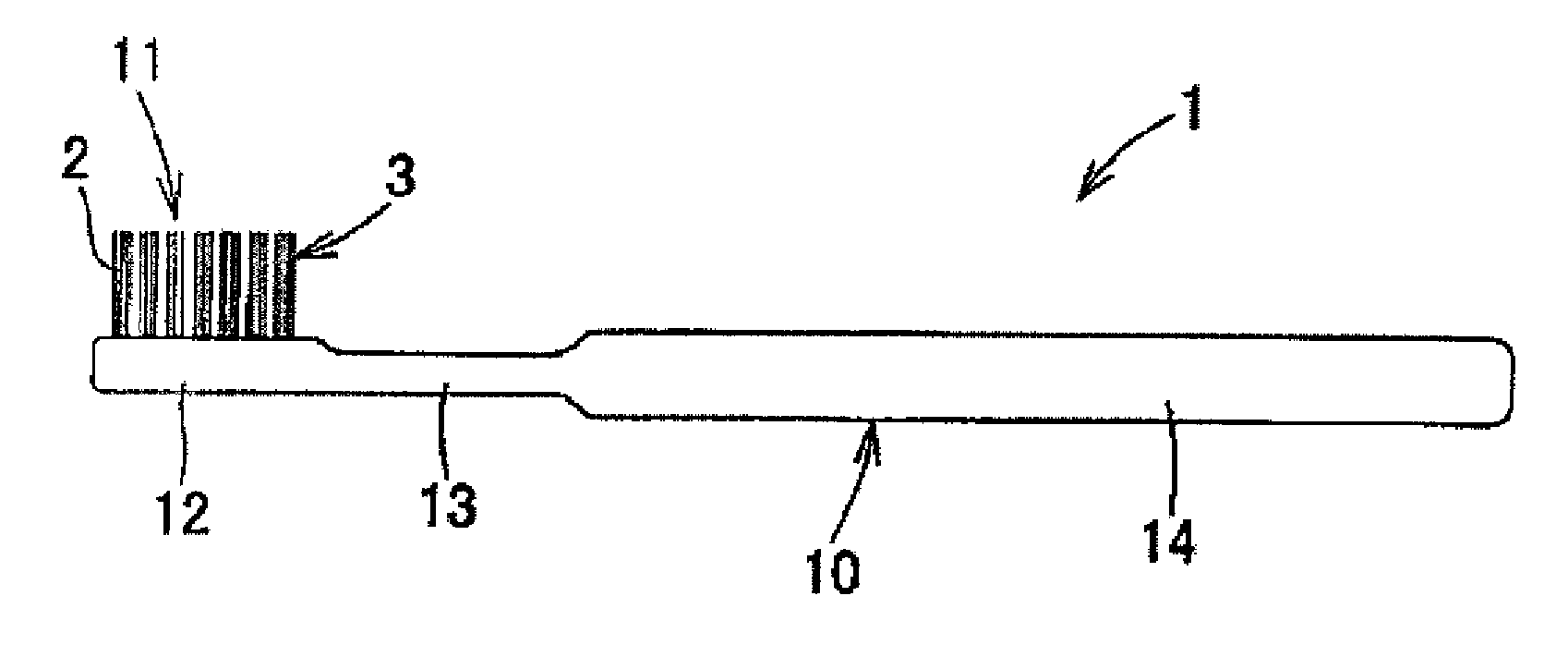

[0019]The toothbrush related to the present invention is a so-called anchorless toothbrush in which the bristled part is formed by fusion-bonding

synthetic resin bristles and thermally fixing them to the bristle base, for example, by in-mold process or fused-in process. Consequently, as compared to the toothbrushes manufactured by driving (fitting) bristle tufts together with anchor into tuft holes formed in the bristle base of the brush main body, the bristle base is able to be made with the thickness of the bristle base reduced, and the toothbrush is highly easy to be used in the

oral cavity and at the same time, has a highly attractive appearance, too. In addition, because at least some of the bristles constituting the bristled part (1) contain tapered bristles which are bristles having split free ends, and the split free ends having been tapered beforehand, (2) comprise tapered bristles which have a sectional shape having a core-sheath structure or islands in a sea structure, or (3) are tapered bristles in each of which a core bristle comprising a core or island portion has been formed beforehand so as to be exposed at the free end, the toothbrush has excellent suitability for bristle

insertion into narrow portions, such as the gaps between neighboring teeth and gaps between the teeth and the gums.

[0020]That is, the toothbrush with bristles implanted without any anchor and having a thin bristle base enables us to

handle the toothbrush head more freely in the oral cavity than the toothbrush with bristles implanted by the use of anchor. Consequently, the toothbrush head can be smoothly moved to places suited for cleaning portions where imperfect cleaning is likely to occur and high risk of dental diseases exists, and in cleaning at the position, a high degree of operating freedom can be secured and effective motion of bristles that removes dental plaque can be achieved. Thus, the plaque removing capabilities can be enhanced. In addition, in the present invention, as bristles which are implanted by anchorless, tapered bristles are used, and this enables the bristles to easily reach the gaps between neighboring teeth and gaps between the teeth and the gums, and other narrow portions subject to high dental

disease risk, and the toothbrush can exhibit superb dental plaque removing effects as compared to conventional toothbrushes.

[0021]Furthermore, in the case of regular tapered bristles (simple tapered bristles), because of the taper shape formed to be thinner towards the free end, when the tuft density is low, low elasticity results and

polishing and cleaning properties in flat portions of teeth are likely to be lowered, but the toothbrush related to the present invention can increase the tuft density as compared to the case in which bristles are driven into tuft holes using anchor because the bristles are thermally fixed to the bristle base. Consequently, even though the tapered bristles are used, the tuft achieves high elasticity and the toothbrush provides excellent

polishing and cleaning properties not only in narrow portions such as the between the teeth and the gums or the gaps between neighboring teeth but also in the teeth planar portions, and is highly effective in removing dental plaque for the whole teeth and excels in cleaning power.

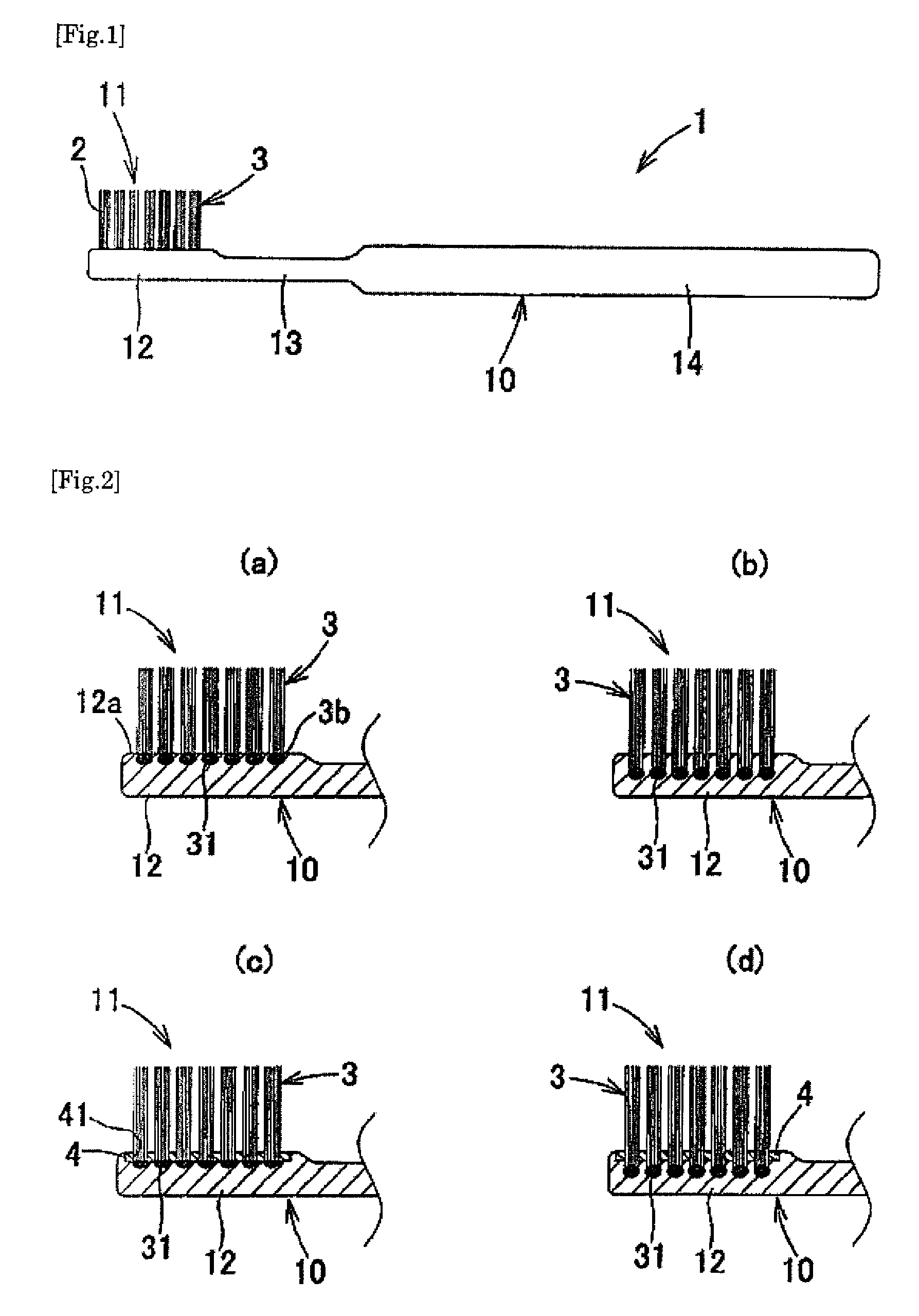

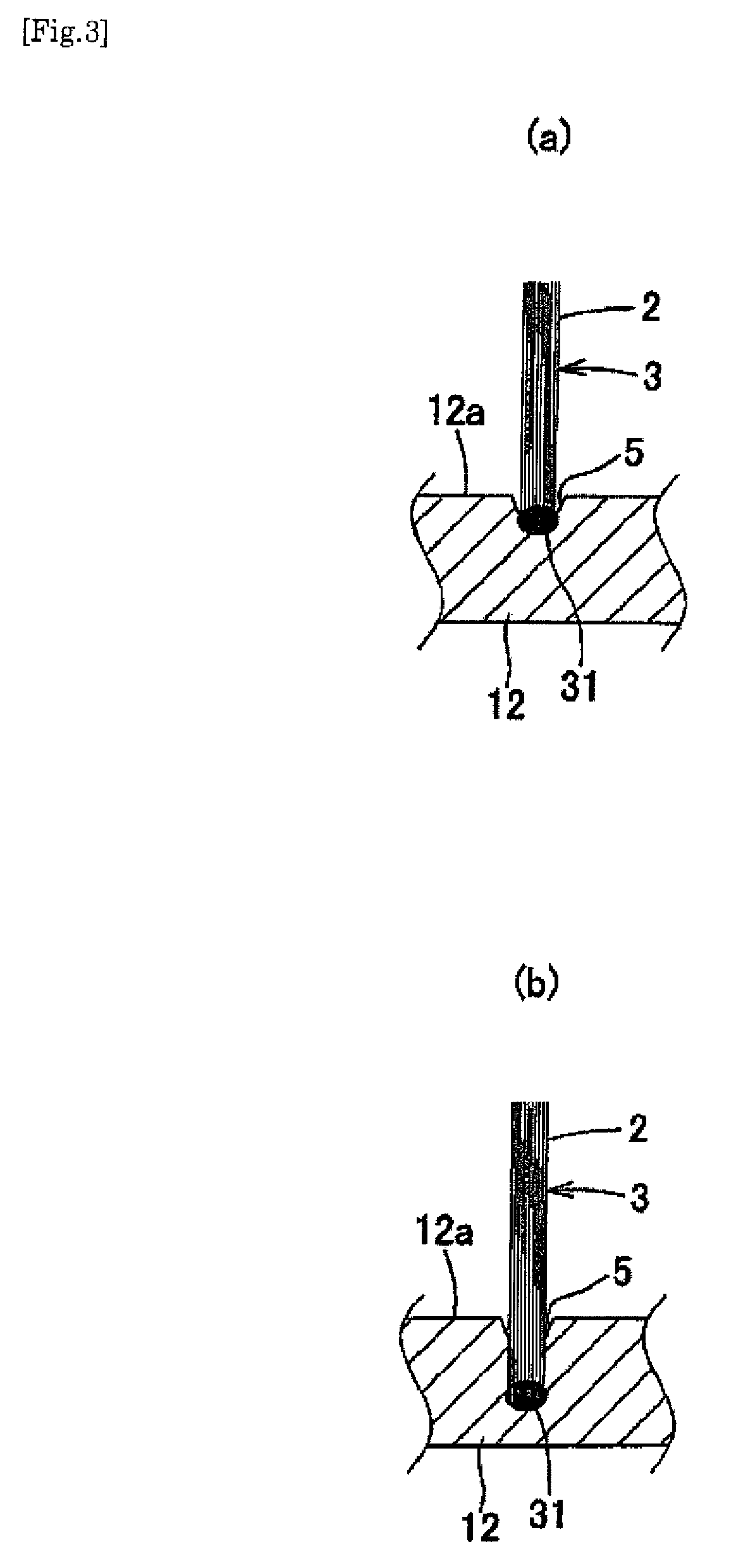

[0022]In the toothbrush related to the present invention, there is no case in that the free end is bent or the free end is not aligned when bristles are fixed to the bristle base, because the free end is elastic due to a plurality of split bristles at the free end of bristles and the free ends of a plurality of split bristles are brought in contact with the backplate surface in the case of tapered bristles whose free end of the foregoing (1) is split, and because the free end is elastic due to core bristles and the core bristles are brought in contact with the backplate surface in the case of tapered bristles in which the cross-sectional shape of the foregoing (2) has a core-sheath structure or islands in a sea structure and tapered bristles in each of which a core bristle including a core or island portion has been formed beforehand so as to be exposed at the free end, when the brush surfaces composed with the free ends of tufts and bristles are adjusted to achieve a desired shape by bringing the free end of bristles is brought in contact with the backplate in the event that bristles are fixed to the bristle base without using anchor, because for the bristles which compose the bristled part, tapered bristles of specific structures of foregoing (1) to (3) are used. Consequently, it is able to form the tuft free-end shape and the brush surfaces composed by the bristles free-end into optional shapes by forming the portion of the backplate which the free end of the bristles come in contact with into a desired shape.

[0023]Furthermore, as is the case of the present invention, when bristles processed to have tapered free end in advance are implanted to the bristle base, in the case of conventional implantation using anchor, the free end is unable to be aligned by trimming after implantation and the bristled surface is kept as implanted, and bristles are folded in a U-shape at the bristles are held between the tuft hole bottom surface and anchor and a slight level difference is generated at the folded position, and this level difference causes the bristled surface to be unaligned, and it is therefore unable to manufacture a toothbrush having the bristled surface with an aligned free end using bristles with the free end processed in advance. On the other hand, the toothbrush according to the present invention, by anchorless implantation, a toothbrush that has the bristled surface with a free end aligned to specific shapes such as protruded, recessed, uneven, and all other surfaces, not to mention a flat surface can be obtained, and a toothbrush with higher cleaning capabilities and higher effects in removing dental plaque can be provided.

[0024]In the event that bristles of the toothbrush are fixed to the bristle base by the thick portion formed at the base end portion, an

undercut section is formed between the thick portions and the bristled surface and by the anchor effect of the thick portion, the fixing strength of bristles to the bristle base is increased, and the bristles are difficult to drop from the bristle base, which is preferable. Furthermore, in the event that the thick portion is composed with a fused

mass formed by heat-fusing the base end portion of bristle tufts, drop of bristles can be definitely prevented by bristles which are heat-fused each other.

Login to View More

Login to View More