Arefaction regeneration method for high-voltage electric field in runner humidity reducing set

A rotary dehumidifier, medium and high pressure technology, applied in the direction of separation methods, chemical instruments and methods, heating methods, etc., can solve the problems of low efficiency of drying hygroscopic materials, and achieve the effect of improving application and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

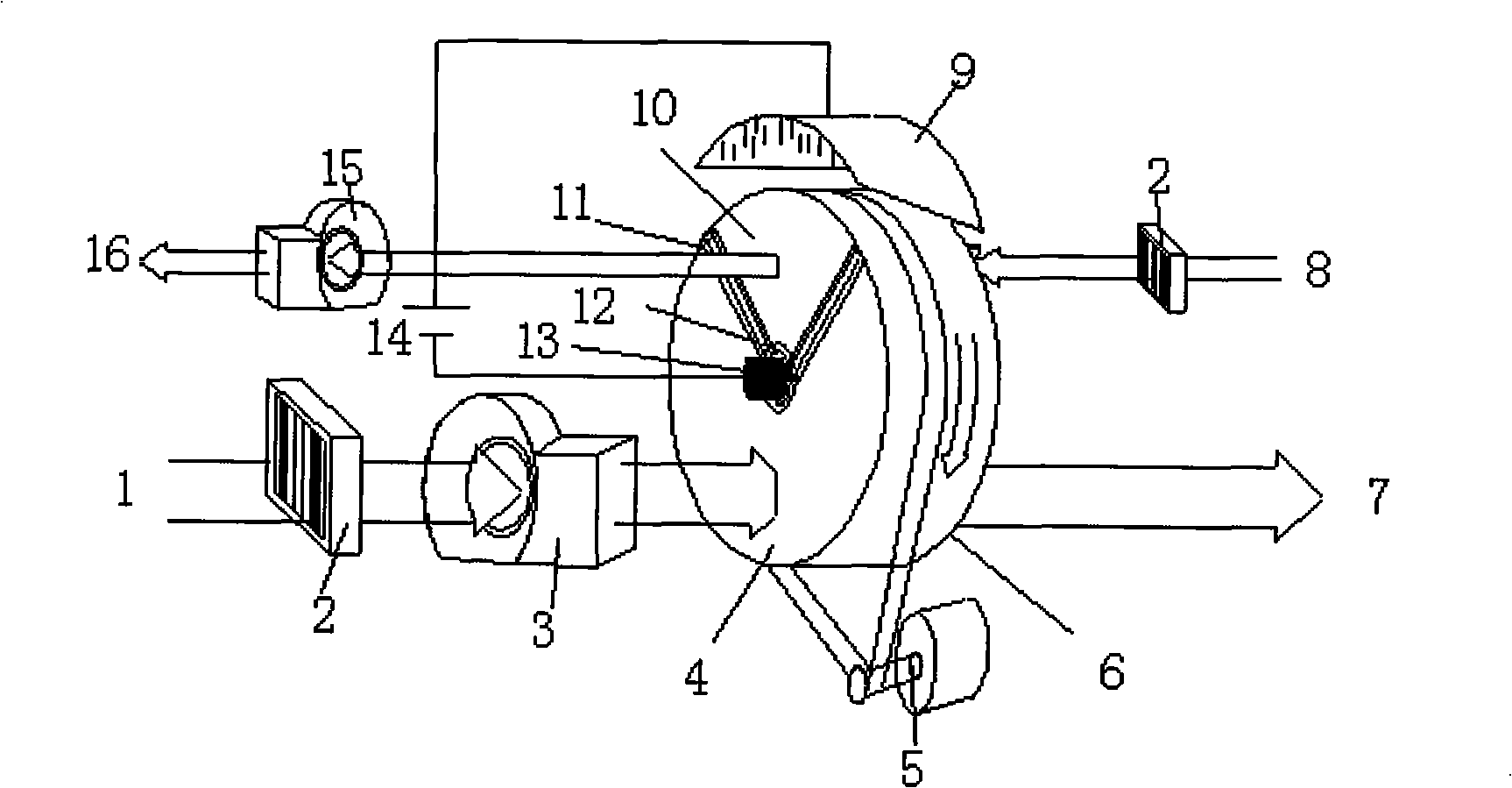

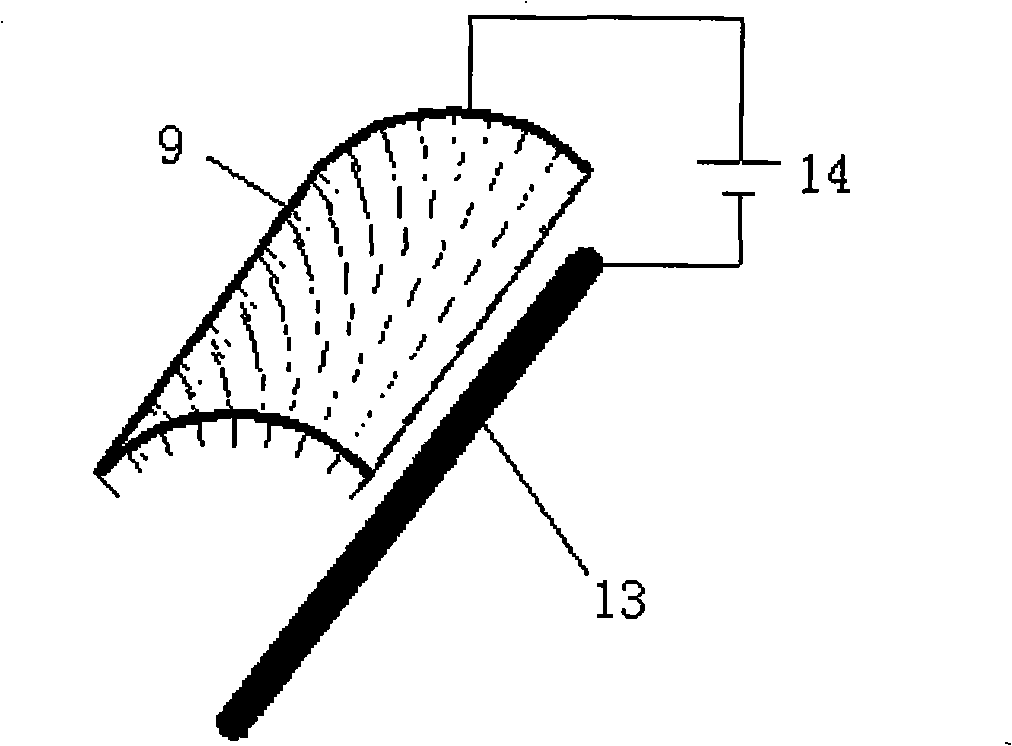

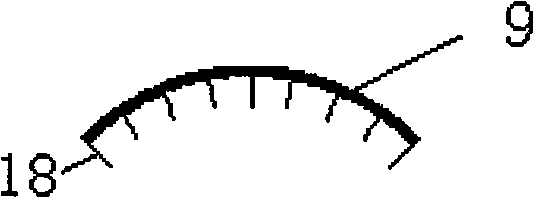

[0022] Such as figure 1 As shown, a rotary dehumidifier for regenerative dehumidification in a high-voltage electric field is composed of two parts: a rotary dehumidification system and a dehumidification regeneration system. The metal plate strip 9, the negative electrode is connected to the axis 13 of the dehumidification rotor 6, and the cover is outside the regeneration area 10 of the dehumidification rotor 6, and the axis 13 of the dehumidification rotor 6 is covered with a sleeve 12, and the regeneration area Both sides of 10 are fixed dividing plates 11, with hygroscopic material 17 in the middle, regeneration air inlet 8 and regeneration humid air outlet 16 are opened at both ends of regeneration zone 10, regeneration fan 15 is installed at regeneration humid air outlet 16, regeneration air inlet 8 A filter 2 is installed, and thorns 18 are arranged on the arc-shaped metal strip 9 .

[0023] The dehumidification regeneration includes the following steps:

[0024] 1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com