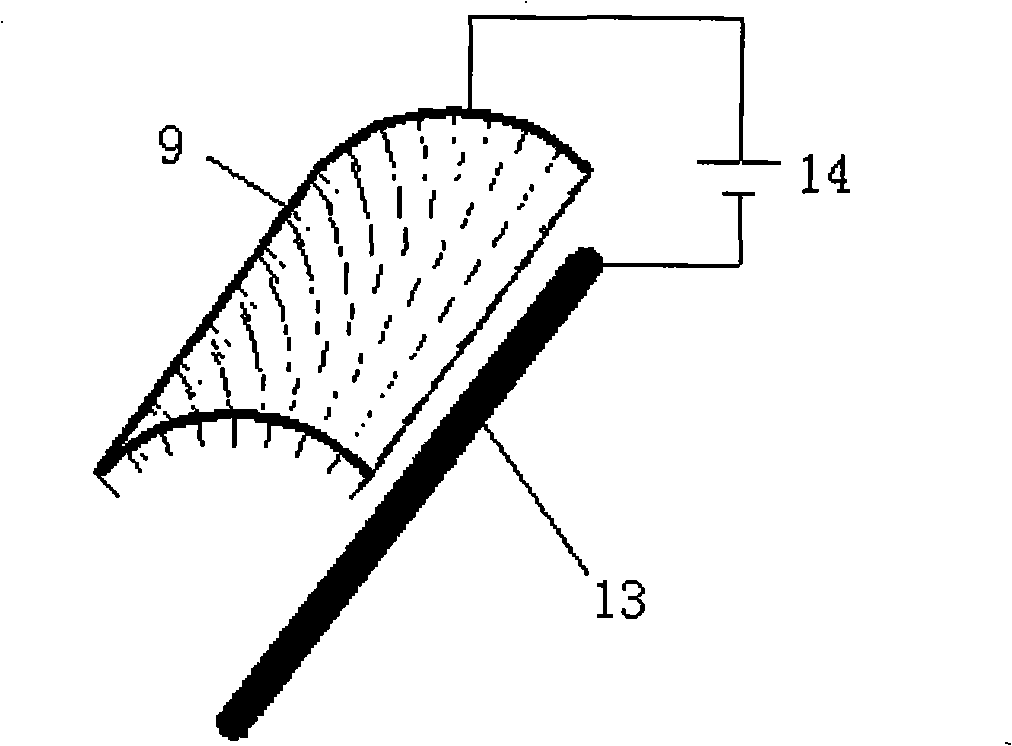

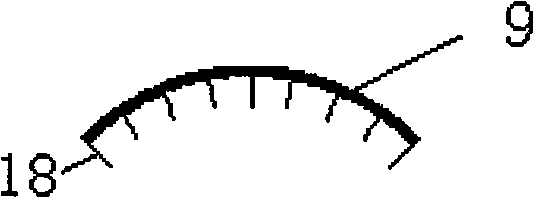

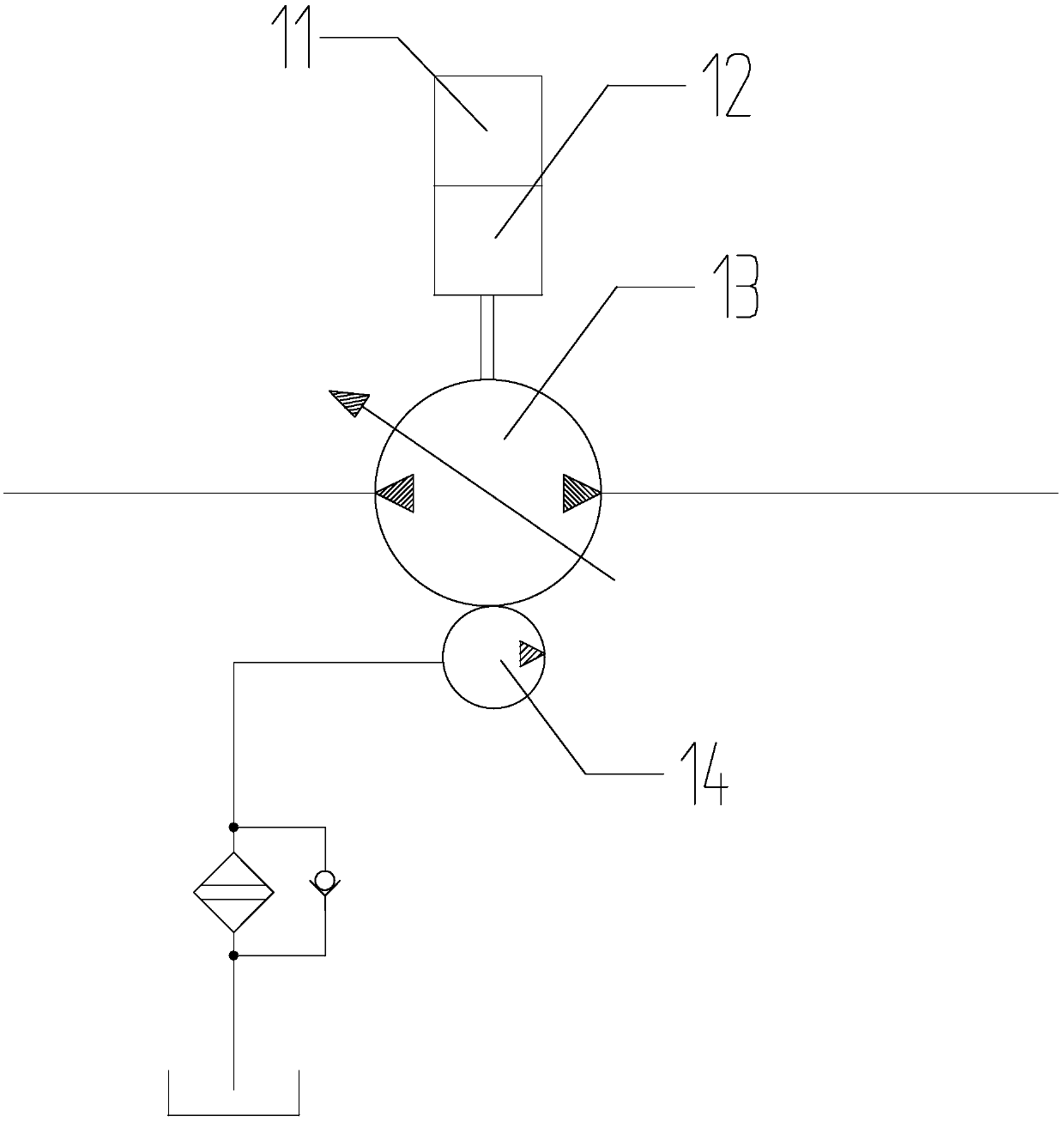

Arefaction regeneration method for high-voltage electric field in runner humidity reducing set

InactiveCN101293169AImprove efficiencyImprove environmental protection requirementsLighting and heating apparatusDispersed particle separationEngineeringHigh pressure

The invention relates to a dehumidification and regeneration method of a high-voltage electric field in a rotary dehumidifier, comprising the following steps: 1) a circuit is switched on; a negative pole of a high tension supply (14) is connected with a central spindle (13) of a rotating shaft; a positive pole is connected with an arc metal plate band (9); all wires and metal junctions are be separated with insulating material; 2) the high tension supply (14) is started up; voltage parameter is regulated; 3) a distance between a positive plate and a negative plate is controlled; 4) the running speed of a dehumidifying rotating wheel (6) is adjusted; 5) an exhaust system is started. The dehumidification and regeneration method of the high-voltage electric field in the rotary dehumidifier provided by the invention utilizes an 'akawasa effect' to realize the purpose of the dehumidification, the regeneration and the energy saving of moisture adsorption material. Compared with the warm air drying technology, the dehumidification and regeneration method of the high-voltage electric field in the rotary dehumidifier has the advantages of higher efficiency, energy saving and environmental protection, thereby greatly improving an application of the technology of the dehumidification and regeneration and energy saving of the high-voltage electric field in a regeneration system of the rotary dehumidifier.

Owner:DONGHUA UNIV

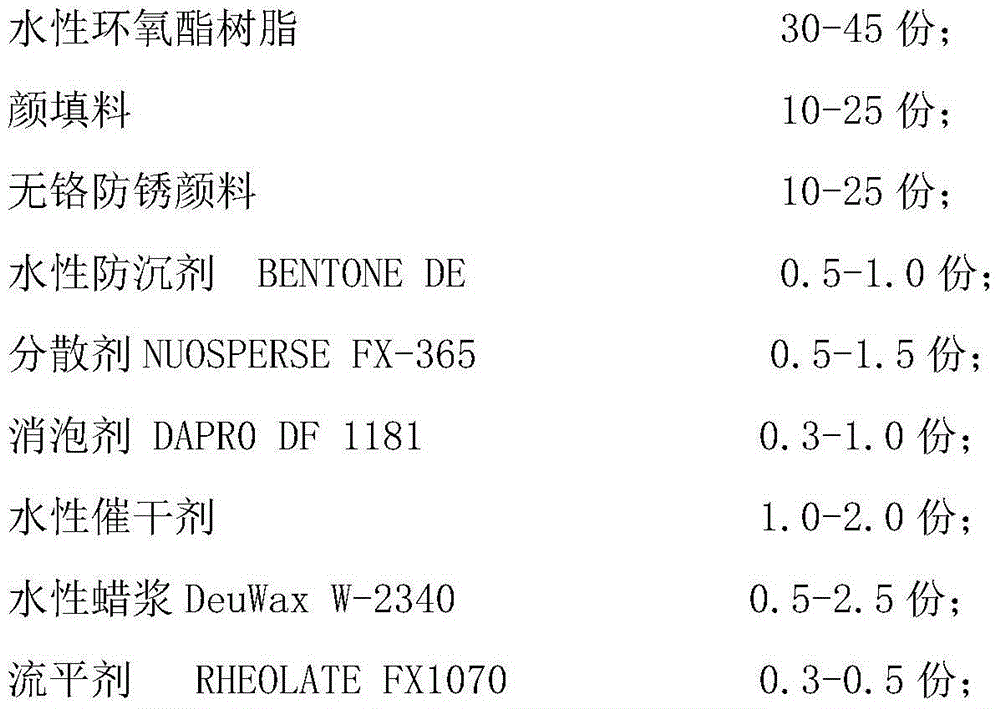

High performance water-based industrial anti-corrosion coating and preparation method thereof

ActiveCN104371507AGood chemical resistanceImprove water resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyWater based

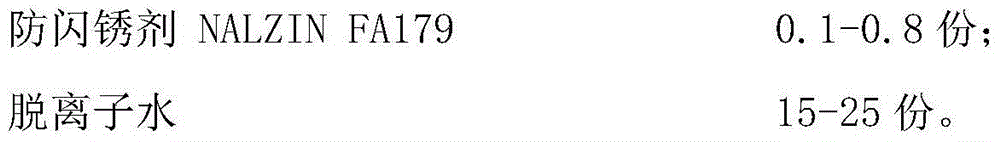

The invention provides a high performance water-based industrial anti-corrosion coating which comprises the following components by weight: 30-45 parts of water-based epoxy ester resin; 10-25 parts of pigments and fillers; 10-25 parts of a non-chromium antirust pigment; 0.5-1 part of water-based anti-settling agent BENTONE DE; 0.5-1.5 parts of dispersing agent NUOSPERSE FX 365; 0.3-1 part of defoaming agent DAPR0DF 1181; 1-2 parts of a water-based drier; 0.5-2.5 parts of water-based wax slurry DeuWax W-2340; 0.3-0.5 parts of leveling agent RHEOLATE FX1070; 0.1-0.8 part of anti flash rust agent NALZIN FA179; and 15-25 parts of deionized water. The high performance water-based industrial anti-corrosion coating has good chemical resistance, water resistance and salt fog resistance, and wide application range.

Owner:山东奔腾漆业股份有限公司

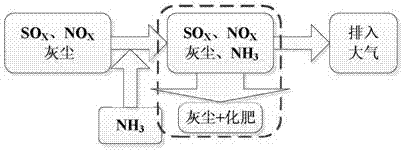

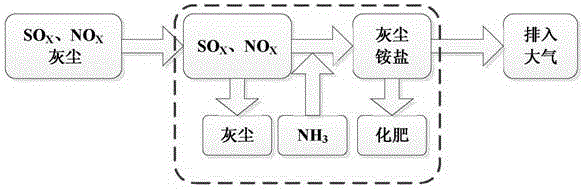

Streamer discharge ammonia flue gas desulfurization, denitrification and fog removal integrated method

InactiveCN102274680AIncrease added valueImprove defogging efficiencyDispersed particle separationAmmonium salt fertilisersFlueDemister

The invention discloses an integrated method for flue gas desulfurization, denitrification and demisting by streamer discharge ammonia method, which comprises the following steps: 1) boiler flue gas containing sulfur dioxide and nitrogen oxides is sent to streamer discharge denitrification reactor after dedusting; 2) The flue gas after the streamer discharge denitrification reactor enters the desulfurization tower and is discharged from the top outlet of the desulfurization tower; 3) The flue gas from the top outlet of the desulfurization tower is demisted and purified by the electric demister and sent to the chimney for discharge. The method of the present invention simultaneously desulfurizes and denitrates, has high demisting efficiency, effectively suppresses ammonia escape, eliminates ammonium salt entrainment, reduces ammonia loss, reduces exhaust smoke turbidity at the outlet, reduces corrosion to tail flue and chimney, and produces nitrogen fertilizer by-product.

Owner:GUANGDONG J TECH ENVIRONMENT SCI CO LTD

Method for preparing multifunctional Chinese medicinal organic bacterial manure

InactiveCN102910970AStir wellIncrease profitBio-organic fraction processingOrganic fertiliser preparationPotassiumEcological agriculture

The invention discloses a method for preparing a multifunctional Chinese medicinal organic bacterial manure. According to the technical scheme, the Chinese medicinal organic bacterial manure comprises the following raw material in percentage by weight: 30 percent of Chinese herbal medicines, 20 percent of rice husk meal, 20 percent of humic acid, 15 percent of plant ash, 10 percent of bone powder, 2 percent of syrup, 1 percent of yeast and 2 percent of strains (including 40 percent of EM (Effective Microorganisms), 630 percent of DA (Dopi Amine) and 30 percent of bacillus subtilis). The multifunctional Chinese medicinal organic bacterial manure has the advantages of simple processing technic, viable count per gram of over 150,000,000, the function of improving a plurality of enzymes and beneficial bacteria of soil, and increase in the utilization ratio of nitrogen, phosphorous and potassium, and is a superior fertilizer for developing green ecological agriculture due to balanced nutrition and freeness from nuisance.

Owner:河南金正佳生物肥业有限公司

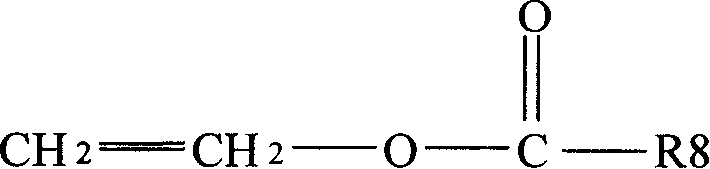

Neoprene adhesive subjected to secondary graft modification and preparation method of neoprene adhesive

InactiveCN103865451AImprove environmental protection requirementsImprove performanceGraft polymer adhesivesShoe industryPolymer science

The invention discloses a neoprene adhesive subjected to secondary graft modification and a preparation method of the neoprene adhesive. The neoprene adhesive comprises the following raw materials (in percentage by weight): 10%-15% of neoprene, 6.3%-13% of grafted monomers, 0.1%-0.5% of initiating agents, 5%-10% of acetone, 15%-30% of butanone, 10%-20% of ethyl acetate, 10%-20% of dimethyl carbonate, 8%-20% of methyl cyclohexane, 5%-10% of thickening agents and 0.3%-1% of terminating agents. The preparation method comprises the following steps of sequentially adding acetone, butanone, ethyl acetate, dimethyl carbonate and methyl cyclohexane, and uniformly mixing and stirring; adding neoprene, and stirring for 2-4 hours; adding a part of the initiating agents, further stirring, then dropping first grafted monomers to react for 0.5-1 hour, and adding second grafted monomers and the rest of initiating agents; adding a terminating agent, and then adding tackifying resin; regulating viscosity, and then discharging. The neoprene adhesive disclosed by the invention is subjected to the secondary graft modification through multiple monomers. The product has the characteristics of high comprehensive property and good environmental friendliness and is suitable for industries, such as furniture making, shoe making and luggage.

Owner:ZHUHAI YUTIAN CHEM PROD

Method for manufacturing multienzyme-complex organic fertilizer by using Chinese herbal medicine

The invention provides a method for manufacturing a multienzyme-complex organic fertilizer by using Chinese herbal medicine. The technical proportioning scheme is that rice husk meal 30%, humic acid 30%, plant ash 19%, bone meal 10%, medical stone 3%, Chinese herbal medicine 3%, syrup 2%, saccharomycetes 1% and strain 2%. The manufacturing method comprises the following steps: (1) smashing raw materials and filtering the raw materials through a sieve with 80-100 meshes, (2) mixing filtered raw materials, the syrup 2% and the saccharomycetes 1% and adding water into mixture to perform fermentation, (3) performing pile turning for one time after fermenting for 24 hours, recovering temperature in a pile to normal temperature after 48 hours, adding the strain 2% into the pile according to the proportion and performing even mixing and package to produce organic fertilizer powder, and (4) pelletizing and packing the organic fertilizer powder according to the organic fertilizer pelletizing process, wherein organic fertilizer pellets are produce when the temperature in processing does not exceed 80 DEG C and pellet humidity is 20-30%.

Owner:河南丰沃生物科技有限公司

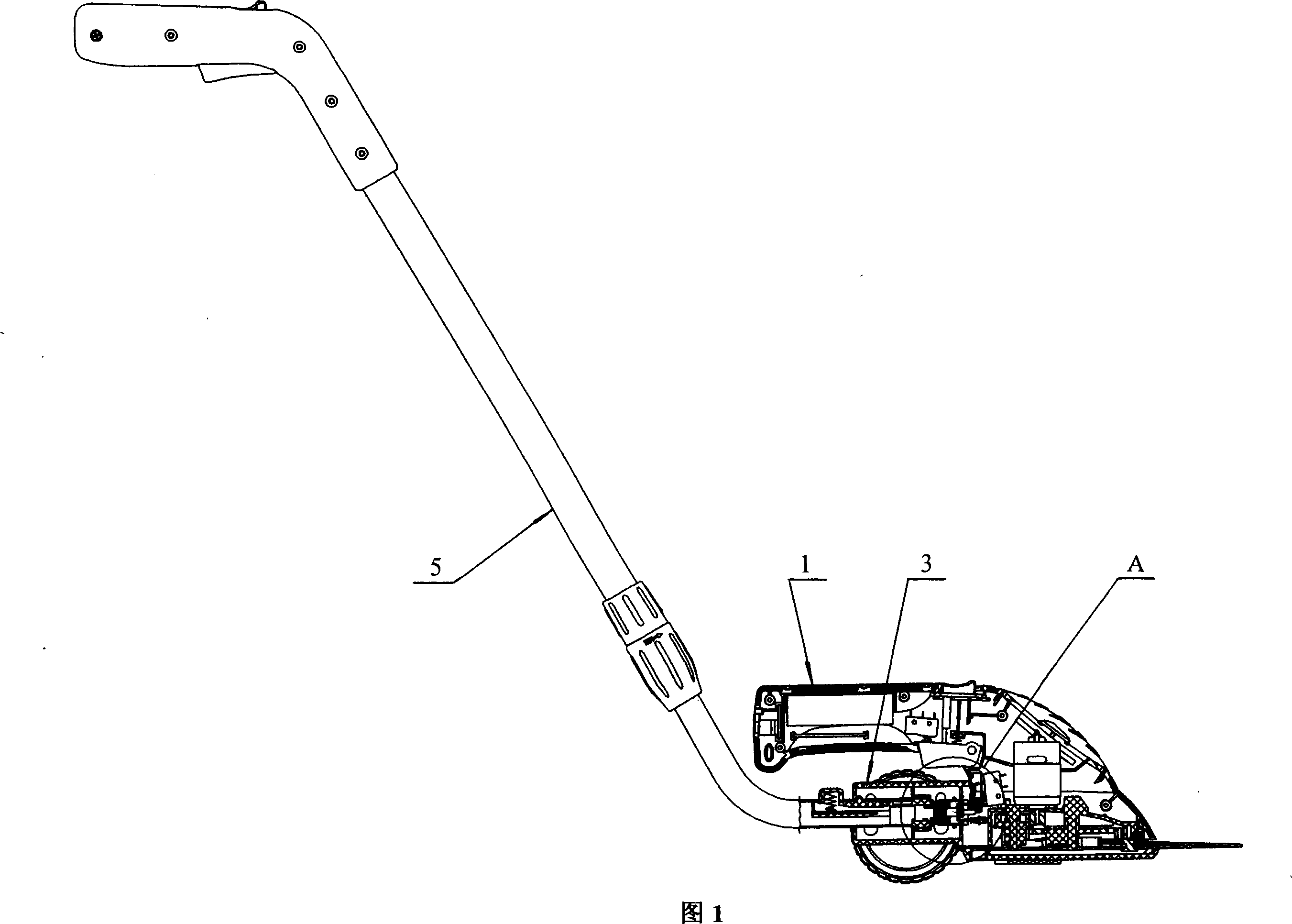

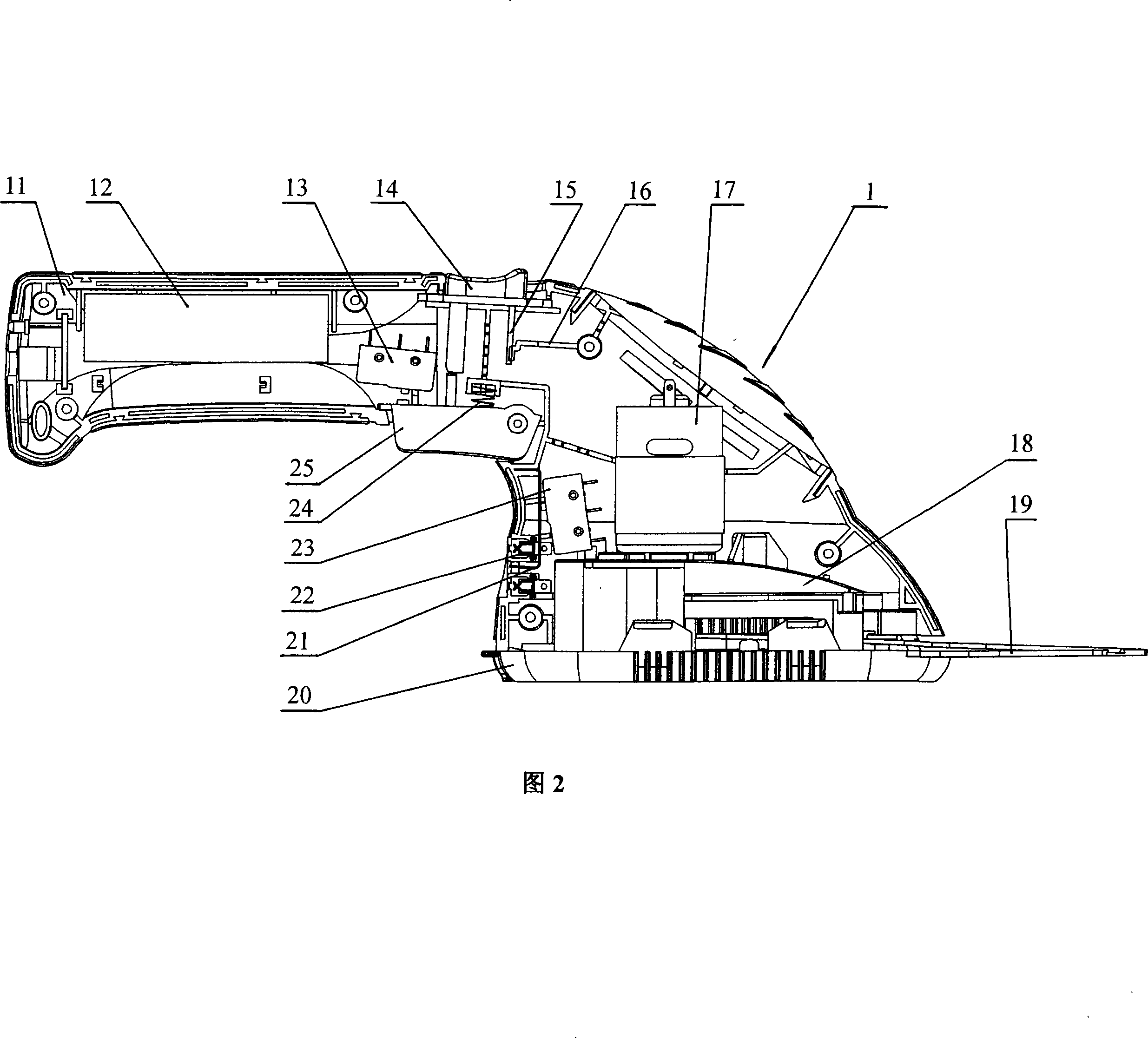

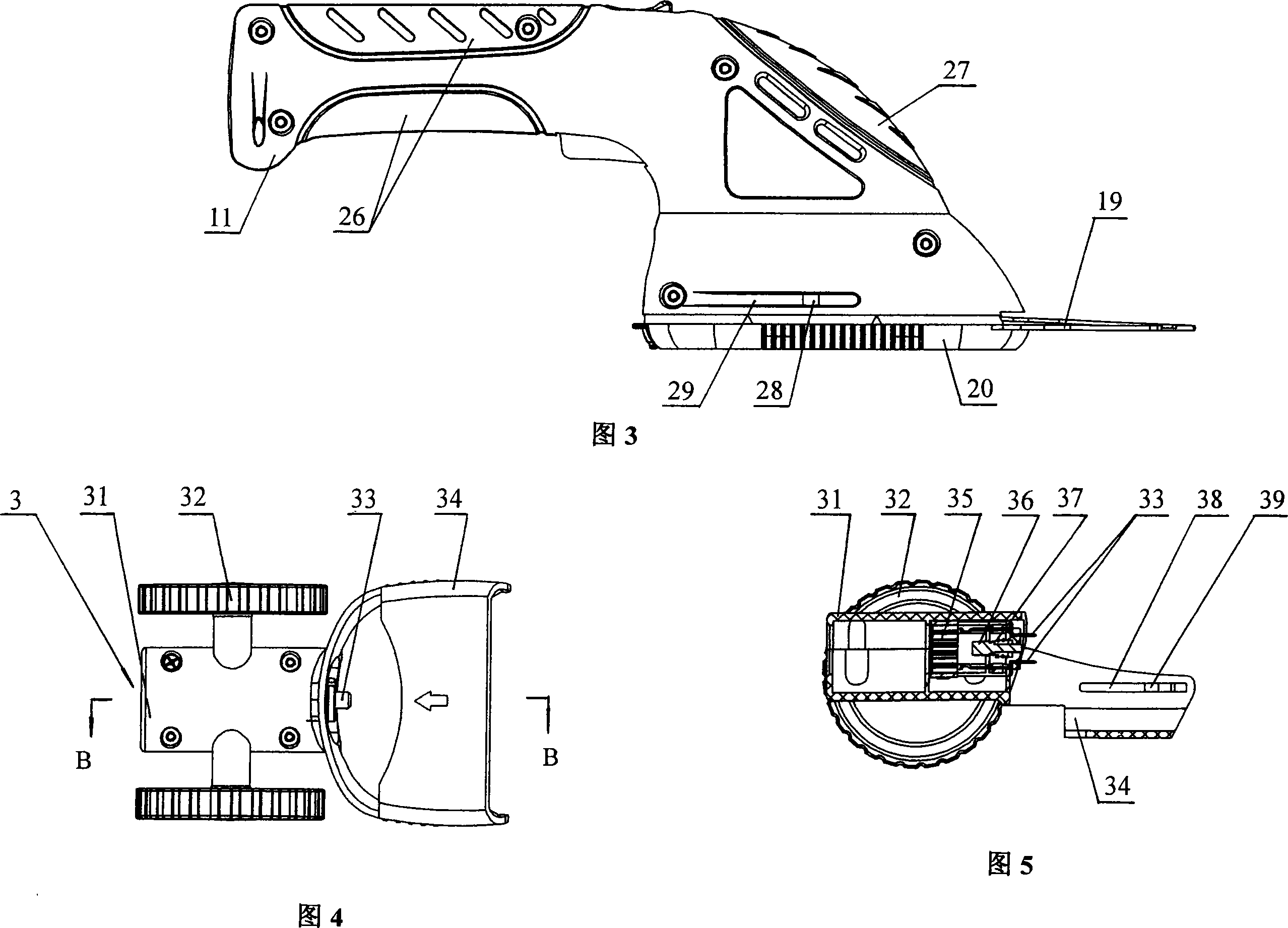

Grass-mowing pruning shear

The present invention relates to pruning shears which consist of a main frame, a wheel component and a prolonged handle, wherein, the shell of the main frame is provided with a power source, a first micro switch, a motor, a first switch button and a first self-locking push button, which start and stop the motor; the output of the motor drives a shearing mechanism through a gear box and an eccentric mechanism; the shell is also provided with a pair of shell pole pieces, a switch pressing rod and a second micro switch; the bottom of the shell can be disassembly connected with a wheel component that is composed of a base, a wheel seat and a wheel, and a positioning-part pole piece that is arranged on the wheel component is supported against the pole pieces of the shell; the prolonged handle can be disassembly connected with the wheel component at different angles and a fixed-block pole piece on the prolonged handle is supported against the positioning-part pole piece, the fixed-block pole piece is electrically connected with a third micro switch, and the startup of the motor is realized by a second switch button and a second self-locking push button. The design of the present invention has three application modes which can be independently used or used in combinational way according to different usages, thereby enlarging the application range and being convenient to be used; lithium battery is adopted as the power source, thereby, the environment-protection property is good; the shearing mechanism can be mutually exchanged, thereby the present invention has multiple functions; the double safety switches have good safety.

Owner:NINGBO EAST ENVIRONMENTAL PROTECTION MACHINERY CO LTD

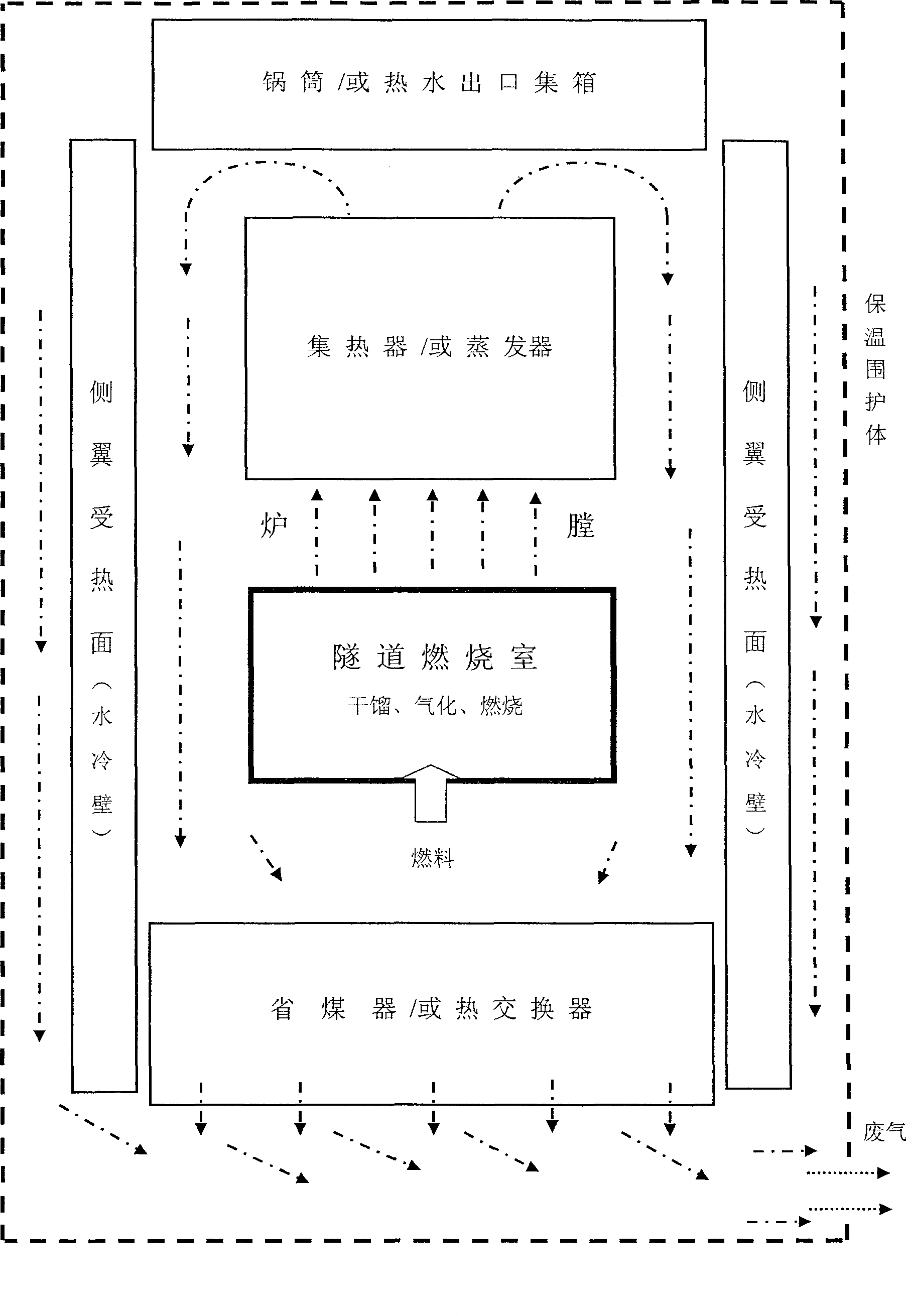

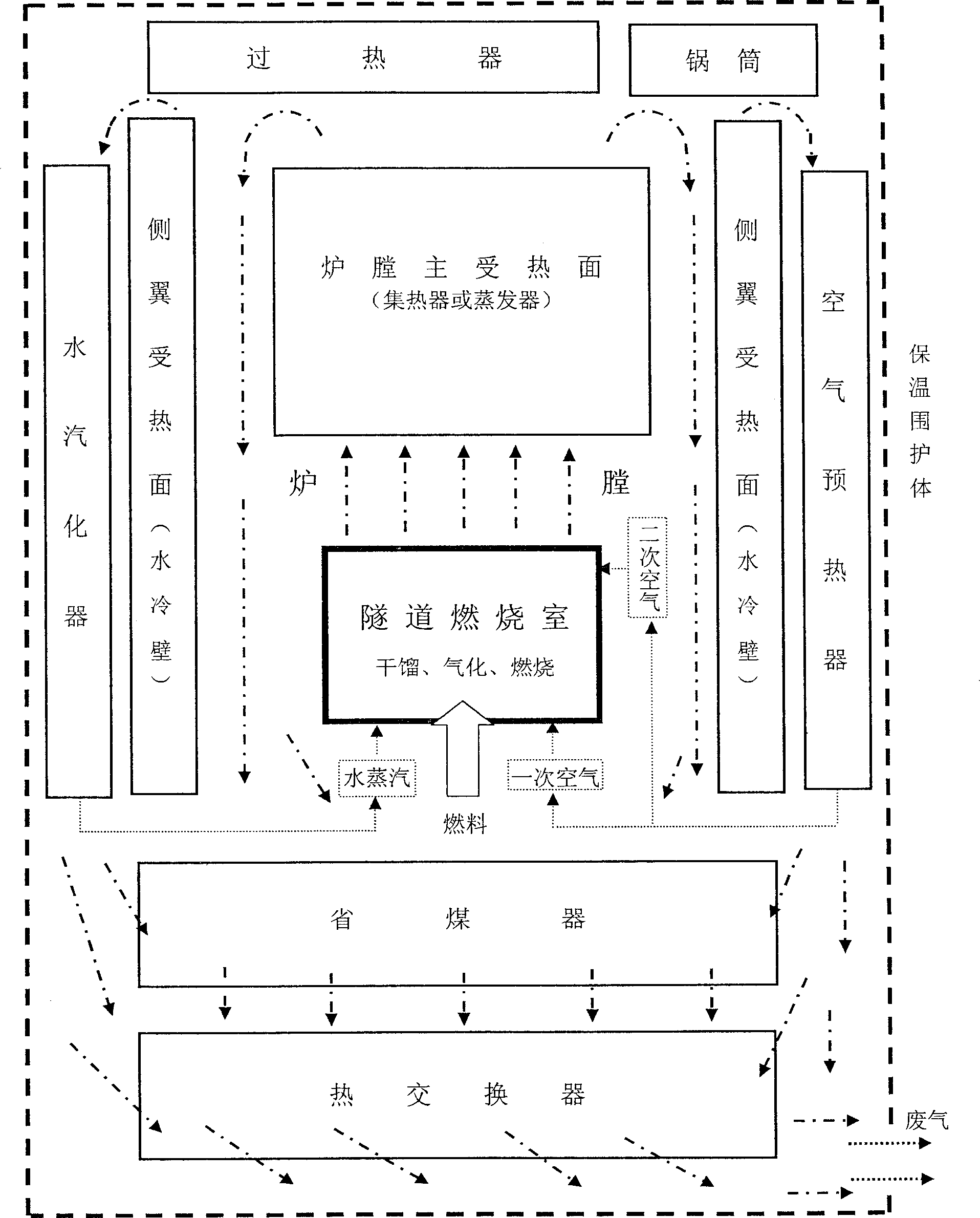

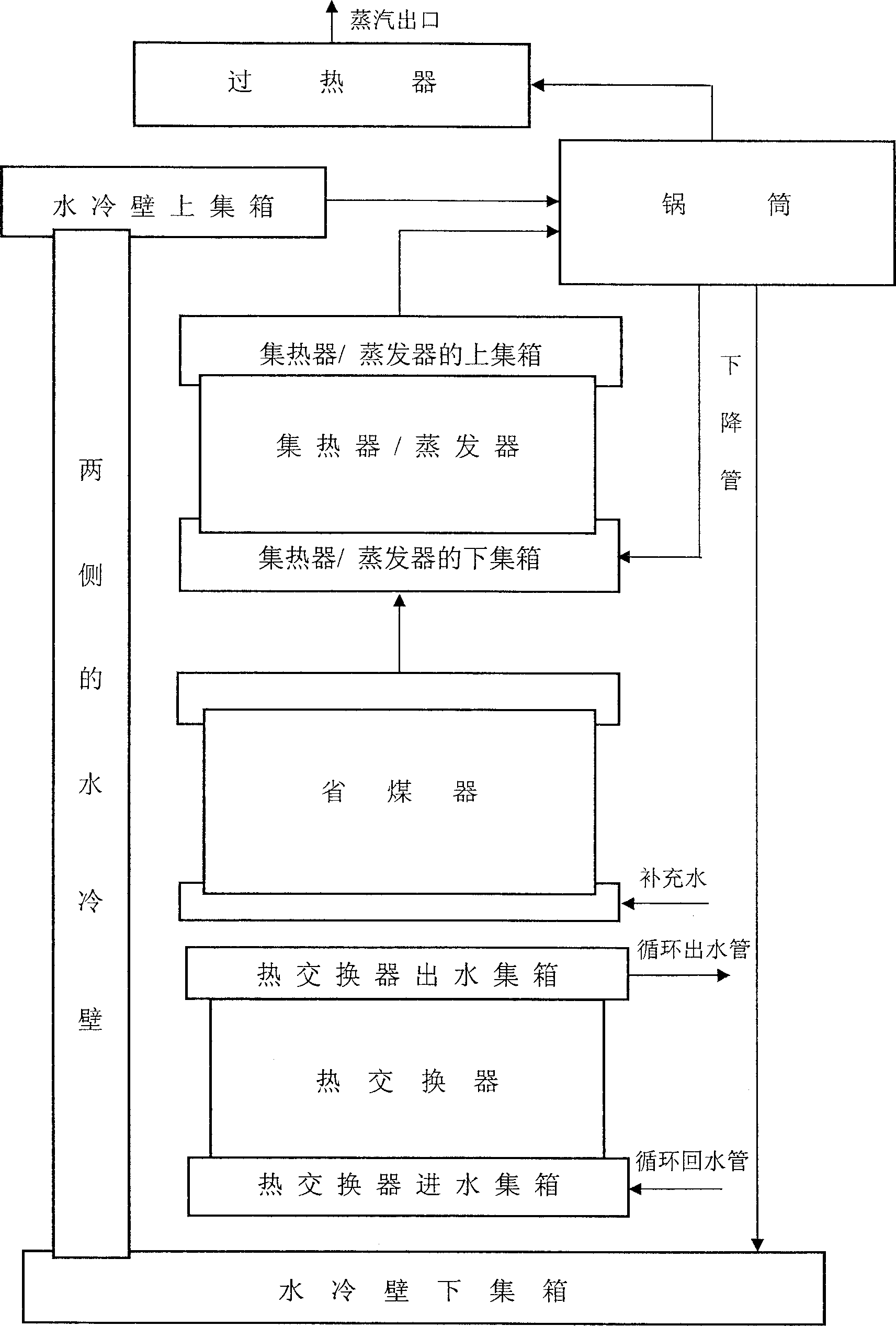

Tunnel combustion chamber and its constructed smoke dust less fuel coal and biomass equipment

InactiveCN1904479ARaise the gradePrevent escapeCasings/liningsNon-combustible gases/liquids supplyResource depletionCombustion chamber

The tunnel combustion chamber and its constitute of burning coal and organism without smoke and dust relate to boiler, furnace and aerify equipment whose fuel is coal and organism. The tunnel combustion chamber has wide fuel scope. It can carry out the cleanness combustion of the smoke raw coal, the spread coal, the organism, the type coal and the biologic coal. It applies the biologic fuels reasonably and has high thermal efficiency. It realizes the large-scale and mechanical burning. The invention resolves the problem of pollution atmosphere environment by coal burning device. It makes the equipments the cleanness combustion when burning the coals. The small equipment doesn't need air blast and induced air and it can burn. And it doesn't need the ash handling equipment to protect the environment. The invention sends the vapour to the tunnel combustion chamber. It is used to restrain the smoke and translate to the gas fuel. It carries out cleanness combustion when realizes the increase the combustion value of the fuels. It lowers the resources depletion and relief the energy strain. It creates a condition for pushing economy social overall coordination sustained developing.

Owner:周开根

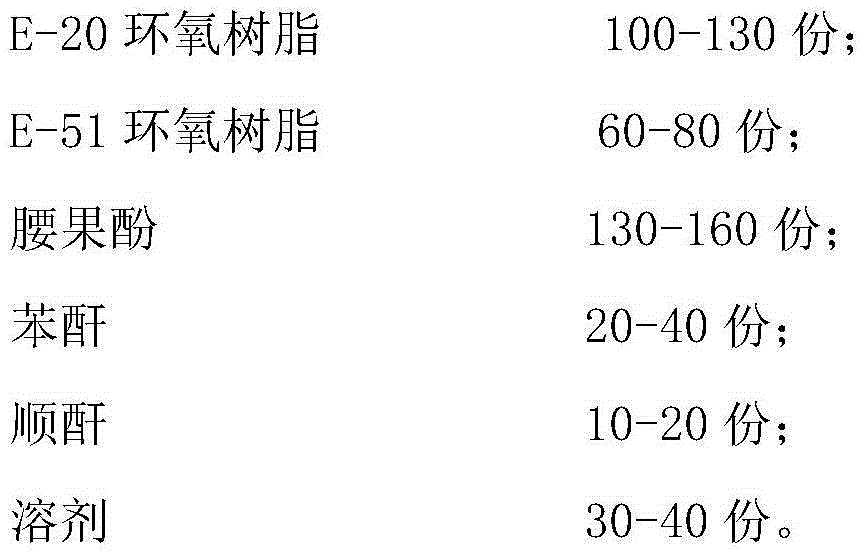

Anti-corrosion paint for low heavy metal automobile parts and method for preparing same

The invention relates to an anti-corrosion paint for low heavy metal automobile parts and a method for preparing the same, wherein the anti-corrosion paint comprises the following components in part ratio(part): 30 to 40 parts of resin specially used for an anti-corrosion primer, 10 to 20 parts of zinc phosphate, of which the zinc content is lower than 20mg / kg, 10 to 20 parts of solution of nitrocotton resin, 5 to 15 parts of talc powder, 5 to 10 parts of calcium carbonate, 3 to 6 parts of carbon black, 3 to 6 parts of anti skinning agent, 0.5 to 1.0 part of dispersing agent YB-201A, 20 to 35parts of mixed solvent, 0.5 to 1 part of anti-settling agent bentonite, 0.3 to 0.6 part of defoaming agent and 3 to 5 parts of dryer; and the preparation method comprises the following steps of: adding the raw materials in a stirring container in sequence and evenly stirring, dispersing the mixture at a high speed, grinding the mixture by grinding equipment until the fineness of the mixture is below 35mum, and adding the solution of nitrocotton resin, the dryer and the mixed solvent and evenly stirring. The anti-corrosion paint has the advantages of having excellent adhesive force, covering force, decorative property, stability and construction application, withstanding salt fog for 600 hours, meeting higher use requirements on environmental protection and also meeting the requirements oflimiting amount of four types of soluble heavy metals in the national mandatory standards.

Owner:天津灯塔涂料工业发展有限公司

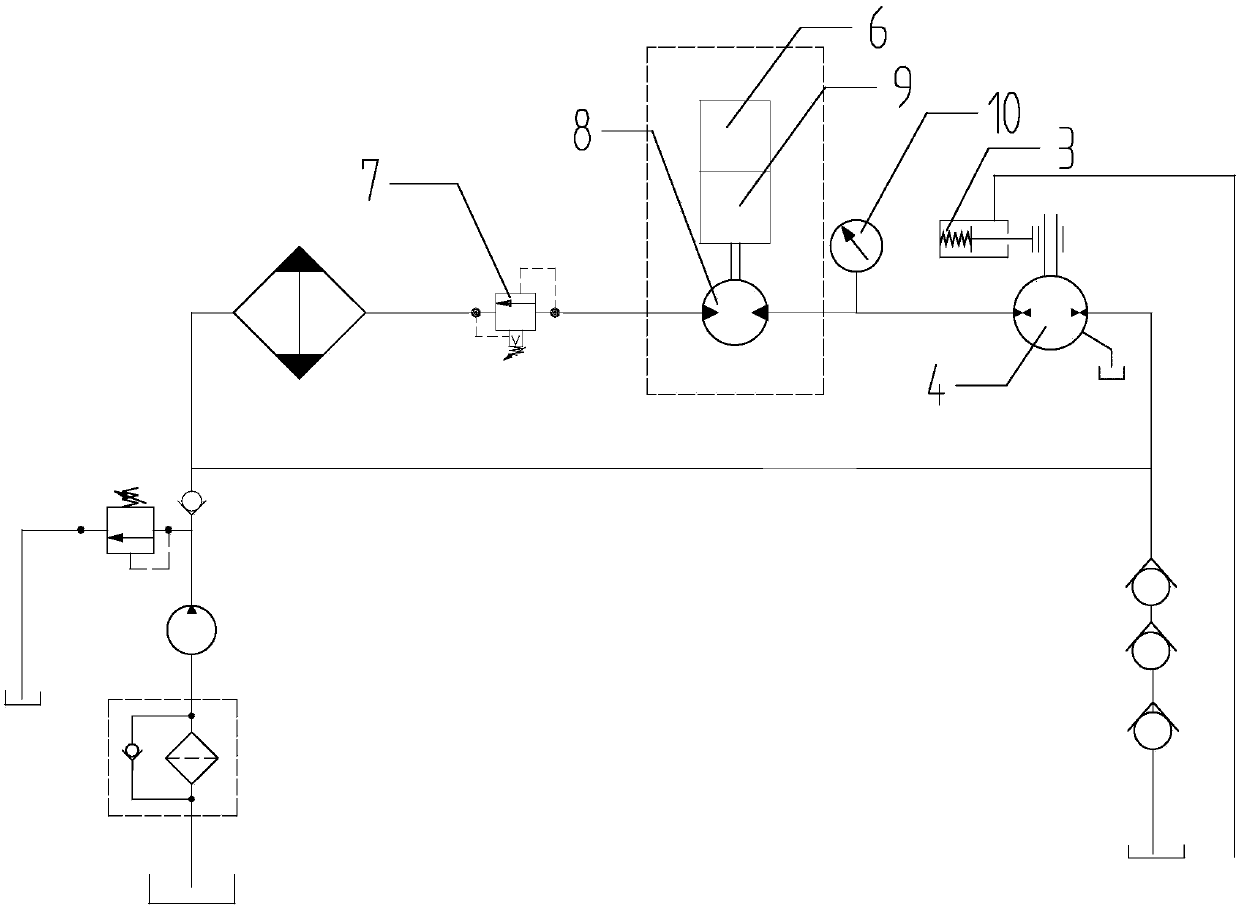

New energy tensioner and working method thereof

PendingCN109667814ASave work energyProduce pollutionBatteries circuit arrangementsFilament handlingNew energyHydraulic pump

The invention discloses a new energy tensioner and a working method thereof and relates to the field of tensioners. At present, a tensioner used in construction of line stringing under tension in transmission line engineering basically adopts a diesel engine as a power, the equipment noise is large, the environment is polluted, the engine is relatively high in maintenance cost and relatively poorin economy, and the field diesel filling easily causes pollution at the same time. For the new energy tensioner, by fully utilizing the characteristic that a tensioner mainly focuses on passive worksand adding a power generator, a power battery, a motor for driving a hydraulic pump and the like, the original diesel engine is cancelled, so that external passive work is converted to an electric energy as much as possible, and the electric energy is provided to the motor for driving the hydraulic pump; meanwhile, the configured power battery can store redundant electric energy and can provide the power to a system if needed by the system, so that work of the tensioner saves more energy; and after the diesel engine is cancelled, pollution to the surrounding environment can not be caused, andequipment running noise can be greatly reduced, the operation environment is optimized, and higher environmental protection requirements are realized.

Owner:蒋晓峰

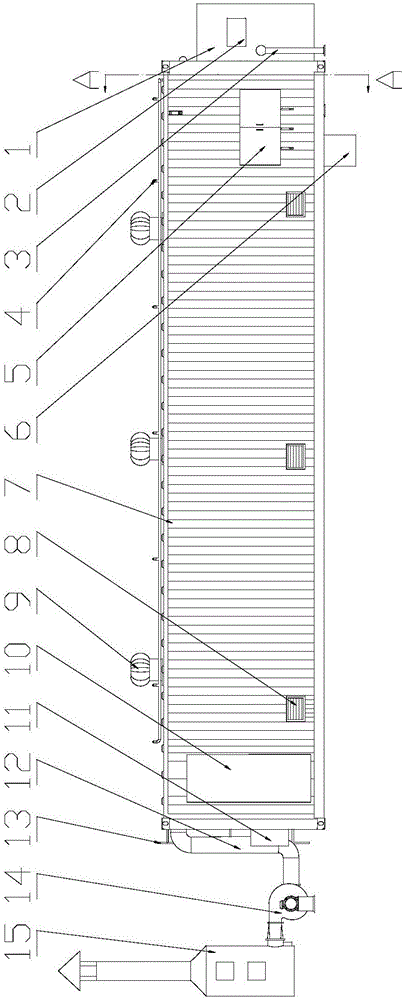

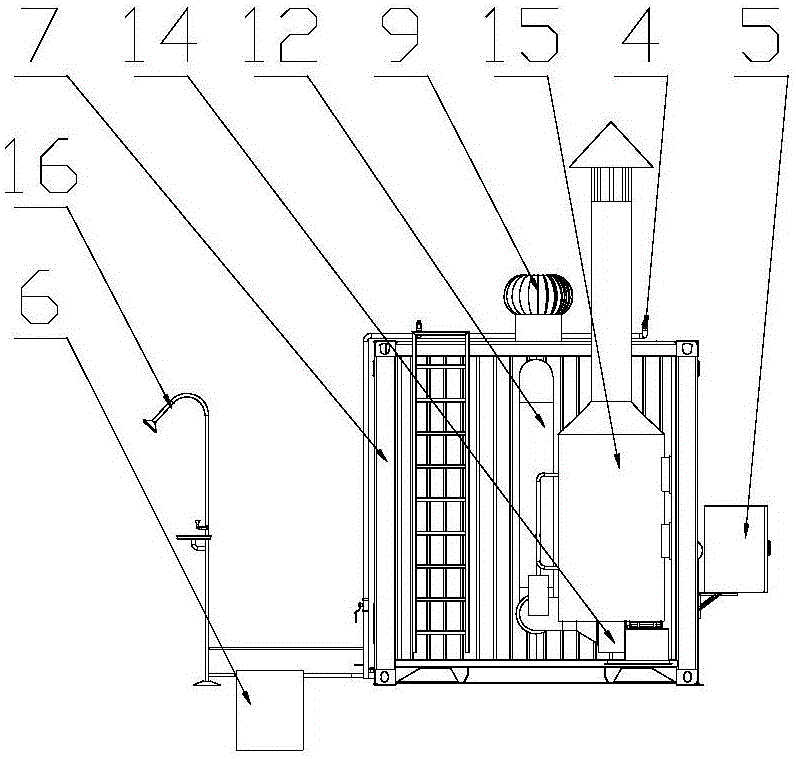

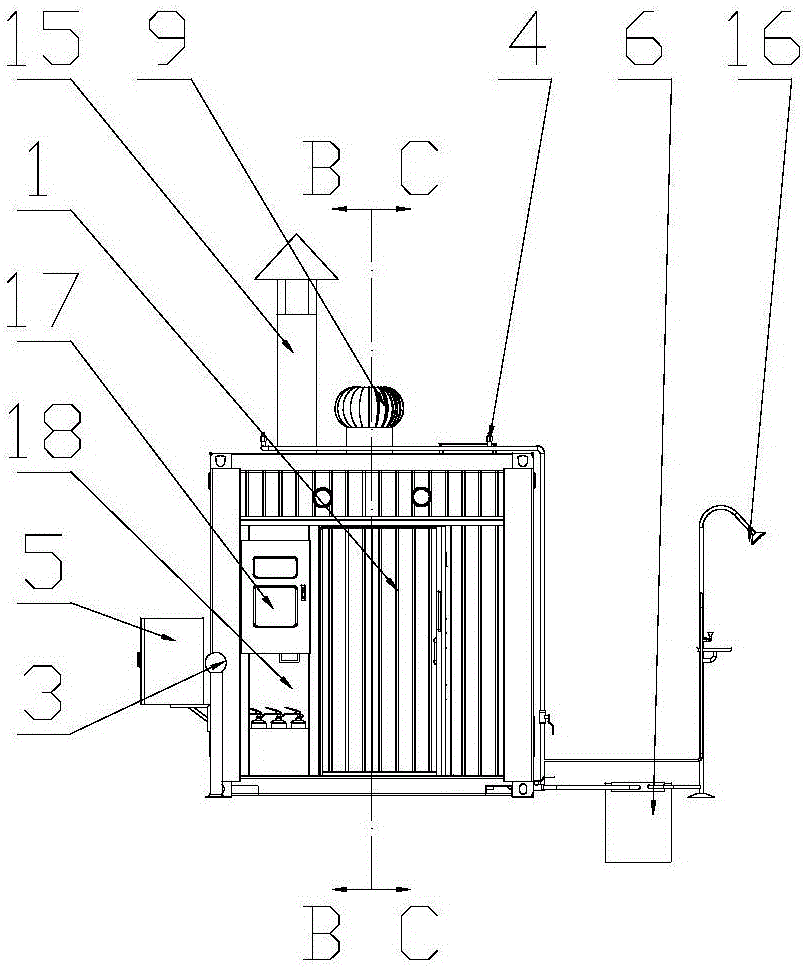

Movable type laboratory waste transit system

ActiveCN105836352AMeet security requirementsMeet environmental protection requirementsDirt cleaningRefuse transferringTemperature controlTransit system

The invention discloses a movable type laboratory waste transit system and relates to the technical field of laboratory waste treatment equipment. The movable type laboratory waste transit system consists of a box body 7, an exhaust fan, a refrigerating plant, a sprinkling cooling device, a personal washing device 16 and a protective article cabinet 5. The movable type laboratory waste transit system is characterized by being fireproof, explosion-proof, leakage-proof and anti-static, being low in noise and the like, can realize all-weather intelligent exhaust purification and temperature control, can meet the transit and storage safety and environment-friendliness requirements of laboratory wastes, has the characteristics of safe use and the like, and can be used for temporarily storing various wastes produced in laboratories.

Owner:长沙永乐康仪器设备有限公司

Non-chlorine shrink-proof method of wool fabric

InactiveCN105421028AWith anti-shrink effectImprove environmental protection requirementsShrinking resistant fibresAnimal fibresEnvironmental resistanceEngineering

The invention relates to a non-chlorine shrink-proof method of wool fabric. The non-chlorine shrink-proof method comprises an oxidation process and a reduction process, wherein the oxidation process is proceeded in a solution which contains a non-chlorine oxidizing agent; the reduction process is proceeded in a solution which contains a reducing agent. According to the non-chlorine shrink-proof method of the wool fabric, disclosed by the invention, the fabric obtained through the non-chlorine shrink-proof method is environmental-friendly and is easy to care, and the wool shrinkage of the processed wool fabric can be controlled within 8 percent.

Owner:SHANGHAI CHALLENGE TEXTILE

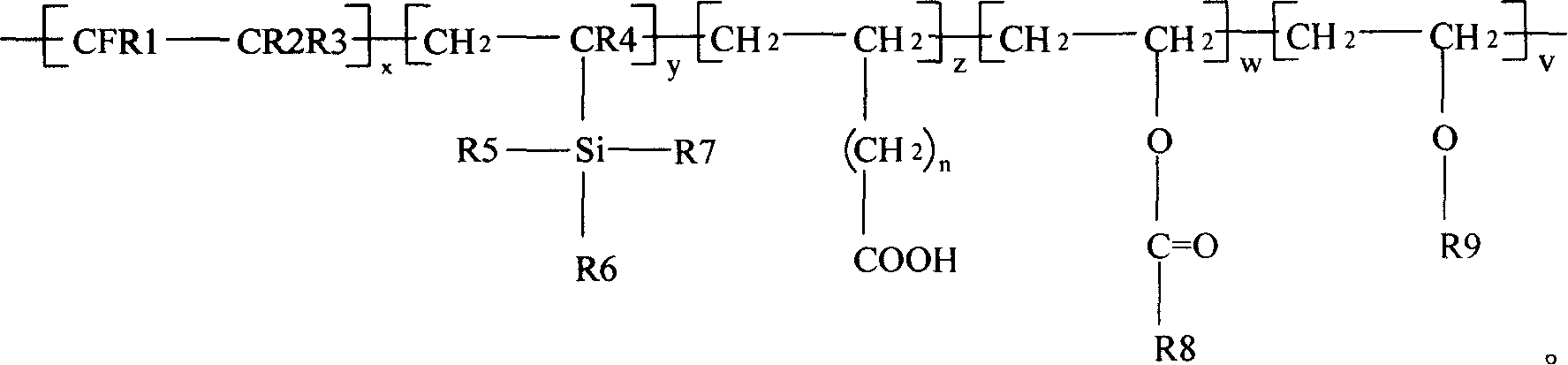

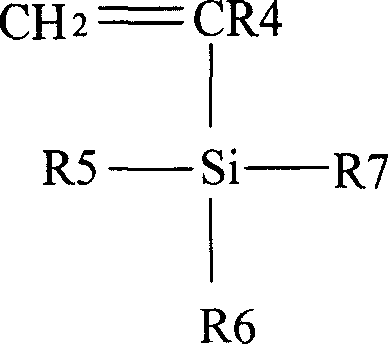

Multipolymer resin water dispersoid containing fluorine and silicon

The invention relates to a multicomponent copolymer resin aqueous dispersion containing fluorin and silicon, which is characterized in that copolymer resin that is polymerized from free radicals of polymer monomer material in solvent and cosolvent can emulsify and disperse naturally in water to form aqueous dispersion without being added with emulgator. The polymer monomer material of the multicomponent copolymer comprises 15-30 mass percent of liquefied olefin containing fluorin, 2-7 mass percent of organosilane containing duplet bond and oxygen atom, 15-25 mass percent of aliphatic carboxylic acid with duplet bond, mixture of aliphatic carboxylic acid esters with duplet bond and alkyl vinyl ether, 1-3 mass percent of cosolvent and 40-65 mass percent of water. The aqueous dispersion prepared by the invention can be taken as base stock of onecomponent coating and also can be made into base stock of two-component coating after being solidified with hydrophilic isocyanate. The coating prepared by adopting the invention has the advantages of photoaging resistance, low surface energy, film forming ability, etc. and can be used in field of external wall coating of building that requires high weatherability.

Owner:BEIHANG UNIV

Multi-enzyme bacterial manure for tea forest, and preparation method thereof

InactiveCN103553809AImprove resistance to pests and diseasesEliminate useFertilizer mixturesBacillus licheniformisActive enzyme

The invention discloses multi-enzyme bacterial manure for a tea forest, and a preparation method thereof. The technical scheme is as follows: the bacterial manure comprises 30% of organic humic acid, 25% of turf, 10% of vegetable protein, 10% of plant active enzyme, 5% of syrup, 5% of saccharomycetes, 5% of marmalade, 3% of trichoderma sp, 4% of bacillus subtilis and 3% of bacillus licheniformis. The formula has activated soil, the plant active enzyme for increasing the fertility, and a plurality of probiotics, so that the tea tree blossoms, and the yield is improved. The formula also has the components for resisting diseases and harmful bacteria, so that the capability of the tea tree for resisting plant diseases and insect pests is improved; use of a pesticide is removed. Therefore, the produced tree does not generate the problem of pesticide residue.

Owner:河南丰沃生物科技有限公司

Method and device for plasma integrated desulfurization, denitrification and dust removal

ActiveCN103566722BIncrease the number ofReduce electric field strengthDispersed particle separationElectrode constructionsChemical reactionHigh energy

The invention discloses an integrated treatment method capable of desulfurizing, denitrating and dust-removing at the same time, and provides a device which adopts the treatment method. Smoke formed after the combustion in a boiler contains the main ingredients of SO2, NOX and dust, and passes through a plasma generation electrode; generated plasmas contain a large amount of high-energy electronics and act on O2 and H2O to generate a large quantity of active particles, such as H, O, OH and O3. The SO2 and the NOX can perform chemical reaction to generate high-valence state sulfur oxides and nitrogen oxides under the effect of the active particles, and then the sulfur oxides and the nitrogen oxides are combined with introduced ammonia gas to generate ammonium salts; the ammonium salts are recovered and serve as secondary products; and therefore, the desulfurizing and the denitrating are realized. In the process, charged particles in the plasmas can electrify dust particles, so that the charged particles can move directionally under the effect of an additional direct-current bias electric field; and therefore, the function of removing the dust is realized. According to the method and the device, the static electricity dust removal and the plasma desulfurizing and denitrating are integrated, so that the number of power supplies is reduced, the efficiency of a discharge power supply is improved, the energy consumption can be reduced, the investment is saved, the occupied area is reduced, and the cost is reduced.

Owner:BEIJING RUIYUDA TECH

Composite additive for industrial gear oil

InactiveCN103725367ASimple preparation protocolImprove thermal stabilityAdditivesHigh resistanceEnvironmental resistance

The invention relates to a composite additive for industrial gear oil. The composite additive for industrial gear oil is basically characterized by comprising, by weight, 9-11% of an antioxidant; 8-10% of an antiwear agent; 10-12% of an anti-extreme pressure agent; 9-11% of a demulsifying agent; 10-12% of a foam inhibitor; 4-6% of a pour-point depressant; 4-6% of a tackifier; 3-4% of nanoscale copper oxide powder; 4-5% of nanoscale magnesium powder; and the balance base oil. The antioxidant is sterically hindered phenol; the antiwear agent is dialkyl dithiophosphate; the anti-extreme pressure agent is chlorinated paraffin; the demulsifying agent is polyalkoxyl polyol; the foam inhibitor is polyacrylic ester; the pour-point depressant is polyalkyl methacrylate; and the tackifier is polyisobutylene. Being economical and practical, the composite additive for industrial gear oil provided by the invention has the advantages of simple preparation scheme, strong thermal stability, good high temperature extrusion performance, strong oxidation resistance and high wear resistance, can prolong the demulsibility life, and can enhance the anti-foaming performance, and is superior to similar products in terms of comprehensive performance. The waste oil is degradable, thus improving the environmental protection requirements.

Owner:TIANJIN ZEYA TECH

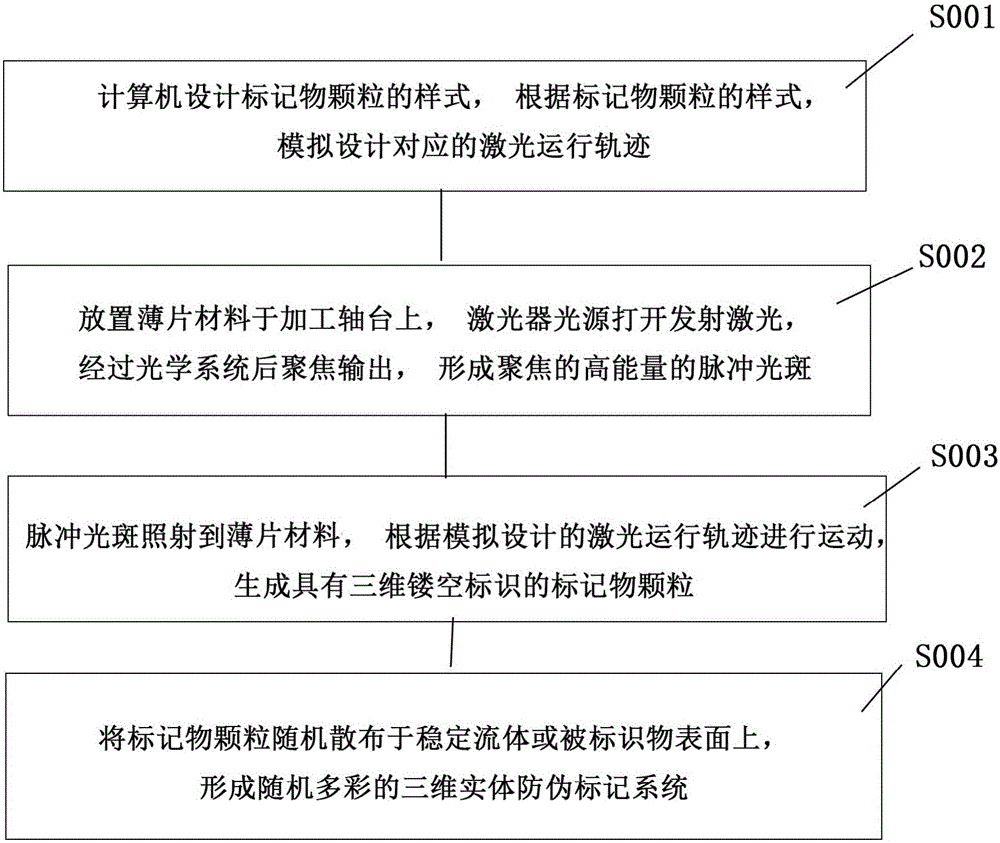

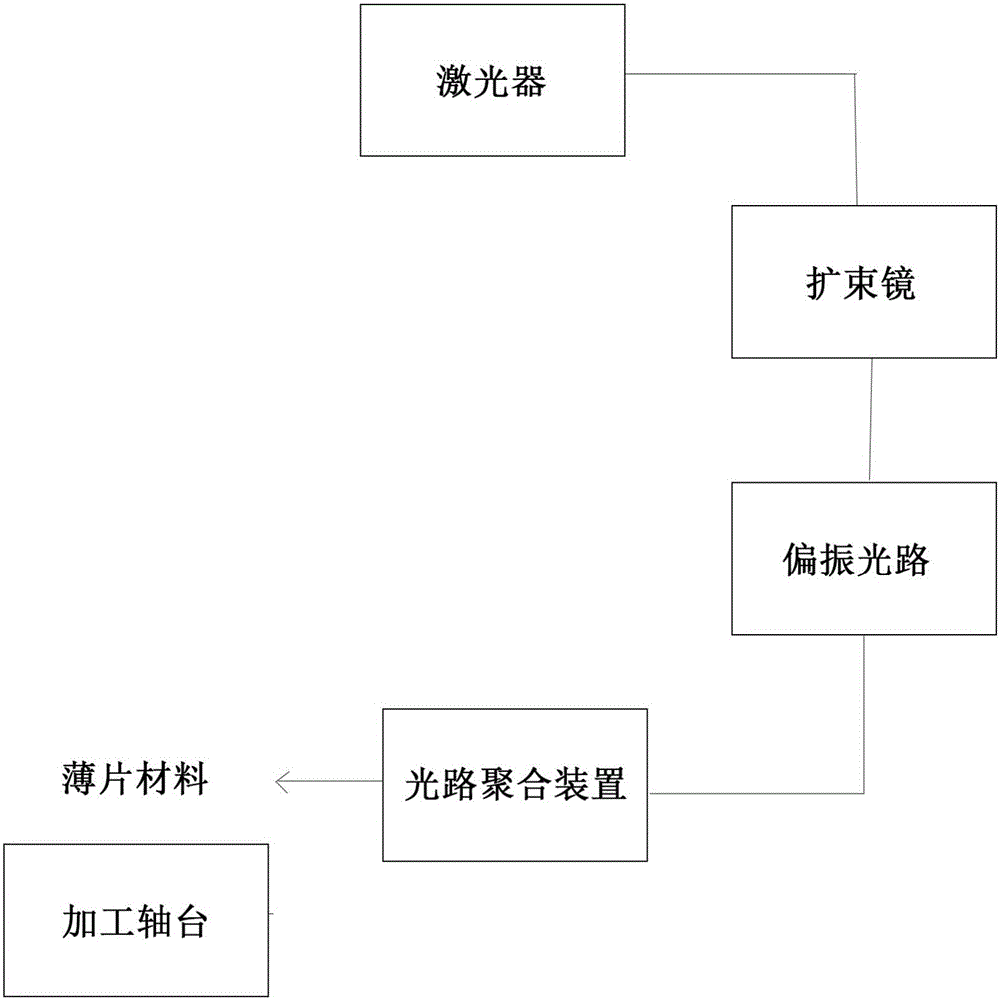

Random colorful three-dimensional entity false proof mark and manufacturing device and method

The invention discloses a random colorful three-dimensional entity false proof mark and a manufacturing device and method. The pattern of marker particles and a laser moving trajectory are designed through a computer, a sheet is placed on a machining shaft table, focused high-energy pulse spots irradiate the sheet, the marker particles with three-dimensional hollowed-out markers are generated, the marker particles are scattered on transparent colloid or the surface of a marked object randomly, and the random colorful three-dimensional entity false proof mark is formed. By means of the random colorful three-dimensional entity false proof mark and the manufacturing device and method, the cost of raw materials is lowered, the production processes are reduced, production efficiency is improved, emission of waste water, waste materials and waste liquid is reduced, and environmental friendliness is further achieved.

Owner:郑国义

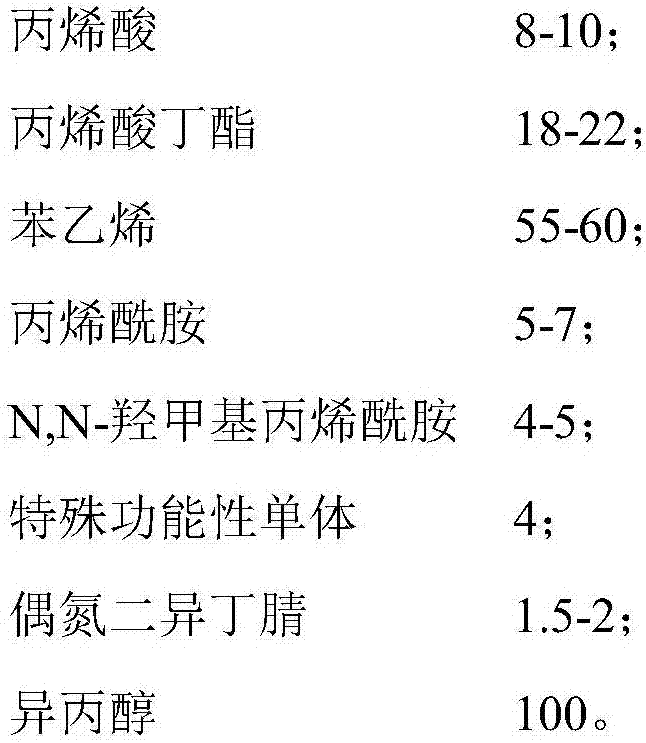

Low-VOC (volatile organic compound) hydroxylated acrylic resin and preparation technology thereof

ActiveCN106084143AImprove environmental protection requirementsFast dryingCoatingsAcrylic resinHigh pressure

The invention discloses low-VOC (volatile organic compound) hydroxylated acrylic resin and a preparation technology thereof. Raw materials of the hydroxylated acrylic resin comprise a component A, a component B, a component C and a component D in parts by weight, wherein the component A comprises 7-12 parts of xylene, 3-6 parts of butyl acetate and 20-30 parts of polyester resin; the component B comprises 0-1.5 parts of acrylic acid, 0-1.5 parts of methacrylic acid, 8-22 parts of butyl acrylate, 2-4 parts of 2-hydroxyethyl methacrylate, 20-40 parts of styrene, 2-5 parts of isobornyl acrylate, 0-0.8 parts of di-tert-amyl peroxide, 0-2.0 parts of tert-butyl peroxide and 0-0.6 parts of dicumyl peroxide; each of the component C and the component D comprises 0.5-1 part of butyl acetate and 0.1-0.3 parts of tert-butyl peroxide. A product is prepared with a high pressure method. The hydroxylated acrylic resin has higher drying speed and lower VOC, the preparation technology is simple, the production cost is lower, and the application is convenient.

Owner:WEIFANG FULE NEW MATERIAL CO LTD

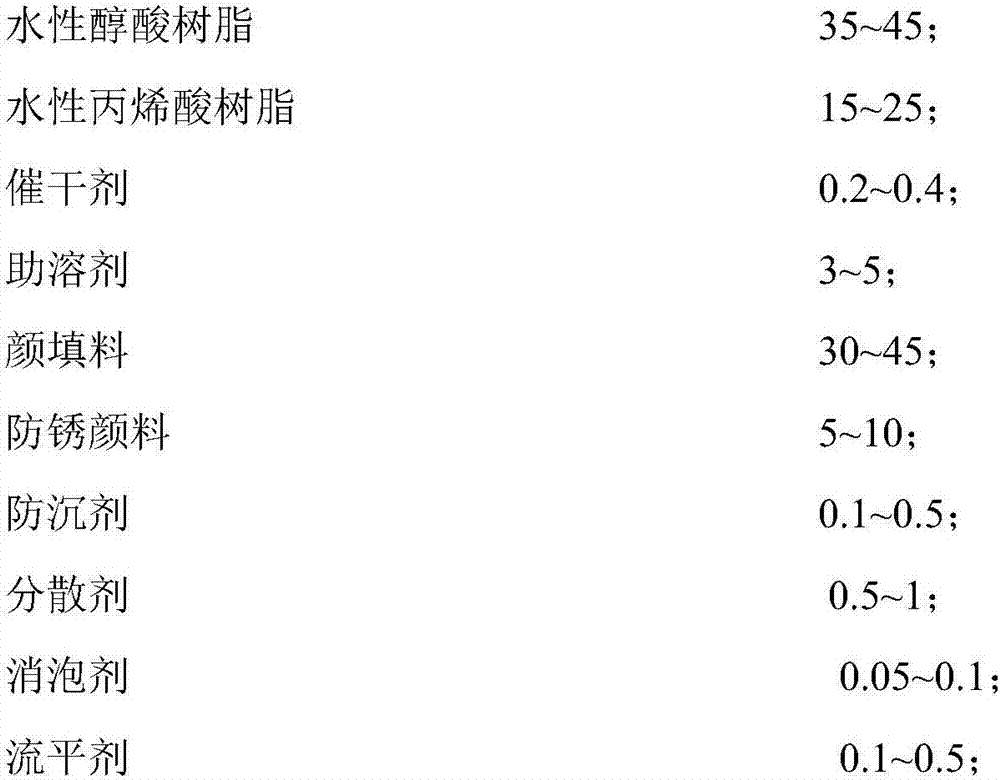

Modified industrial anti-corrosion aqueous alkyd coating and preparation method of same

InactiveCN107286822AHigh solid contentLow Volatile Organic Compounds (VOC)Anti-corrosive paintsEmulsion paintsEpoxyAcrylic resin

The invention provides a modified industrial anti-corrosion aqueous alkyd coating and a preparation method of same. The alkyd coating includes, by weight, 35-45 parts of aqueous alkyd resin, 15-25 parts of aqueous acrylic resin, 0.2-0.4 parts of a drier, 3-5 parts of a cosolvent, 30-45 parts of pigment filler, 5-10 parts of an antirust pigment, 0.1-0.5 parts of an anti-settling agent, 0.5-1 part of a dispersant, 0.05-0.1 parts of a defoamer, 0.1-0.5 parts of a flatting agent, 0.3-1 part of an anti-flash-rust agent and 15-20 parts of water. The modified industrial anti-corrosion aqueous alkyd coating is high in solid content and low in volatile organic compounds (VOCs), is low in environment pollution, has good adhesion force, is excellent in recoatability, and has good chemical product resistance, water resistance and salt fog resistance. In the invention, through specially designed epoxy-ester resin and selection of the weather resistant pigment and antirust pigment, a paint film, formed by the coating, has excellent comprehensive performances, such as fullness, adhesion force, salt fog resistance and chemical product resistance; especially, the salt fog resistance of the coating is greatly higher than that of epoxy-ester resin in the prior art.

Owner:杭州鼎时新材料研究院有限公司

Metal ceramic lubricating oil couplant

The invention relates to a metal ceramic lubricating oil couplant, which is composed of: 2-16% of metal ceramic; 1-9% of shielding phenol; 1-8% of diphenylamine; 2-9% of ethoxyphenol; 2-12% of benzotriazole; 1-11% of polymethacrylate; 2-12% of phosphorodithioate; 1-11% of polyalkoxyphenol; 1-12% of polyisobutylene succinate; 1-11% of sulfurized isobutylene; and the balance base oil. The invention adopts the boride base metal ceramic, which has high hardness and melting point, low density and is resistant to corrosion, abrasion and extreme pressure. Thus, the prepared product has strong thermal stability, good high temperature extreme pressure performance, strong oxidation resistance, high wear resistance, and strong demulsification ability.

Owner:杨伟光 +2

Volume type continuously burning type engine

InactiveCN1948730AImprove utilization efficiencyChange dependenciesGas turbine plantsJet propulsion plantsCombustion chamberCompression device

This invention provides a kind of capacity sustained combustion engine, including control systems, lubrication system, its features are : its compression device is sliding-vane compression device , the combustion chamber is an independent sustained combustion chamber, apply work installation is a tangential all multi-level expansion impeller type apply work installation, it also has a exhaust gas heat exchange devices which can preheat the air, This engine's structure is simple and it cost less material, the product cost is low, the rate of energy utilization is high, it can use ethanol, hydrogen, natural gas, methane, dry ice, etc. as fuel, changes the dependence to the petroleum energy; it can achieve zero -idle speed and micro- torque starting, the operation is smooth. It may replace the current engine for automobile in the increasingly shortage situation of the petroleum resources.

Owner:姜志凌

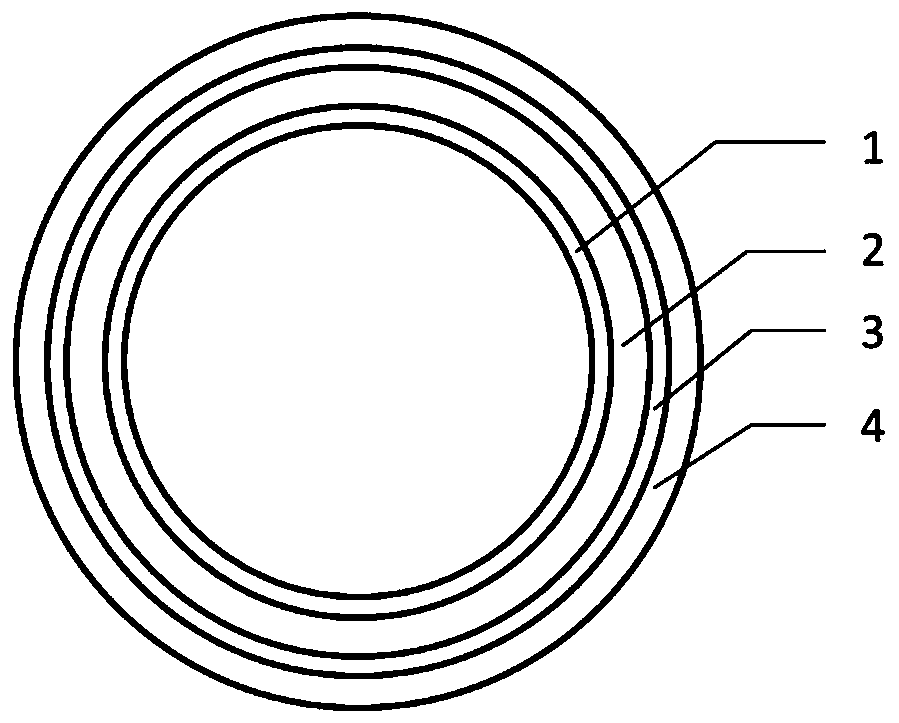

Pipeline suitable for conveying ultralow-temperature medium

PendingCN110513544AMeet craftFulfil requirementsPipeline expansion-compensationThermal insulationInsulation layerInsulation system

The invention discloses a pipeline suitable for conveying an ultralow-temperature medium. The pipeline comprises a pipeline body and a functional layer arranged on the outer surface of the pipeline body; the functional layer is sequentially provided with a heat-insulation system layer and an anti-collision protection outer layer from inside to outside; the heat-insulation system layer comprises acold-insulation material layer and / or a vacuum cold-insulation layer; the cold-insulation material layer is realized in the mode that the pipeline body is directly wrapped with a cold-insulation material; the vacuum cold-insulation layer comprises an inner-wall sleeve and an outer-wall sleeve, two layers of sleeve pipelines are connected through a support, and a vacuum is formed between the two layers of sleeve pipelines; and a concrete sleeve serves as the anti-collision protection outer layer. According to the pipeline, the pipeline body is paved with expansion joints and the cold-insulationto meet process and soil environment requirements, the pressure bearing capacity of the pipeline meets the road requirement, a comprehensive scheme meets the relevant requirements of the burying environment, and the problem that chemical raw materials at the ultralow temperature (minus 162 DEG C) cannot be conveyed in a buried mode can be solved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Cantilever type high rate turbine vacuum pump and its evacuation method

InactiveCN100478571CImprove environmental protection requirementsPump componentsPump installationsChemical industryVacuum pumping

The invention discloses a cantilever-type high-speed vacuum turbine pump and the vacuum pumping method. A high-speed eccentric impeller of 10000 revolutions per minute to 30000 revolutions per minute is used to realize the pumping of vacuum with minus 30kPa to minus 70kPa. The pump comprises a gear increase box, independent pump heads and a high-speed rotor. A large gear of the gear increase box is connected with a prime motor. Independent pump heads stand separately at both sides or a single side of the gear increase box. The pump heads adopt a split structure and comprise a suction inlet, an internal volute body, an impeller stopping cover, a volute shell and an air seal. The high-speed rotor comprises a high-speed gear shaft, a thrust collar, an impeller, and a fastening bolt, and is supported by a sliding bearing on the gear increase box. An impeller cantilever is arranged on the tail end of the high-speed gear shaft. The invention uses a high-speed turbine to realize the rapid vacuum pumping with a large flow. Moreover, a multi-pump head structure can make a single pump realize the multi-position, multi-vacuum degree and simultaneous pumping in the fields of paper making, chlor-alkali chemical industry, and so on and greatly reduce the vacuum system energy consumption. Meanwhile, the pump is provided with the advantage that the pump is concise in the structure, highly reliable, widely applicable, and environment-friendly, and does not need a liquid working ring, and so on.

Owner:ZHEJIANG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com