Coating for LDS (Laser Direct Structuring) plastic component and preparation technology thereof

A technology of plastic workpiece and preparation process, applied in the direction of polyurea/polyurethane coating, coating, device for coating liquid on the surface, etc., to achieve good adhesion, good appearance and functionality, and good matching effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

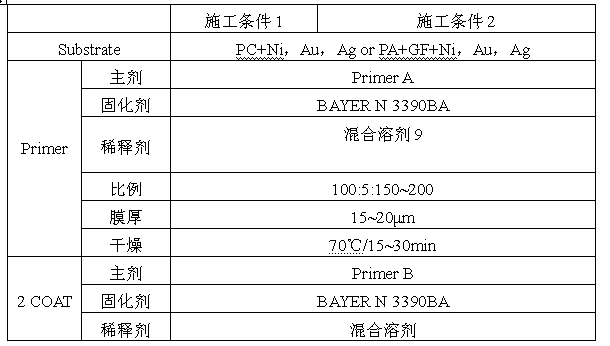

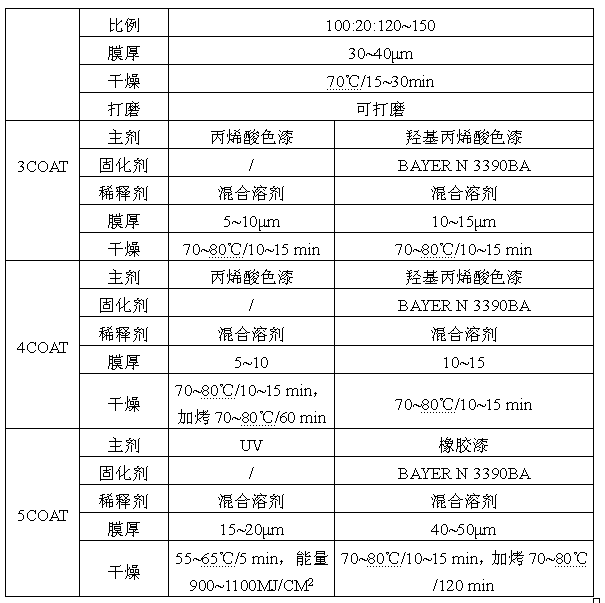

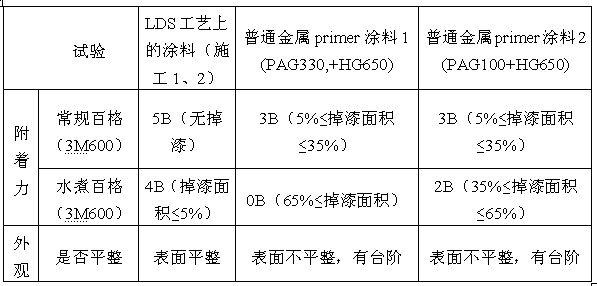

Method used

Image

Examples

Embodiment 1

[0025] This example prepares primer A1:

[0026] (1) Put 11.5 parts of ethyl acetate, 5 parts of toluene and 30 parts of ACRYLIC ZHP-189 polyurethane acrylic resin into the reaction tank and mix them at a speed of 200 rpm for 10 minutes to obtain a premix;

[0027] (2) Add 0.5 parts of BYK-358N polyether modified acrylic leveling agent, 1 part of BYK-163 wetting and dispersing agent, 2 parts of Bayer's HMP polyester adhesion promoter, and Ishihara titanium dioxide CR902 to the premix 20 parts, 20 parts of 10000 mesh talcum powder were stirred at a high speed for 35 minutes at a speed of 500 rpm, and finally 10 parts of ethyl acetate were added, and stirring was continued at a speed of 4500 rpm for 8 minutes;

[0028] (3) Grind the mixture obtained in step (2) 4 times with a blue sand machine, check that the fineness is less than 25 microns (test tool fineness plate 0~100 microns), adjust the mixture measured by KU viscometer The viscosity is 200~250GM, and the temperature con...

Embodiment 2

[0030] This example prepares primer A2:

[0031] (1) Put 10 parts of butyl ester, 12.8 parts of xylene and 45 parts of ACRYLIC ZHP-189 polyurethane acrylic resin into the reaction tank and mix them at a speed of 300 rpm for 5 minutes to obtain a premix;

[0032] (2) Add 0.2 parts of BYK-358N polyether modified acrylic leveling agent, 3 parts of BYK-163 wetting and dispersing agent, 2 parts of BYK-4510 polyester adhesion promoter, Degussa FW to the premix 4 parts of 200 carbon black, 10000 mesh talcum powder 18 high-speed stirring at 800 rpm for 30 minutes, adding 5 parts of butyl ester, and continuing to stir at 300 rpm for 10 minutes;

[0033] (3) Grind the mixture obtained in step (2) 6 times with a blue sand machine, check that the fineness is less than 25 microns (test tool fineness plate 0~100 microns), adjust the mixture measured by KU viscometer The viscosity is 200~250GM, and the temperature condition for testing the viscosity is 25±2°C; the temperature during the san...

Embodiment 3

[0035] This example prepares primer B:

[0036] (1) Put 8.8 parts of butyl acetate, 5 parts of trimethylbenzene and 50 parts of A665BA polyurethane acrylic resin into the reaction tank for mixing, and stir at a speed of 250 rpm for 8 minutes to obtain a premix;

[0037] (2) Add 0.2 parts of BYK-358N polyether modified acrylic leveling agent, 1 part of BYK-163 wetting and dispersing agent, 2 parts of Lubrizol 2063 polyester adhesion promoter, and Ishihara titanium dioxide to the premix 20 parts of CR902, 18 parts of talc powder of 10000 mesh, high-speed stirring at 1200 rpm for 30 minutes, adding 5 parts of butyl acetate, and continuing to stir at 500 rpm for 5 minutes;

[0038] (3) Grind the mixture obtained in step (2) for 3 times with a blue sand machine, check that the fineness is less than 25 microns (test tool fineness plate 0~100 microns), adjust the mixture measured by KU viscometer The viscosity is 200~250GM, and the temperature condition for testing the viscosity is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com