Ordered zirconia-alumina mesoporous material and its preparation method

A technology of mesoporous materials, alumina, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of low specific surface area and pore volume, and achieve high reproducibility and no environment. Contamination, the effect of simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

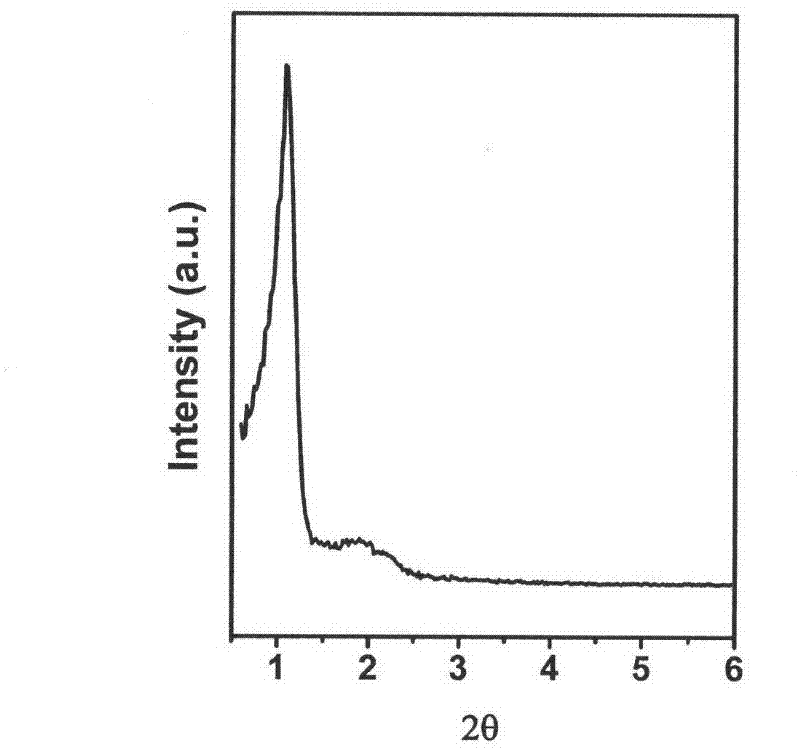

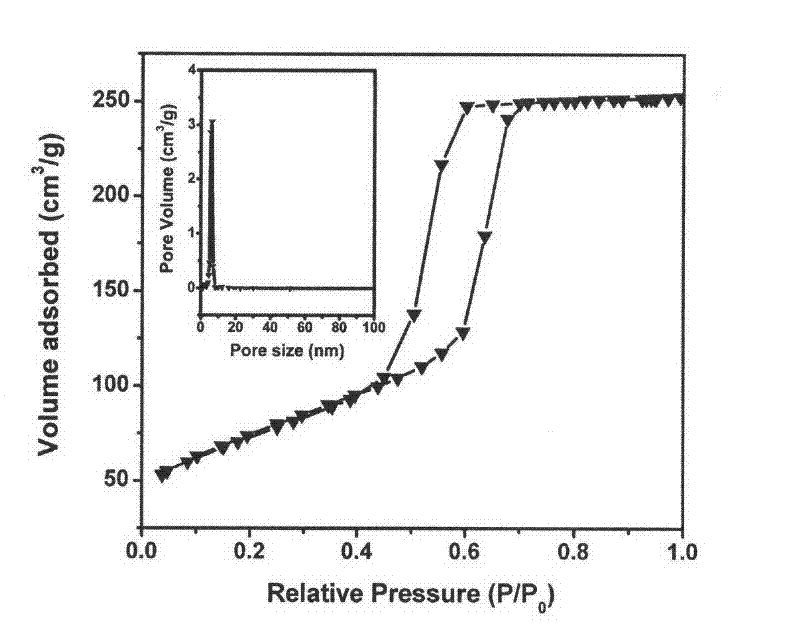

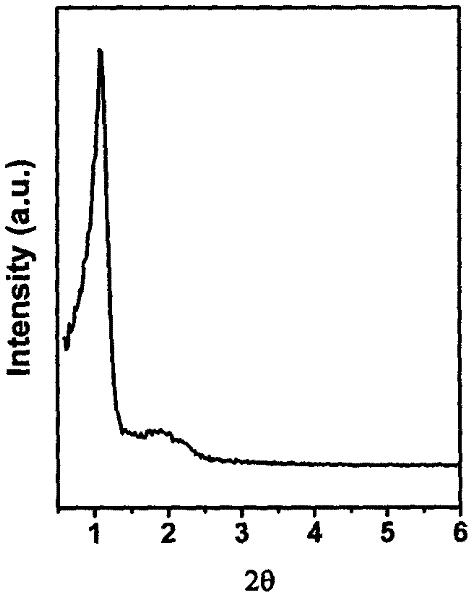

[0023] 3.2g EO 106 PO 70 EO 106 and 0.4g of citric acid were added to 20mL of ethanol solution containing 2.0g of 12M hydrochloric acid, stirred at room temperature to completely dissolve the surfactant, and 0.016mol of aluminum isopropoxide and 0.004mol of zirconium oxychloride were added to the system at the same time, at 30 After stirring at °C for 24 hours, the reaction mixture was poured into a Petri dish and treated at 45°C for 48 hours. Finally, the samples were heat-treated at 100°C for 24 hours and fired at 550°C for 5 hours. get ZrO 2 -Al 2 o 3 Mesoporous materials. Nitrogen adsorption results show that the mesopore diameter is 5.5nm and the specific surface area is 265m 2 / g, the pore volume is 0.39cm 3 / g. Calcined at 650°C for 5 hours, the structure and properties did not change.

Embodiment approach 2

[0025] 3.2g EO 106 PO 70 EO 106 and 0.4g of citric acid were added to 20mL of ethanol solution containing 2.0g of 12M hydrochloric acid, stirred at room temperature to completely dissolve the surfactant, and 0.012mol of aluminum isopropoxide and 0.009mol of zirconium oxychloride were added to the system at the same time, at 30 After stirring at °C for 24 hours, the reaction mixture was poured into a Petri dish and treated at 45°C for 48 hours. Finally, the samples were heat-treated at 100°C for 24 hours and fired at 550°C for 5 hours. get ZrO 2 -Al 2 o 3 Mesoporous materials. Nitrogen adsorption results show that the mesopore diameter is 6.2nm and the specific surface area is 238m 2 / g, the pore volume is 0.32cm 3 / g. Calcined at 650°C for 5 hours, the structure and properties did not change.

Embodiment approach 3

[0027] 3.2g EO 106 PO 70 EO 106and 0.4g of citric acid were added to 20mL of ethanol solution containing 2.0g of 12M hydrochloric acid, stirred at room temperature to completely dissolve the surfactant, and 0.008mol of aluminum isopropoxide and 0.012mol of zirconium oxychloride were added to the system at the same time, at 30 After stirring at °C for 24 hours, the reaction mixture was poured into a Petri dish and treated at 45°C for 48 hours. Finally, the samples were heat-treated at 100°C for 24 hours and fired at 550°C for 5 hours. get ZrO 2 -Al 2 o 3 Mesoporous materials. Nitrogen adsorption results show that the mesopore diameter is 6.5nm and the specific surface area is 214m 2 / g, the pore volume is 0.31cm 3 / g. Calcined at 650°C for 5 hours, the structure and properties did not change.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesopore diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Mesopore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com