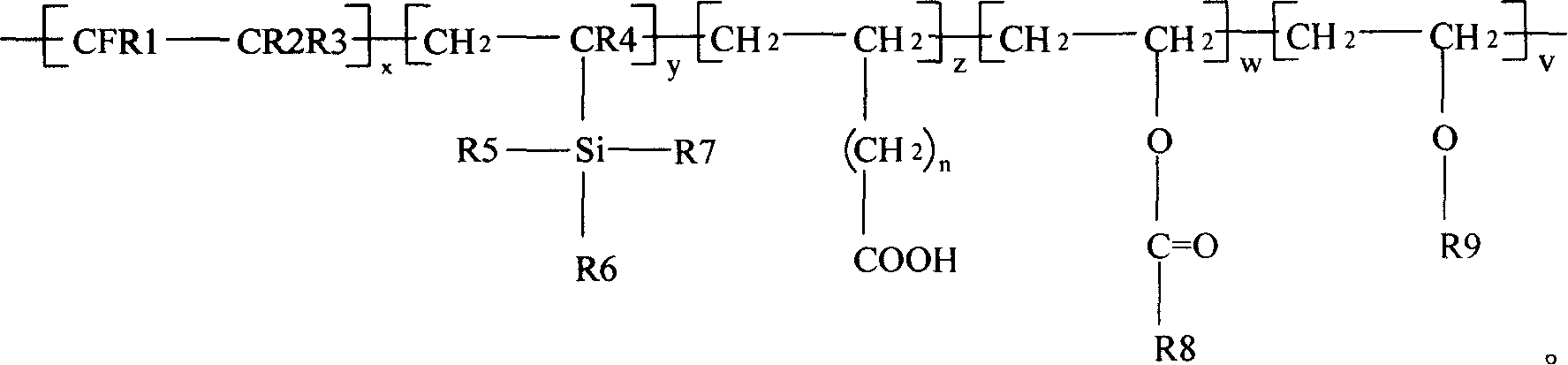

Multipolymer resin water dispersoid containing fluorine and silicon

A multi-copolymer and dispersion technology, applied in the field of multi-copolymer resin water dispersion, can solve problems such as weak adhesion, and achieve the effects of high weather resistance, uniform film formation, and improved light aging resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

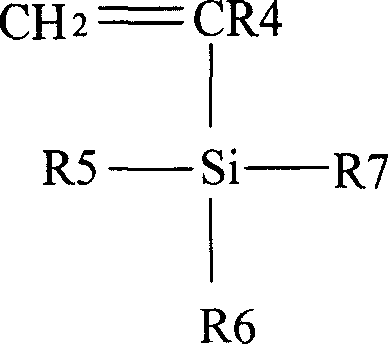

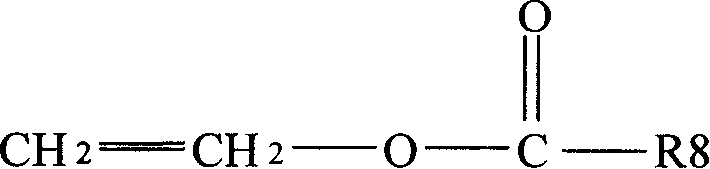

Method used

Image

Examples

Embodiment 1

[0025] 52.8g vinyl acetate, 5.5g isobutyl vinyl ether, 4.5g undecylenic acid, 2.5g acrylic acid, 27g vinyl triethoxysilane, 20g ethylene glycol ether, 25g ethyl acetate, 15g xylene Put it into a 1000ml stainless steel high-pressure reaction kettle, seal the kettle body, and use high-purity N 2 Replace the air in the kettle 4 times to remove oxygen, press in 70g of chlorotrifluoroethylene, increase the pressure to 1.2MPa, stir at 300r / min for 1h, and add 1.7g of azobisisobutyronitrile to the reactor in 4 times within 6h , And gradually increase the temperature to 70°C, keep it for 18h, lower the temperature to 50°C, distill 35g of solvent under reduced pressure, adjust the stirring speed to 1200r / min, add 3.67g triethylamine and 150g water, continue stirring for 3h, continue vacuum distillation Discharge 16 g of solvent, cool and discharge. The resulting water dispersion is translucent and light blue, with a coating viscosity of 6"23 and a solid content of 39%.

[0026] This embodi...

Embodiment 2

[0028] 42.8g vinyl acetate, 6g isobutyl vinyl ether, 15.5g hydroxybutyl vinyl ether, 4.1g undecylenic acid, 3g acrylic acid, 10g vinyl triethoxysilane, 20g ethylene glycol dimethyl ether, Put 25g ethyl acetate and 15g xylene into a 1000ml stainless steel autoclave, seal the body and use high-purity N 2 Replace the air in the kettle 4 times to remove oxygen, press in 80g of chlorotrifluoroethylene, and increase the pressure to 1.2MPa, stir at 300r / min for 1h, and add 1.6g of azobisisobutyronitrile to the reactor in 4 times within 6h , And gradually increase the temperature to 70°C, keep it for 18h, lower the temperature to 50°C, distill 35g of solvent under reduced pressure, adjust the stirring speed to 1200r / min, add 3.67g triethylamine and 150g water, continue stirring for 3h, continue vacuum distillation Discharge 16 g of solvent, cool and discharge. The obtained water dispersion is translucent and light blue, with a coating viscosity of 10"2 and a solid content of 42%.

[0029]...

Embodiment 3 5

[0031] The operation steps of Examples 3 to 5 are the same as Examples 1 and 2. The addition amount of each raw material is shown in Table 1, and the performance of the examples is compared with the acrylic solvent resin and the two-component acrylic polyurethane resin in Table 2.

[0032] Table 1: Examples three to five raw material consumption

[0033] Example

three

Four

Fives

Vinyl acetate (g)

50.8

45.6

38.8

Isobutyl vinyl ether (g)

5.6

5.5

6.0

Hydroxybutyl vinyl ether (g)

2

6.2

18.0

Undecylenic acid (g)

4.5

4.3

4.1

Acrylic (g)

2.7

2.8

3.0

Vinyl triethoxy silane (g)

25

22.1

15

Ethylene glycol ether (initial addition amount g / retention amount after distillation g)

60 / 20

0 / 0

0

Ethylene glycol dimethyl ether (initial addition amount g / retention amount after distillation g)

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com