Modified industrial anti-corrosion aqueous alkyd coating and preparation method of same

A water-based alkyd and anti-corrosion coating technology, used in anti-corrosion coatings, polyester coatings, coatings, etc., can solve the problems of poor weather resistance, slow drying of paint films, and unmatched matching properties, and achieve water resistance and salt spray resistance. Good, good adhesion, less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

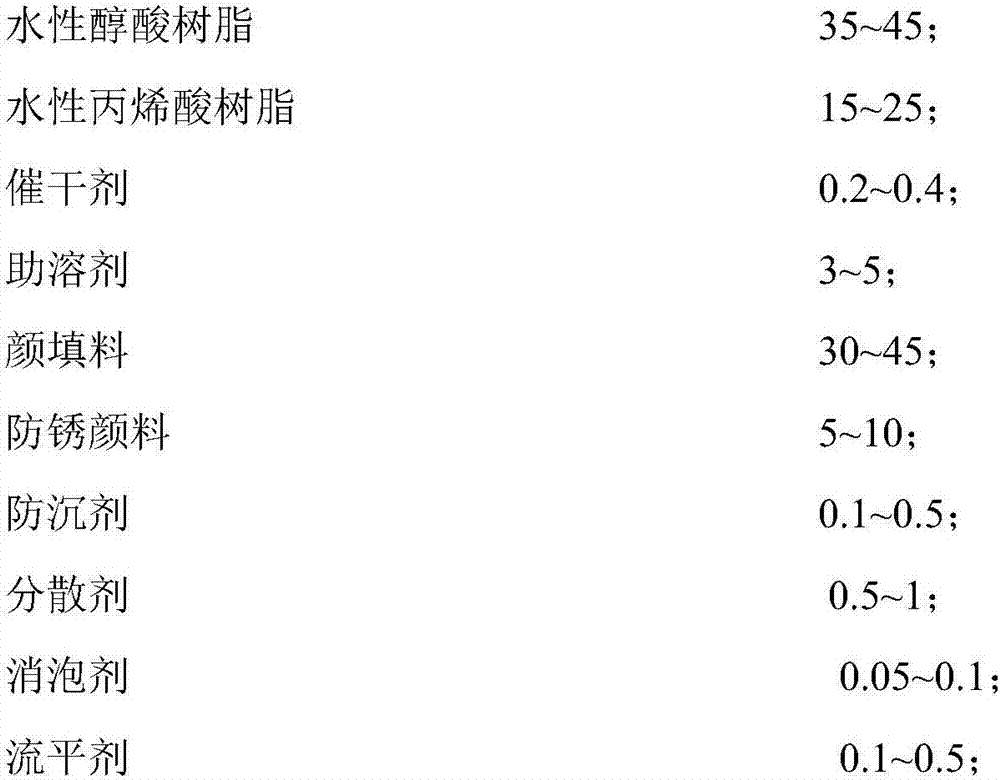

[0031] Modified water-based alkyd industrial anticorrosion paint, comprising the following components by weight:

[0032]

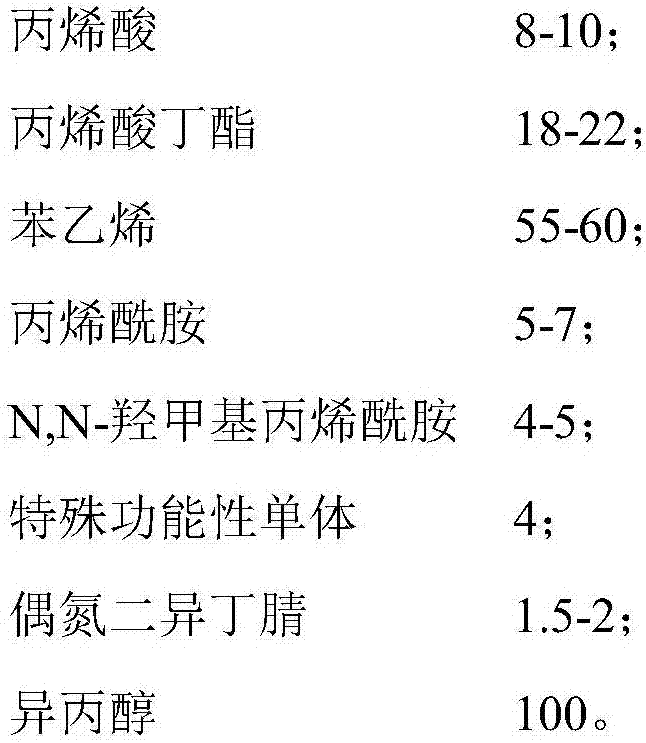

[0033] Wherein, the mass solid concentration of described aqueous acrylic resin is 50%, comprises the component of following parts by weight:

[0034] monomer name

Remark

8-10

industrial grade

18-22

industrial grade

55-60

industrial grade

5-7

industrial grade

N,N-Methylolacrylamide

4-5

industrial grade

special functional monomer

4

industrial grade

1.5-2

industrial grade

Isopropanol

100

industrial grade

[0035] Above-mentioned waterborne acrylic resin is made by following method:

[0036] Put 1 / 3 of isopropanol, special functional monomers, and part of azobisisobutyronitrile into the flask, blow nitrogen, start stirring and raise the tempe...

Embodiment 2

[0044] Highly modified water-based alkyd industrial anticorrosion coatings, comprising the following components by weight:

[0045]

[0046] Wherein, the mass solid concentration of described aqueous acrylic resin is 70%, comprises the component of following parts by weight:

[0047]

[0048]

[0049] The preparation method of the water-based acrylic resin and the modified water-based alkyd industrial anti-corrosion coating of this embodiment is the same as that of Example 1.

Embodiment 3

[0051] Highly modified water-based alkyd industrial anticorrosion coatings, comprising the following components by weight:

[0052]

[0053] Wherein, the mass solid concentration of described aqueous acrylic resin is 60%, comprises the component of following parts by weight:

[0054] monomer name

Remark

8-10

industrial grade

18-22

industrial grade

55-60

industrial grade

5-7

industrial grade

N,N-Methylolacrylamide

4-5

industrial grade

special functional monomer

4

industrial grade

1.5-2

industrial grade

Isopropanol

67

industrial grade

[0055]The preparation method of the water-based acrylic resin and the modified water-based alkyd industrial anti-corrosion coating of this embodiment is the same as that of Example 1.

[0056] The modified water-based alkyd indust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com