Neoprene adhesive subjected to secondary graft modification and preparation method of neoprene adhesive

A chloroprene rubber, graft modification technology, applied in the direction of graft polymer adhesives, adhesives, adhesive types, etc., can solve the problems of low comprehensive performance of adhesives, low conversion rate of grafting reaction, high production cost, etc. , to achieve the effect of good yellowing resistance, good operability and comprehensive cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

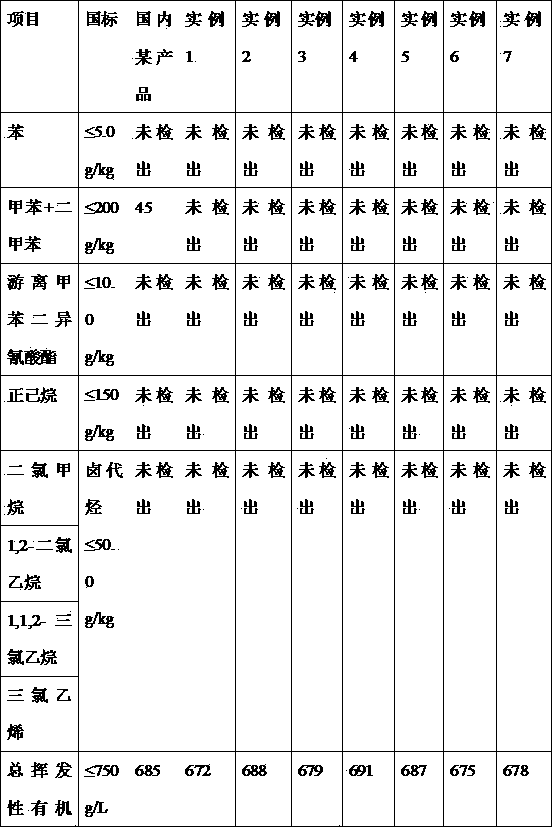

Examples

Embodiment 1

[0031] 1) Install the reflux device, turn on the power, start the mixer, and at a speed of 300r / min-500r / min, add 50 parts of acetone, 204 parts of butanone, 125 parts of ethyl acetate, and dimethyl carbonate to the reaction kettle in sequence 120 parts, 195 parts of methylcyclohexane, mixed and stirred evenly;

[0032] 2) Turn on the reflux device, adjust the heating mantle to raise the temperature to 50-60°C, control the stirring speed at 500r / min-800r / min, add 130 parts of neoprene, and stir for 2-4 hours until the film is completely dissolved;

[0033] 3) Keep the reflux temperature at 70-90°C and the stirring speed at 20-80r / min. Add 1 part of initiator, continue to stir for 15 minutes, then add 91 parts of methyl methacrylate dropwise, and react at constant temperature for 0.5-1 hour;

[0034] 4) Keep the reflux temperature at 70-90°C, add 9.3 parts of acrylic acid and 2 parts of the remaining initiator, and react at a constant temperature of 70-90°C for...

Embodiment 2

[0038] 1) Install the reflux device, turn on the power, start the mixer, at the speed of 300r / min-500r / min, add 65 parts of acetone, 190 parts of butanone, 118 parts of ethyl acetate, 140 parts of dimethyl carbonate, methyl 200 parts of cyclohexane, mixed and stirred evenly;

[0039] 2) Turn on the reflux device, adjust the heating mantle, raise the temperature to 50-60°C, control the stirring speed at 500r / min-800r / min, add 128 parts of neoprene, stir for 2-4 hours, until the film is completely dissolved;

[0040] 3) Keep the reflux temperature at 70-90°C and the stirring speed at 20-80r / min. Add 0.9 parts of initiator, continue to stir for 15 minutes, then add 89 parts of methyl methacrylate dropwise, and react for 0.5-1 hour;

[0041] 4) Keep the reflux temperature at 70-90°C, add quantitative 8.1 parts of butyl methacrylate and 2.1 parts of the remaining initiator, react at 70-90°C for 2-5 hours, when the viscosity reaches 3000-5000cps, it is regarded as ...

Embodiment 3

[0045]1) Install the reflux device, turn on the power, start the mixer, at the speed of 300r / min-500r / min, add 55 parts of acetone, 245 parts of butanone, 118 parts of ethyl acetate, 140 parts of dimethyl carbonate, methyl 200 parts of cyclohexane, mixed and stirred evenly;

[0046] 2) Turn on the reflux device, adjust the heating mantle, raise the temperature to 50-60°C, control the stirring speed at 500r / min-800r / min, add 128 parts of neoprene, stir for 2-4 hours, until the film is completely dissolved;

[0047] 3) Keep the reflux temperature at 70-90°C and the stirring speed at 20-80r / min. Add 1.2 parts of initiator, continue to stir for 15 minutes, then add 90 parts of methyl methacrylate dropwise, and react for 0.5-1 hour;

[0048] 4) Keep the reflux temperature at 70-90°C, add 9 parts of quantitative hydroxyethyl methacrylate and 2.3 parts of the remaining initiator, react at 70-90°C for 2-5 hours, when the viscosity reaches 3000-5000cps, depending on for t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com