Pipeline suitable for conveying ultralow-temperature medium

A technology of ultra-low temperature and pipelines, which is applied in the direction of pipeline protection, pipeline protection through heat insulation, pipeline damage/wear prevention, etc. It can solve the problems that chemical raw materials cannot be buried in the ground, so as to save pipeline laying costs, solve routing problems, and improve environmental protection. required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0050] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

[0051] The present invention will be further described below in conjunction with the drawings, but the present invention is not limited to the following embodiments.

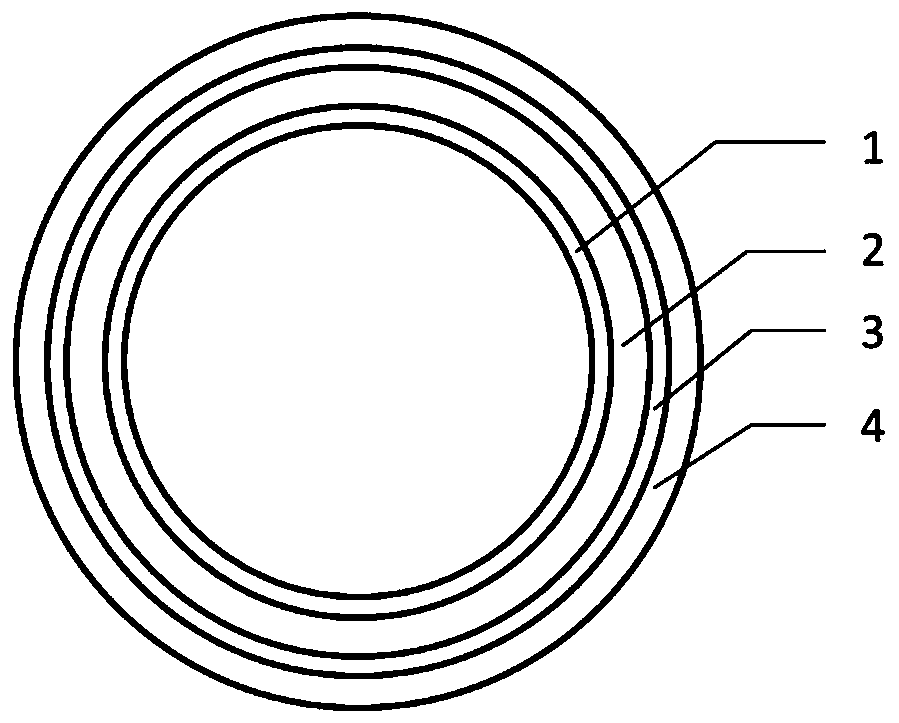

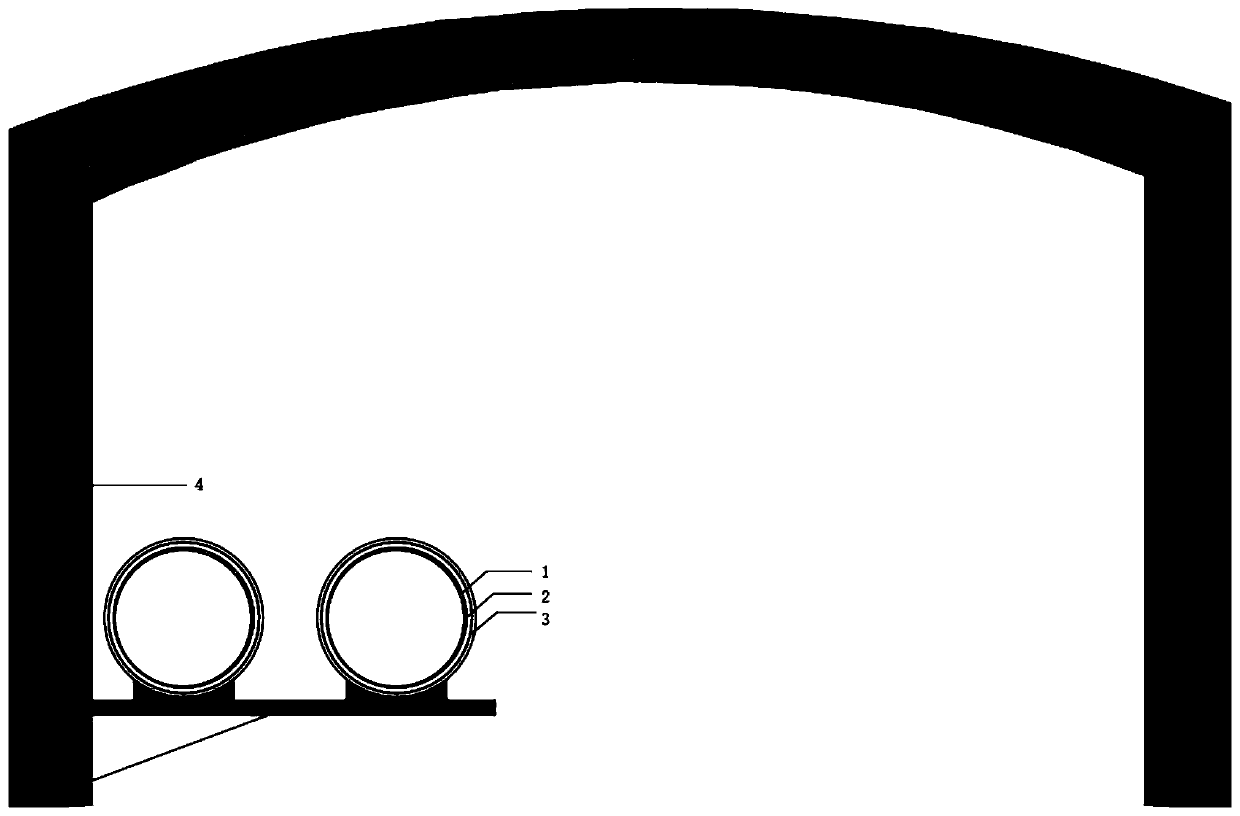

[0052] Such as figure 1 Shown is a schematic structural diagram of the pipeline of the present invention. The pipeline of the present invention suitable for transporting ultra-low temperature medium includes a pipeline body (specifically, a steel pipe 1) and an insulation system layer 2 and an anti-collision protection outer layer 4 which are sequentially arranged on the outer surface of the pipeline body.

[0053] The insulation system layer 2 includes a cold insulation material layer and / or a vacuum cold insulation layer from inside and outside; the vacuum cold insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com