ZnIn2S4 photocatalyst obtained by hydrothermal synthesis of ionic liquid microemulsion and preparation method of ZnIn2S4 photocatalyst

An ionic liquid, photocatalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, inorganic chemistry, etc., can solve the problems of large specific surface area, high catalytic activity, low catalytic activity, etc., to achieve high catalytic efficiency, preparation Simple method, convenient operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

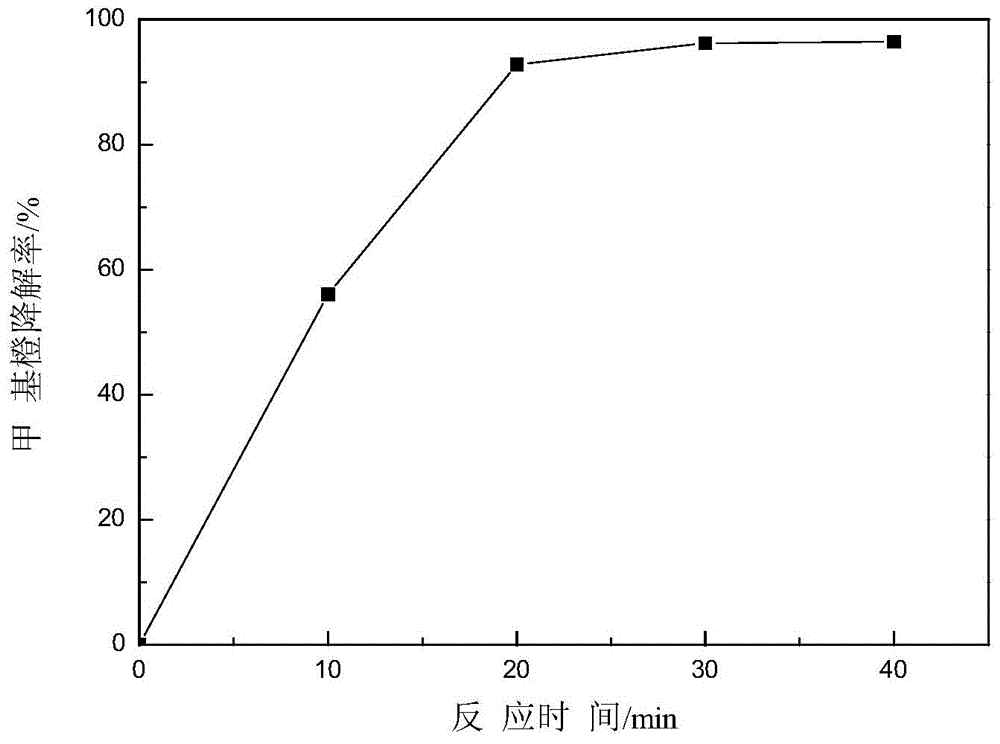

Examples

Embodiment 1

[0038] 1) Weigh raw materials according to the following weight percentages: zinc chloride 1%, indium nitrate 4.41%, thioacetamide 4.41%, surfactant octylphenyl polyoxyethylene ether 27%, ionic liquid 1-butyl-3 - Methylimidazolium hexafluorophosphate 8%, deionized water 55.18%.

[0039] 2) At 20°C, add thioacetamide to a mixture of ionic liquid 1-butyl-3-methylimidazolium hexafluorophosphate and surfactant octylphenylpolyoxyethylene ether and mix evenly to The stirring speed was 300 rpm, and the mixture was stirred for 5 minutes to obtain a clear and transparent mixture solution A.

[0040] 3) Under the condition of 20°C, fully dissolve zinc chloride and indium nitrate in deionized water, and stir at a stirring speed of 300 rpm for 5 minutes to obtain a clear and transparent mixture solution B.

[0041] 4) Transfer and mix solution A and solution B in a polytetrafluoroethylene-lined autoclave with a magnetic speed of 300 rpm and stir for 5 minutes to form a stable and uniform...

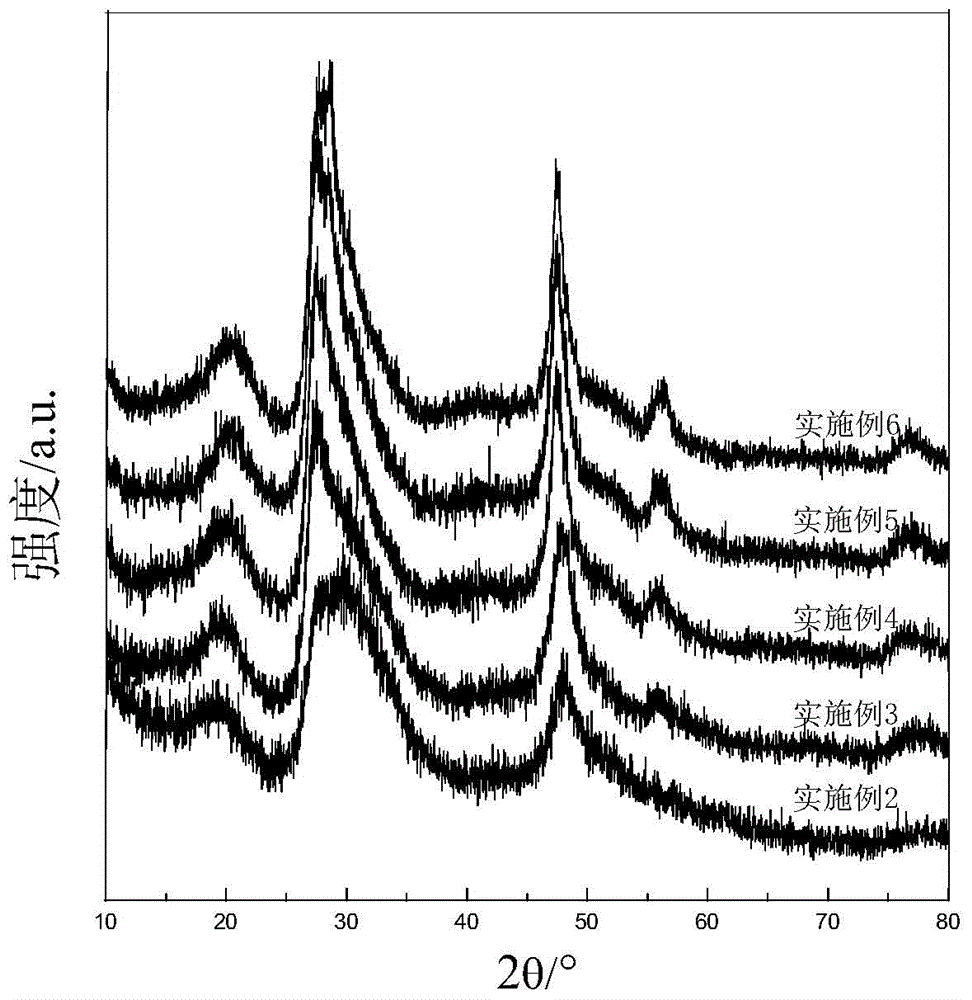

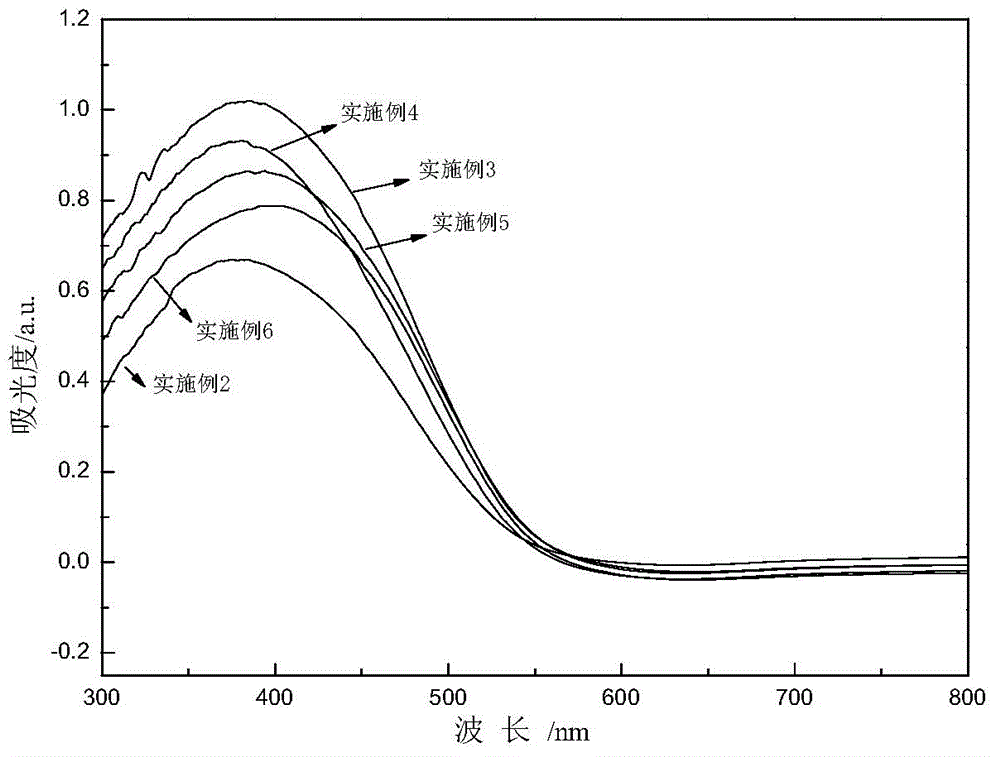

Embodiment 2

[0046] 1) Weigh raw materials according to the following weight percentages: zinc sulfide 0.01%, indium acetate 0.06%, thioacetamide 0.062%, surfactant cetyltrimethylammonium bromide 7.788%, ionic liquid 1-butyl- 3-methylimidazolium tetrafluoroborate 2%, deionized water 90%.

[0047] 2) Add thioacetamide to a mixture of ionic liquid 1-butyl-3-methylimidazolium tetrafluoroborate and surfactant cetyltrimethylammonium bromide at 50°C Evenly, stir at a stirring speed of 800 rpm for 15 minutes to obtain a clear and transparent mixture solution A.

[0048] 3) Under the condition of 50°C, fully dissolve zinc sulfide and indium acetate in deionized water, and stir at a stirring speed of 800 rpm for 15 minutes to obtain a clear and transparent mixture solution B.

[0049] 4) Transfer and mix solution A and solution B into a polytetrafluoroethylene-lined autoclave with a magnetic speed of 1200 rpm and stir for 10 minutes to form a stable and uniform microemulsion system.

[0050] 5) S...

Embodiment 3

[0054] 1) Weigh raw materials according to the following weight percentages: zinc nitrate 0.495%, indium chloride 0.736%, thioacetamide 1.0%, surfactant bis(2-ethylhexyl) succinate sodium sulfonate 31.3%, ionic liquid 1-butyl-3-methylimidazolium bromide 5.87%, deionized water 60.599%.

[0055] 2) Add thioacetamide to ionic liquid 1-butyl-3-methylimidazolium bromide and surfactant bis(2-ethylhexyl) sodium sulfosuccinate (AOT) at 60°C Mix evenly in the mixture, and stir at a stirring speed of 800 rpm for 15 minutes to obtain a clear and transparent mixture solution A.

[0056] 3) Under the condition of 60°C, fully dissolve zinc nitrate and indium chloride in deionized water, and stir at a stirring speed of 800 rpm for 15 minutes to obtain a clear and transparent mixture solution B.

[0057] 4) Transfer and mix solution A and solution B in a polytetrafluoroethylene-lined autoclave with a magnetic speed of 1200 rpm and stir for 15 minutes to form a stable and uniform microemulsio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com