Total-tailings paste filling and stockpiling combined treatment method based on deep-cone thickener

A technology of deep cone thickener and disposal method, which is applied in the field of combined disposal of full tailing paste filling and stockpiling, which can solve the problems of increasing construction and maintenance costs of tailings ponds, difficulty in drainage of stope slurry, and serious underground pollution. Achieve the effect of continuous operation of preparation quality, short concentration time and improved safety level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

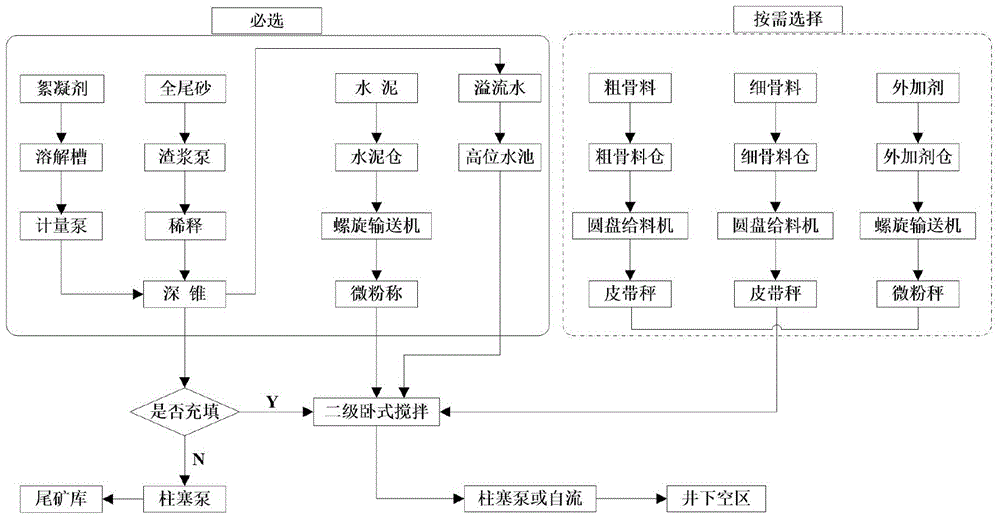

Method used

Image

Examples

Embodiment

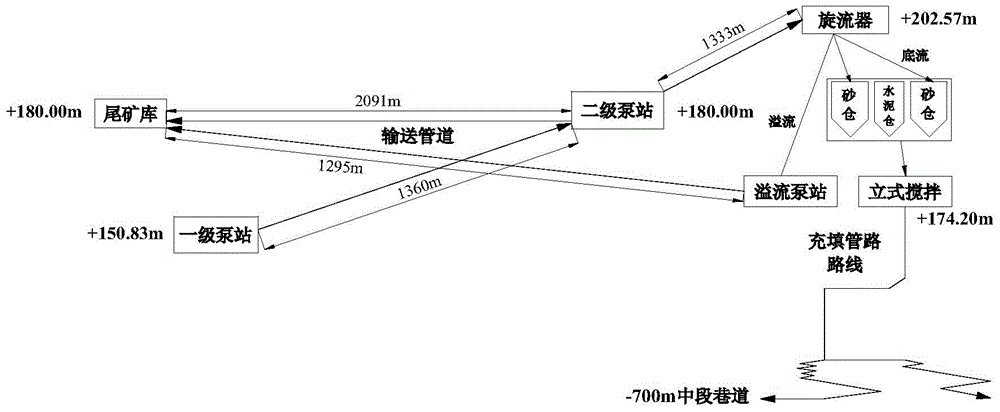

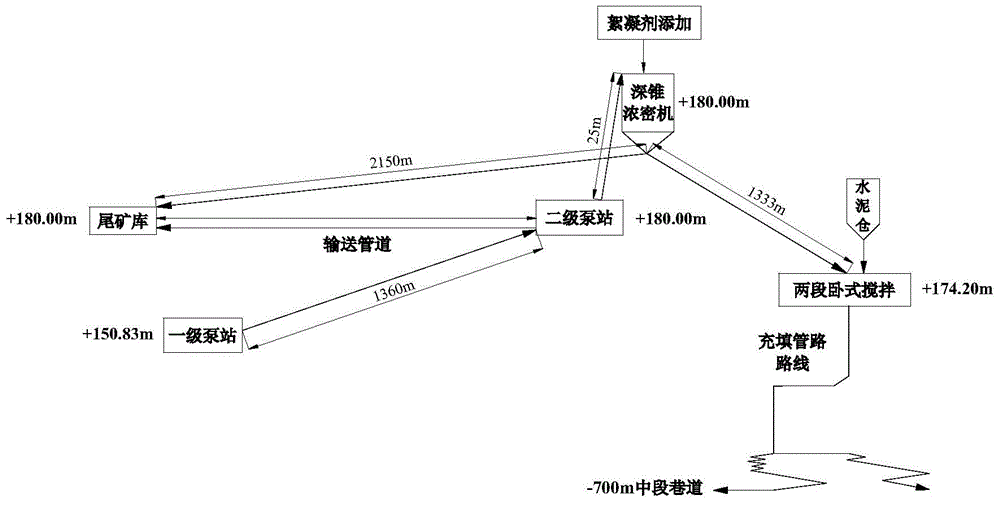

[0029] A gold mine adopts the upward horizontal filling mining method, and the mining scale reaches 6000t / d, which can meet the ore supply demand of the dressing plant. At present, the mine filling system mainly uses graded tailings gravity conveying for filling, and the filling concentration is 60%-65%. According to the physical properties of the tailings, the filling concentration is obviously low. At the same time, the traditional vertical sand bin is used for the dehydration of the filling aggregate, which makes the slurry concentration relatively low and the underflow concentration unstable. The low filling concentration brings many problems: the filling lime-sand ratio of the gold mine reaches 1:4, and the cement consumption is high; the excess water in the filling slurry causes high dehydration pressure in the stope, and the ultra-fine particles in the tailings and cement blockage Filling the filter cloth of the retaining wall makes it difficult to dehydrate the filling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com