Patents

Literature

107results about How to "High appearance requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

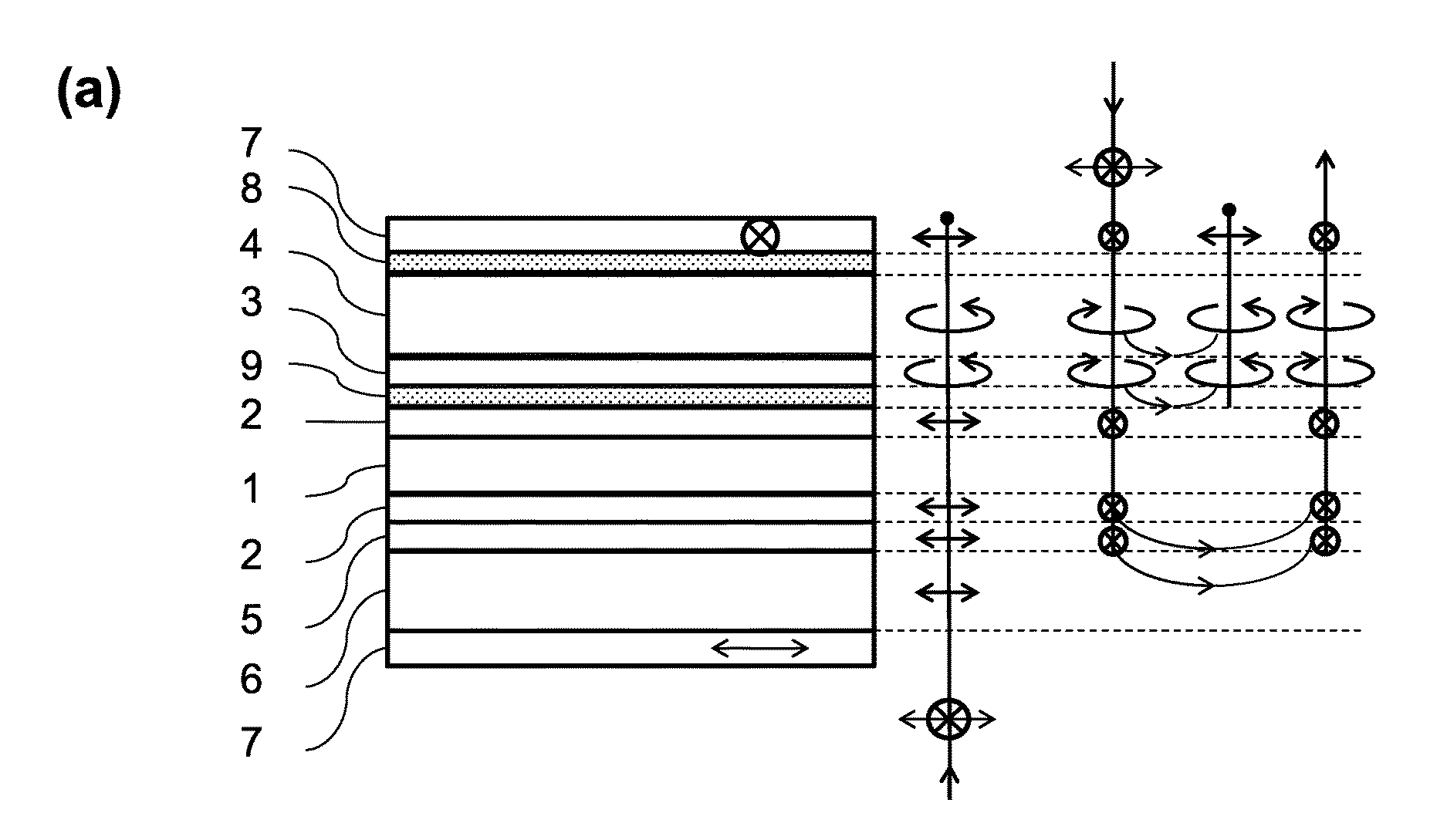

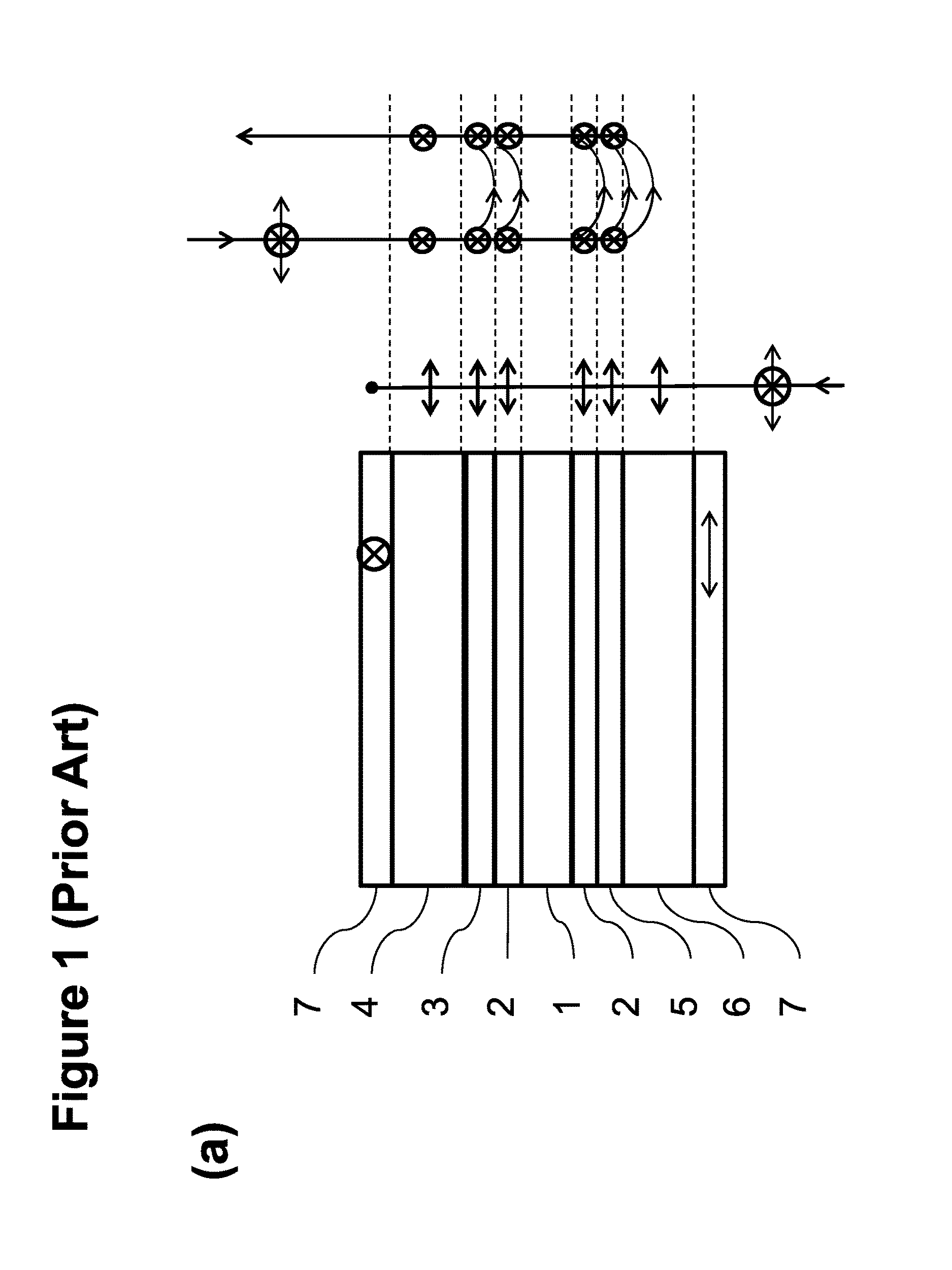

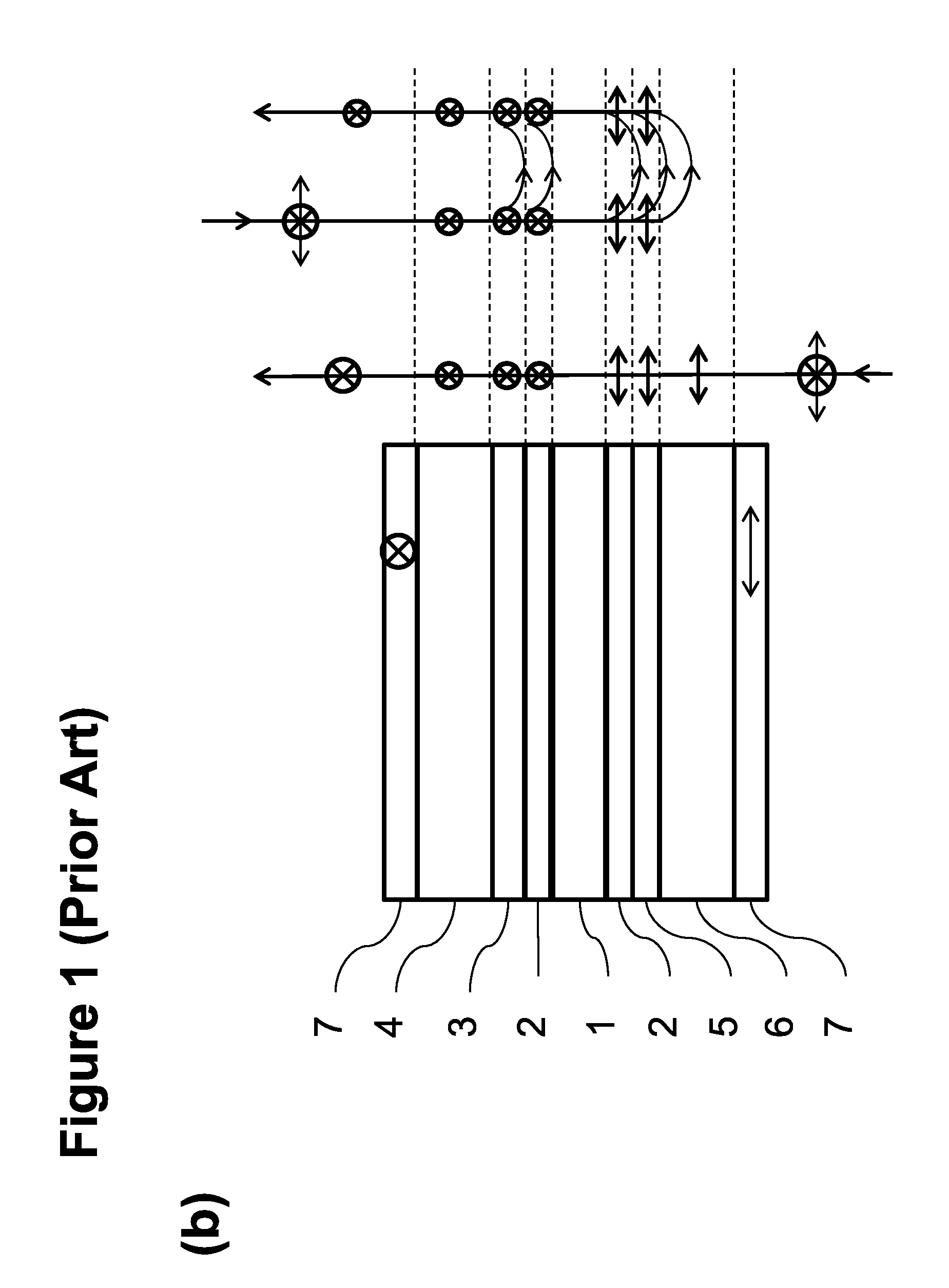

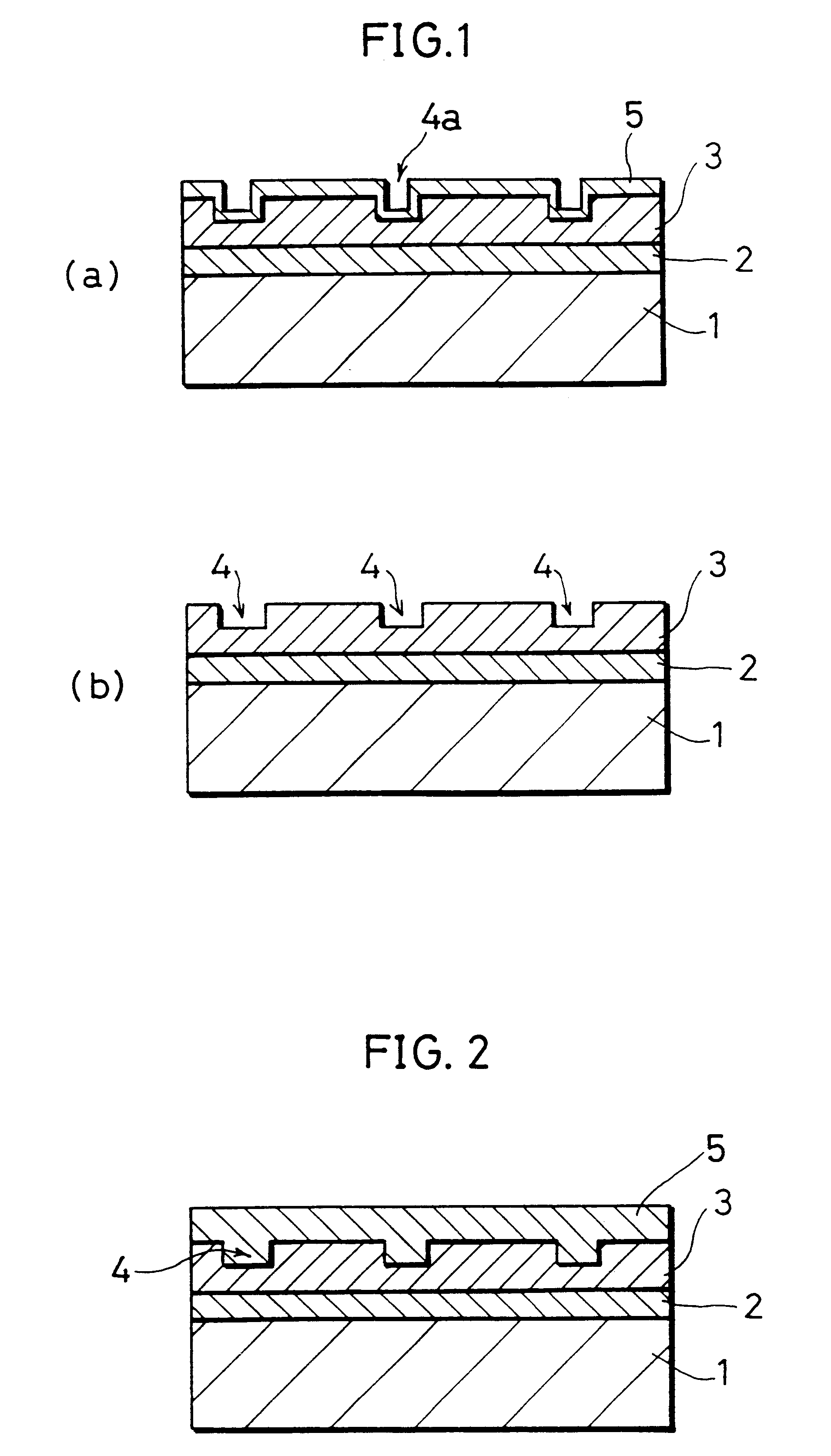

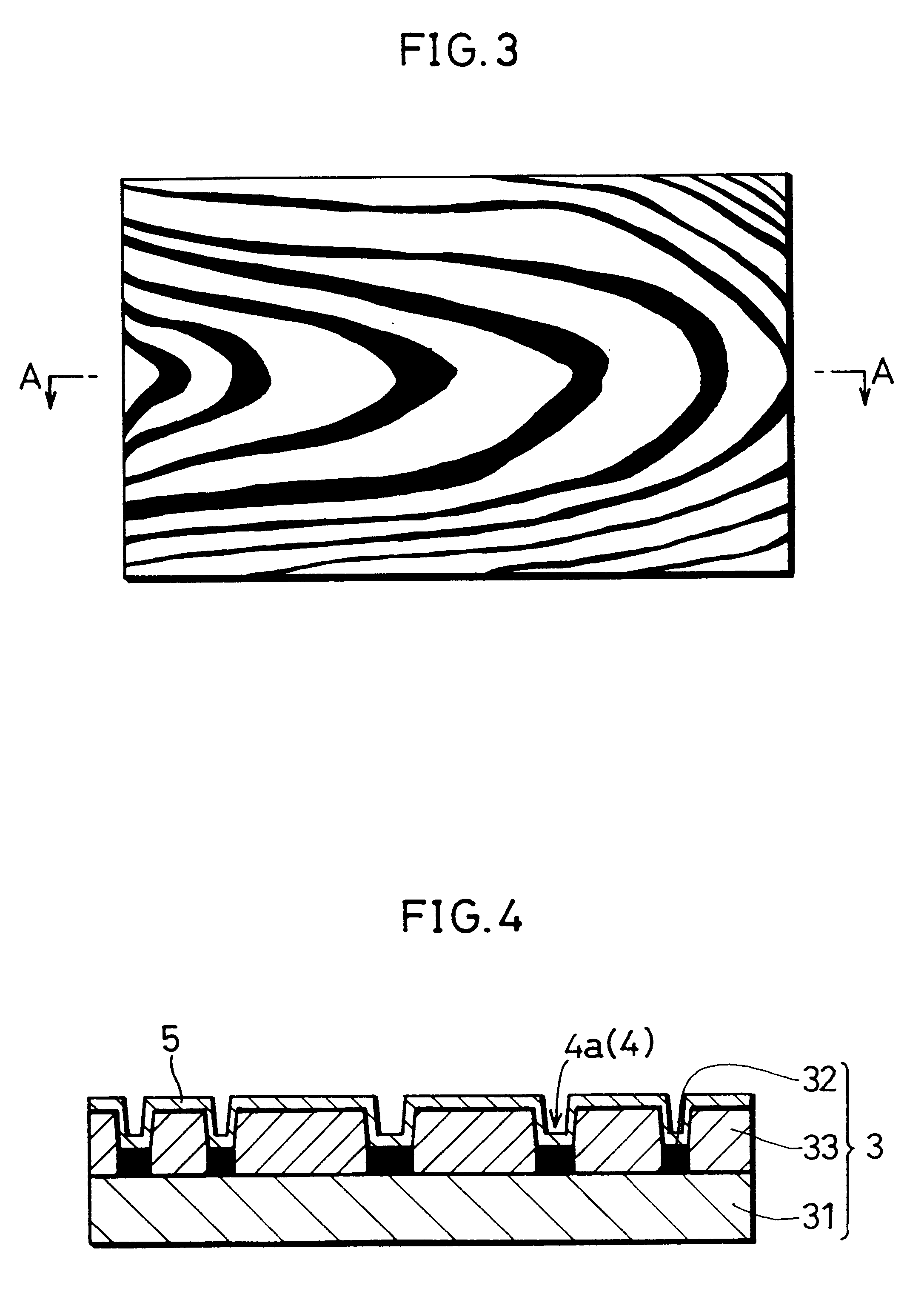

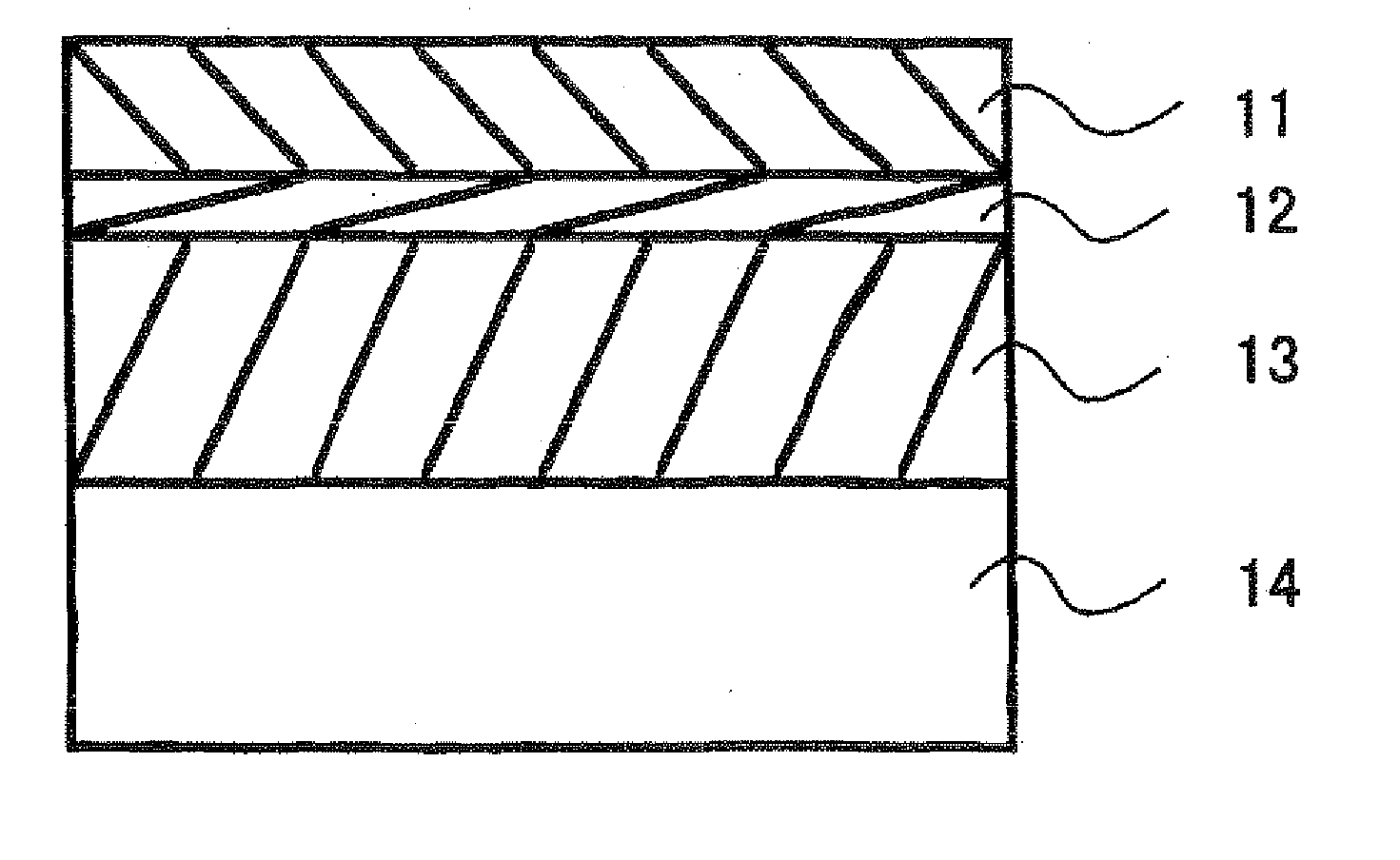

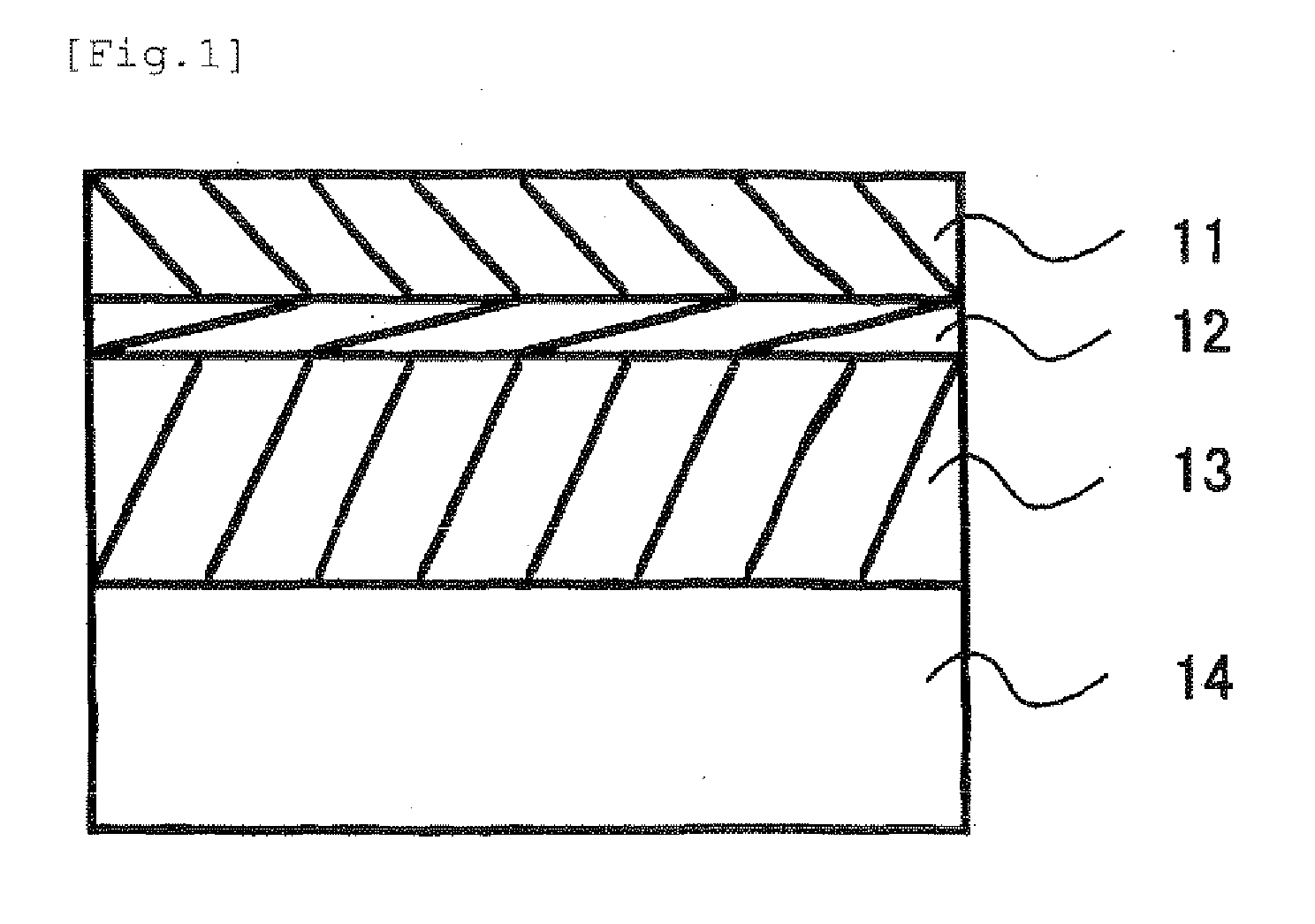

Sunlight readable LCD with uniform in-cell retarder

ActiveUS20170031206A1Improve its high ambient lighting appearanceReduce image qualityNon-linear opticsDisplay deviceLight reflection

A display device in which ambient light reflections, for example, from IPS or FFS type displays are reduced by a circular polariser (e.g., linear polariser combined with external quarter waveplate) to make the light circular polarized, as it traverses the multiple reflective layers between the polariser and LC layer, and then an internal quarter waveplate converts the light back to linear polarisation before it enters the LC, so the display can operate as normal, while the circular polariser absorbs unwanted reflections of ambient light from within the display.

Owner:SHARP KK

Polycarbonate Resin Composition with Improved Scratch Resistance and Melt Flow Index

ActiveUS20100168272A1High fluidityImprove liquidityAntifouling/underwater paintsPaints with biocidesPolycarbonateChemistry

Owner:LOTTE ADVANCED MATERIALS CO LTD

Weather resistant halogen-free flame retardant ABS resin and preparation process thereof

The present invention discloses a weather-proof anti-flaming ABS resinoid. The compositions and the weight percentage thereof are as follows: 45 to 75 percent of ABS resinoid, 5 to 30 percent of polyester, 10 to 20 percent of fire retardant, 1 to 10 percent of plasticizer, 0.3 to 5 percent of photo-thermal stabilizer, 0.2 to 5 percent of nucleating agent, and 1 to 5 percent of processing accessory ingredient. The weather-proof anti-flaming ABS resinoid obtains largely improved fire retardancy and weatherability because polyester components are added, can be applied to the occasions such as electric switches, transformer cases, control panels of various electric appliances, and the like which directly contact light ray, have higher requirement on appearance and environment, can not use PVC alloy, and have strict requirement on the fire retardancy of the material. The resinoid has wide application prospect. In addition, the adopted twin-screw extrusion preparation process has the advantages of simple flow, high production efficiency, stable product quality, low cost, environment protection, easy industrial implementation, and the like.

Owner:SHANGHAI KINGFA SCI & TECH +1

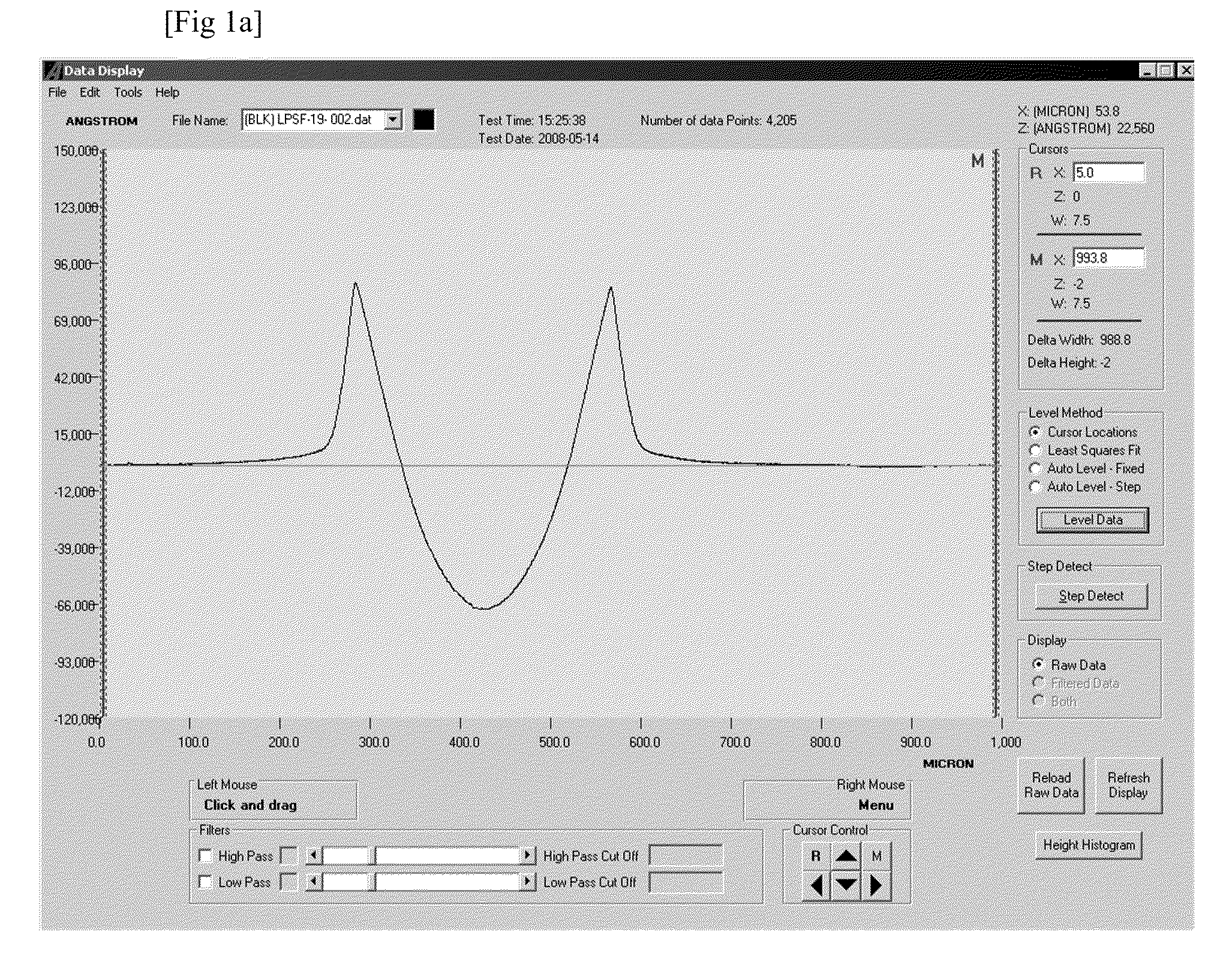

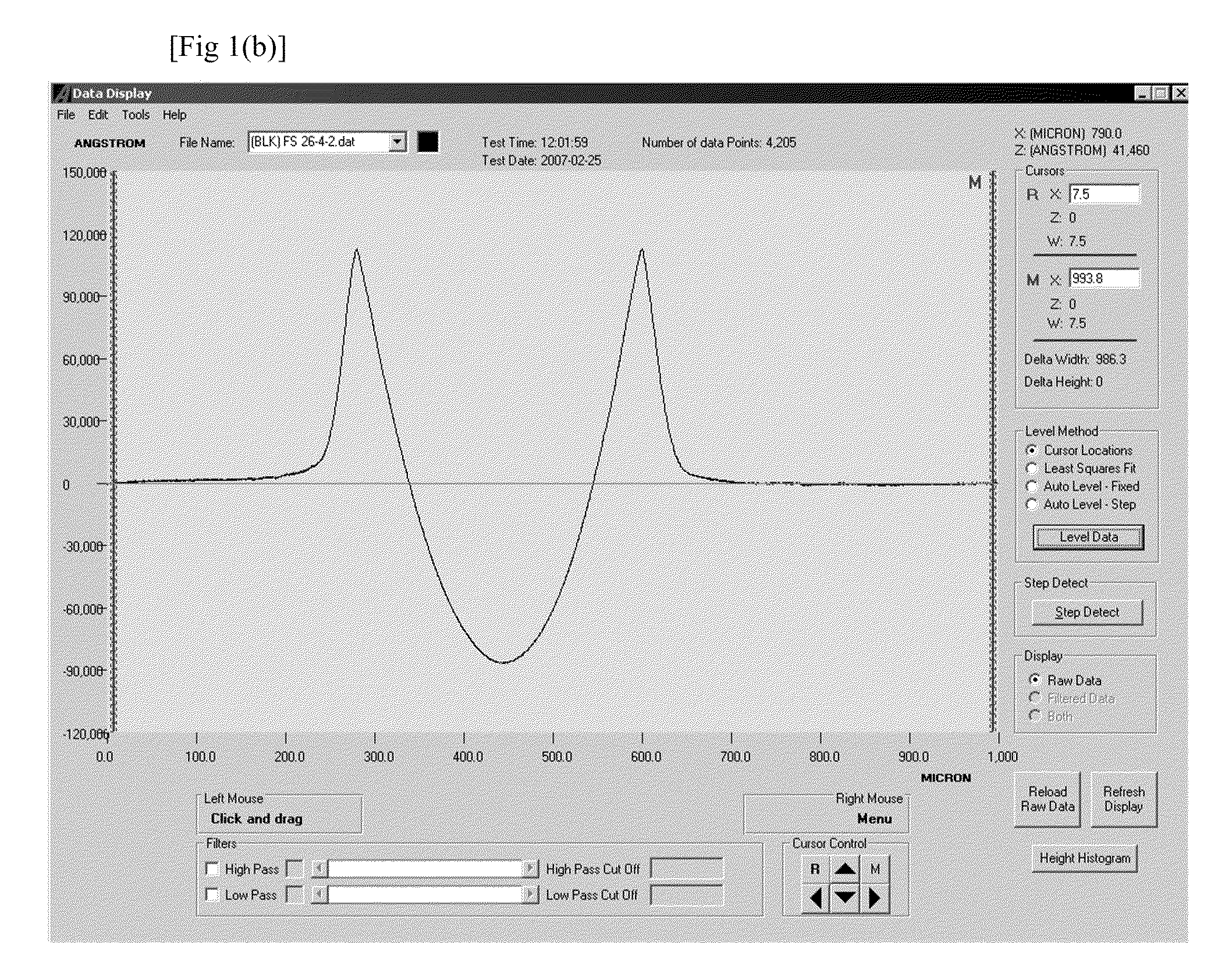

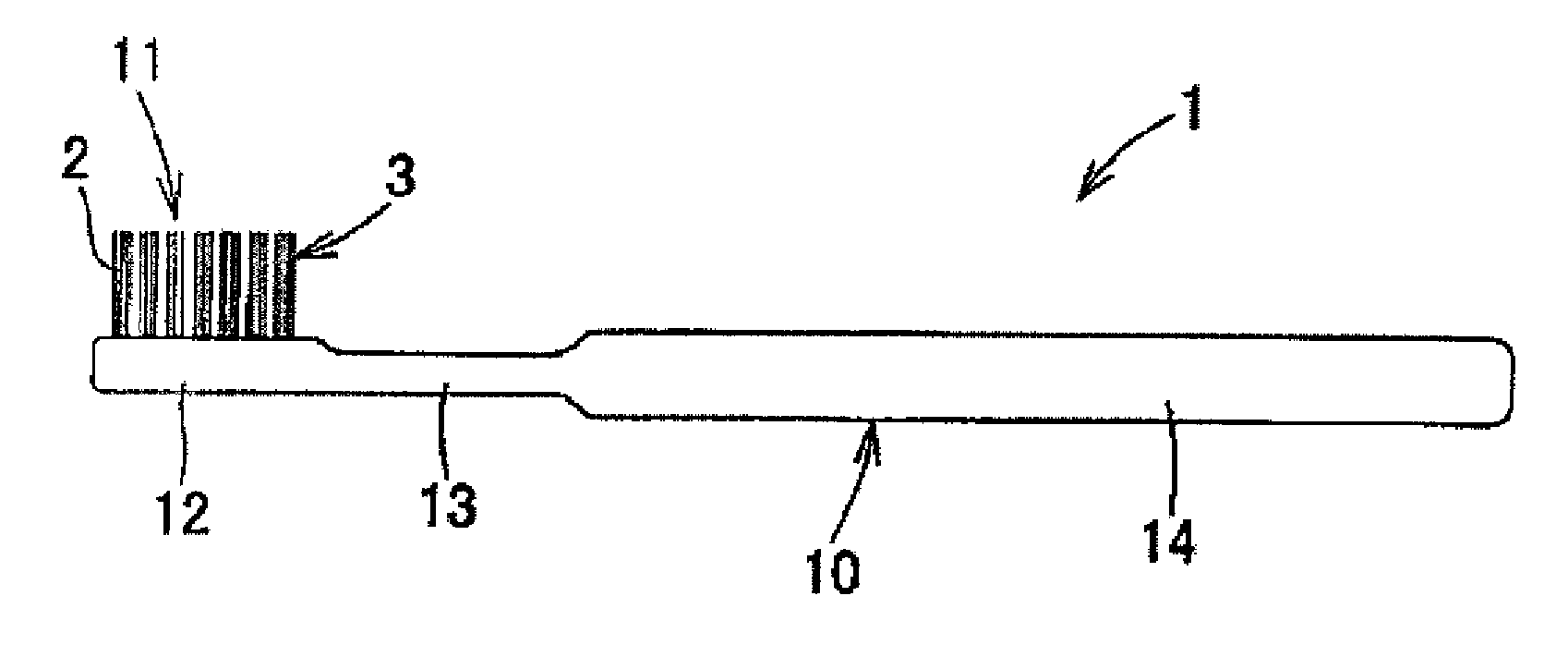

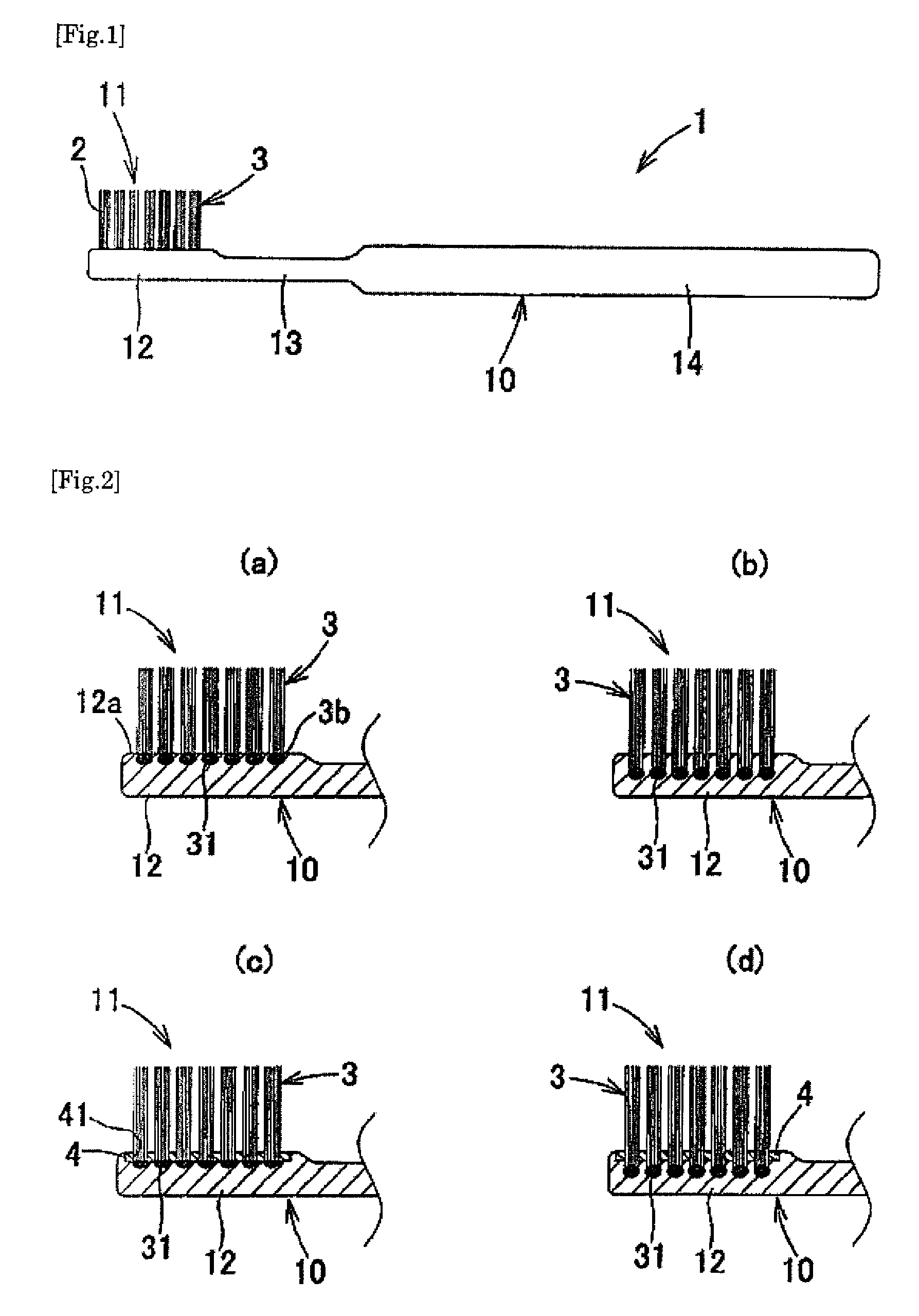

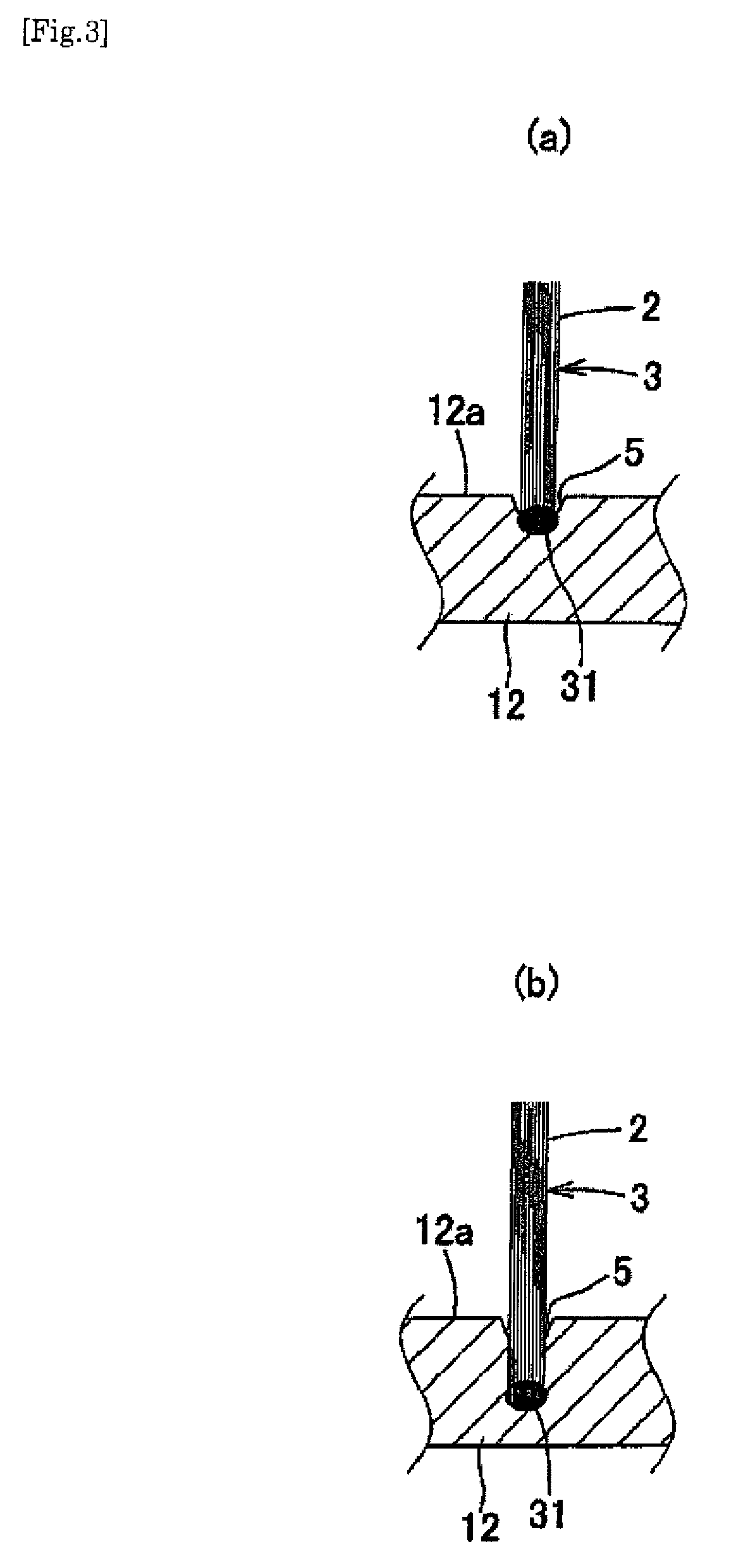

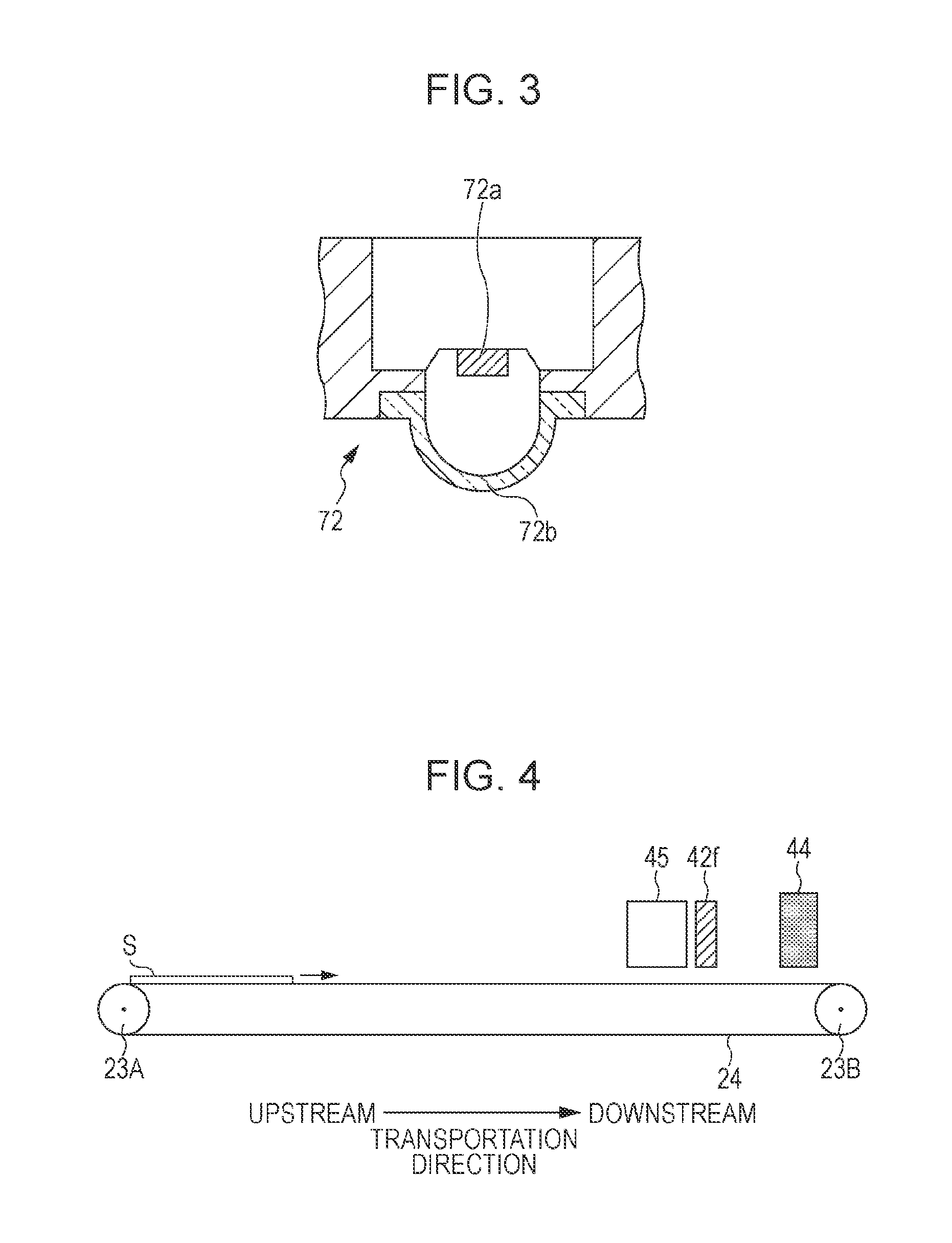

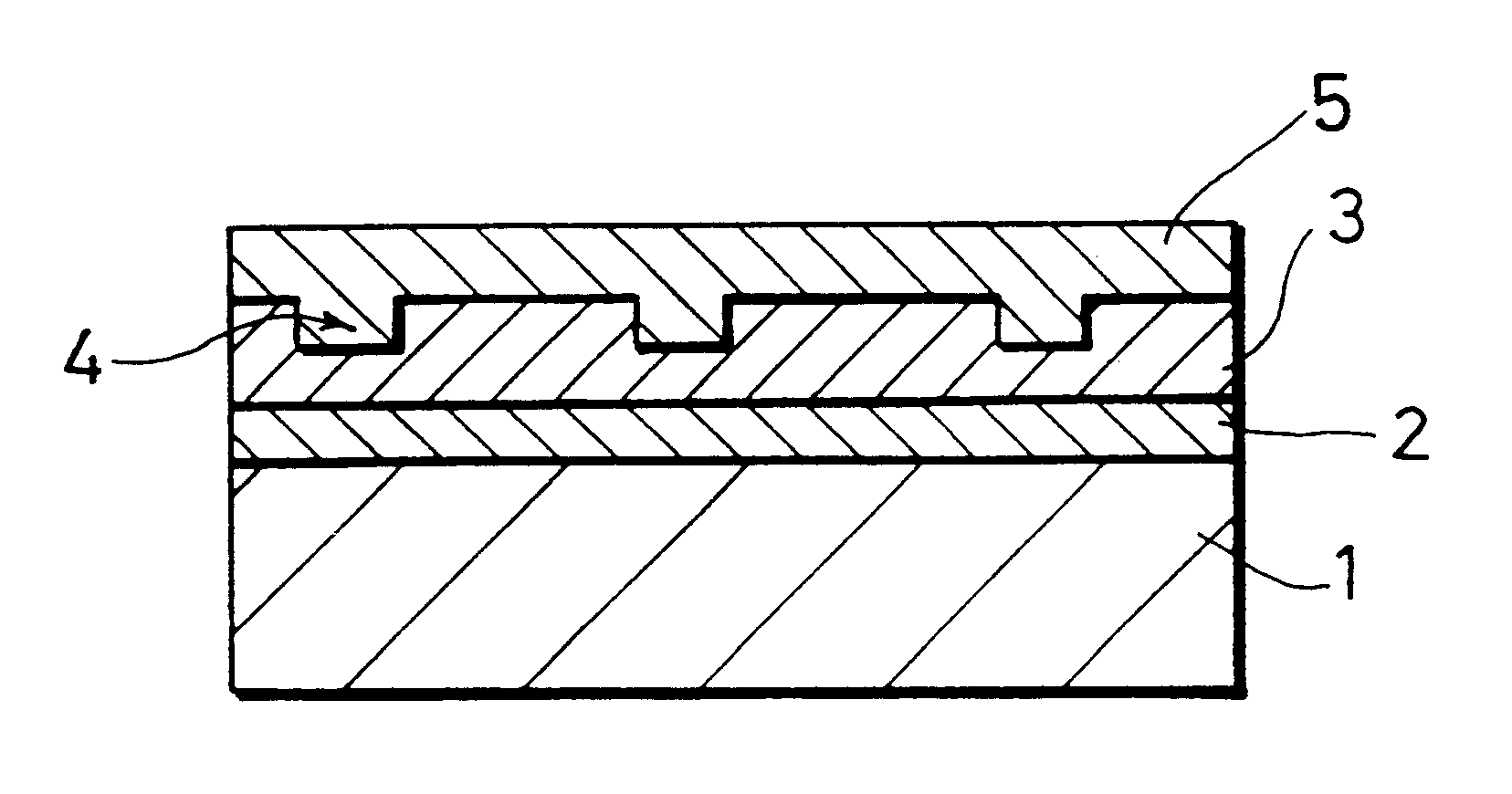

Toothbrush

InactiveUS20090013488A1Easy to useHighly attractive appearanceBristleDomestic articlesBristleEngineering

A toothbrush which comprises a brush main body made of a synthetic resin and having a bristle base and bristles made of a thermoplastic resin which have been fusion-bonded to the bristle base to constitute a bristled part, wherein the bristles constituting the bristled part at least partly comprise: tapered bristles which are bristles having split free ends, the split free ends having been tapered beforehand; tapered bristles which have a sectional shape having a core-sheath structure or islands in a sea structure; or tapered bristles in each of which a core bristle comprising a core or island part has been formed beforehand so as to be exposed at the free end. The toothbrush has excellent suitability for bristle insertion into narrow parts. It is highly effective in removing dental plaque and cleaning the teeth. It is highly easy to use in the oral cavity. It further has a highly attractive appearance.

Owner:SUNSTAR INC

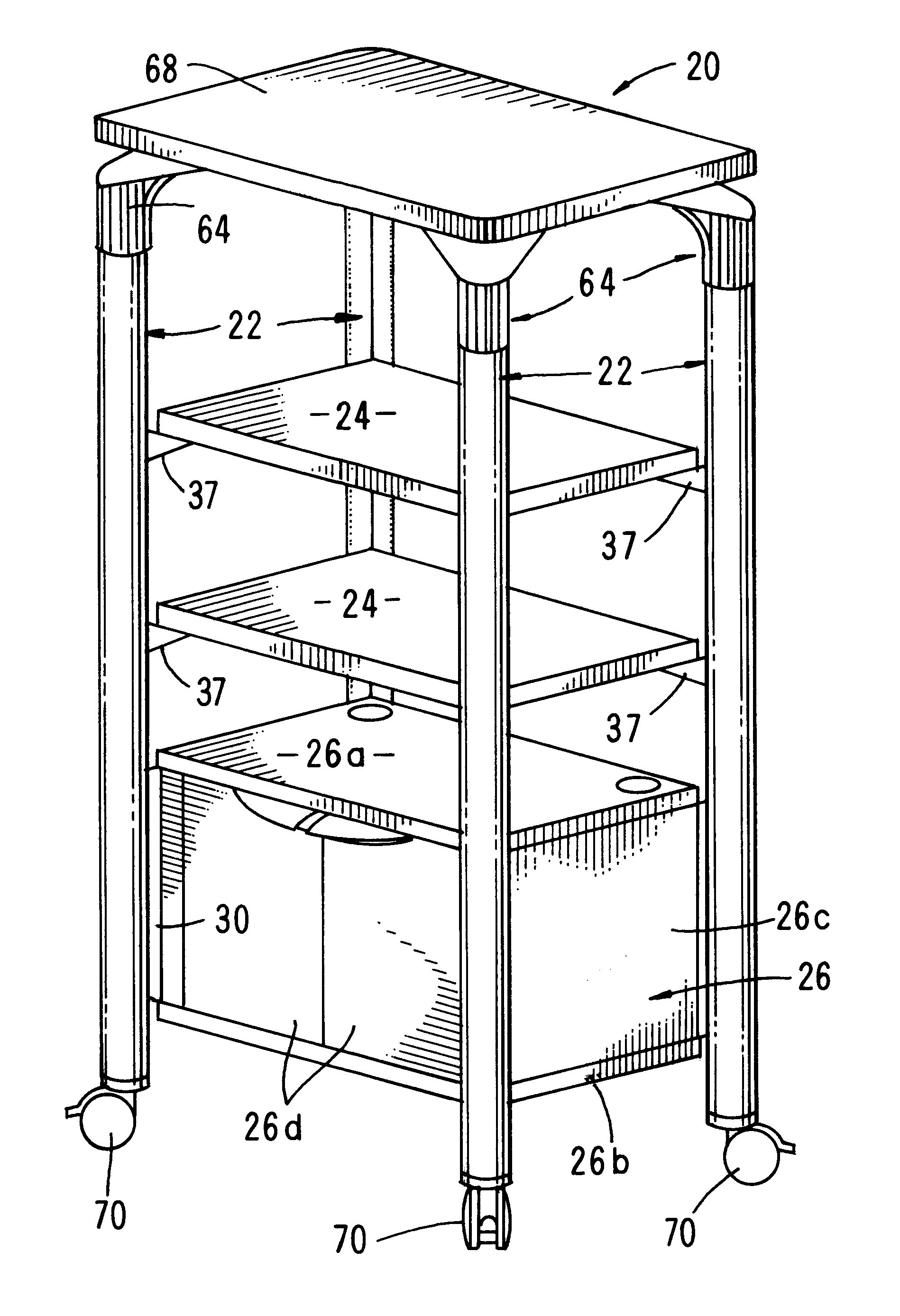

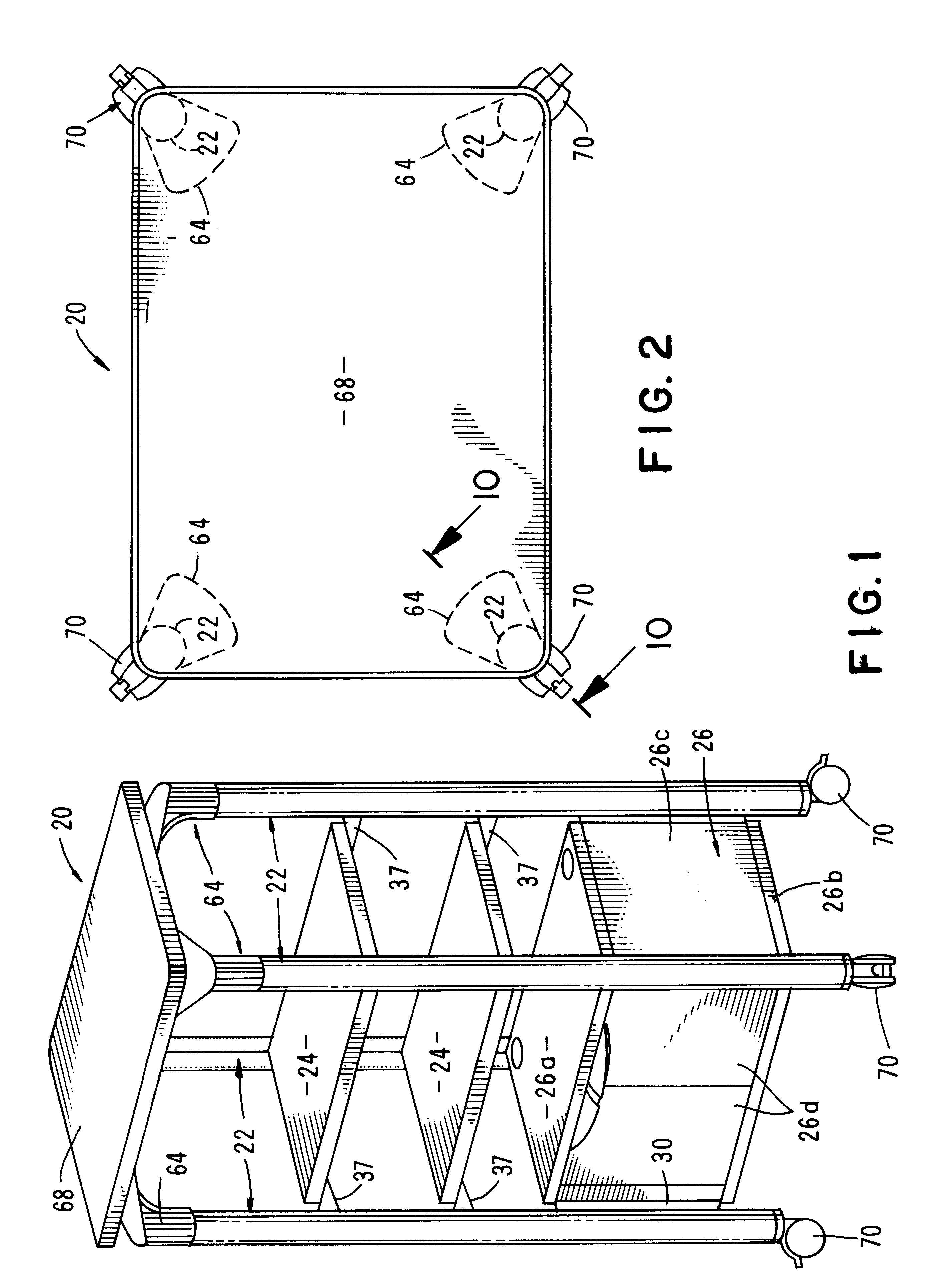

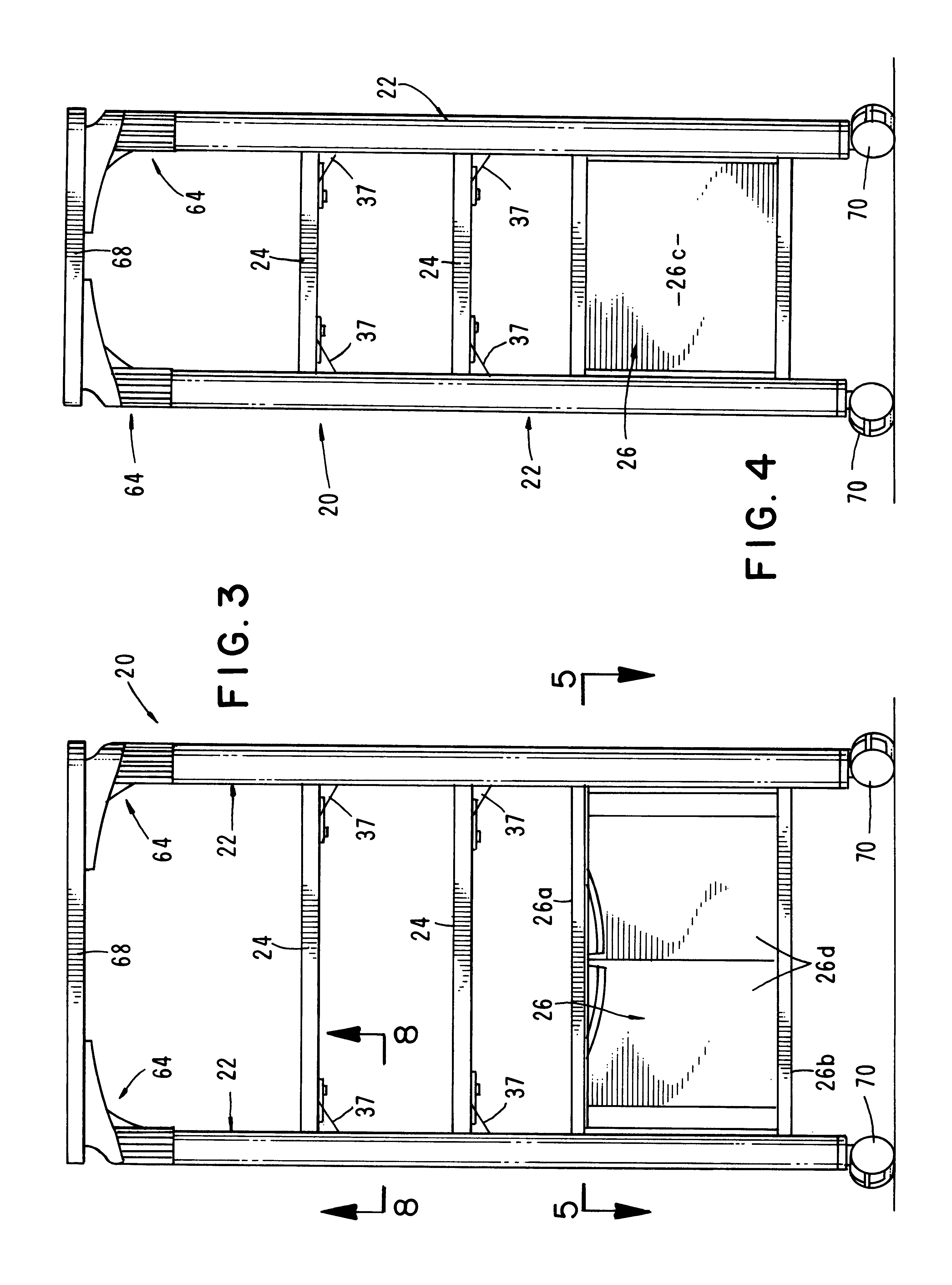

Furniture construction

InactiveUS6247770B1Quick and easy and secureEasy to useFurniture partsKitchen equipmentSlide projectorOverhead projector

Specially designed articles of furniture for use in conference and office settings which include a plurality of uniquely configured supporting legs, one or more article support structures disposed centrally of the supporting legs and a novel connector member for interconnecting the support structures of the legs. The connector member also enables the quick and easy interconnection of the polygonal panels that make up certain of the article support structures of the apparatus. The articles of furniture can be used to support and transport a wide variety of devices such as audio and video equipment, slide projectors, overhead projectors and the like.

Owner:VIRCO MFG

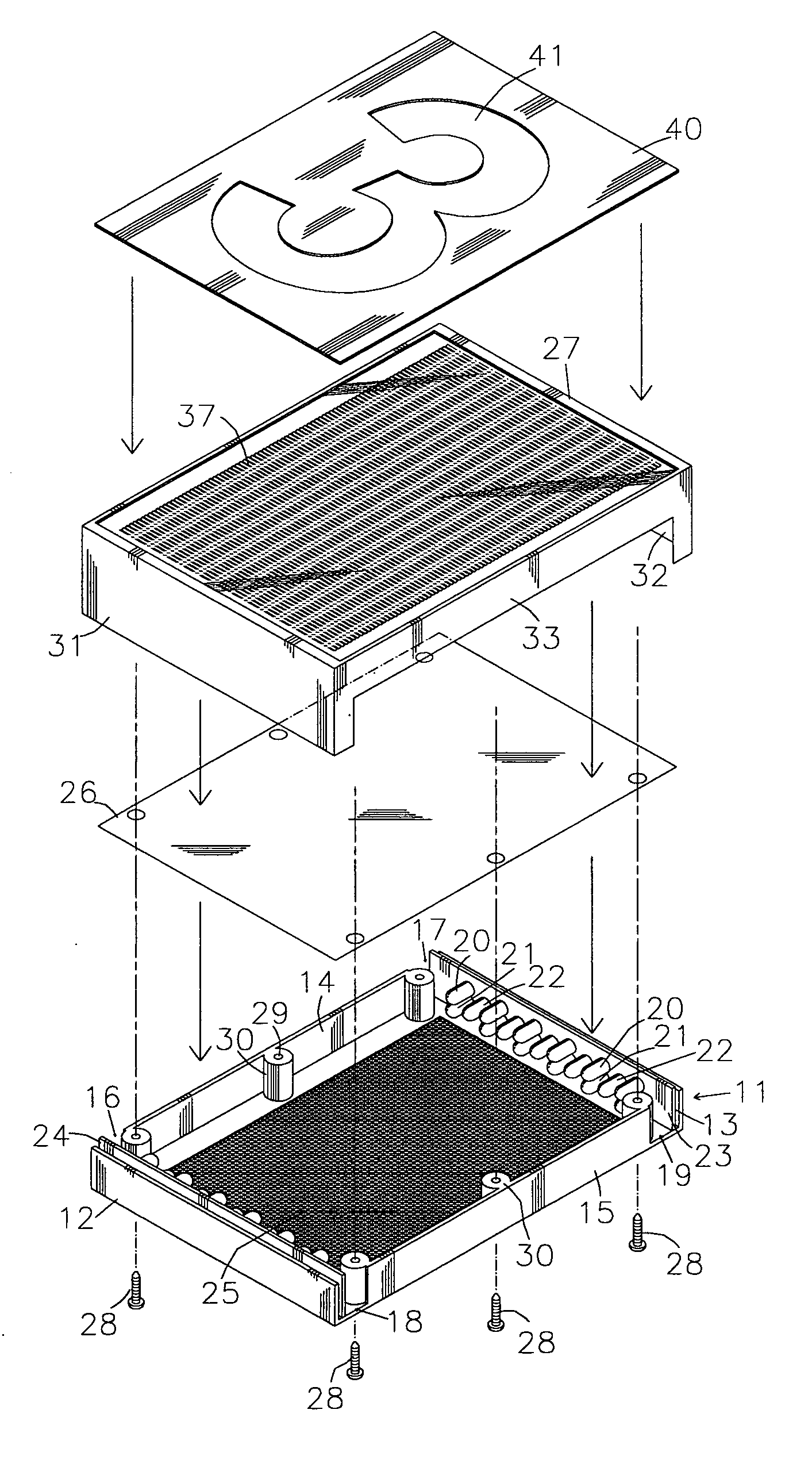

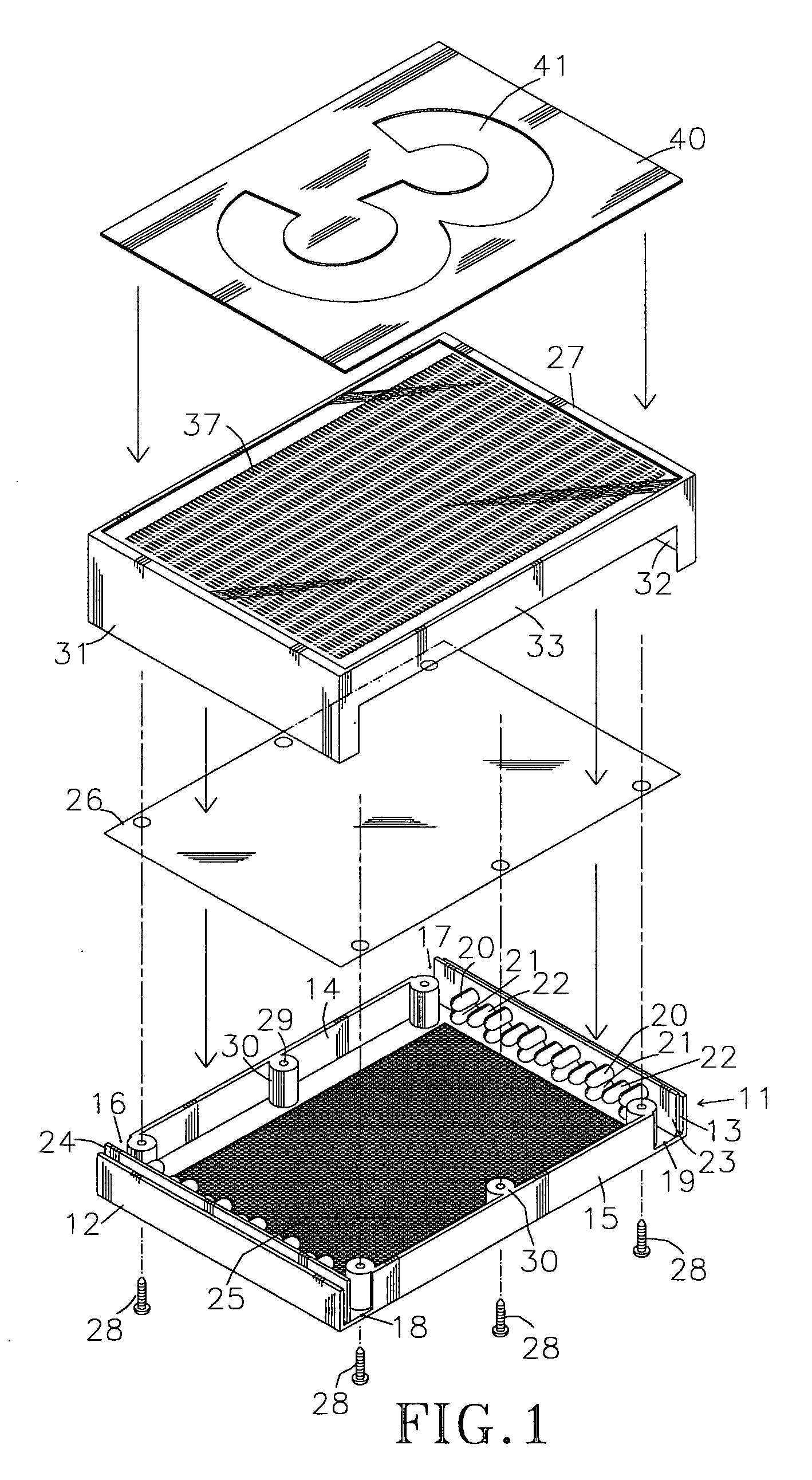

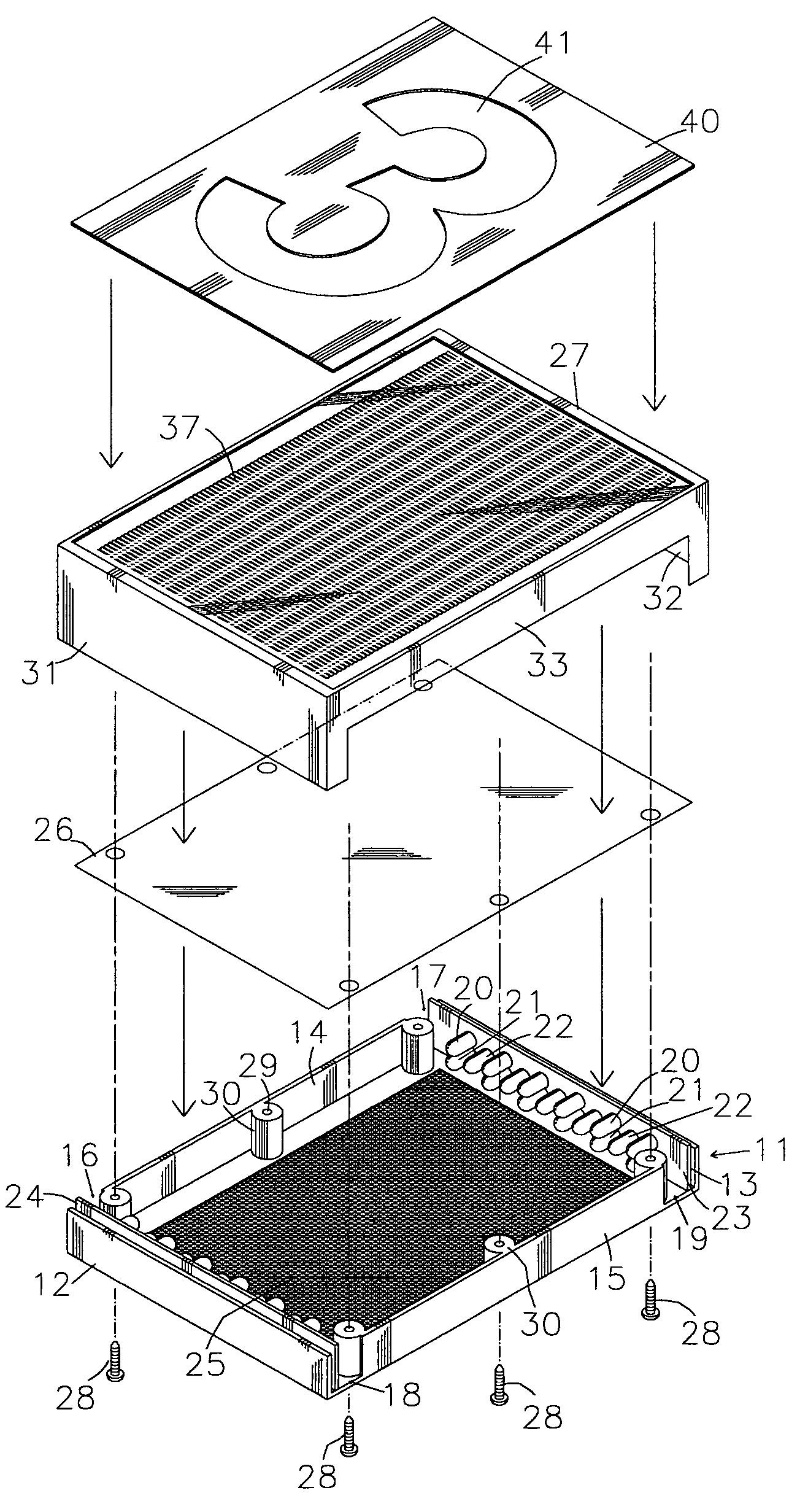

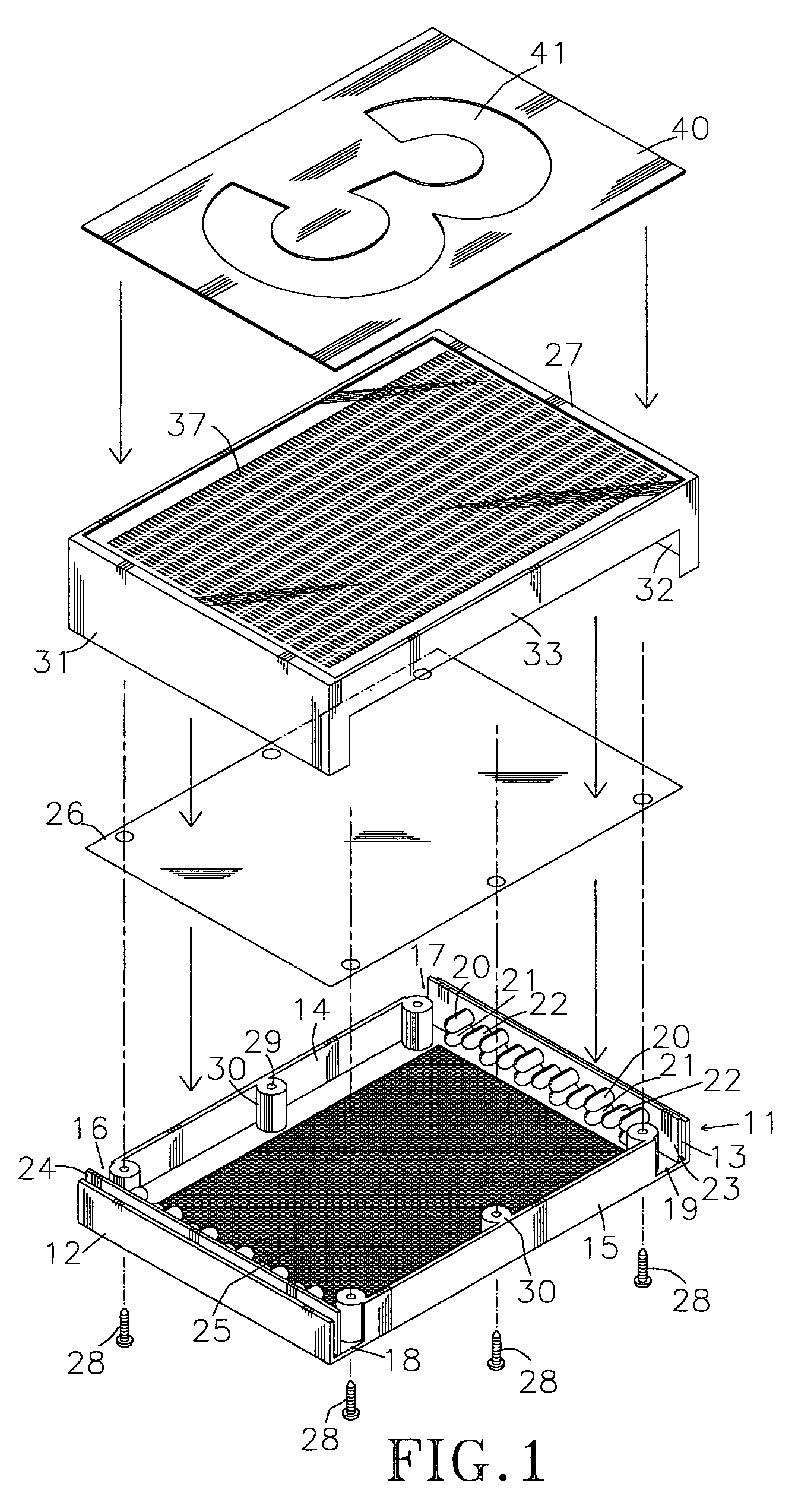

Multi-color illuminated sign

InactiveUS20060248761A1High appearance requirementsNon-electric lightingPoint-like light sourceVisibilityEffect light

The multi-color illuminated sign displays an indicia or house address number in changing sequence of colors. The back lighting is provided by three groups of plurality of light emitting diodes. One group of the light emitting diodes is operative to generate a primary blue light, a second group of light emitting diodes is operative to generate a primary green light, and a third group of light emitting diodes is operative to generate a primary red light. Varying combinations of these primary lights produces a plurality of color back lighting which are reflected and refracted by various reflective and refractive patterns to enhance the visibility and aesthetic appearance of the indicia.

Owner:CHEUNG TIN FU +1

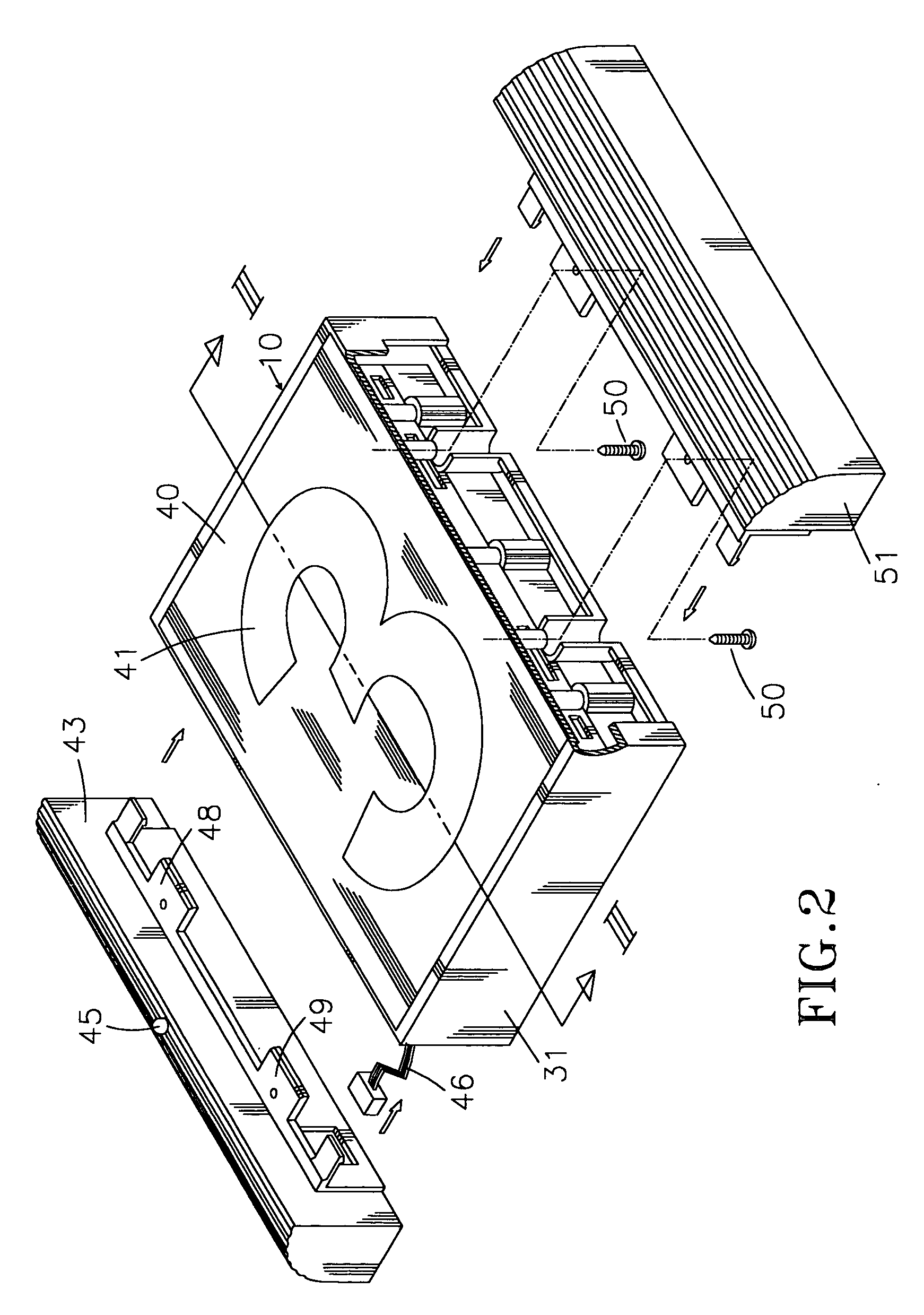

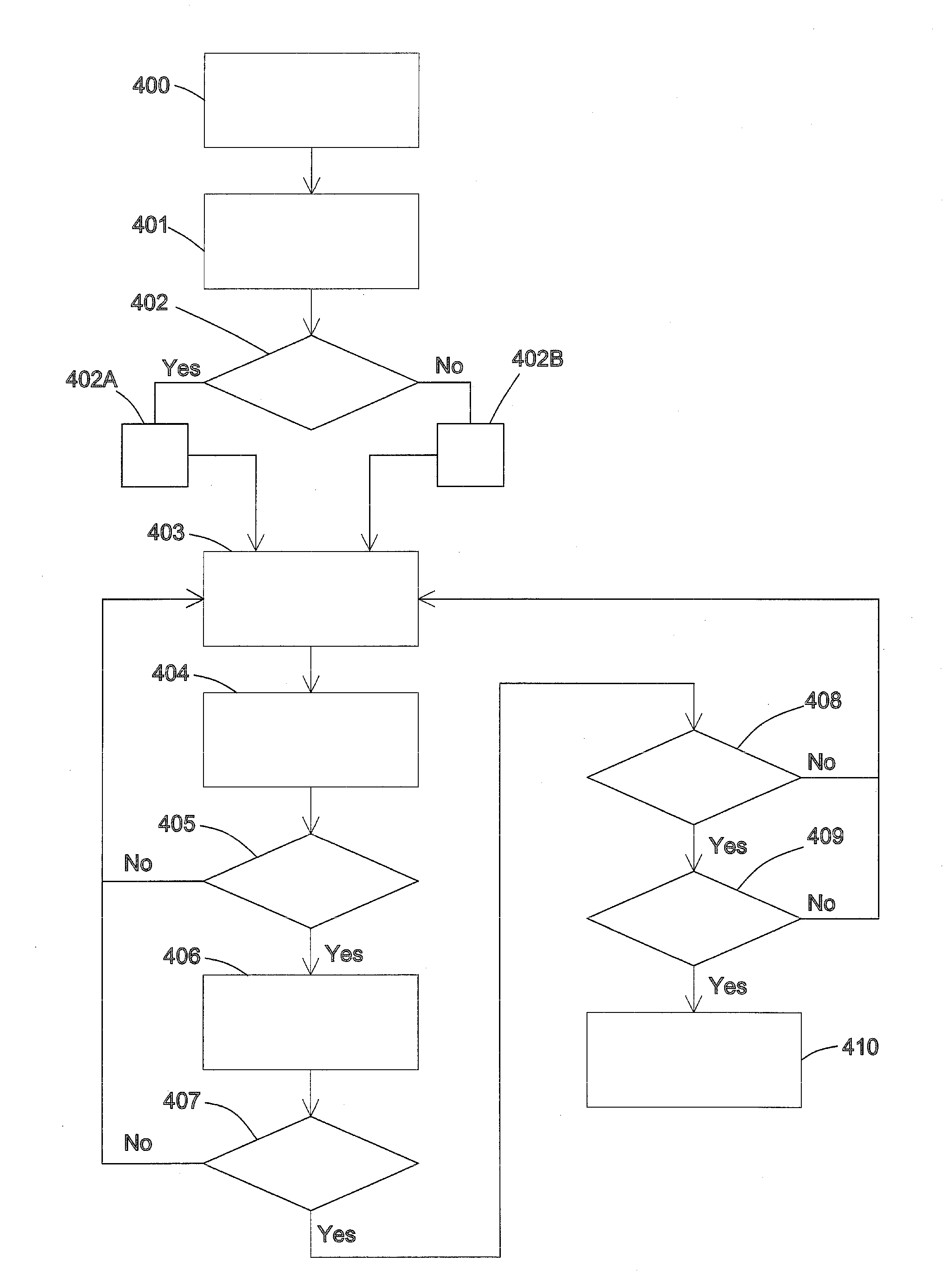

Firmware upgrading method for bluetooth electronic scales

InactiveUS20160299753A1Highly attractive appearanceNo compromise of measuring accuracyProgram loading/initiatingWireless commuication servicesMobile deviceComputer engineering

A firmware upgrading method for Bluetooth electronic scales. The firmware upgrading method provides a function to resume firmware upgrading for the Bluetooth electronic scale, and conduct the Bluetooth electronic scale firmware upgrading through batch-by-batch transmission of the data packets containing parameter information. The steps include: Establish Bluetooth networking, Transmit data packets, Compare the data packets in stages, Record the firmware upgrading progress, and Check completeness of the upgrading. In view of the problem that general Bluetooth networking is unable to ensure correctness of the data transmitted, the firmware upgrading method of the present invention can be applied for communication between a Bluetooth mobile device and a Bluetooth electronic scale paired through Bluetooth networking, and ensure correctness of the data packets received. Even if the Bluetooth transmission is paused due to disconnection, the firmware upgrading can be resumed and successfully completed.

Owner:ACAIA

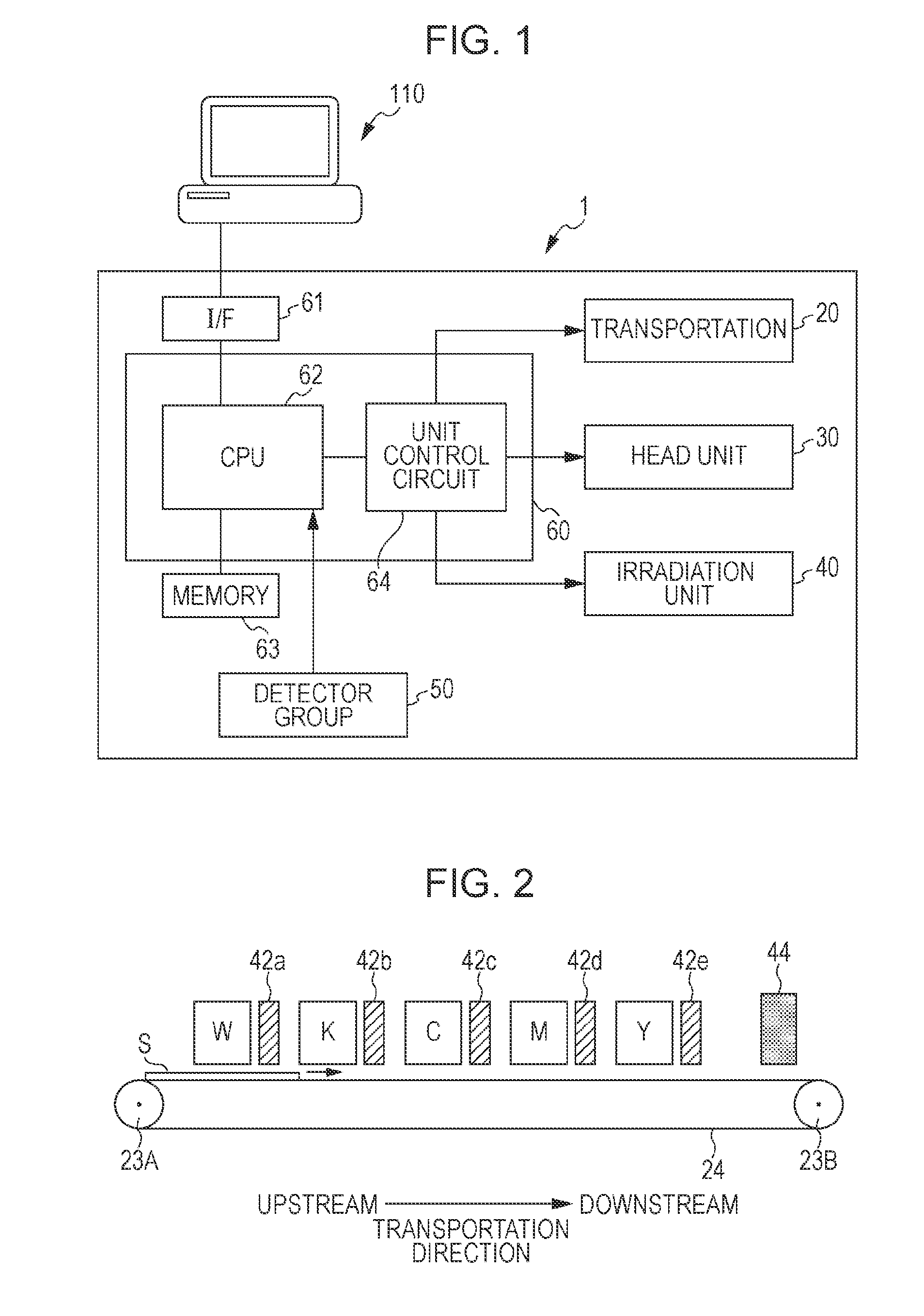

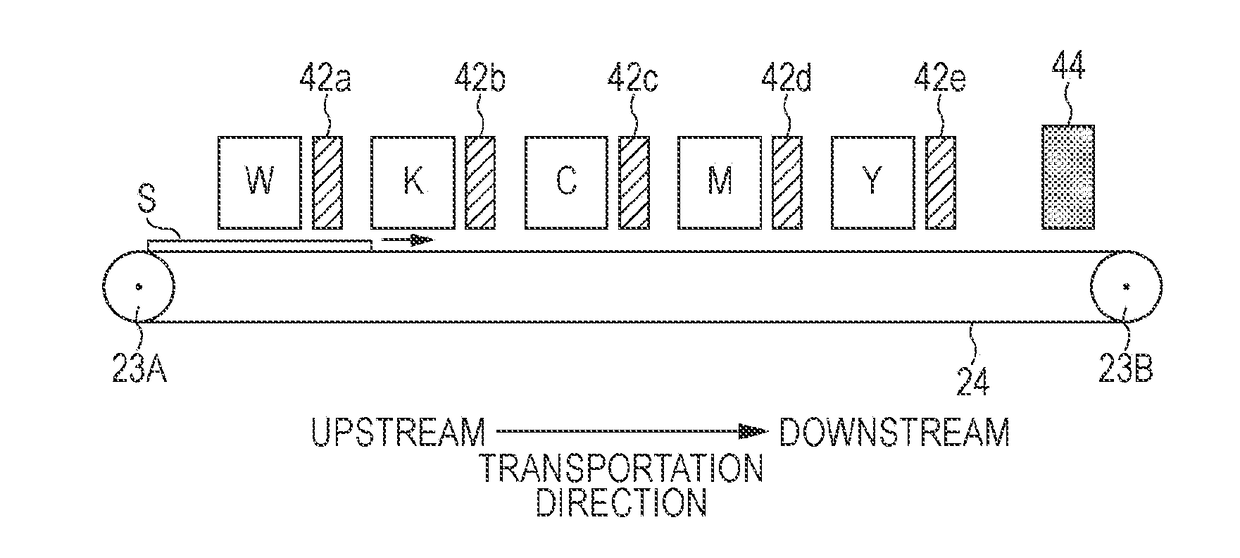

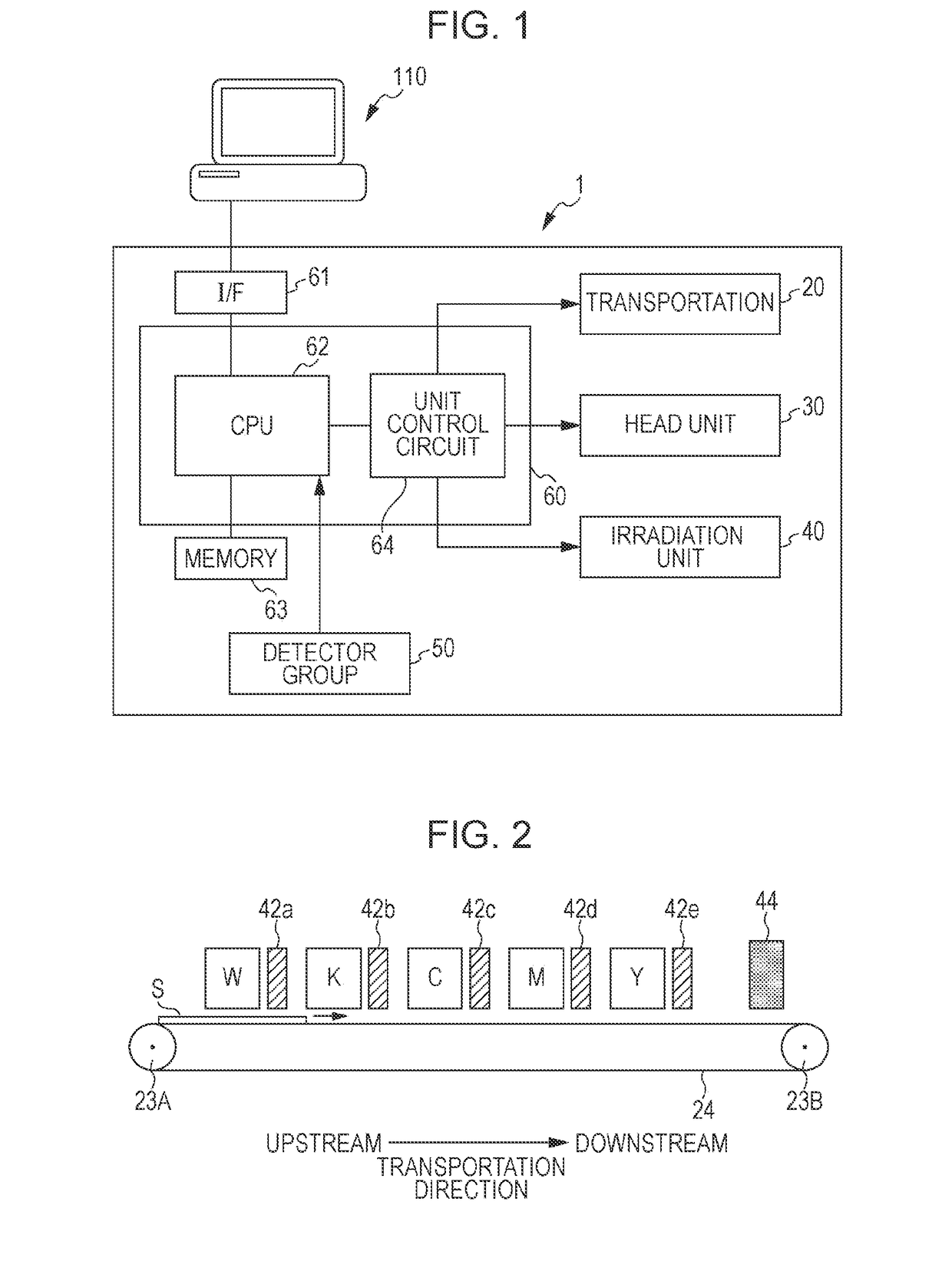

Ink jet recording method, ultraviolet curable ink, and ink jet recording apparatus

ActiveUS20130258018A1Avoid generatingUneven brightnessDuplicating/marking methodsInksTransmittanceRadical polymerization

Provided is an ink jet recording method including: discharging first ultraviolet curable ink of a radical polymerization reaction type which contains a radical photopolymerization initiator and a radical polymerization compound and in which transmittance at a wavelength of 395 nm is equal to or less than 1%, onto a recording medium; and curing the first ultraviolet curable ink which is landed on the recording medium by irradiating the ink with ultraviolet light, in which a light source which initially emits the ultraviolet light in the curing of the ink is an ultraviolet light emitting diode in which peak intensity of the irradiated ultraviolet light is equal to or more than 800 mW / cm2.

Owner:SEIKO EPSON CORP

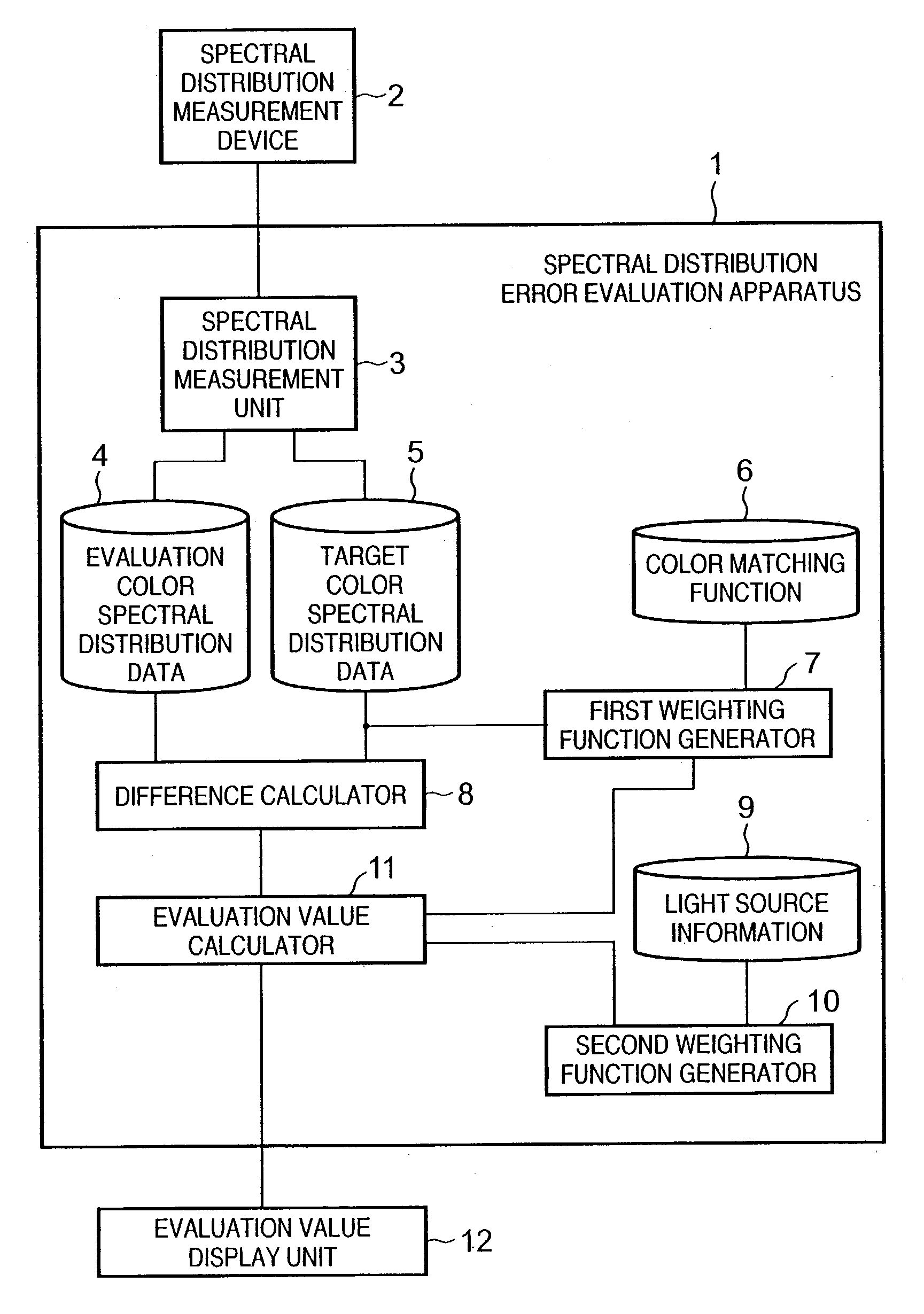

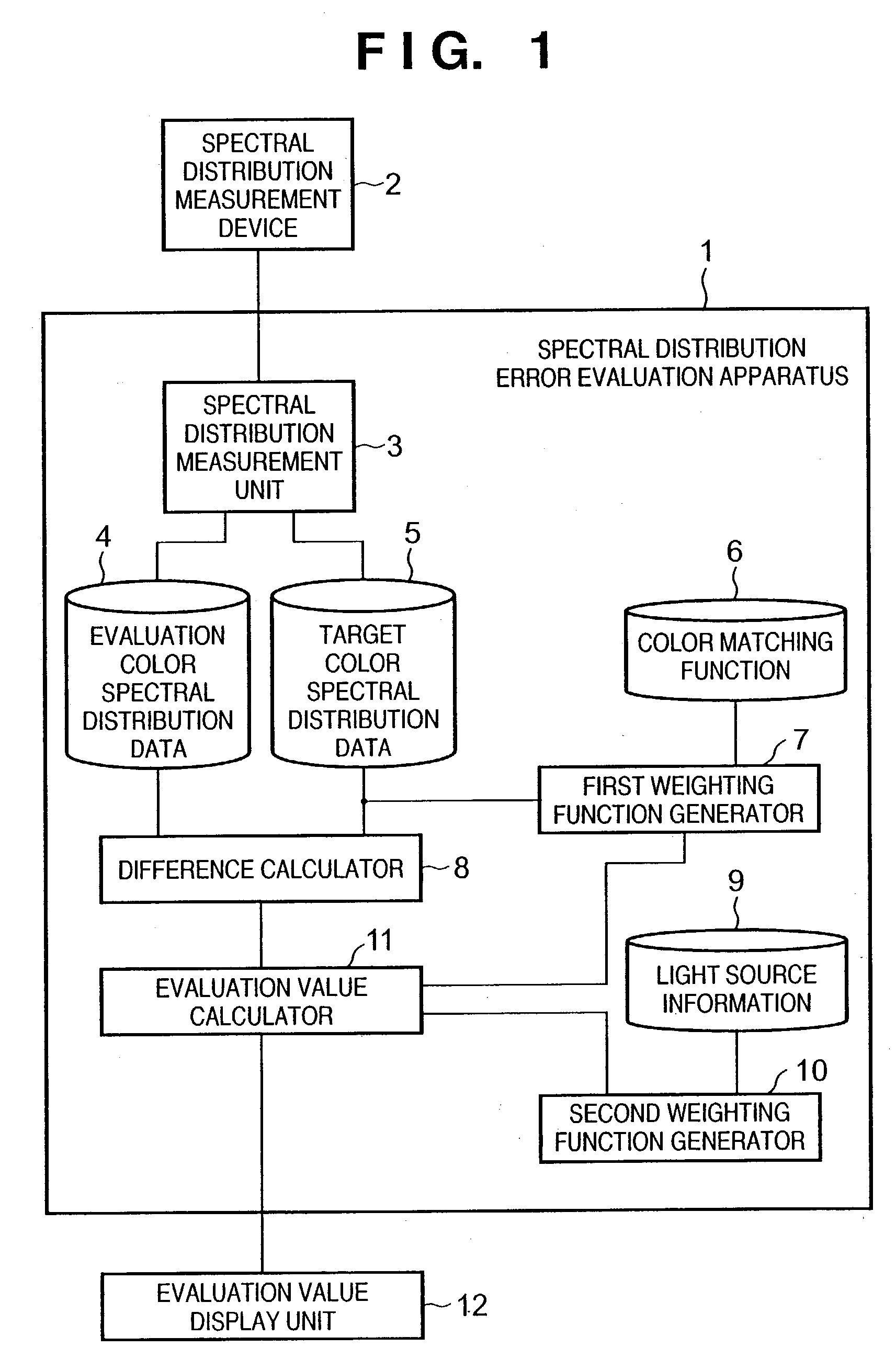

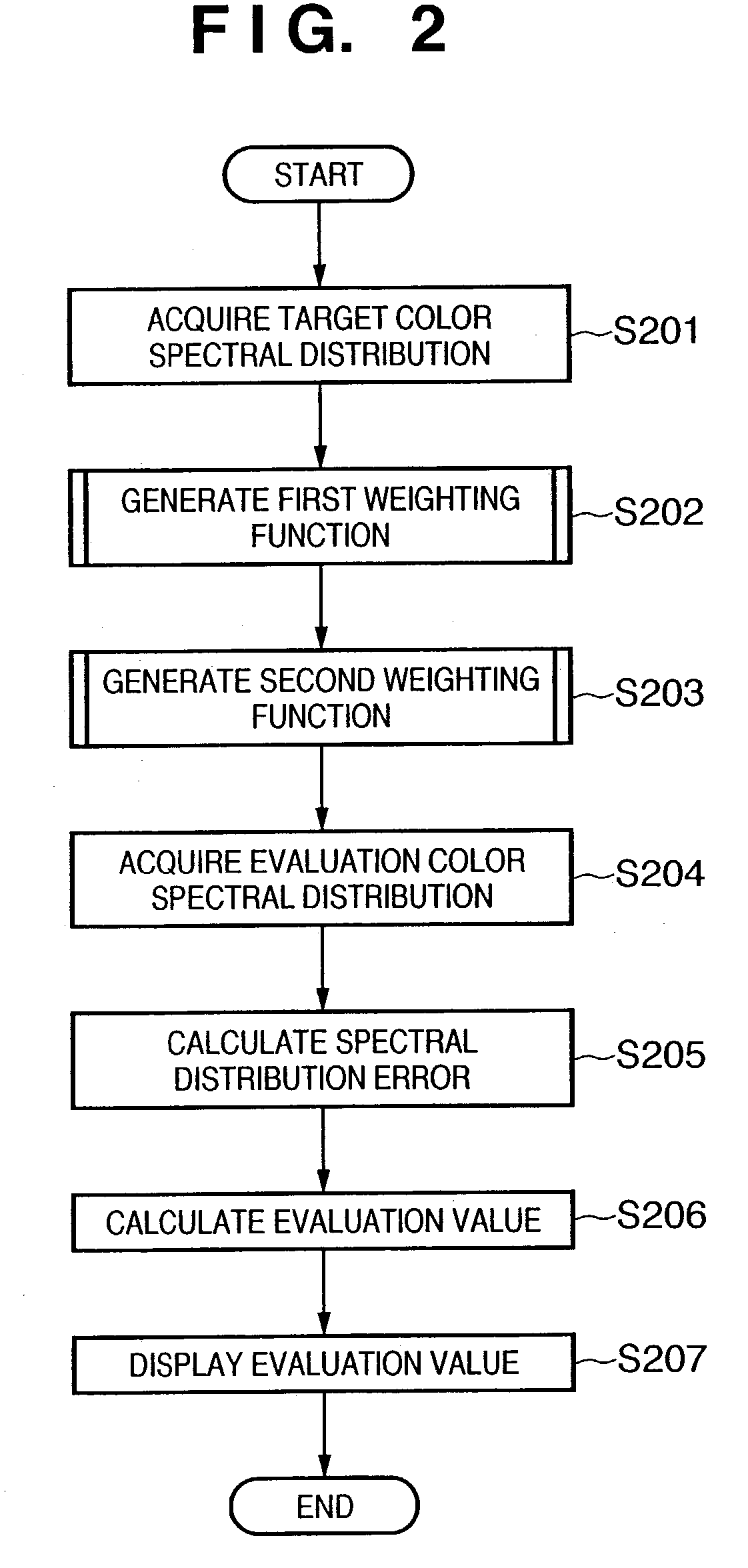

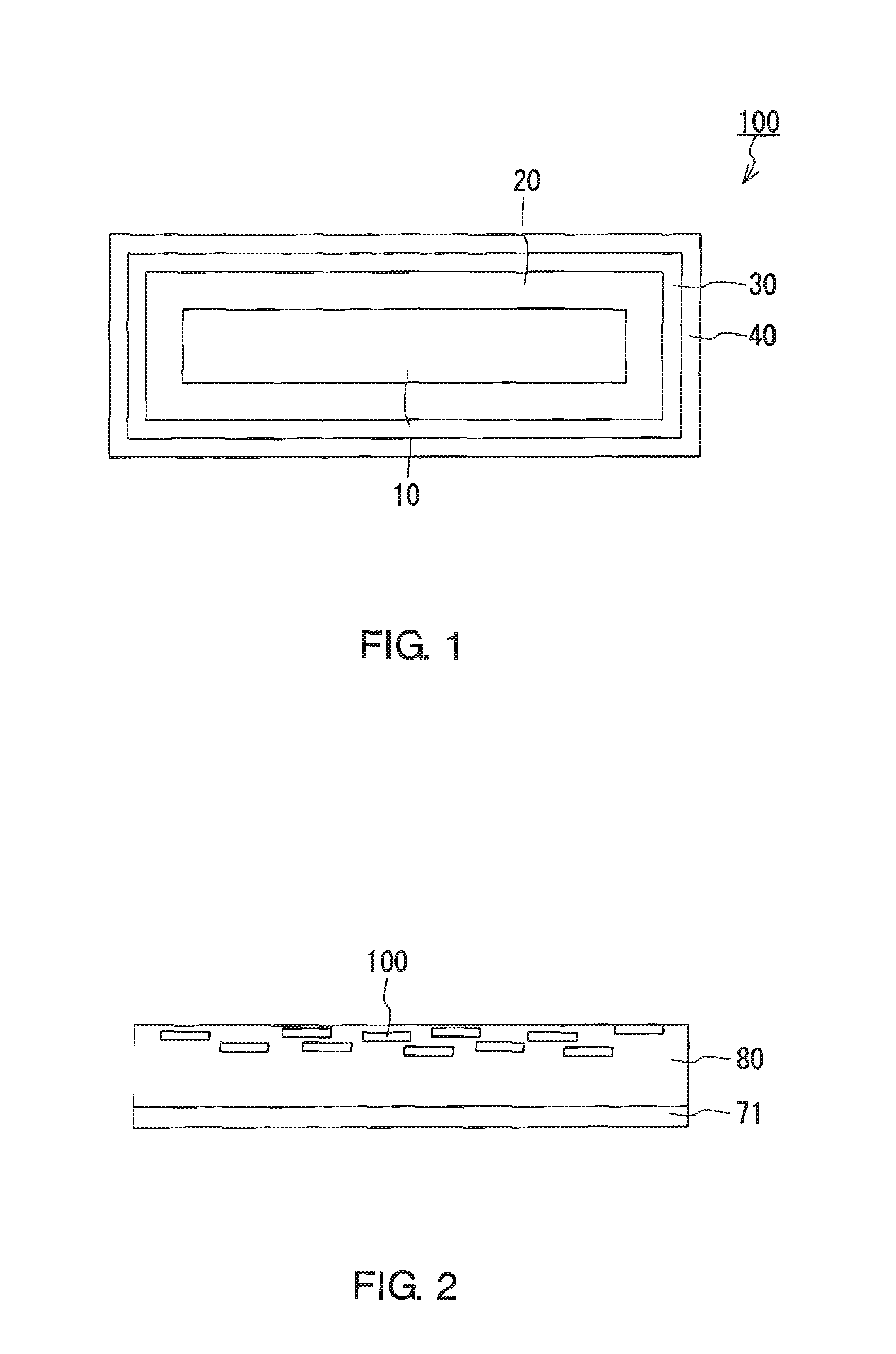

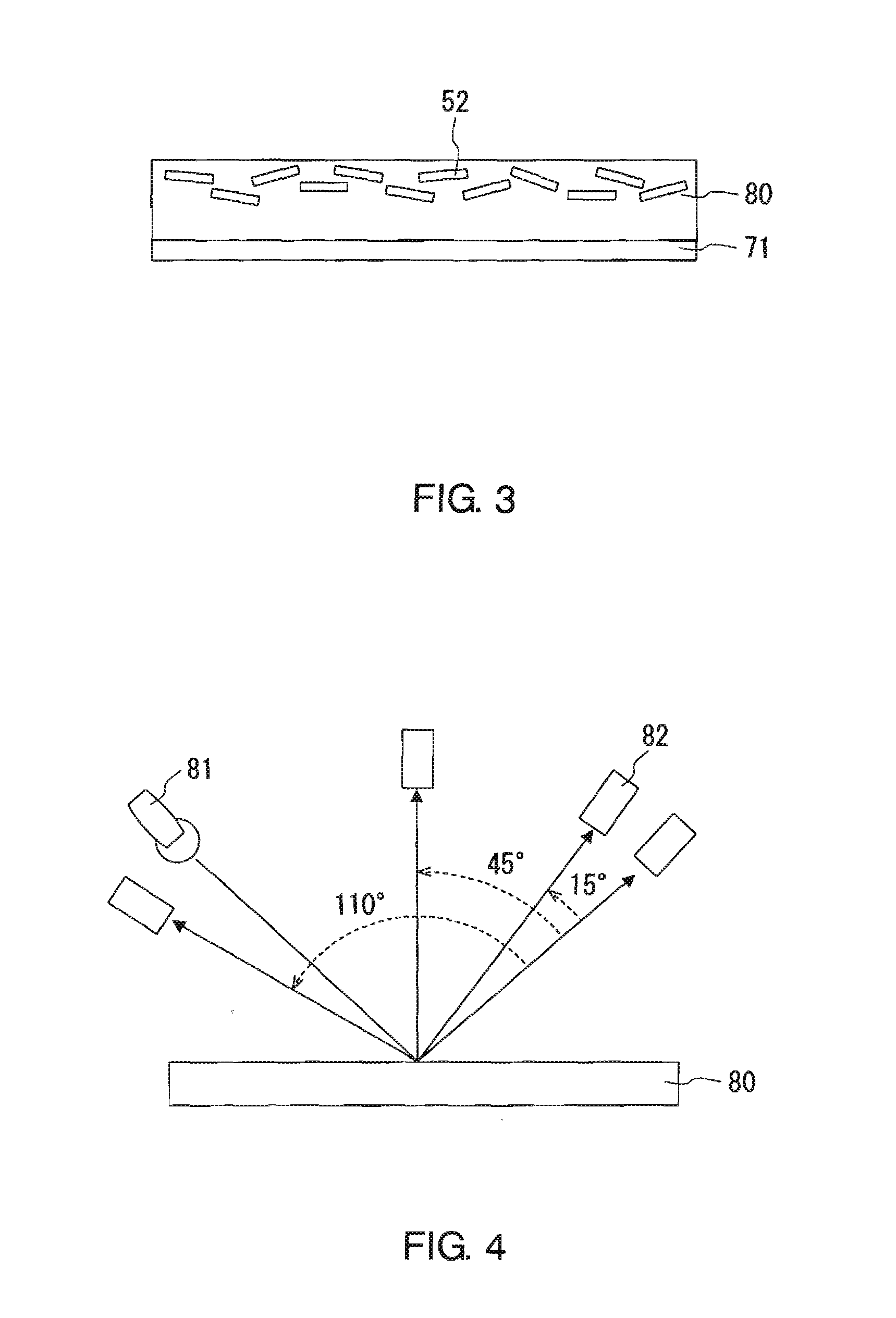

Color evaluation apparatus and method

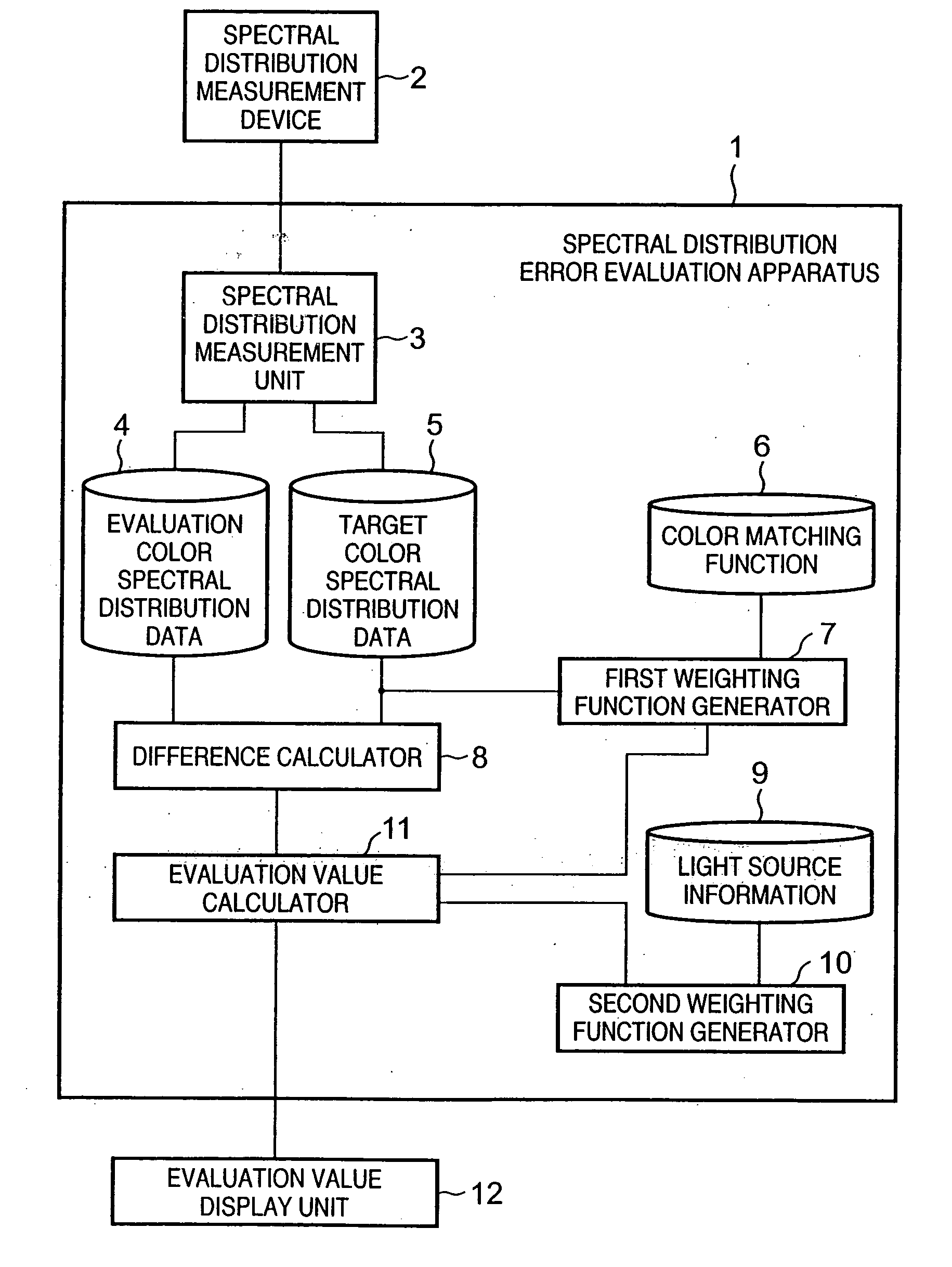

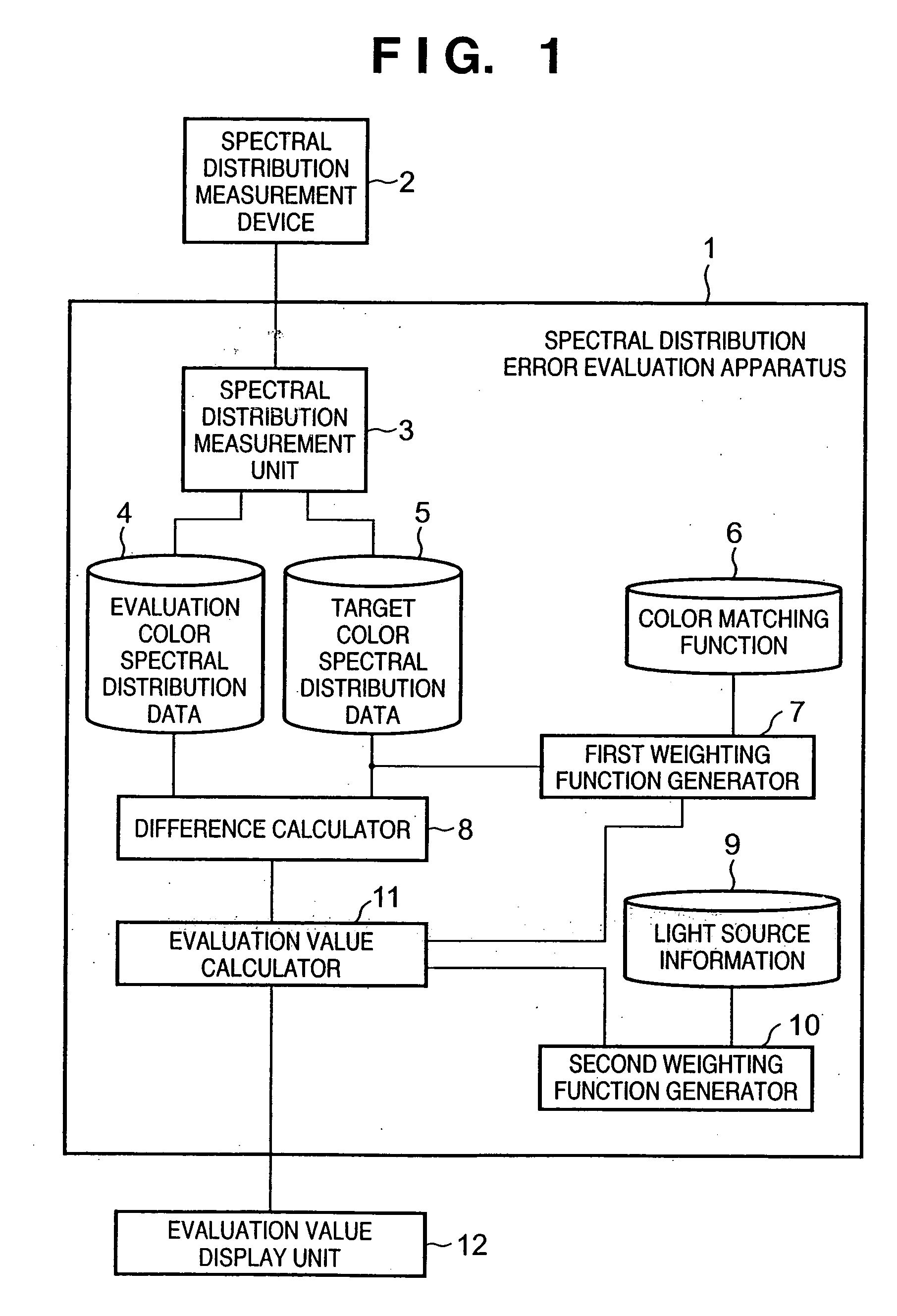

InactiveUS6987567B2High appearance requirementsGood colorColor/spectral properties measurementsImage data processing detailsCalculation errorLength wave

A spectral distribution error evaluation apparatus is used to evaluate precision of color matching between evaluation and target colors. A first weighting function generator generates a first weighting function on the basis of color matching functions, wavelength characteristics which are independent of a light source of the target color, and visual characteristics which depend on wavelengths. A second weighting function generator generates a second weighting function on the basis of light source information of selected light sources. A difference calculator calculates error values between the evaluation and target colors for respective frequencies. An evaluation value calculator applies the first and second weighting functions to the error values, and calculates the sum total of the error values as an evaluation value. In this way, a precision evaluation value which has high correlation with actual color appearance and is used to improve the color matching precision can be calculated independently of a change in condition such as a light source or the like.

Owner:CANON KK

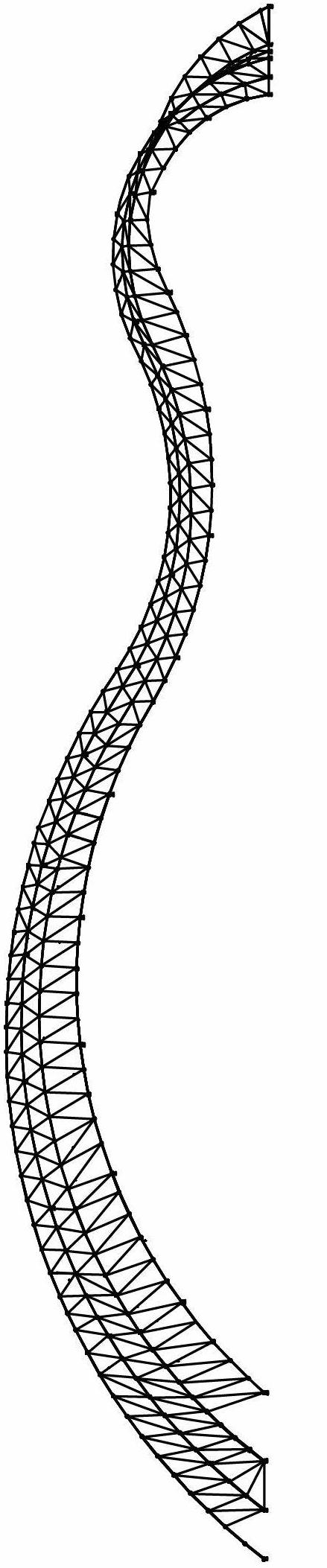

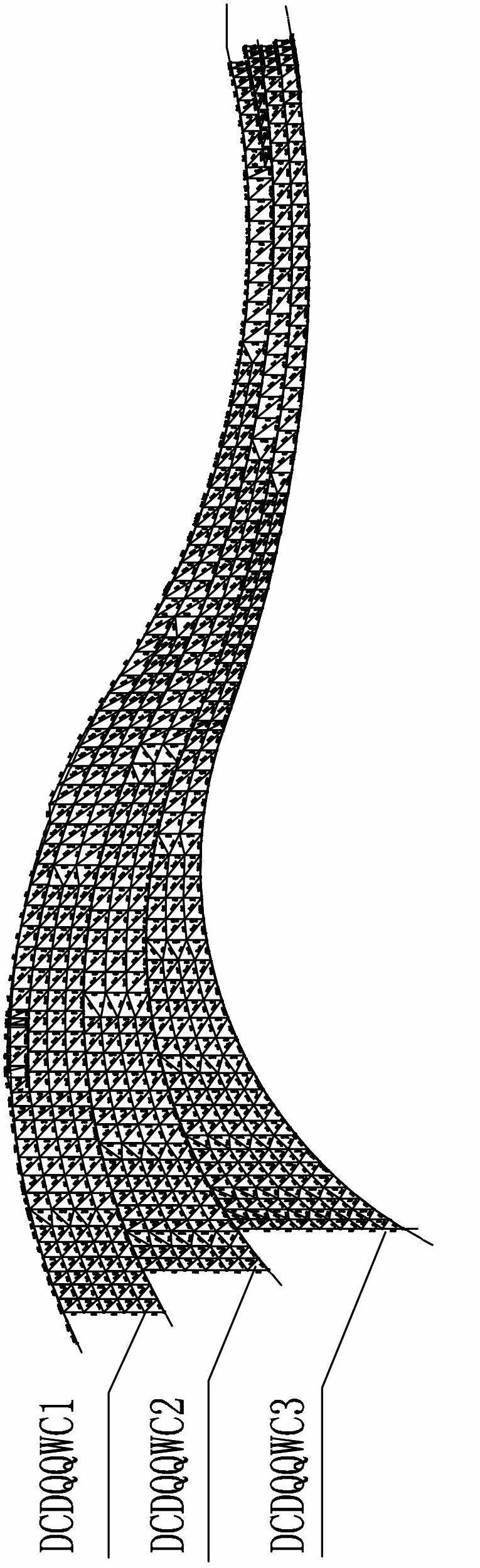

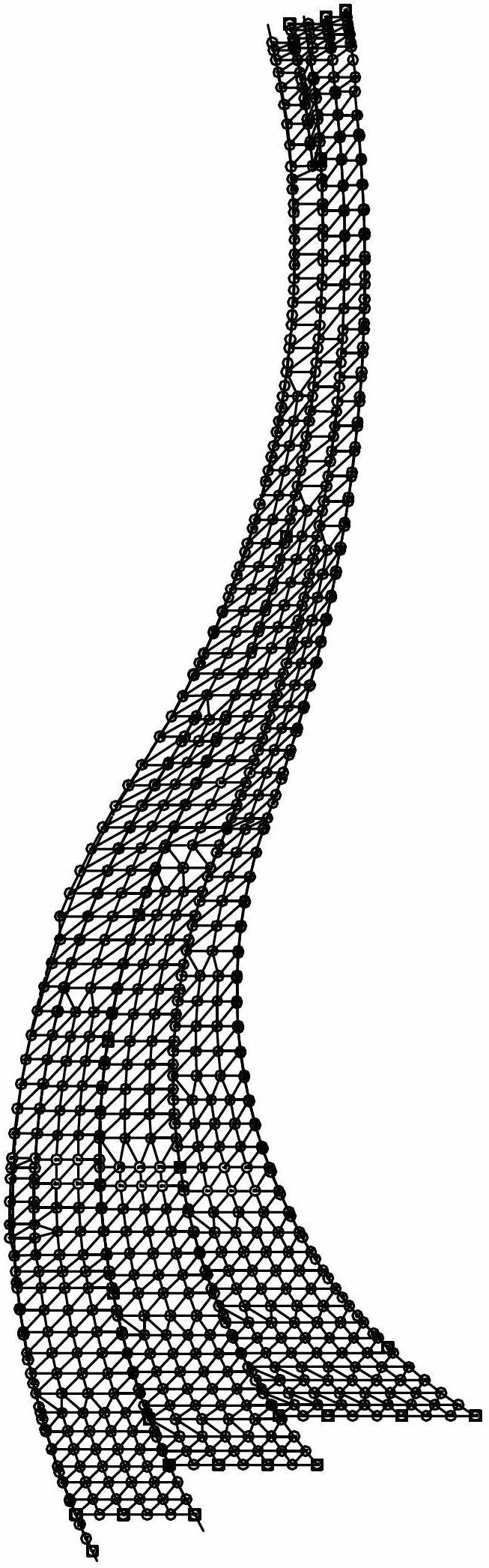

Multilevel multi-curve single-layer welding ball steel structure net rack and construction method thereof

InactiveCN102660996AFair useReasonable designBuilding roofsBuilding material handlingReinforced concreteRebar

Disclosed is a multilevel multi-curve single-layer welding ball steel structure net rack. Each layer of the multilevel multi-curve single-layer welding ball steel structure net rack comprises a structurally separated rod and a hollow ball which are connected into a whole in a welded manner; an elastic support positioned on a reinforced concrete vertical column is connected with each layer of the multilevel multi-curve single-layer welding ball steel structure net rack through a net rack supporting part; the elastic support is capable of inching in a certain direction or an optional direction, and the net rack further comprises a cable-supported structure consisting of a cable-supported structure support, a cable-supported ball, a pull cable and a cable-supported ball supporting rod. The net rack is unique in appearance and suitable for serving as a building steel structure support which has high requirements on the appearance of a building, is unique in appearance and needs to display arc shapes, line shapes, shell shapes and staggered levels, and the construction method of the net rack can be used for effectively controlling space coordinates and positional accuracy of components of the net rack, structural stability and structural appearance diversity of the net rack during installation, so that the requirements of a building structure on high, large, difficult and multidirectional change can be met.

Owner:广西建工第五建筑工程集团有限公司

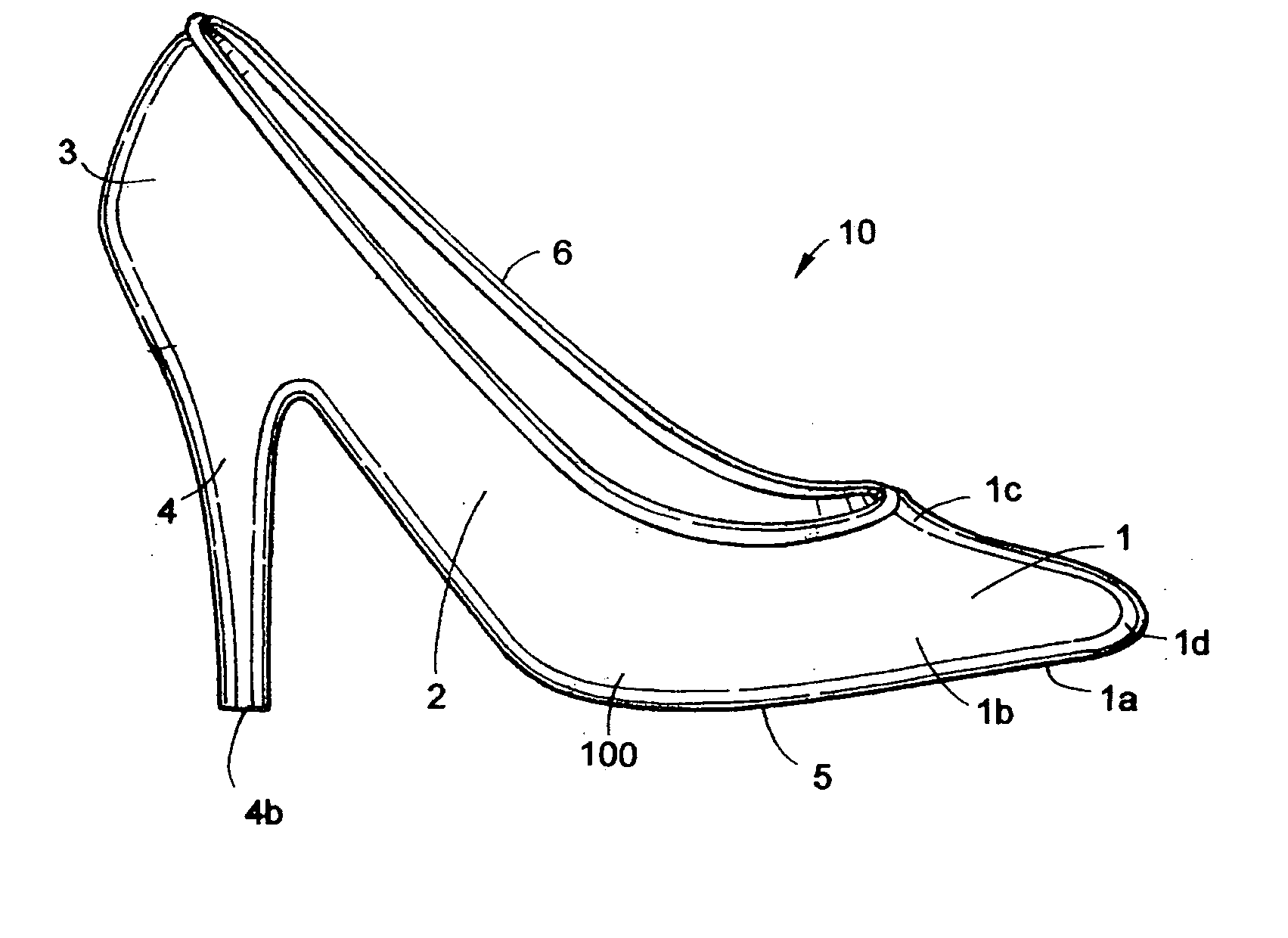

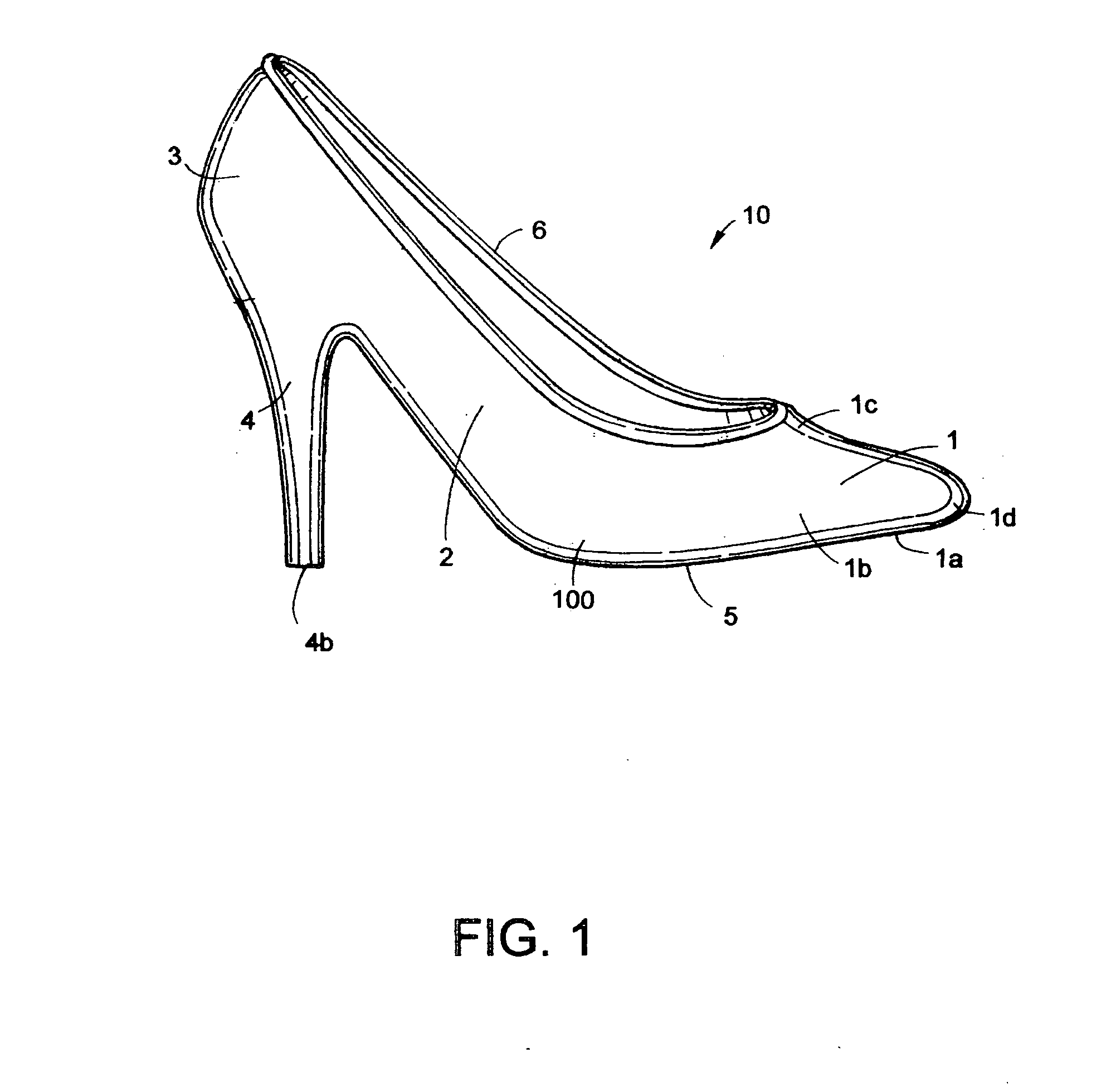

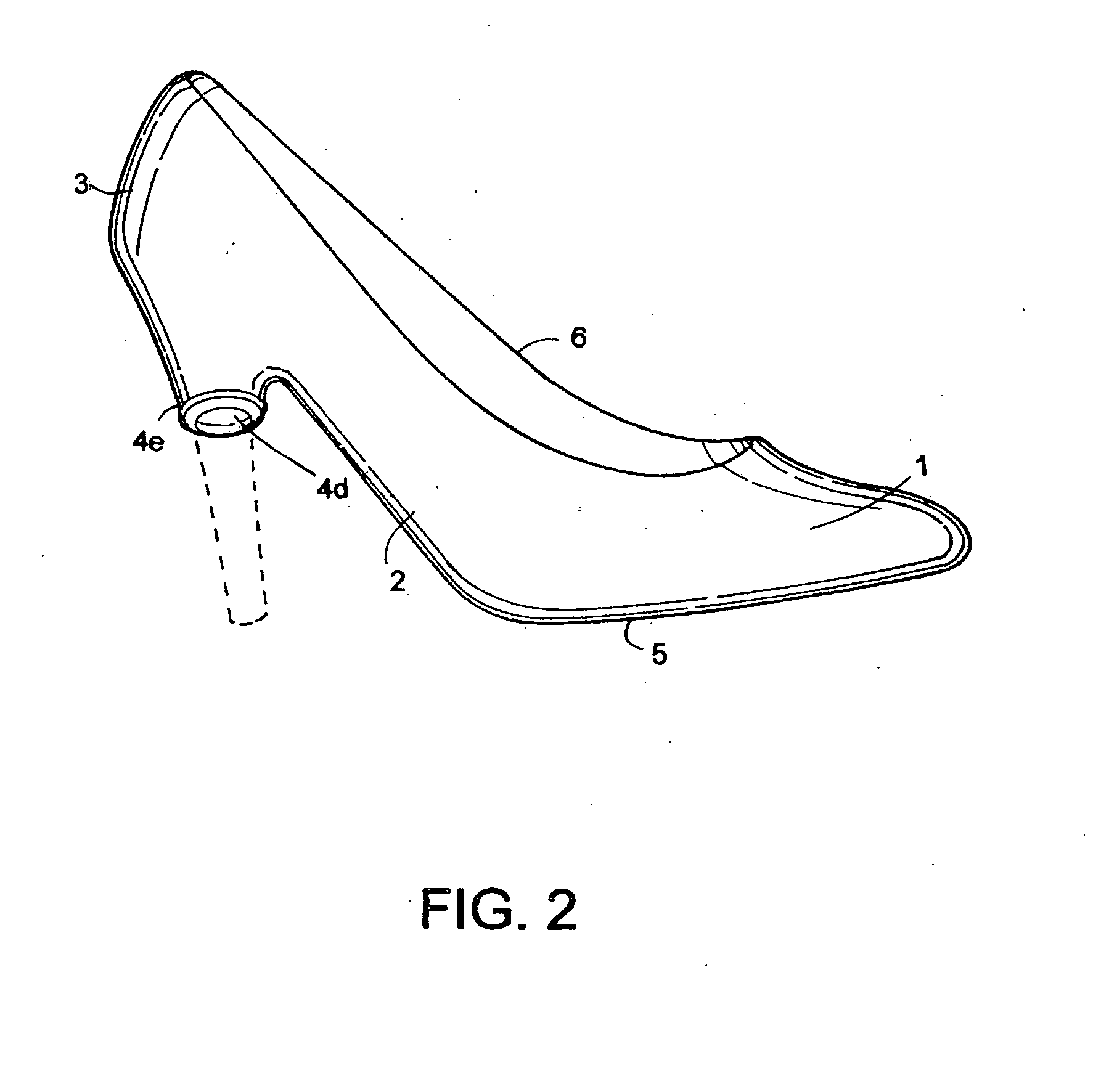

Form fitting cover for high heel shoes

A shoe cover for high heel shoes has a body comprising a waterproof expandable elastic rubber or other flexible material in a shape of a high heel shoe, the body shaped to form fit and cover an outside of the high heel shoe. The body includes an expandable form fitting front portion, two expandable form fitting lateral side portions, a form fitting back portion, a slip-resistant textured form fitting underside portion, a reinforced rim portion, and an expandable form fitting elongate heel portion.

Owner:METZGER JULIETTE

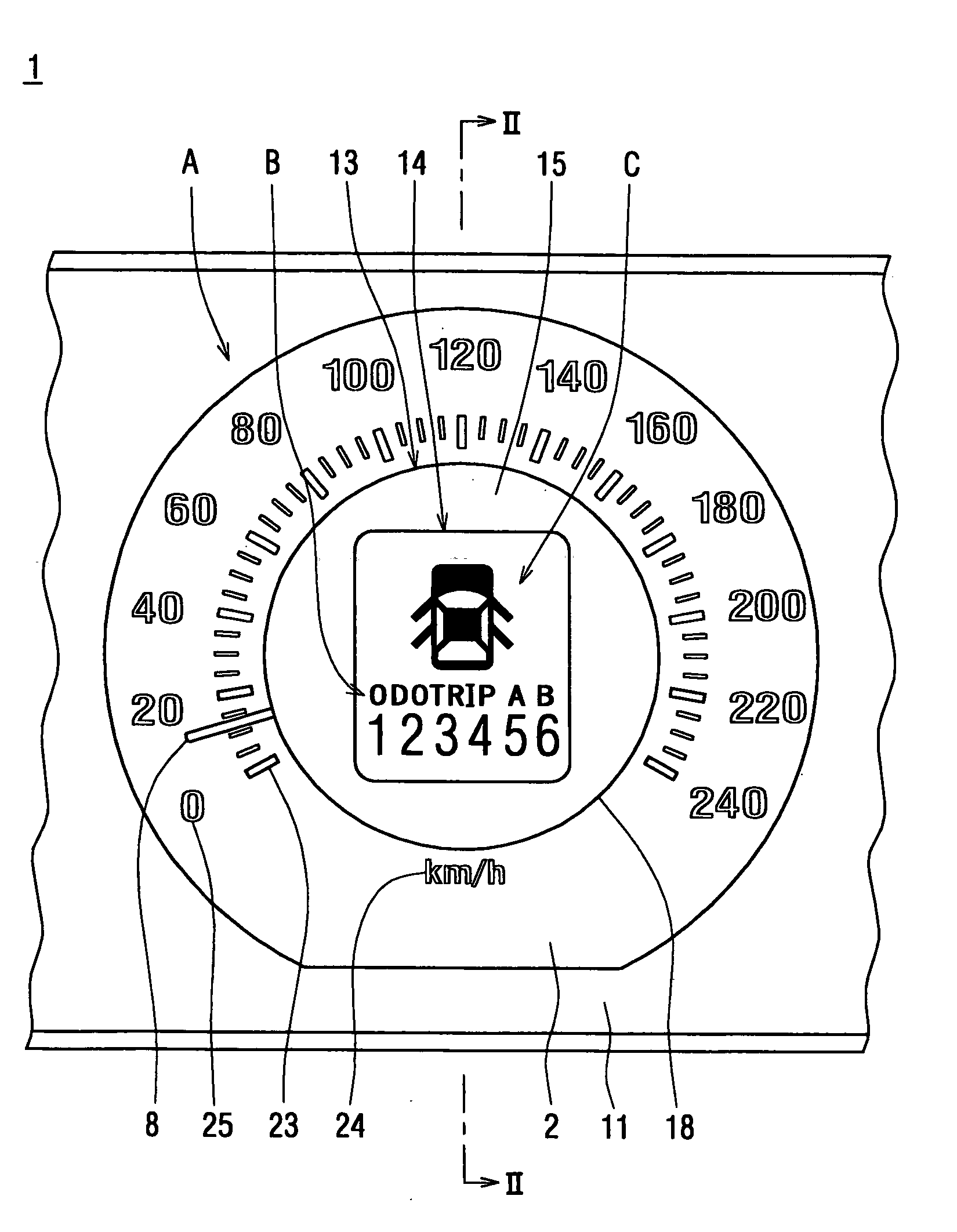

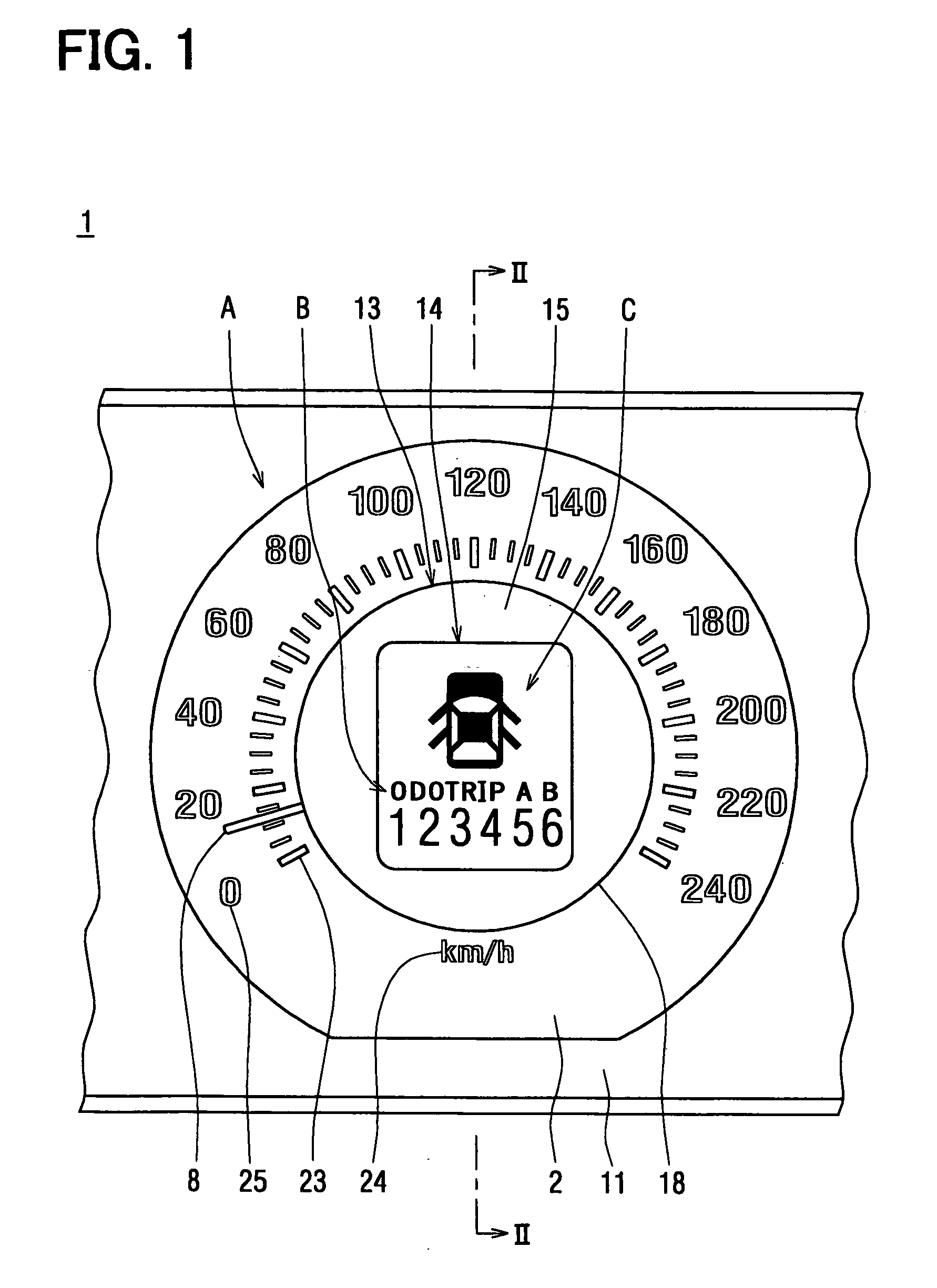

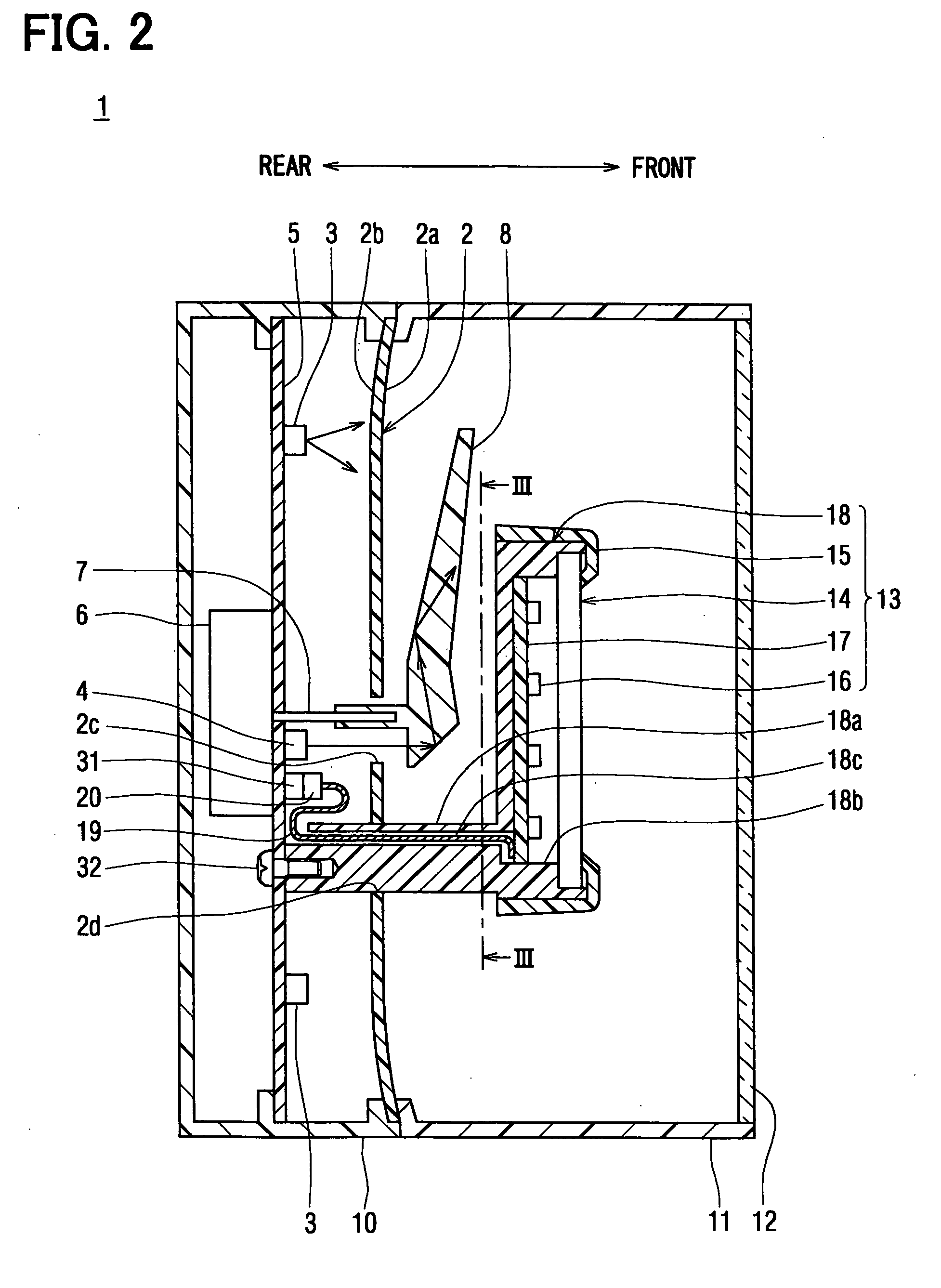

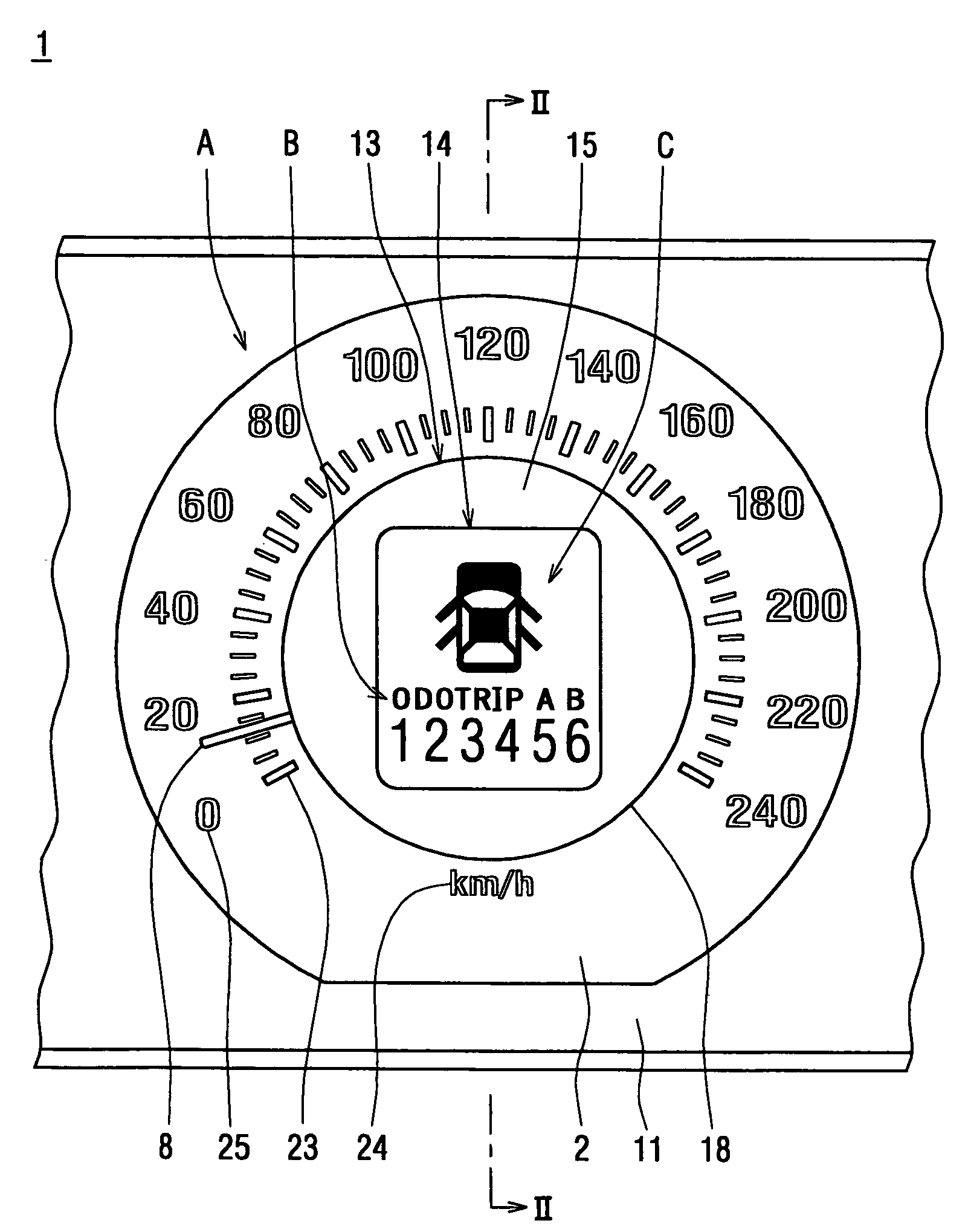

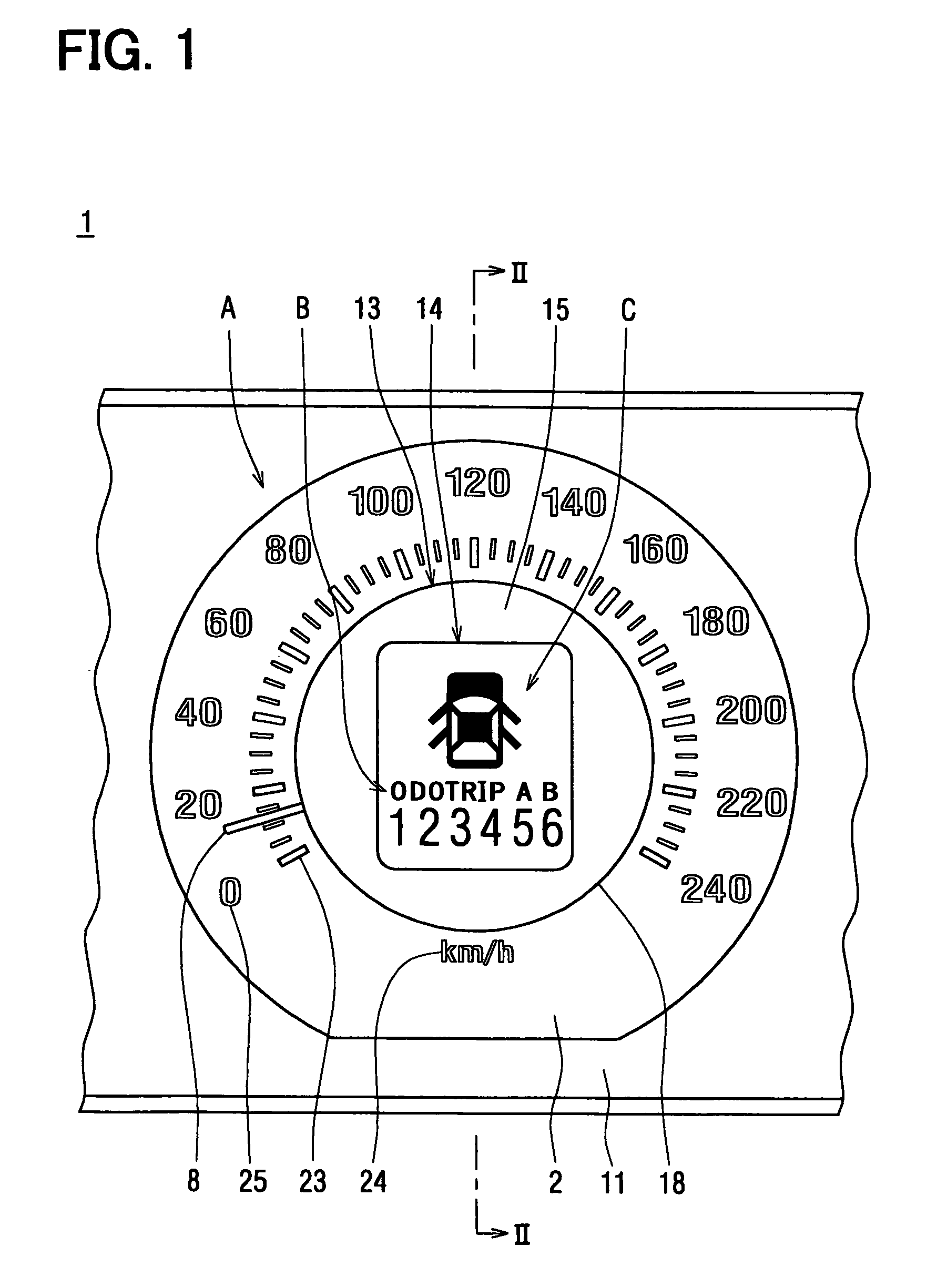

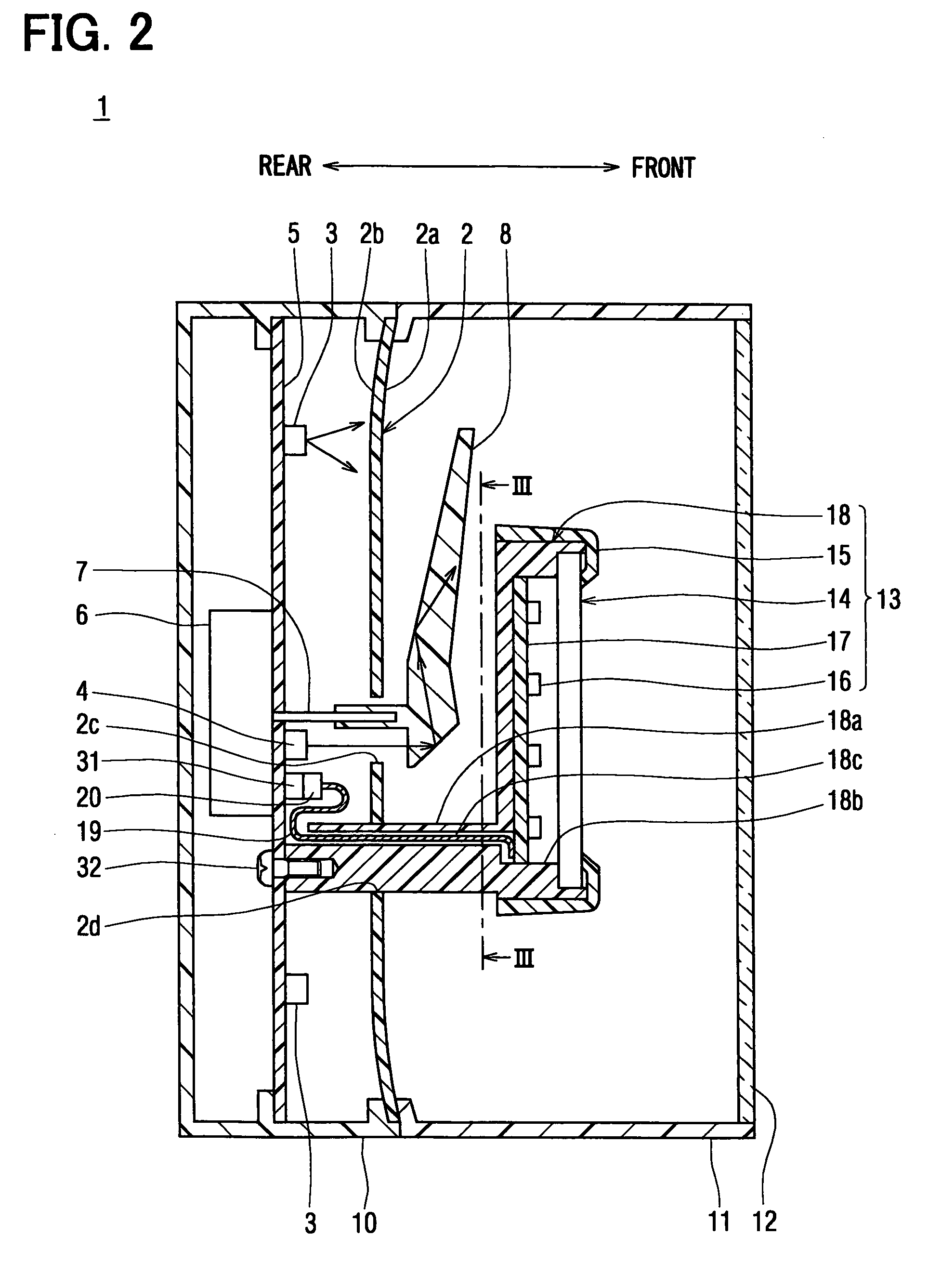

Vehicular display device

InactiveUS20060290486A1High appearance requirementsImprove visibilityAnalog and numerical indicationStatus displaysInstrument clusterPrinted circuit board

A center panel is closer to a viewer in the viewing direction than a speedometer A is and overlapped with the speedometer. The center panel includes an attachment portion extending from a rear side of the center panel towards a dial plate of the speedometer. The center panel is fixed to a printed circuit board of the speedometer via the attachment portion. Accordingly, when a combination meter is viewed, the attachment portion is concealed rearward of the center panel to be invisible. The center panel looks floating separately from the speedometer towards a viewer, which provides a combination meter having excellent visibility and aesthetic cosmetic appearance. Thus, a vehicular display device having excellent visibility and aesthetic cosmetic appearance can be provided by improving a method for supporting a displaying unit on a pointer instrument.

Owner:DENSO CORP +1

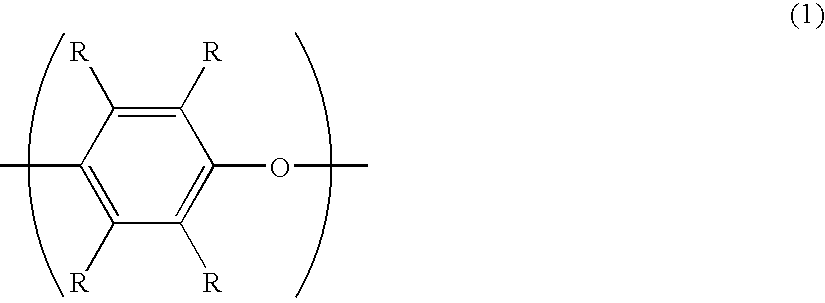

Resin Composition Having Excellent Heat Resistance

InactiveUS20090029138A1Impact resistance can be maintained without a deterioration in fluidityImprove heat resistanceSynthetic resin layered productsConductive materialPolymer sciencePolyamide

Disclosed is a resin composition comprising 10 to 90 parts by weight of a mixture of two or more aromatic polyamides having different intrinsic viscosities [η] and 90 to 10 parts by weight of a polyphenylene ether, both relative to 100 parts by weight of the sum total of the aromatic polyamides and the polyphenylene ether. The resin composition is extremely useful for an automotive exterior panel (e.g., a car fender), an SMT-compatible part, a lamp-related part, and the like.

Owner:ASAHI KASEI CHEM CORP

Paper laminated metal sheet

InactiveUS6277468B1Soft and warm touchHighly aesthetic appearanceSpecial ornamental structuresDwelling equipmentEngineeringMetal sheet

Owner:KOBE STEEL LTD

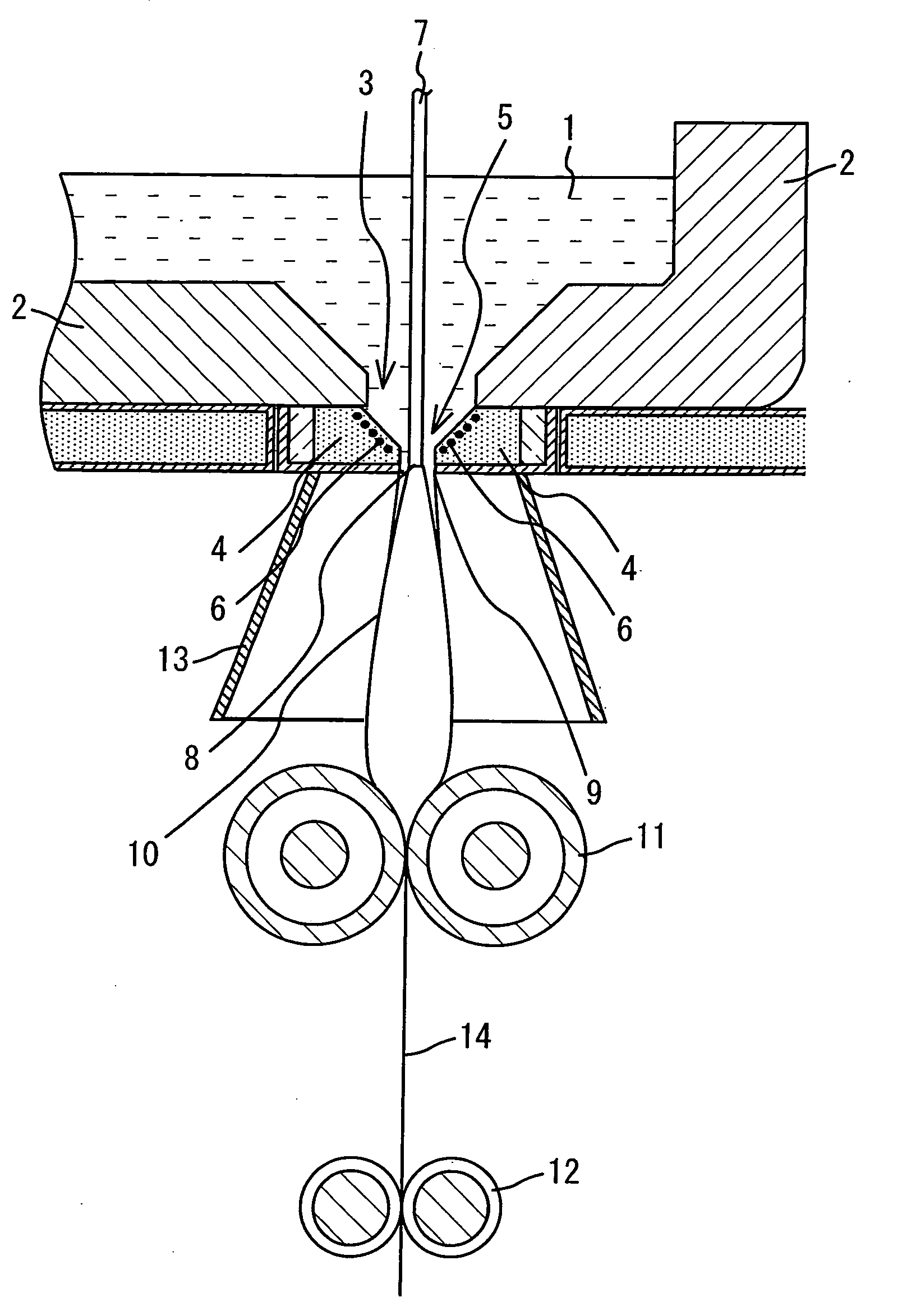

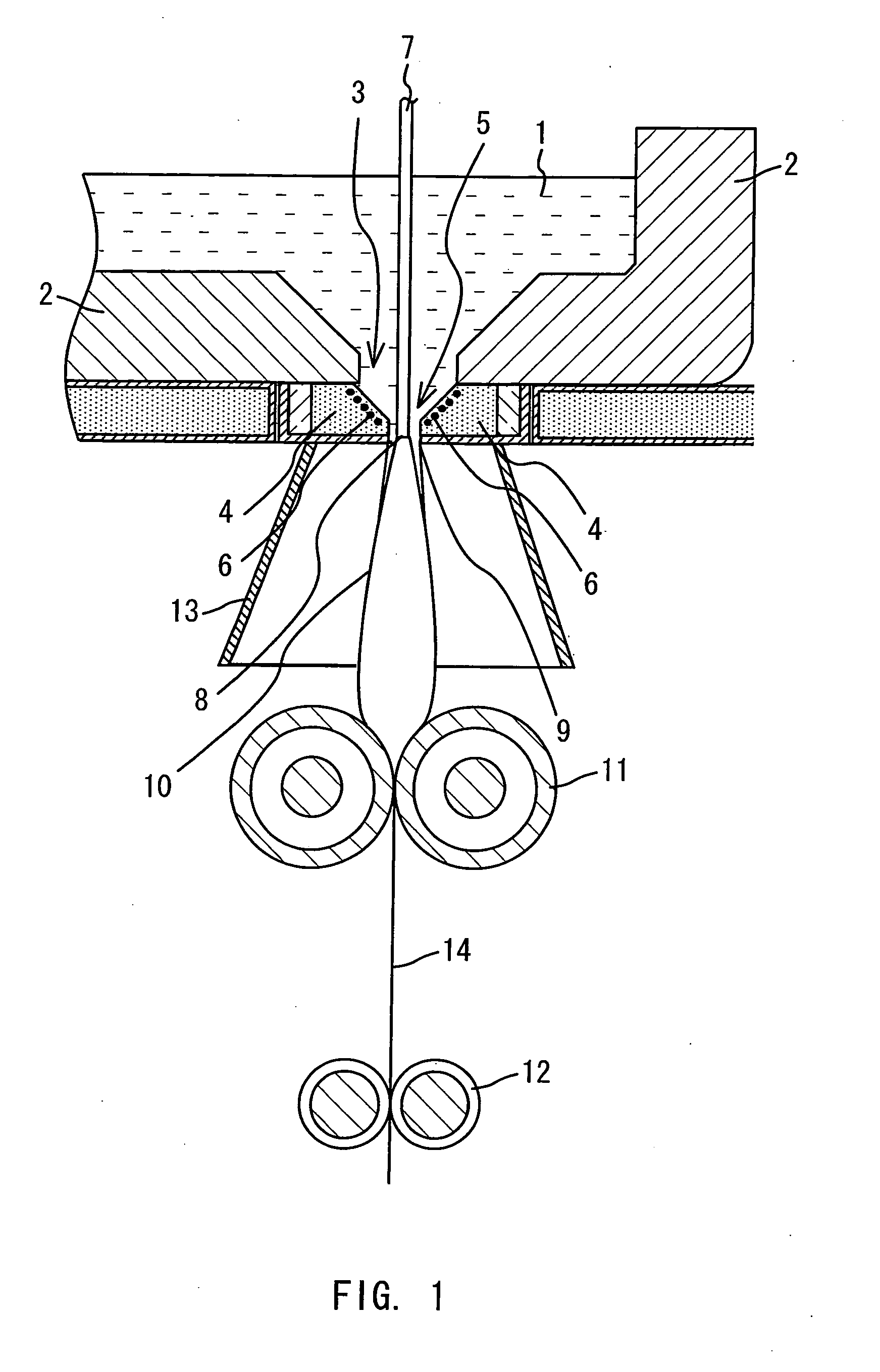

Ink jet recording method, ultraviolet curable ink, and ink jet recording apparatus

ActiveUS20170087876A1Uneven brightnessHigh appearance requirementsDuplicating/marking methodsInksUV curingUltraviolet lights

Provided is an ink jet recording method including: discharging first ultraviolet curable ink of a radical polymerization reaction type which contains a radical photopolymerization initiator and a radical polymerization compound and in which transmittance at a wavelength of 395 nm is equal to or less than 1%, onto a recording medium; and curing the first ultraviolet curable ink which is landed on the recording medium by irradiating the ink with ultraviolet light, in which a light source which initially emits the ultraviolet light in the curing of the ink is an ultraviolet light emitting diode in which peak intensity of the irradiated ultraviolet light is equal to or more than 800 mW / cm2.

Owner:SEIKO EPSON CORP

Metal powder composition

ActiveUS8992659B2High green strengthEnsure durabilityTransportation and packagingMetal-working apparatusPolyolefinOligomer

A metal powder composition including: an iron or iron-based powder composition, and a lubricating combination including a substance A, a substance B, and a substance C; wherein: substance A is a polyolefin, substance B is chosen from a group of saturated and unsaturated fatty acid amides, saturated and unsaturated fatty acid bisamides, saturated fatty alcohols and fatty acid glycerols, and substance C is an amide oligomer having a molecular weight between 500 g / mol and 30 000 g / mol; and wherein the amounts of respective substances A, B and C in weight percent of the iron or iron-based powder composition are: 0.05≦A+B<0.4 wt %, C≧0.3 wt %, A+B+C≦2.0 wt %, and the relation between substances A and B is: B / A>0.5. Also, a method of producing a metal powder composition and a method for producing a green component.

Owner:HOGANAS AB

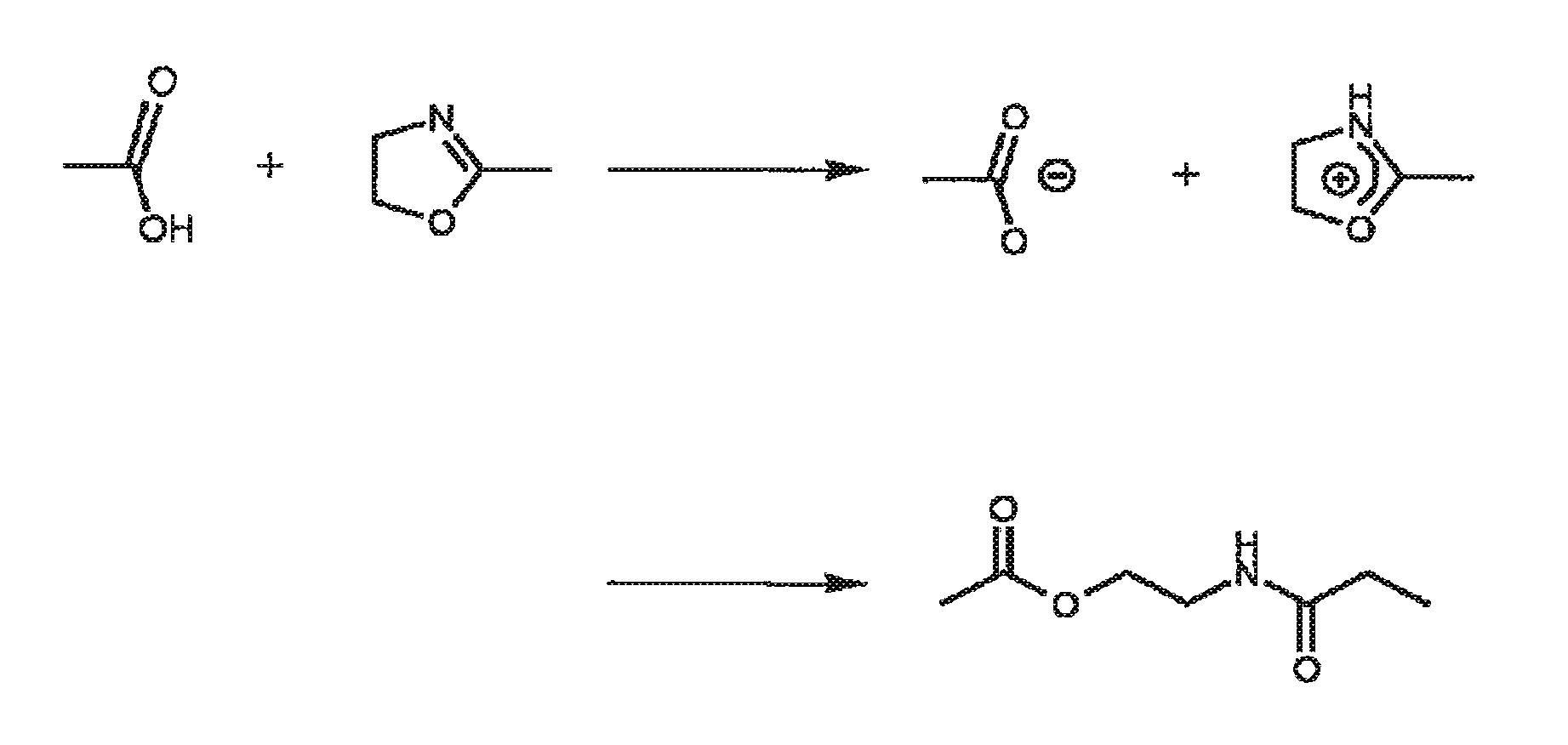

Pearlescent pigment

ActiveUS20100249304A1Convenient lightingHigh appearance requirementsNon-macromolecular adhesive additivesPigment preparation by wet methodsPigmentTitanium dioxide

A pearlescent pigment (100) includes: a flaky substrate (10); a titanium dioxide layer (20) that is formed on the flaky substrate (10); and an oxazoline compound layer (40) that is formed on the titanium dioxide layer (20) with the titanium dioxide layer (20) being interposed between the flaky substrate (10) and the oxazoline compound layer (40), and serves as a top surface of the pearlescent pigment (100).

Owner:NIPPON SHEET GLASS CO LTD

Flaky Particles and Luster Pigment, and Cosmetic, Coating Composition, Resin Composition and Ink Composition Each Containing the Same

ActiveUS20090274735A1Highly lustrous appearanceAvoid clogging the filterCosmetic preparationsMake-upParticle-size distributionMaterials science

Flaky particles of the present invention have a particle size distribution in which a value of D90 / D10 is at least 2.0 but not more than 3.0, a value of D10 is at least 4.7 μm but not more than 25 μm, and a maximum particle diameter is 90 μm or less, where D10 is defined as a particle diameter at which a cumulative volume of particles reaches 10% when counted from the smaller side, and D90 is defined as a particle diameter at which a cumulative volume of particles reaches 90% when counted from the smaller side. A luster pigment of the present invention contains flaky particles and at least one selected from a metallic layer and a metallic oxide layer that are formed on at least a part of the surface of each of the flaky particles. The luster pigment has a particle size distribution in which a value of D90 / D10 is at least 2.0 but not more than 3.0, a value of D10 is at least 4.7 μm but not more than 25 μm, and a maximum particle diameter is 90 μm or less, where D10 is defined as a particle diameter at which a cumulative volume of particles reaches 10% when counted from the smaller side, and D90 is defined as a particle diameter at which a cumulative volume of particles reaches 90% when counted from the smaller side.

Owner:NIPPON SHEET GLASS CO LTD

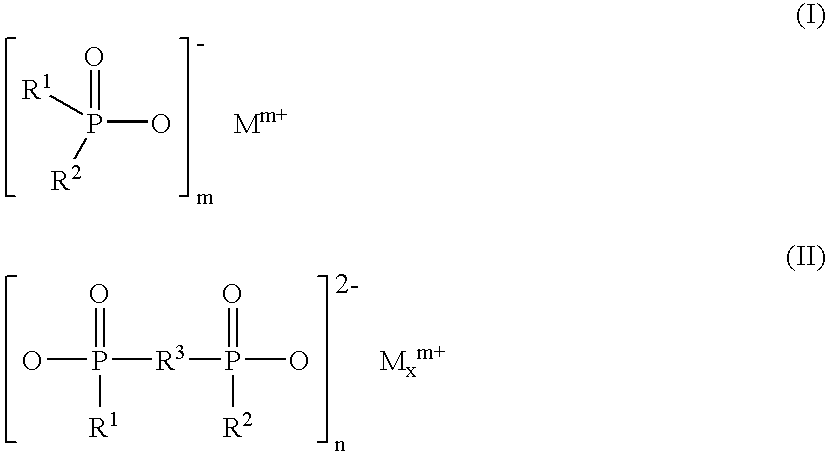

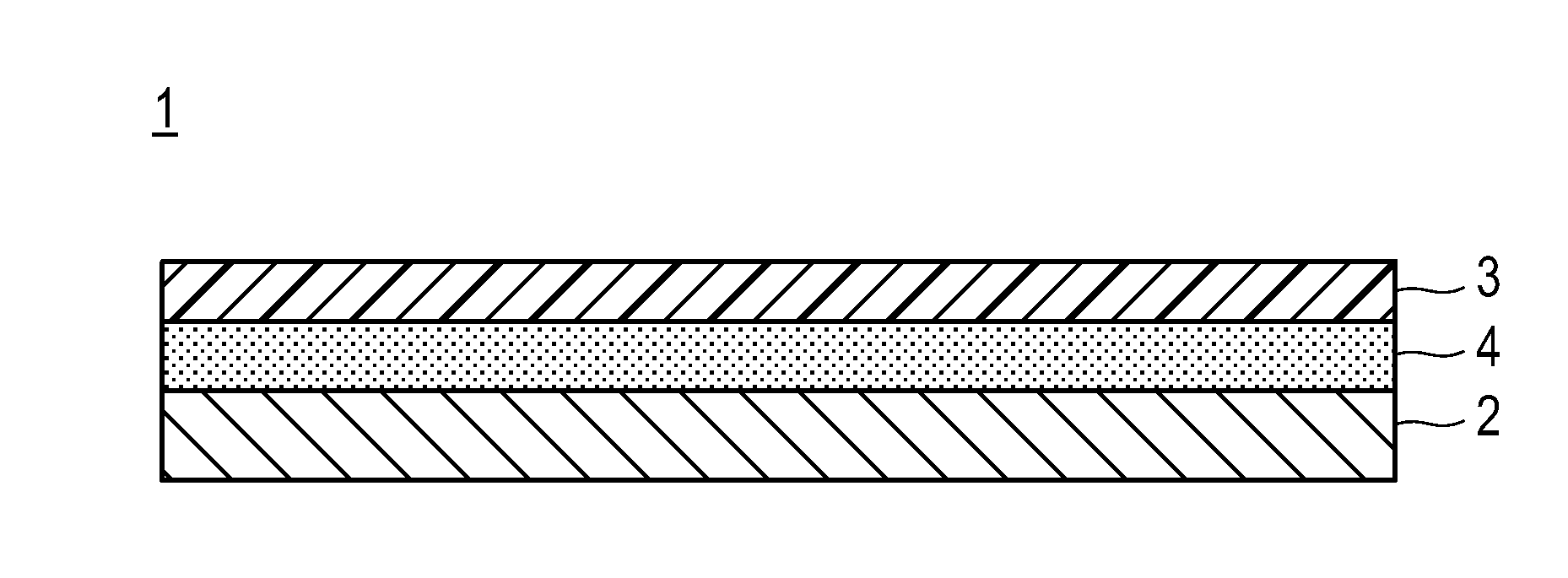

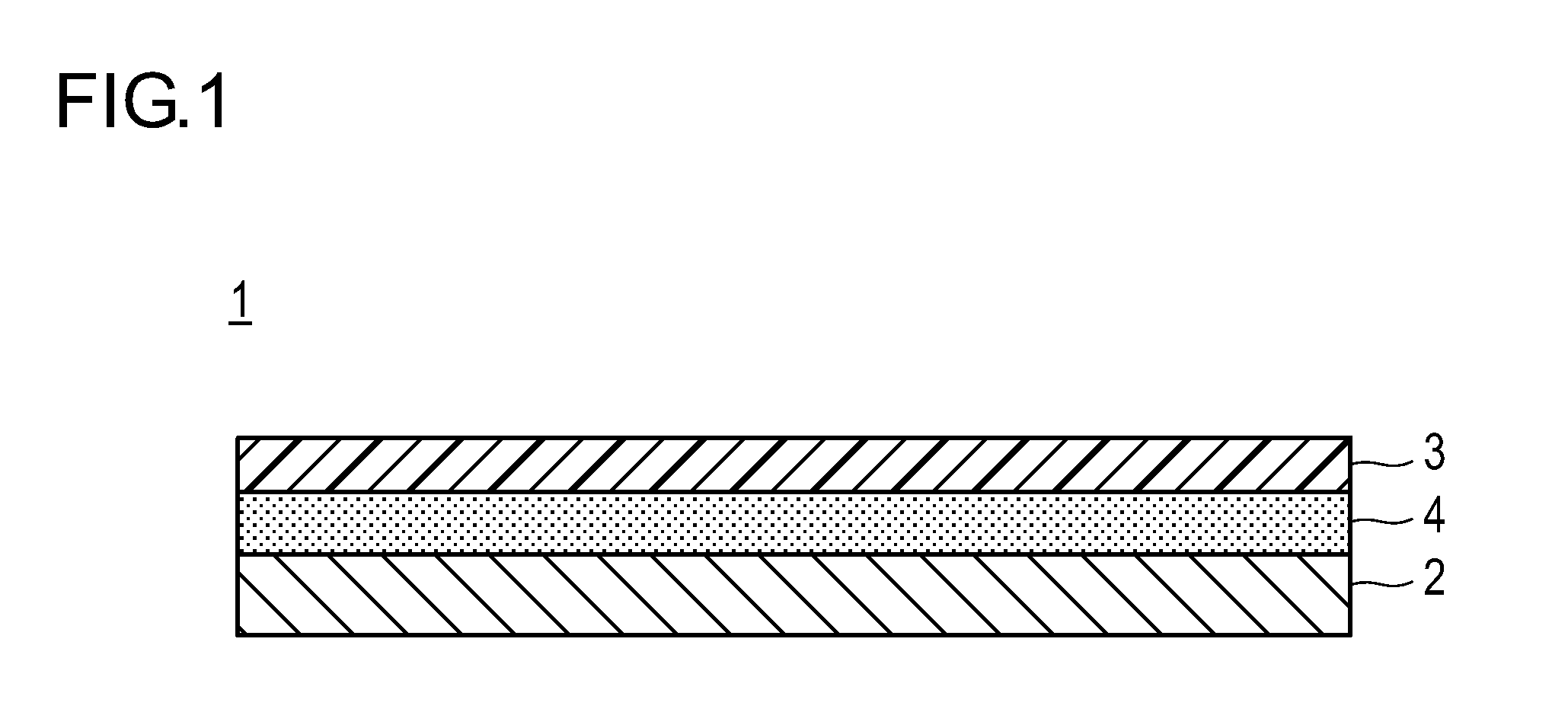

Photocurable sheet-type adhesive composition for optical use

ActiveUS20150024218A1Reduced stabilityHigh appearance requirementsImpression capsNon-macromolecular adhesive additivesMethacrylatePolymer science

An object of the present invention is to provide a photocurable sheet-type adhesive composition for optical use, which is used for bonding cover glass and a touch panel, a touch panel and a display module, or the like, and has high appearance reliability and storage stability even under high temperature and high humidity.The present invention is a photocurable sheet-shape adhesive for optical use, which contains the following components (A) to (D): (A) 100 parts by mass of a urethane (meth)acrylate oligomer having a weight average molecular weight of 20,000 to 100,000; (B) 3 to 70 parts by mass of a phenoxy resin having a glass transition temperature of 50 to 120° C.; (C) 0.1 to 10 parts by mass of a photopolymerization initiator; and (D) 1 to 50 parts by mass of a (meth)acrylate monomer which has 8 to 30 repeated blocks having an ether linkage in the molecule and containing at least one (meth)acryloyl group in the molecule.

Owner:THREEBOND FINE CHEM CO LTD

Decorative part

InactiveUS20100255338A1Improvement in finishing color toneIncrease brightnessVacuum evaporation coatingSputtering coatingGold colourCarbide

[Subject] To provide a decorative part having a hardening layer containing Au on the surface, particularly a gold colored decorative part having gloss and color tone inherent in gold, high brightness and high quality.[Means for Problem the Subject] The decorative part of the present invention comprises a substrate and, superimposed on the substrate, a hardening layer wherein the hardening layer comprises a primary layer comprising a nitride, a carbide or a carbonitride of one or two or more metals selected from Ti, Zr and Hf, a finishing layer comprising Au or an Au alloy having an arbitrary composition such as an Au—Ni alloy, an Au—Cu—Pd alloy etc. and, disposed between the primary layer and the finishing layer, a reflecting layer comprising a metal having a higher reflectance than one constituting the finishing layer, such as Ru, Pd, Rh, Ag, Os, Ir pr Pt.Thus, the gold colored decorative part having gloss and color tone inherent in gold, high brightness and high quality can be efficiently prepared.

Owner:CITIZEN WATCH CO LTD

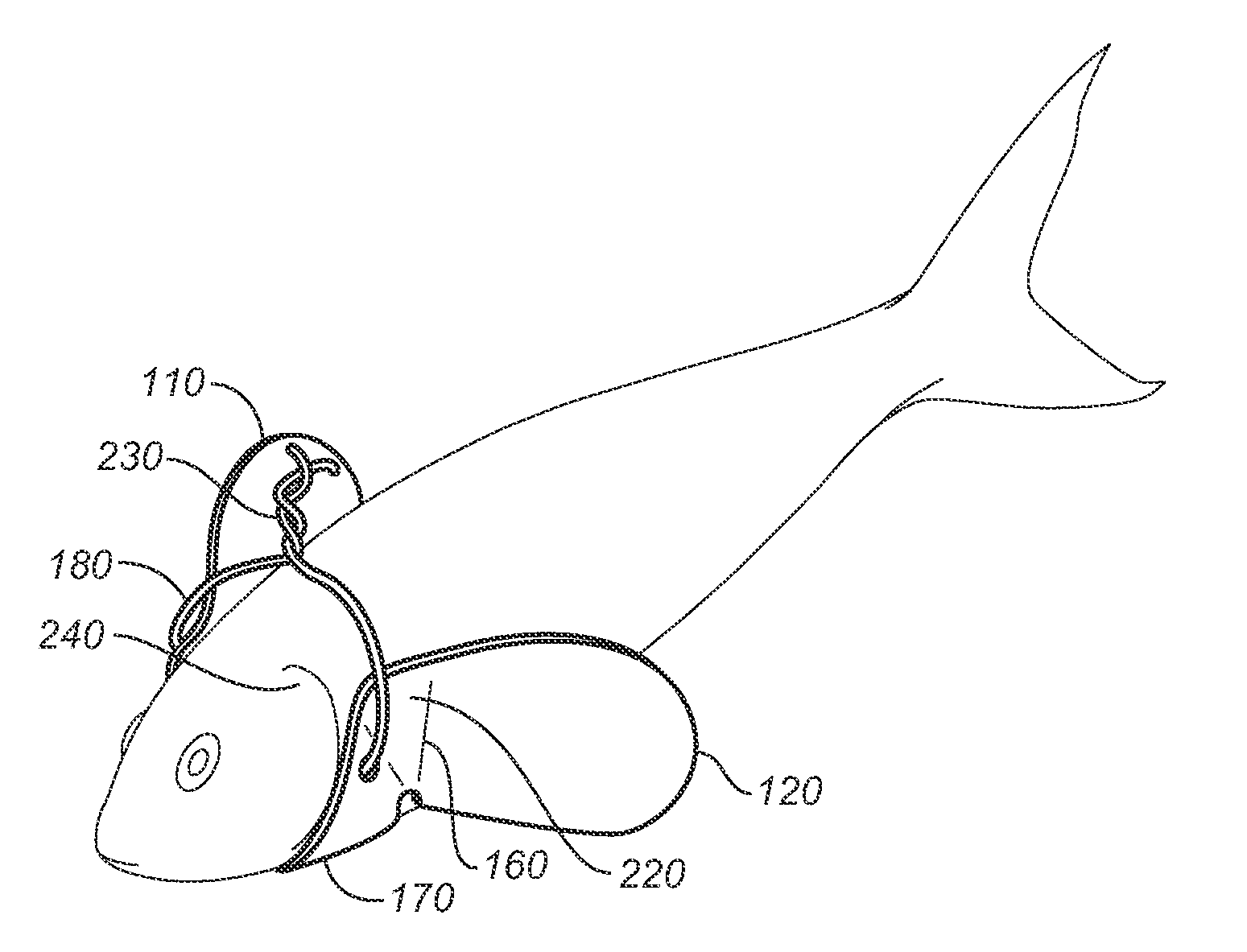

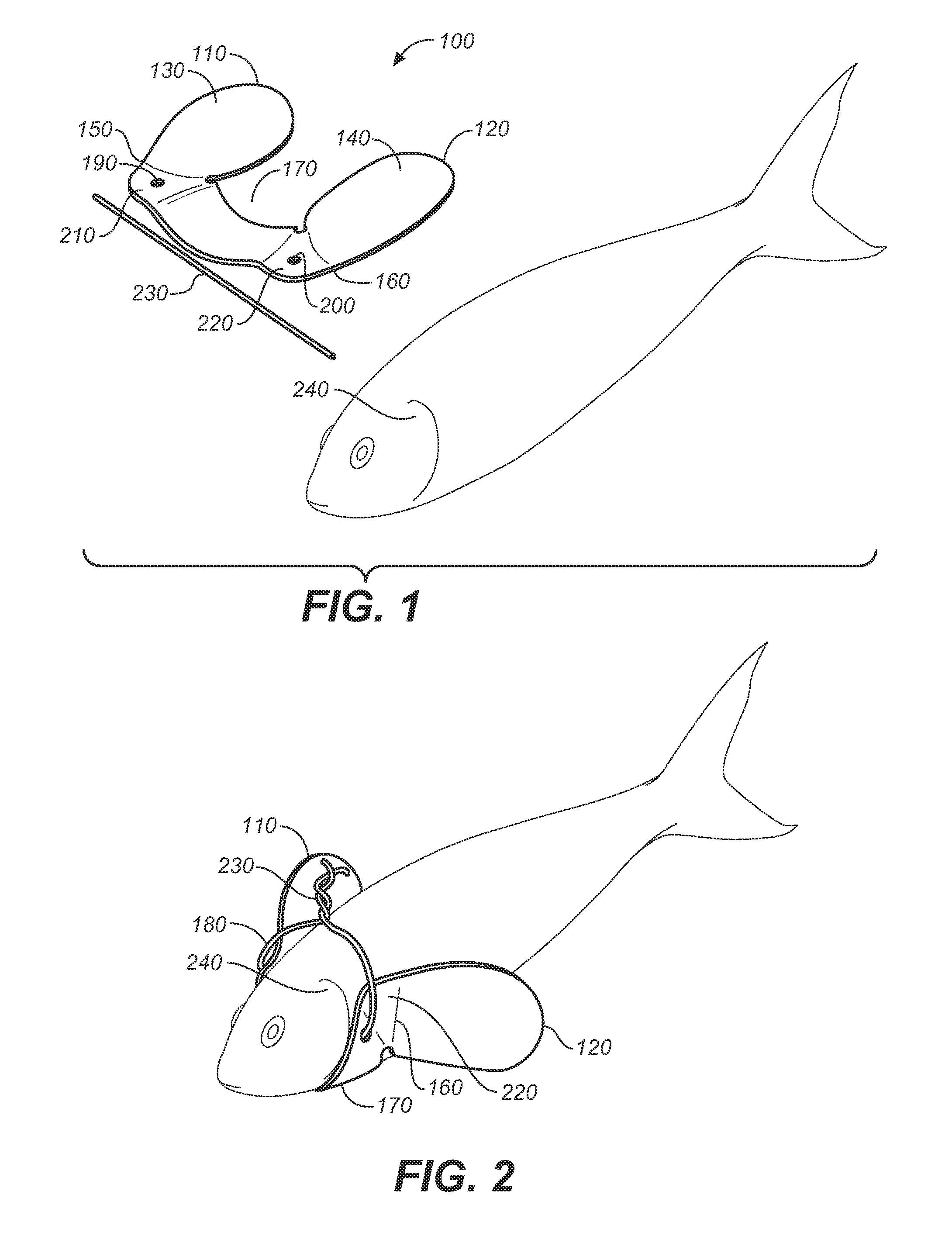

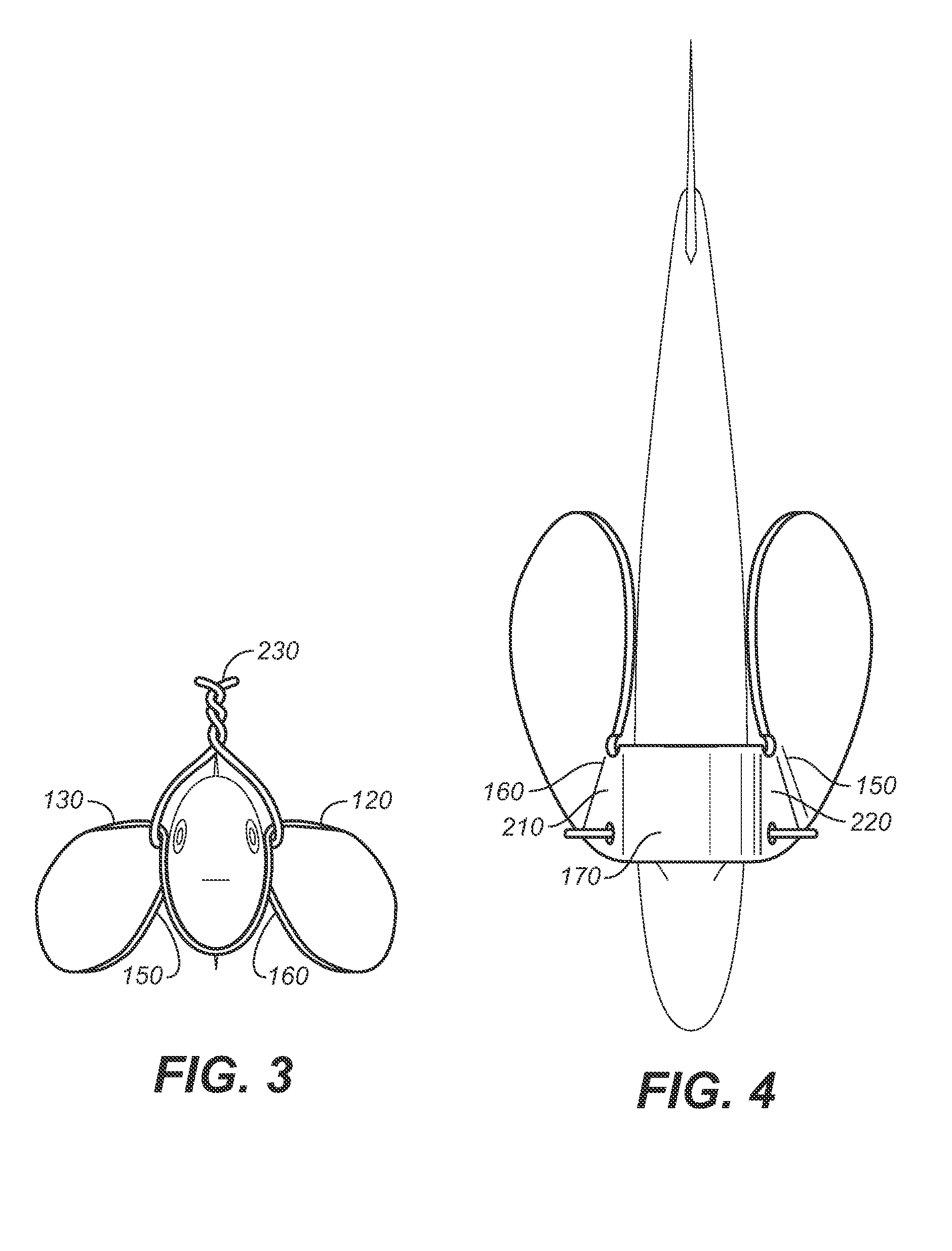

Live and dead bait spinner apparatus

A fishing lure and spinner apparatus that includes first and second fin elements, a flexible medial band disposed between the first and second fin elements, first and second corner portions, one each disposed between and connecting the first and second adjustable fin elements to the medial band, first and second adjustment creases, one each interposed between the flexible medial band and the first and second adjustable fin elements, and a fastener assembly to secure said apparatus to a live or dead bait fish.

Owner:HUNTER DARREN

Vehicular display device

InactiveUS7482915B2High appearance requirementsImprove visibilityAnalog and numerical indicationStatus displaysVisibilityDisplay device

A center panel is closer to a viewer in the viewing direction than a speedometer A is and overlapped with the speedometer. The center panel includes an attachment portion extending from a rear side of the center panel towards a dial plate of the speedometer. The center panel is fixed to a printed circuit board of the speedometer via the attachment portion. Accordingly, when a combination meter is viewed, the attachment portion is concealed rearward of the center panel to be invisible. The center panel looks floating separately from the speedometer towards a viewer, which provides a combination meter having excellent visibility and aesthetic cosmetic appearance. Thus, a vehicular display device having excellent visibility and aesthetic cosmetic appearance can be provided by improving a method for supporting a displaying unit on a pointer instrument.

Owner:DENSO CORP +1

Multi-color illuminated sign

InactiveUS7220019B2High appearance requirementsNon-electric lightingPoint-like light sourceVisibilityEffect light

The multi-color illuminated sign displays an indicia or house address number in changing sequence of colors. The back lighting is provided by three groups of plurality of light emitting diodes. One group of the light emitting diodes is operative to generate a primary blue light, a second group of light emitting diodes is operative to generate a primary green light, and a third group of light emitting diodes is operative to generate a primary red light. Varying combinations of these primary lights produces a plurality of color back lighting which are reflected and refracted by various reflective and refractive patterns to enhance the visibility and aesthetic appearance of the indicia.

Owner:CHEUNG TIN FU +1

Thermoplastic Resin Composition

A purpose of the invention is to provide a thermoplastic resin composition which enhances crystallization during molding, has high thermal deformation temperature, has high rigidity, induces less pealing on the molding surface, and gives excellent appearance, thus being preferably used as the facility parts of automobiles, and those of electric and electronics products. The (A) 100 parts by weight of a polyamide resin structured by the following monomers (1) and (2) is blended with (B) 5 to 100 parts by weight of a liquid crystalline polyester amide resin:(1) a diamine component containing an aliphatic diamine component unit having 4 to 12 carbon atoms arranged in straight chain and / or an aliphatic diamine component unit having 4 to 12 carbon atoms having side chain, and a derivative thereof; and(2) a dicarboxylic acid component containing 40 to 100% by mole of terephthalic acid component unit and 0 to 60% by mole of isophthalic acid component unit, and a derivative thereof.

Owner:POLYPLASTICS CO LTD +1

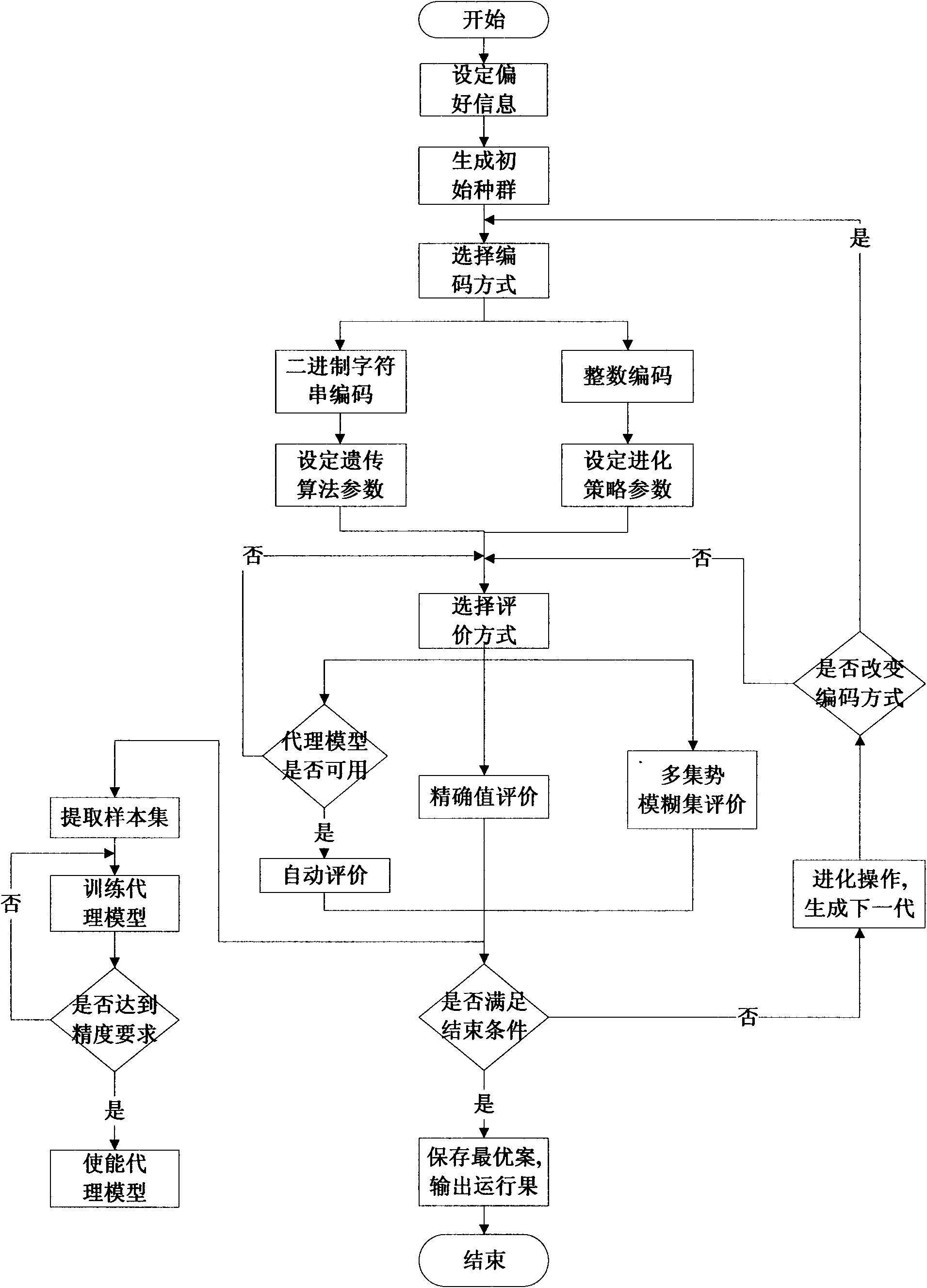

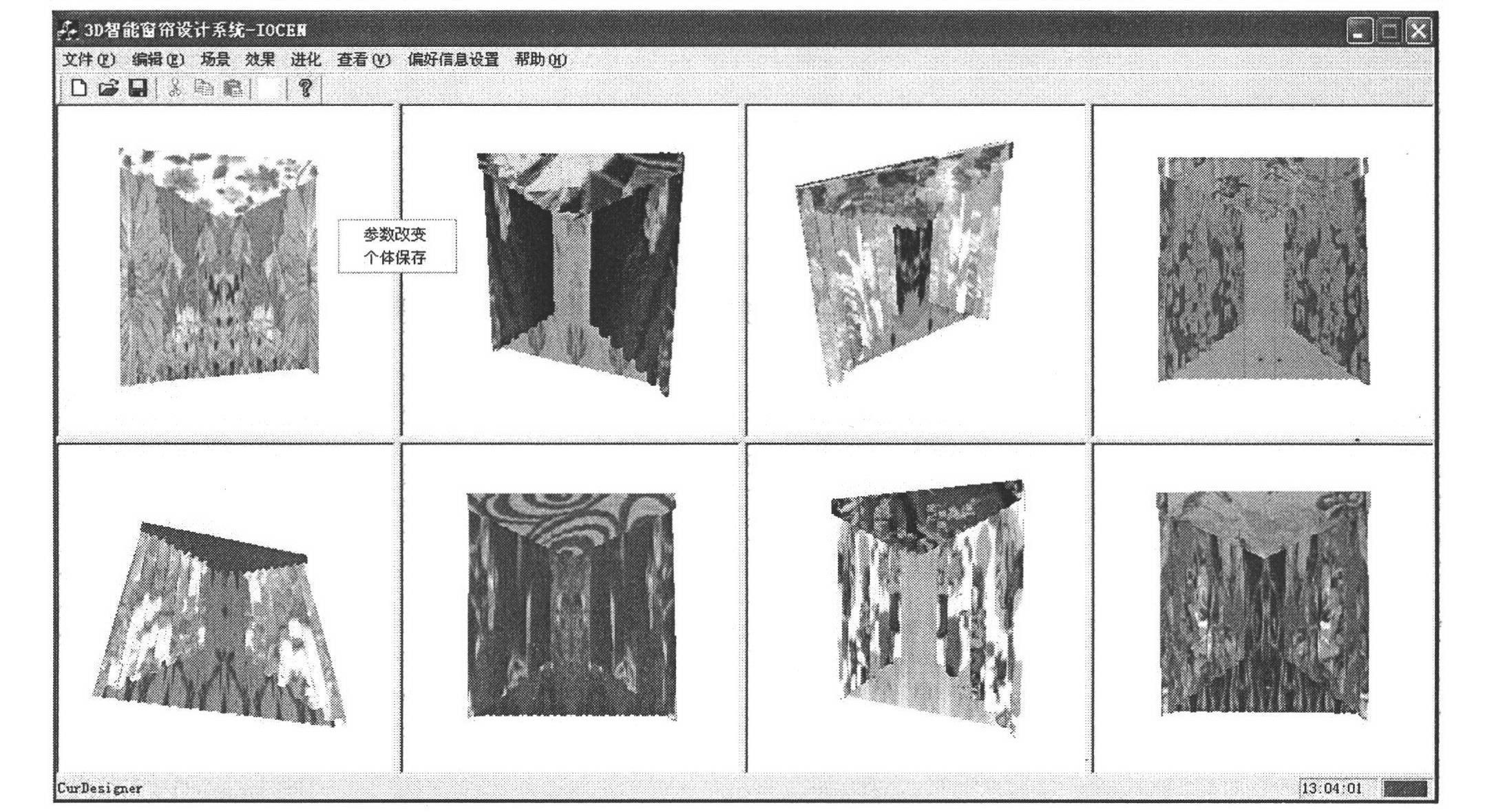

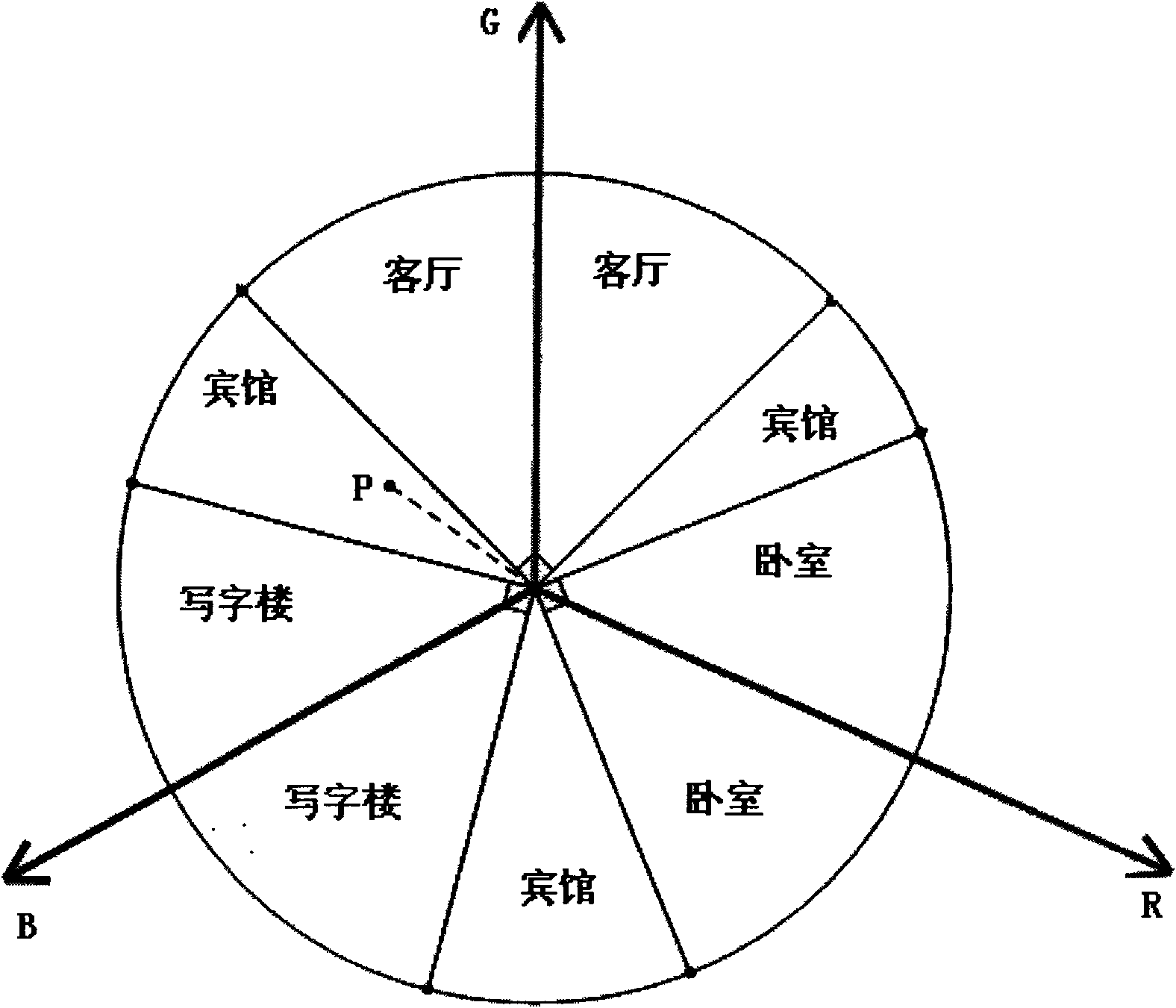

Interactive evolution optimization method for curtain design

InactiveCN102163249AEvolution fineEvolutionary EfficiencySpecial data processing applicationsInteractive evolutionHuman–robot interaction

The invention discloses an interactive evolution optimization method for curtain design, which guides user to look for the preferred design scheme and specifically comprises the steps of: (1) before evolution begins, allowing a user to set fuzzy preference information, including the degree of influence of using occasion, style and preference information of curtain on individuals, and generating aparticular initial population therefrom by a computer; (2) providing a plurality of individual evaluation ways for the user in the process of human-computer interaction, including multi-set type fuzzy set evaluation, exact value evaluation and automatic evaluation, and designing selection methods of different evaluation ways; and (3) in the process of evolution, supporting the use of different coding manners and corresponding evolution algorithms between different evolution generations in order to facilitate the search of the user for curtain schemes in different areas. While the above methodis provided, the corresponding system is hereby developed. The method of the invention aims at inspiring the user creation and enhancing the efficiency of designing curtain product in order to raise the market competitiveness of curtain.

Owner:CHINA UNIV OF MINING & TECH

Method and apparatus for exterior surface treatment of insulated structural steel panels

ActiveUS8458907B1Reduce glossHighly diverse textured appearanceLamination ancillary operationsLayered product treatmentSheet steelHigh pressure

A method for providing a natural stucco appearance for a steel structural panel comprises providing a steel sheet and coating the exterior surface with a low gloss protective coating, and then embossing the exterior surface with a low relief pattern. The steel sheet is then embossed with a second, higher relief pattern under high pressure. The double embossment together with the low gloss coating achieves a natural stucco appearance.

Owner:PRE INSULATED METAL TECH

Color evaluation apparatus and method

InactiveUS20050237553A1High correlationImprove color matching precisionDigitally marking record carriersRadiation pyrometryCalculation errorLength wave

A spectral distribution error evaluation apparatus is used to evaluate precision of color matching between evaluation and target colors. A first weighting function generator generates a first weighting function on the basis of color matching functions, wavelength characteristics which are independent of a light source of the target color, and visual characteristics which depend on wavelengths. A second weighting function generator generates a second weighting function on the basis of light source information of selected light sources. A difference calculator calculates error values between the evaluation and target colors for respective frequencies. An evaluation value calculator applies the first and second weighting functions to the error values, and calculates the sum total of the error values as an evaluation value. In this way, a precision evaluation value which has high correlation with actual color appearance and is used to improve the color matching precision can be calculated independently of a change in condition such as a light source or the like.

Owner:CANON KK

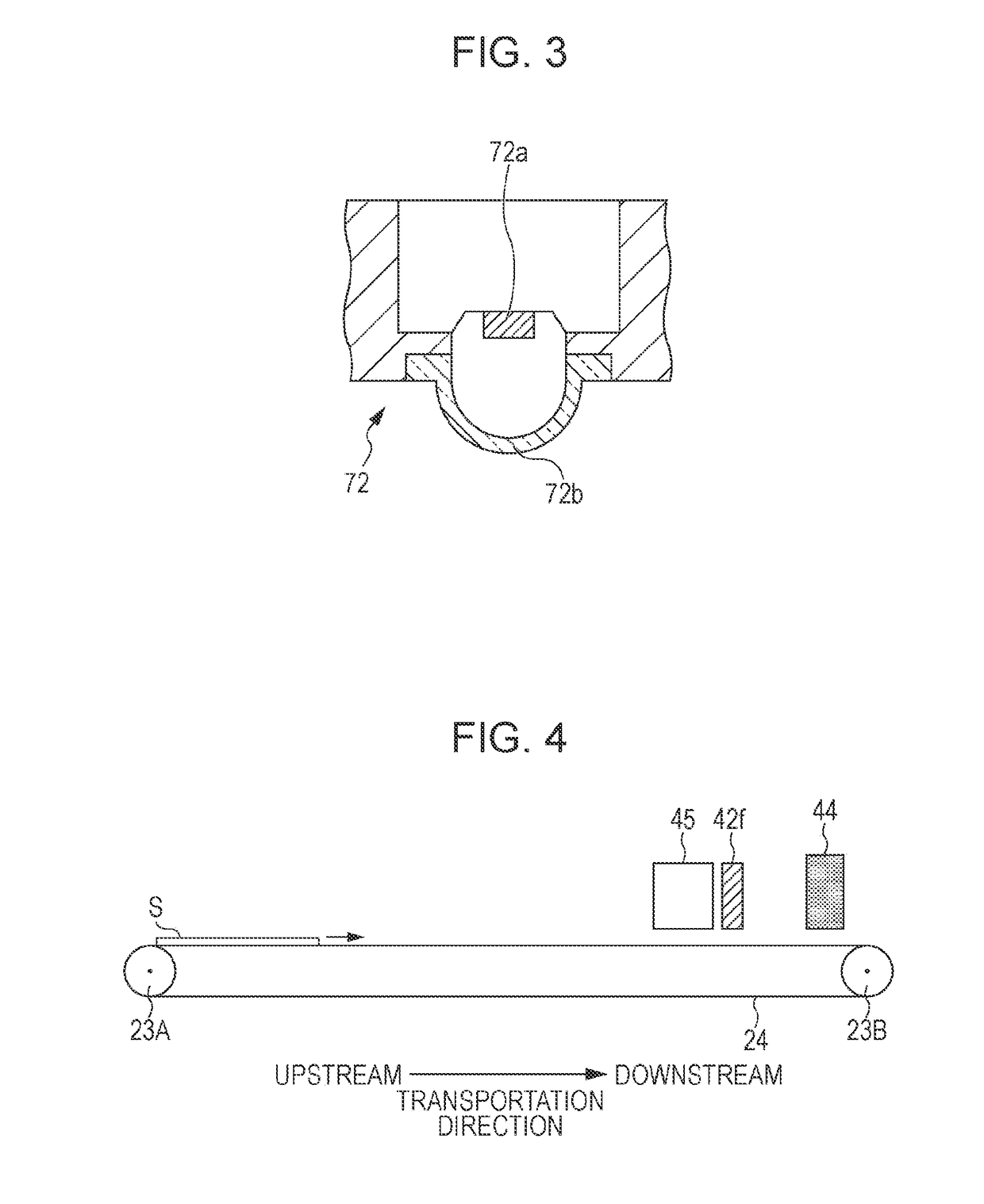

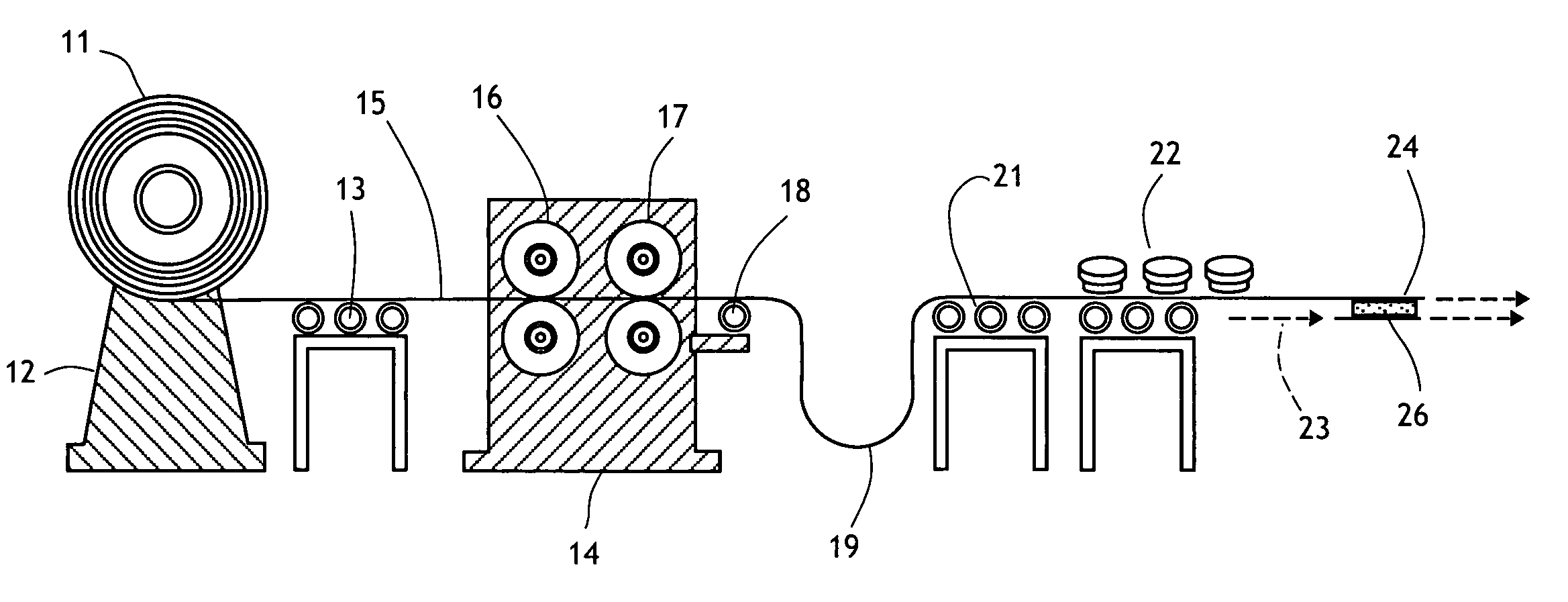

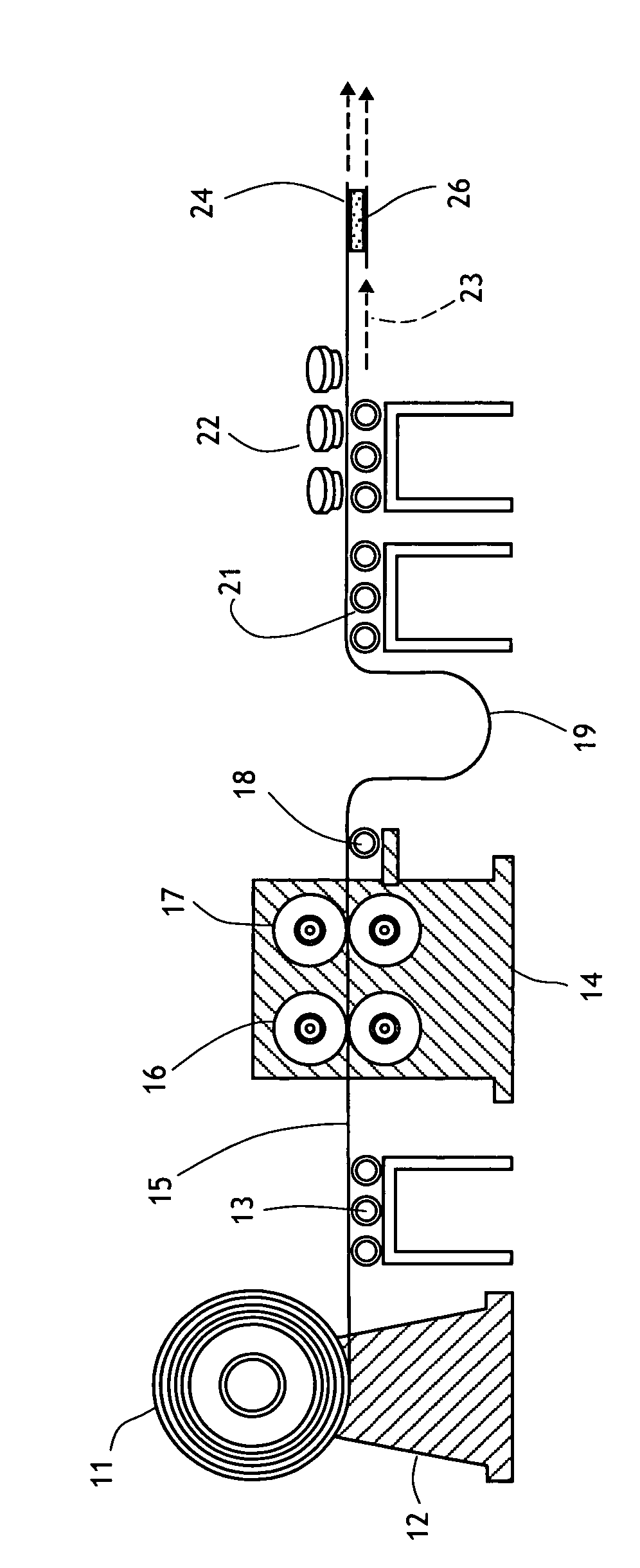

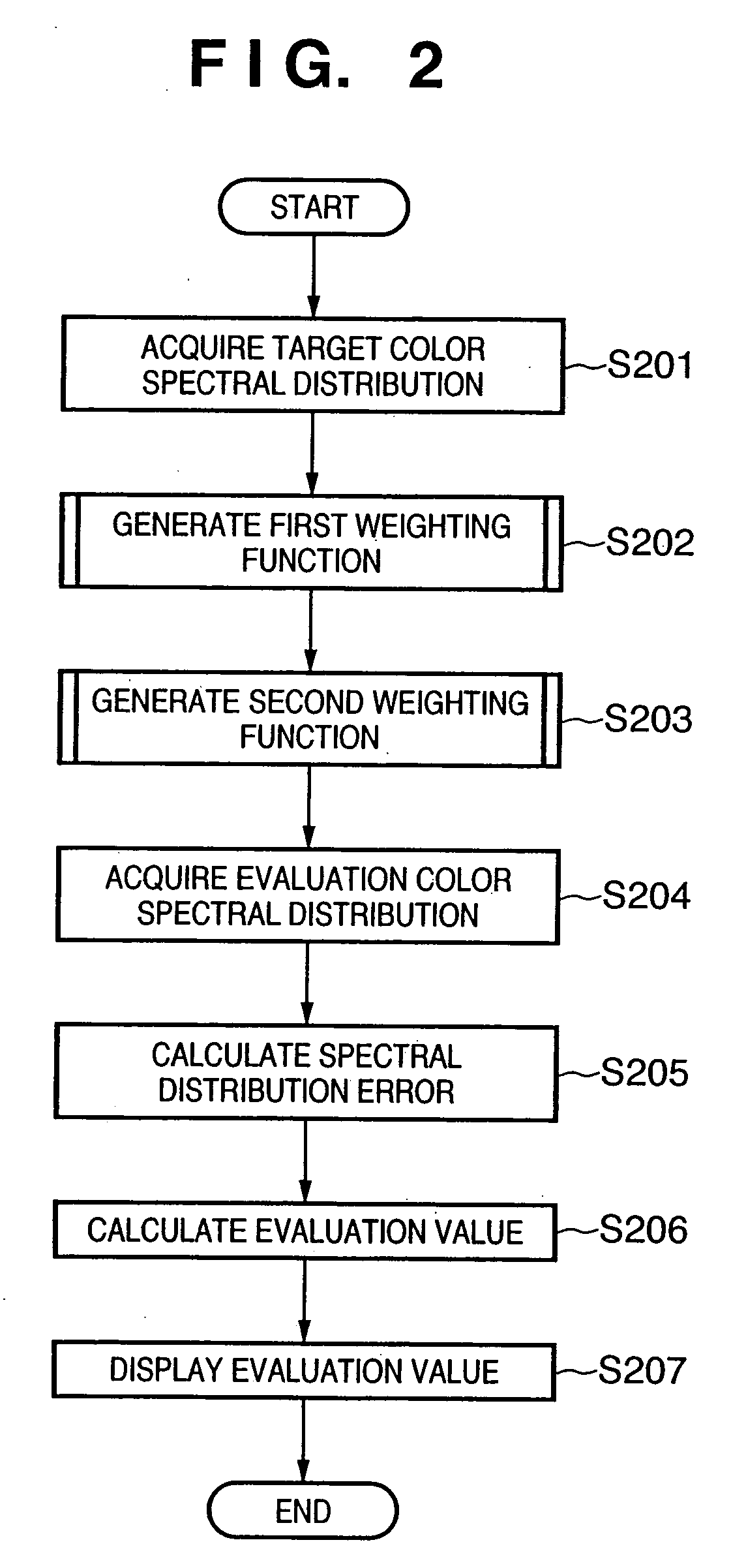

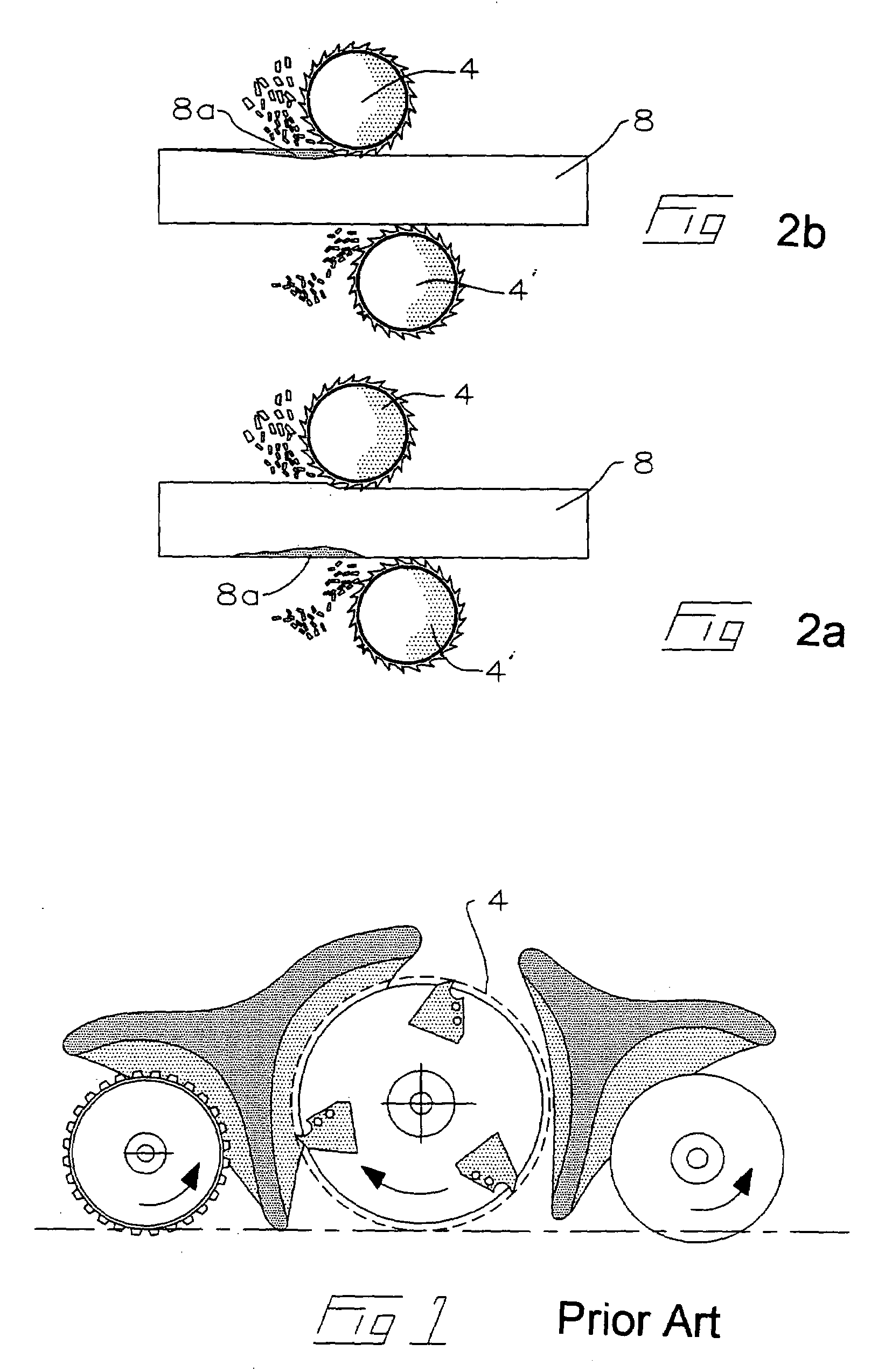

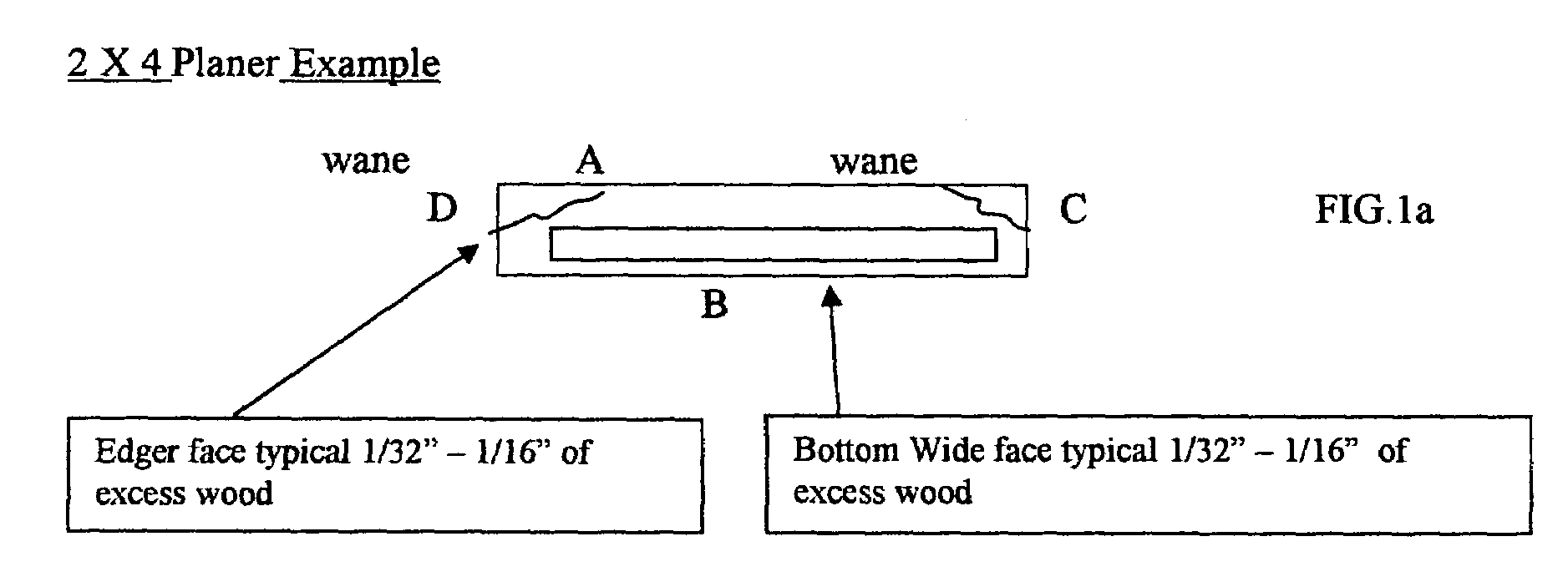

Optimized planer feeder system and method

ActiveUS7171278B2Promote recoveryImprove throughputSawing apparatusMulti-purpose machinesEngineeringMechanical engineering

An apparatus for optimizing orientation of a workpiece in a planermill for feeding of the workpiece into a planer includes an infeed to the planer, a workpiece turner for selectively turning the workpiece end-for-end upstream of the planer on the infeed a workpiece flipper for selectively flipping the workpiece one hundred eighty degrees about a longitudinal axis of the workpiece upstream of the planer on the infeed, a scanner on the infeed upstream of the workpiece turner and workpiece flipper for detecting defects on the workpiece, a processor cooperating with the scanner, the workpiece turner and the workpiece flipper for optimizing the orientation of the workpiece relative to status and actively translatable cutterheads in the planer.

Owner:USNRKOCKUMS CANCAR

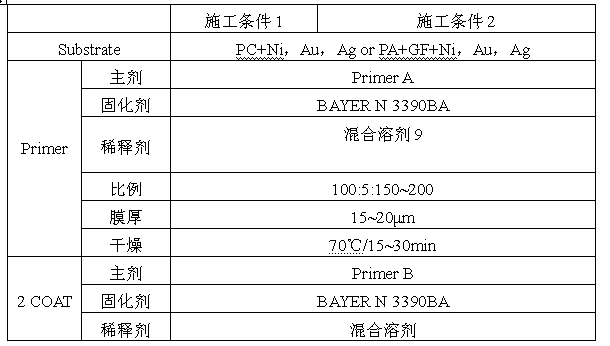

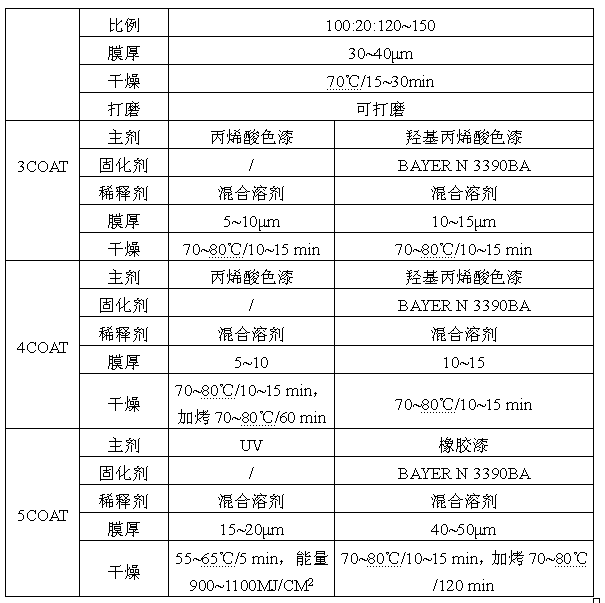

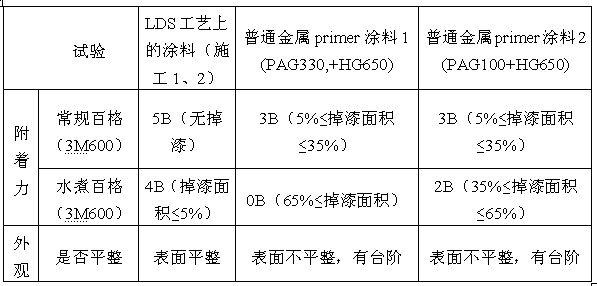

Coating for LDS (Laser Direct Structuring) plastic component and preparation technology thereof

ActiveCN103013326AImprove protectionEnhanced Service Life RequirementsLiquid surface applicatorsPolyurea/polyurethane coatingsPolymer scienceMetallic coating

The invention provides a coating for an LDS (Laser Direct Structuring) plastic component. The coating includes two coatings, namely, a primer A and a primer B which comprise the raw materials composed of the following components in parts by weight: 30 to 60 parts of resin, 2 to 4 parts of carbon black or 15 to 20 parts of titanium dioxide, 0.2 to 0.5 part of crylic acid flatting agent, 1 to 3 parts of wetting dispersant, 1 to 2 parts of adhesion promoter, 10 to 20 parts of talcum powder, 10 to 30 parts of esters solvent, and 5 to 15 parts of benzene solvent. The coating can be sprayed to form a plurality of films with thickness up to 150 microns, and steps on plastic and metal films of a formed component can be filled and covered, thus nice appearance can be brought, and the requirement of performances can be met.

Owner:卡秀万辉(无锡)高新材料有限公司

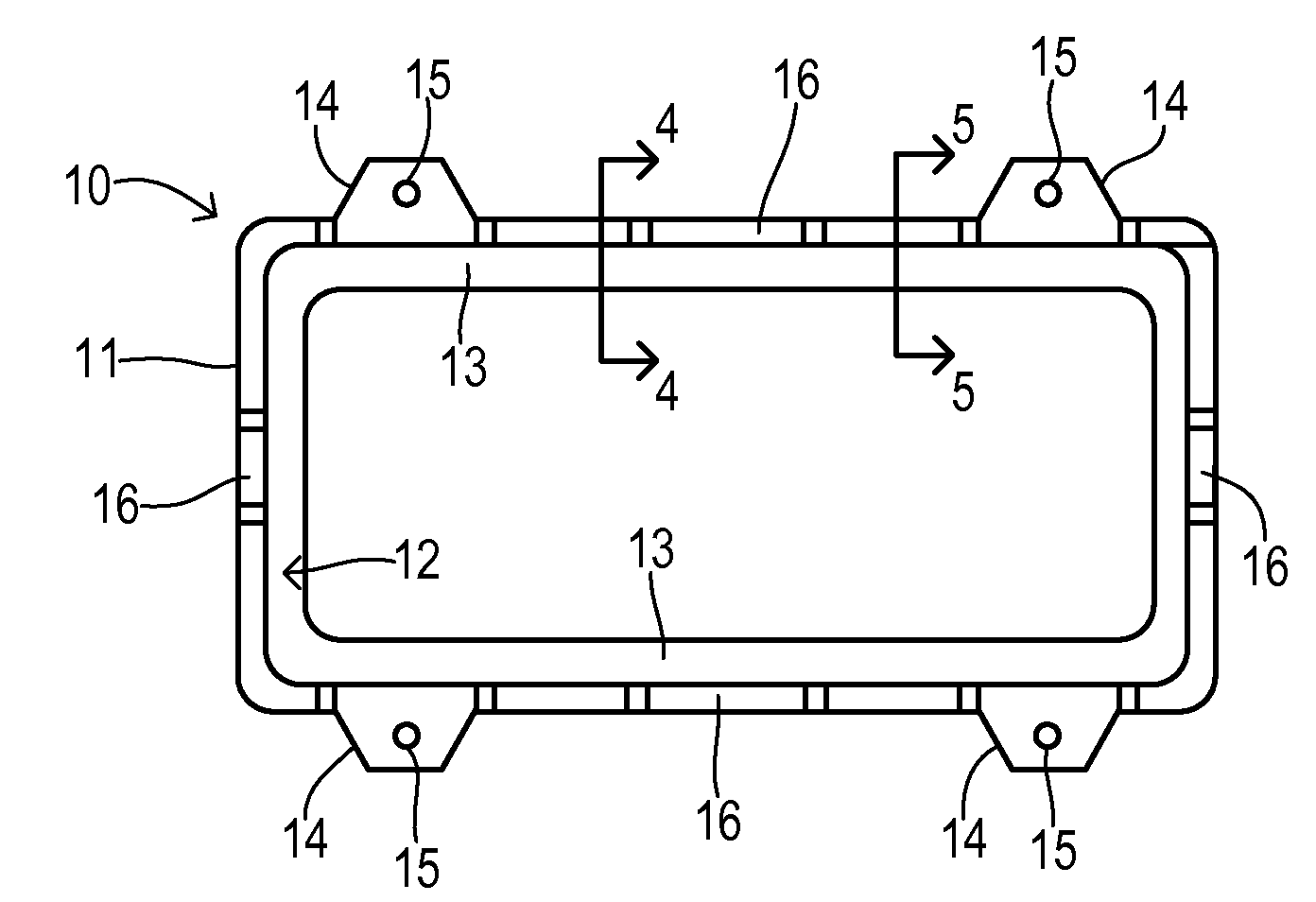

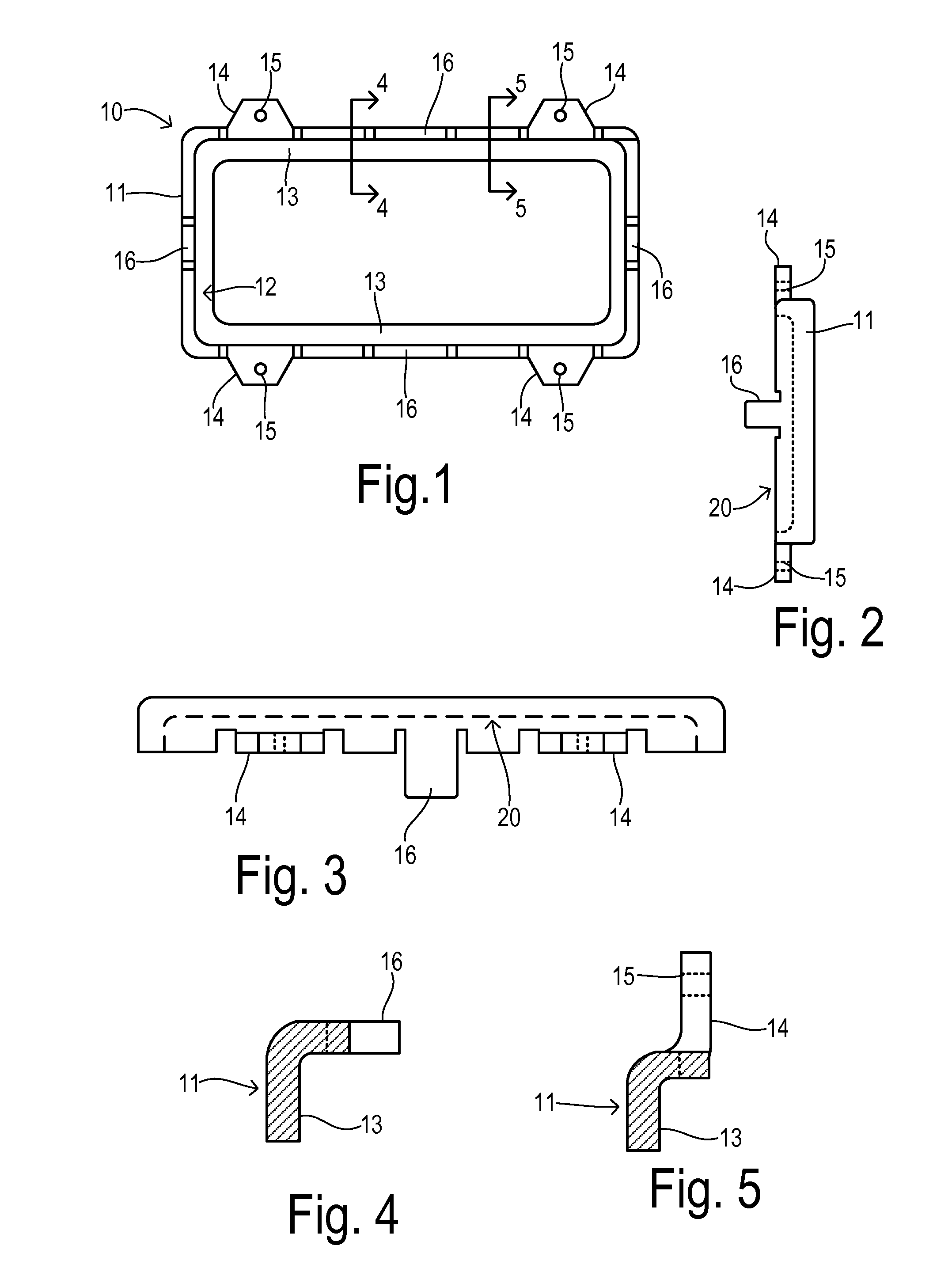

Active bolster mounting system

InactiveUS8308186B1High of deployment performanceHigh appearance requirementsPedestrian/occupant safety arrangementStructural elementBolster

An active bolster system for a vehicle includes a trim substrate panel adapted to be mounted to a structural element of the vehicle, wherein the substrate panel has a bolster opening. A bolster has a main body configured to fit within the bolster opening, wherein the main body has an A-side substantially flush with the substrate panel and a B-side facing the structural element. The main body has a plurality of lateral side tabs extending from the main body, and the main body expands during a deployment of the active bolster system so that a distance between the A-side and B-side increases. A retainer bracket retains the bolster against the substrate panel, wherein the retainer bracket comprises a frame extending around a periphery of the main body. The frame includes a reaction surface disposed against at least a portion of the B-side, a plurality of pinch tabs each pressing a respective lateral side tab against the substrate panel, and a plurality of rigid attachments for directly attaching the is retainer bracket to the substrate panel. Reaction forces applied by the bolster against the reaction surface during at least an initial expansion of the main body during the deployment are transmitted by the retainer bracket to the substrate panel so that separation is urged between the main body and the substrate panel, and the substrate panel is urged against the structural element.

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com