Streamer discharge ammonia flue gas desulfurization, denitrification and fog removal integrated method

A streamer discharge, desulfurization and denitrification technology, applied in chemical instruments and methods, separation methods, air quality improvement and other directions, can solve the problems of serious emission of acid mist and aerosol in tail gas, affecting the popularization and application of ammonia desulfurization, and entrainment of ammonium salt in tail gas. , to achieve the effect of reducing ammonium salt entrainment, high demisting efficiency, and inhibiting ammonia escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

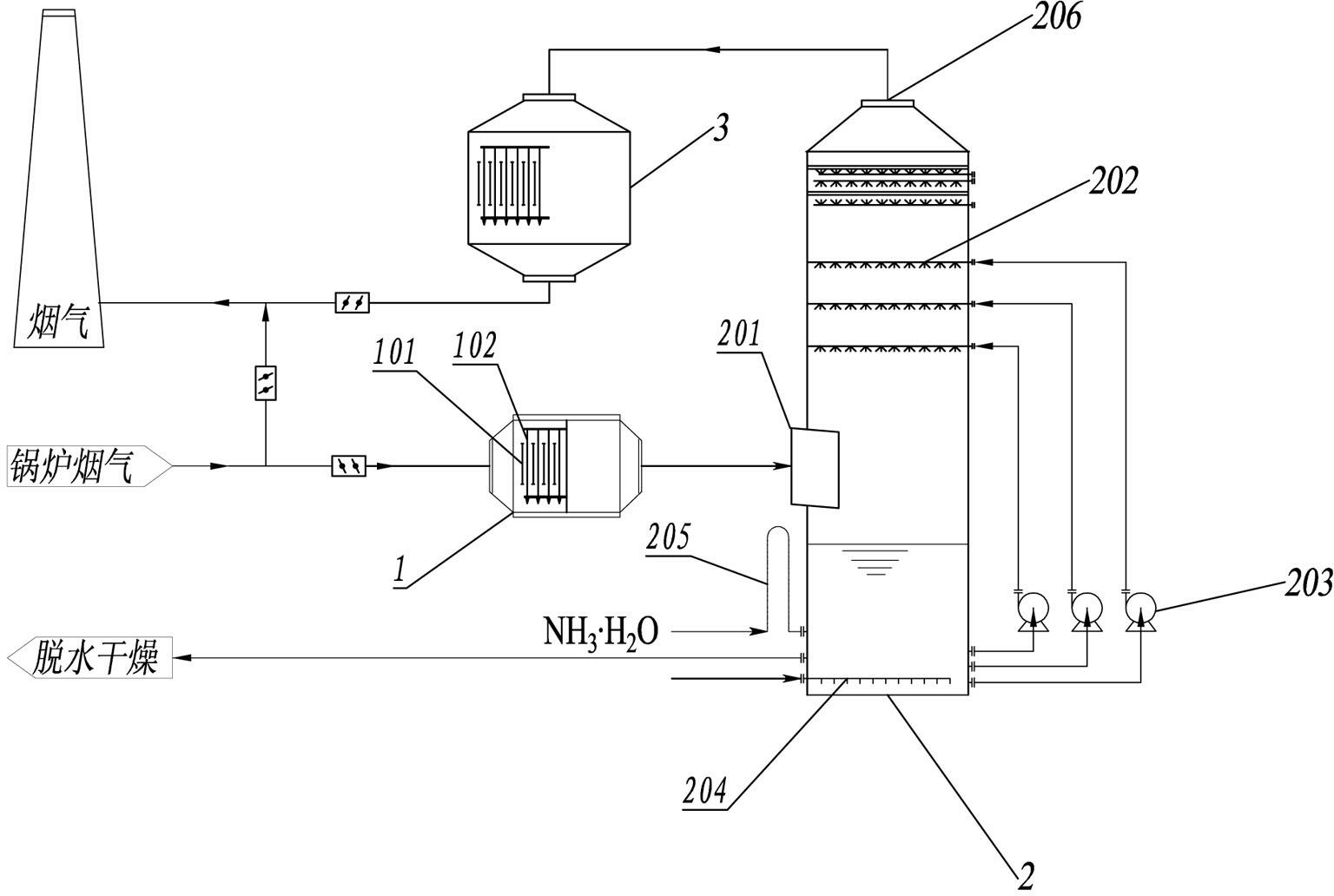

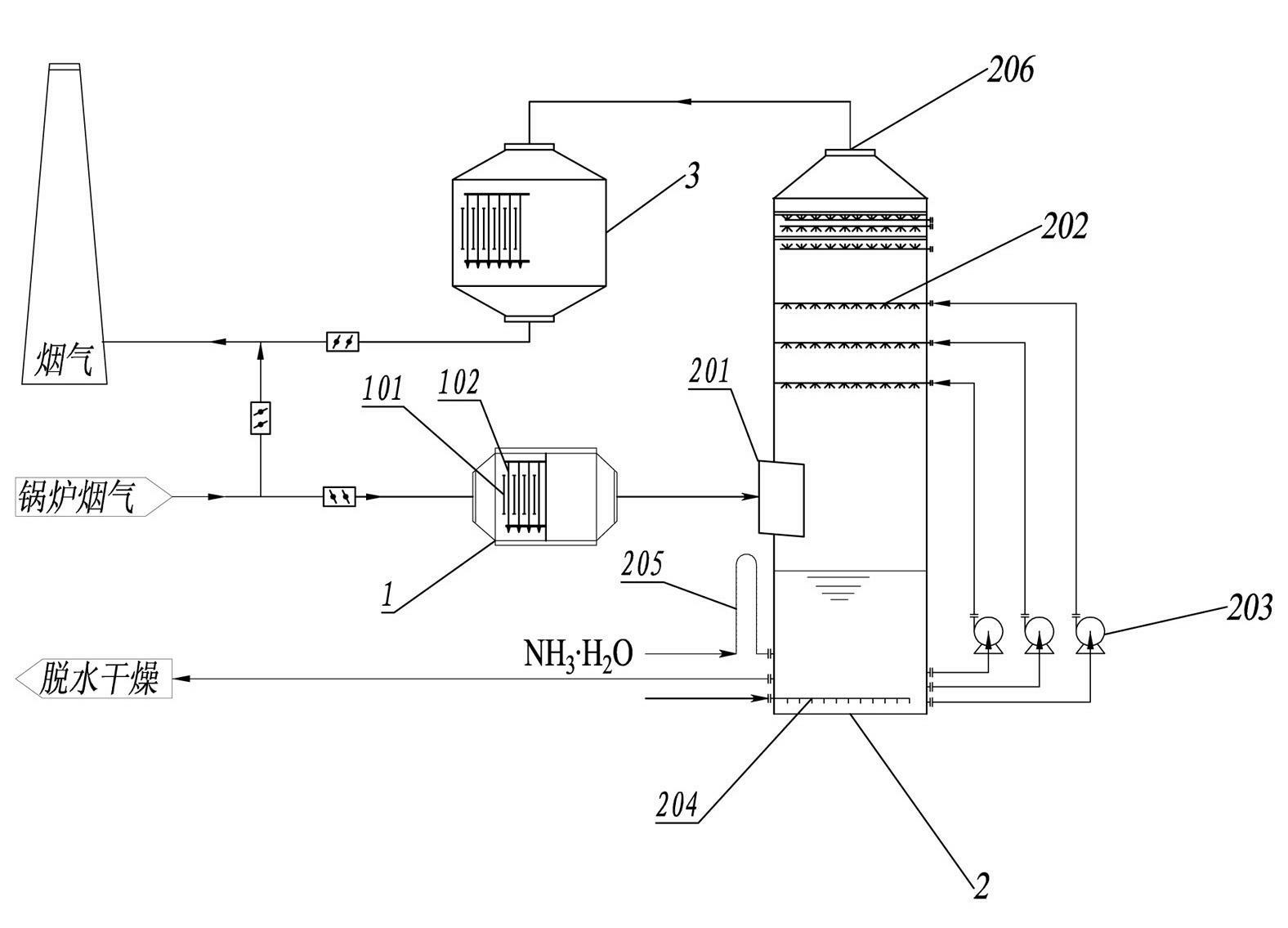

[0050] refer to figure 1 , an integrated method for flue gas desulfurization, denitrification and demisting by streamer discharge ammonia method, comprising the following steps:

[0051] 1) The flue gas produced by the coal-fired boiler is dusted by the electrostatic precipitator, so that the dust concentration reaches 50mg / m 3 the following;

[0052] 2) After the dust is removed, the flue gas is sent into the streamer discharge denitrification reactor 1 through the fan. The streamer discharge denitrification reactor 1 is equipped with an alternate ground electrode 101 and a discharge electrode 102. The discharge electrode is discharged by a positive electrode, and the distance between the two electrodes is 30~100mm. The applied DC voltage is 10~50kV, and a streamer corona discharge is generated under high voltage, and the generated plasma radicals oxidize NO in the flue gas to NO 2 and other substances that are easy to absorb by wet method;

[0053] 3) The flue gas passing...

Embodiment 2

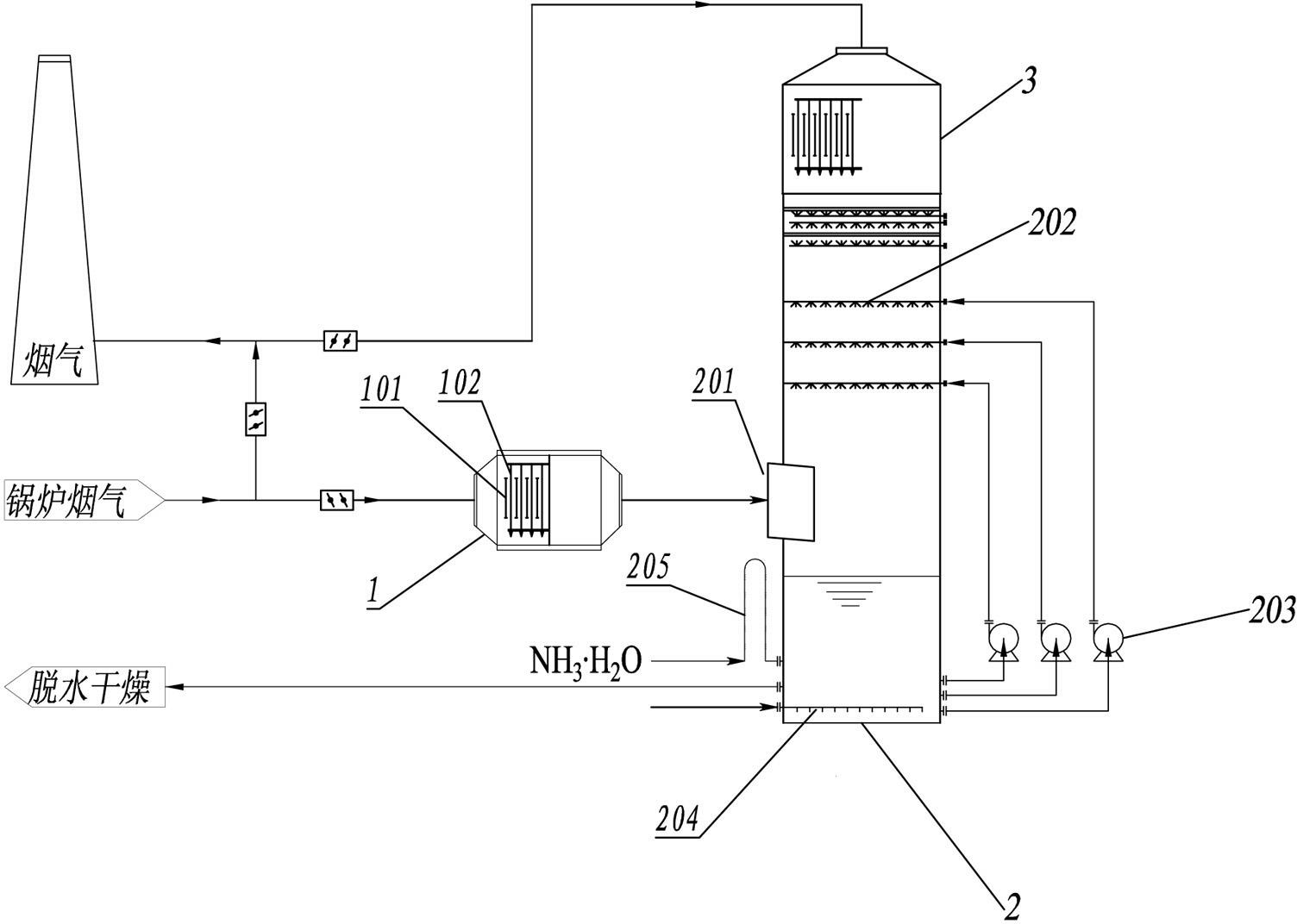

[0058] refer to figure 2 , an integrated method for flue gas desulfurization, denitrification and demisting by streamer discharge ammonia method, comprising the following steps:

[0059] 1) The flue gas produced by the coal-fired boiler is dedusted by the bag filter to make the soot concentration reach 50mg / m 3 the following;

[0060] 2) After the dust is removed, the flue gas is sent to the streamer discharge denitrification reactor 1 through the fan. The streamer discharge denitrification reactor 1 is equipped with an alternate ground electrode 101 and a discharge electrode 102. The discharge electrode adopts a positive electrode for discharge, and the distance between the two electrodes is 150~300mm. The applied DC voltage is 110~120kV, and a streamer corona discharge is generated under high voltage, and the generated plasma radicals oxidize NO in the flue gas to NO 2 and other substances that are easy to absorb by wet method;

[0061] 3) The flue gas passing through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com