Preparation method of low-sodium active aluminum oxide

A technology of activated alumina and alumina, applied in chemical instruments and methods, aluminate/alumina/aluminum hydroxide purification, inorganic chemistry, etc., can solve problems such as high cost, high sodium, silicon content, high impurity content, etc. , to achieve the effects of low production cost, porous volume, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

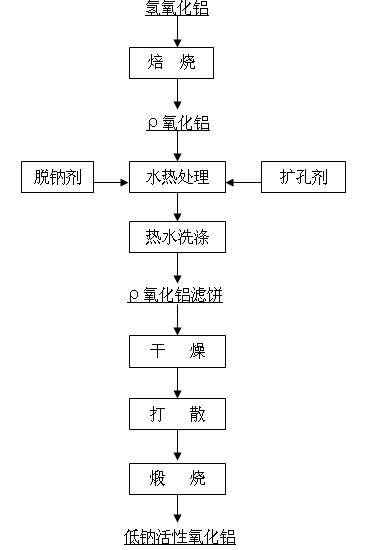

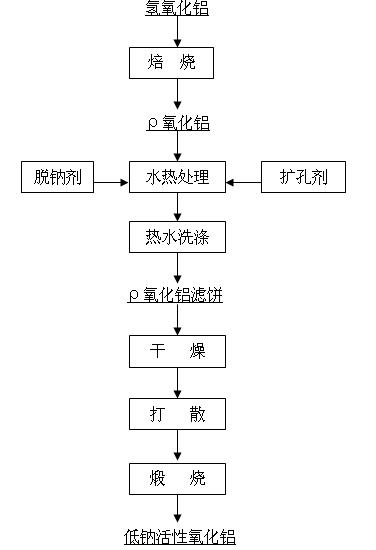

[0016] A method for preparing low-sodium activated alumina, using Na 2 Aluminium hydroxide with an O content of 0.1%-0.5% and a particle size of 50-100μm is calcined at 400-600°C to obtain the intermediate product ρ-alumina, which is formulated into a slurry with a concentration of 100-500 g / l. Perform hydrothermal treatment at 90-200℃ for 0.5-6 hours, add one or two of nitric acid, acetic acid, citric acid, and one or two of polyethylene glycol, polyvinyl alcohol, and methylcellulose A kind of pore expander, the dosage is 0.1-10% and 0.1-40% of the alumina mass. After the hydrothermal reaction, the ρ alumina after the hydrothermal treatment is filtered and washed with hot pure water at 50℃~95℃. Neutral, dry at a temperature of 60°C to 150°C, and the dried powder is mechanically broken up and calcined at 600-800°C for 2-4 hours to obtain activated alumina.

[0017] The steps are:

[0018] a. First adopt Na 2 Aluminium hydroxide with an O content of 0.1%-0.5% and a particle size of...

Embodiment 1

[0022] The present invention uses Na 2 Aluminum hydroxide with an O content of 0.1% and a particle size of 60 μm is calcined at 400°C to obtain an intermediate product of rho alumina, which is formulated into a slurry with a concentration of 100 g / L, and subjected to hydrothermal treatment at 120°C for 4 hours. Among them, nitric acid and polyethylene glycol are added, and the amounts are respectively 0.2% and 0.5% of the alumina mass. After the hydrothermal reaction, the rho alumina after the hydrothermal treatment is filtered and washed with 95 ℃ hot pure water, and washed until it is neutral. Drying at a temperature of 60°C, the dried powder is broken up by a dispersing machine, and calcined at 600°C for 4 hours to obtain activated alumina. Na 2 O content is 0.041%, specific surface area=172m 2 / g, pore volume=0.48ml / g, average particle size (d 50 ): 50μm.

Embodiment 2

[0024] The present invention uses Na 2 Aluminum hydroxide with an O content of 0.2% and a particle size of 40 μm is calcined at 500°C to obtain an intermediate product of rho alumina, which is formulated into a slurry with a concentration of 300 g / l, and subjected to hydrothermal treatment at 90°C for 2 hours. Among them, acetic acid and polyethylene glycol are added, and the dosage is 0.1% of the alumina mass. After the hydrothermal reaction, the rho alumina after the hydrothermal treatment is filtered and washed with hot pure water at 75°C, and washed to neutrality at 80°C. After drying at a lower temperature, the dried powder is broken up by a dispersing machine and calcined at 700°C for 4 hours to obtain activated alumina. Na 2 O content is 0.046%, specific surface area=168m 2 / g, pore volume=0.5ml / g, average particle size (d 50 ): 30μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com