SMAW (shielded metal arc welding) process method for steel plates with 9% of Ni

An electrode arc welding and process method technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of low temperature toughness of magnetic bias blowing, high equipment dependence, difficulty in implementation, etc., and achieve easy operation, quality assurance, Effect of Solving Welding Defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

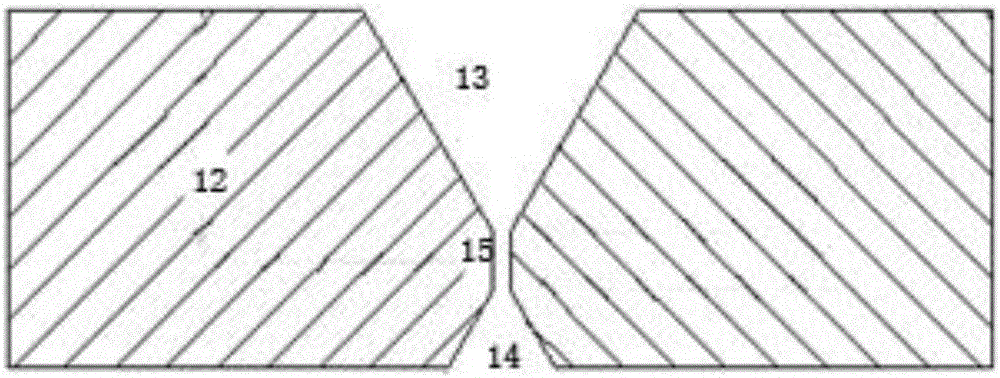

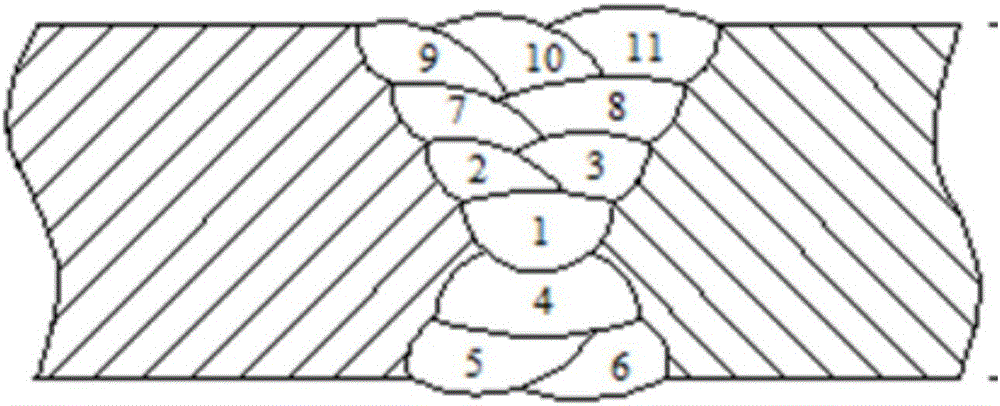

[0020] Such as figure 1 , figure 2 As shown, the reference signs are as follows: 1 is the bottom weld bead, 2-4, 7, 8 is the filling weld bead, 5-6, 9-11 is the cover weld bead, 12 is 9% Ni steel plate, 13 Be a large groove, 14 is a small groove, and 15 is a blunt edge.

[0021] In view of the welding process of common stainless steel is not suitable for welding 9%Ni steel plate, the present invention is realized like this:

[0022] 1. Preparation before welding

[0023] 1. Selection of welding equipment and electrodes

[0024] The welding machine is an AC welding machine, the welding rod is ENiCrFe-9, the diameter is 3.2mm, and it is dried before welding. The drying temperature is 300 ° C ~ 350 ° C, and the drying time is one hour. If a good electrode is not used for more than four hours, it sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com