Cantilever type high rate turbine vacuum pump and its evacuation method

A vacuum pump and cantilever technology, which is used in the field of vacuum equipment and turbo machinery, can solve the problems of difficult to achieve high speed and large volume, and achieve the effects of high mechanical efficiency, reduced energy consumption, and efficient extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

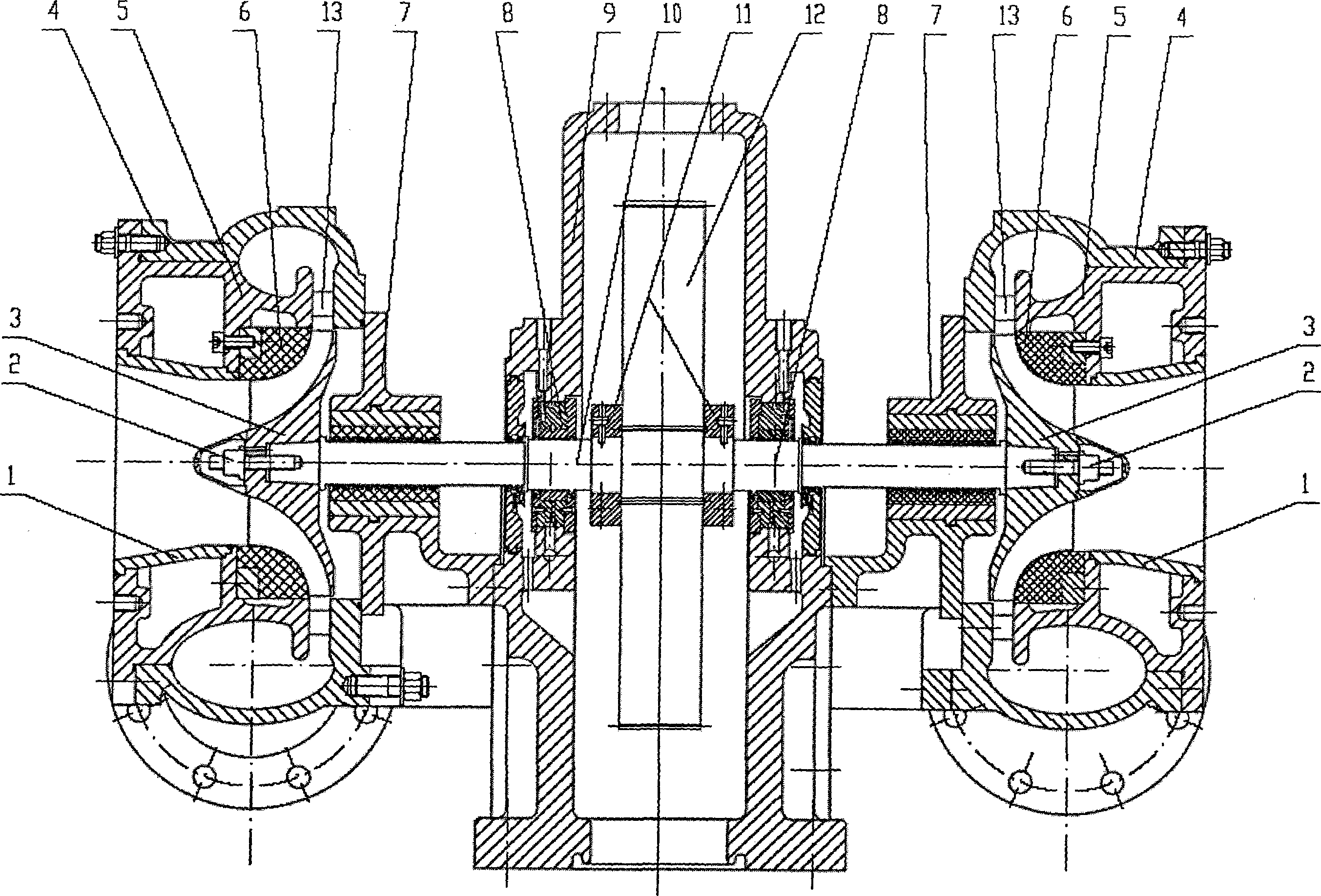

[0031] The cantilever type high-speed turbo vacuum pump of this embodiment has a detailed structure as shown in the accompanying drawings. It includes a gear speed-up box 9, two independent pump heads and a high-speed rotor. The gear speed-up box 9 adopts a single-stage speed-up, and the large gear The shaft on 12 is connected with the prime mover; two independent pump heads are separated on both sides of the gear speed increaser box 9, and are in a symmetrical structure. The cover 6, the volute 4 and the air seal 7, the suction port 1 and the impeller static wheel cover 6 are installed on the inner body of the volute 5 to form an integral body embedded in the volute 4, which is formed by the combination of the inner body 5 of the volute and the cavity of the volute 4 Diffuser and medium outflow channel, air seal 7 are installed on the side of volute 4 through flange; The sliding bearing 8 on the top is supported and driven by the bull gear 12. The thrust plate 11 is fixedly i...

Embodiment 2

[0039] The cantilever type high-speed turbo vacuum pump of this embodiment has a detailed structure as shown in the accompanying drawings. It includes a gear speed-up box 9, four independent pump heads and two high-speed rotors. The gear speed-up box 9 adopts a single-stage speed-up, The shaft on the large gear 12 is connected to the prime mover; the four independent pump heads are separated on both sides of the gear speed increaser box 9, and the two on each side have a symmetrical structure. Body 5, impeller stationary wheel cover 6, volute 4 and air seal 7, suction port 1 and impeller stationary wheel cover 6 are installed on the volute inner body 5 to form an integral body embedded in the volute 4, composed of the volute inner body 5 and the volute The cavity of the casing 4 is combined to form a diffuser and a medium outflow channel, and the air seal 7 is installed on the side of the volute 4 through a flange; the high-speed rotor includes a high-speed gear shaft 10, a thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com