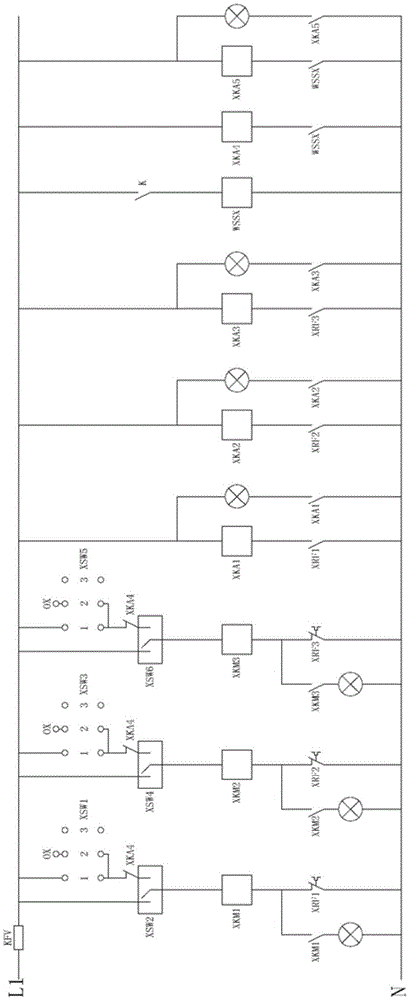

motor control circuit

A motor control and electric control technology, which is applied in the direction of furnace control devices, furnaces, lighting and heating equipment, etc., can solve problems such as unstable work and unstable performance of electrostatic precipitators, achieve convenient operation, and improve the control of excessive discharge of electrostatic precipitators Concentration, simple effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present invention, and not to limit the present invention.

[0017] The present invention provides a motor control circuit, which includes: a selector switch configured to be connected to the positive electrode of the power source for switching between manual control or automatic control; a contactor, one end of the contactor is connected In the selector switch, the contactor controls the closing of the contactor switch through power-off, and controls the opening of the contactor switch through power-off; a thermal relay, one end of the thermal relay is connected to the contactor, and the other end When the motor is connected to the negative pole of the power supply, the temperature of the thermal relay exceeds a preset value, the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com