Patents

Literature

32results about How to "High emission concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

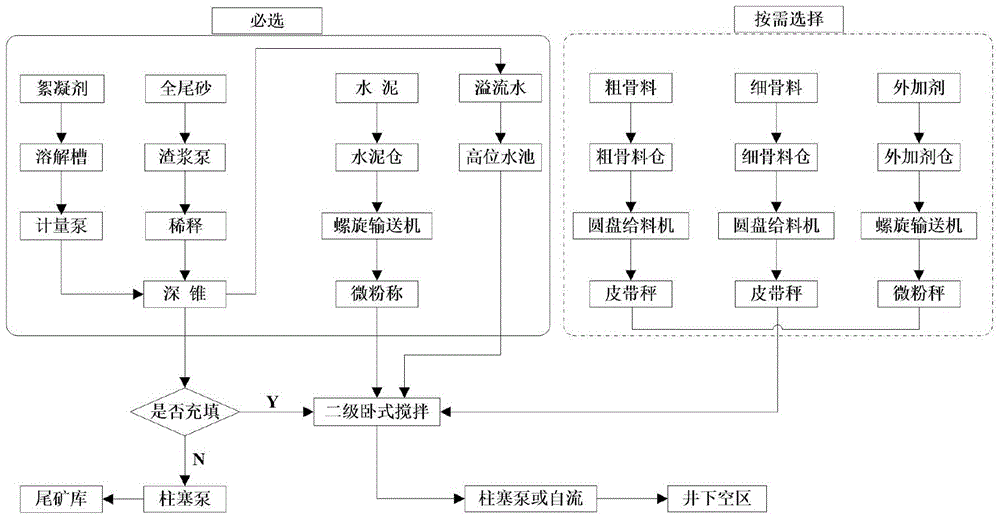

Total-tailings paste filling and stockpiling combined treatment method based on deep-cone thickener

ActiveCN104929683AHigh emission concentrationImprove security levelMaterial fill-upMining engineeringCombined treatment

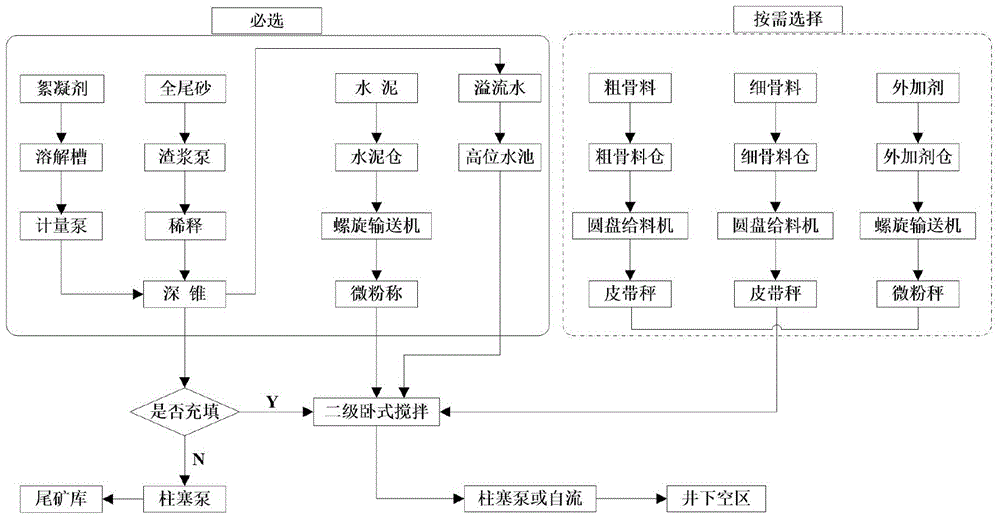

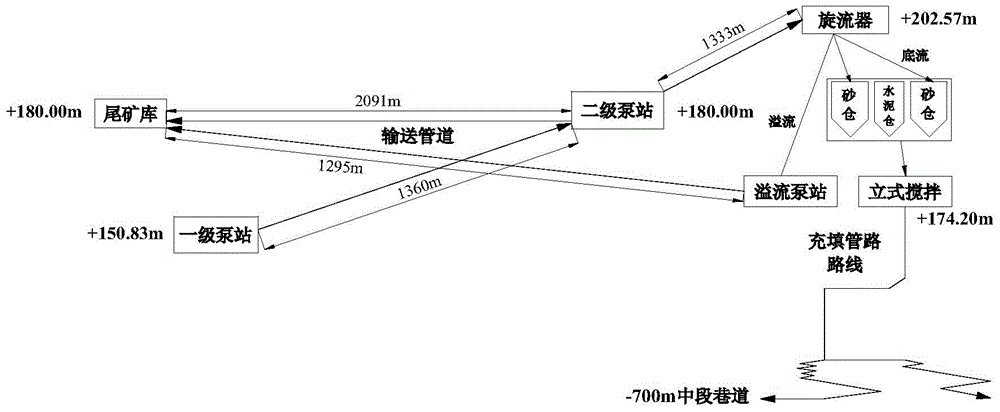

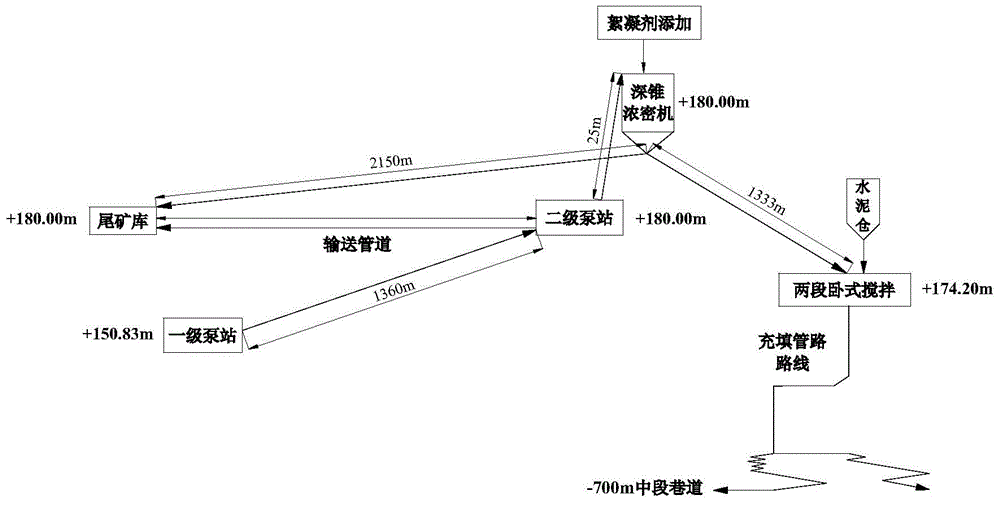

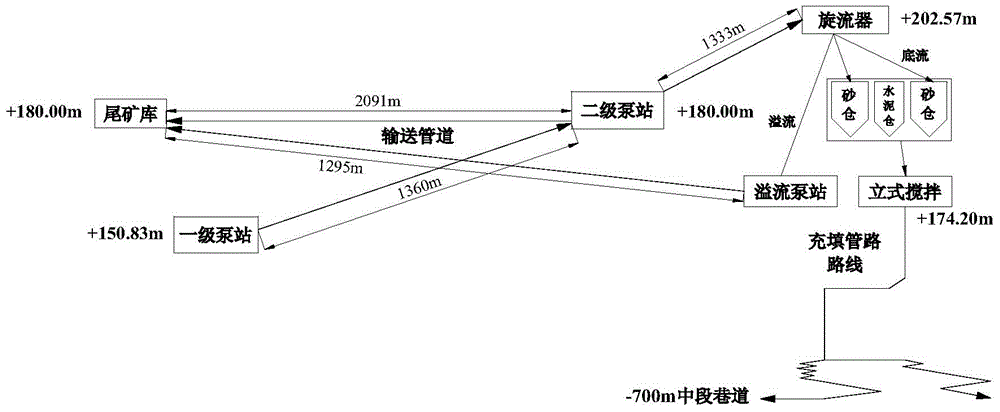

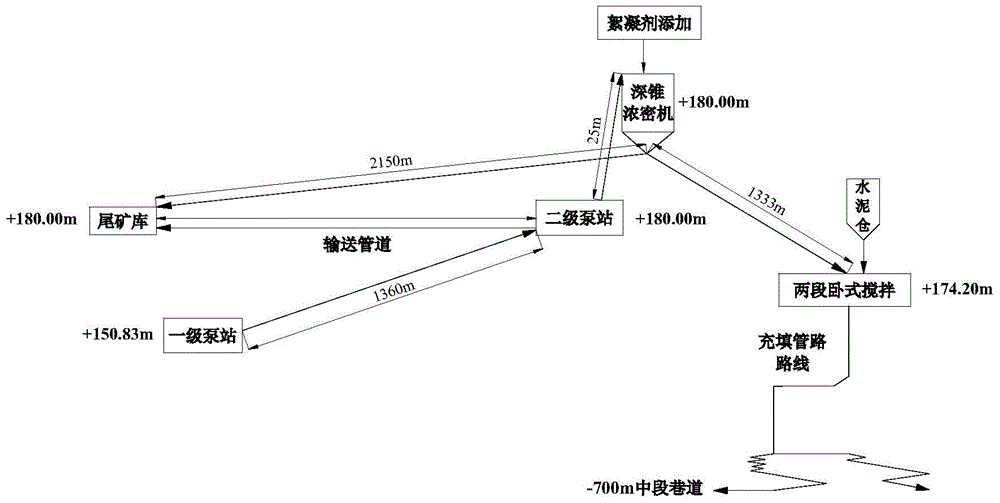

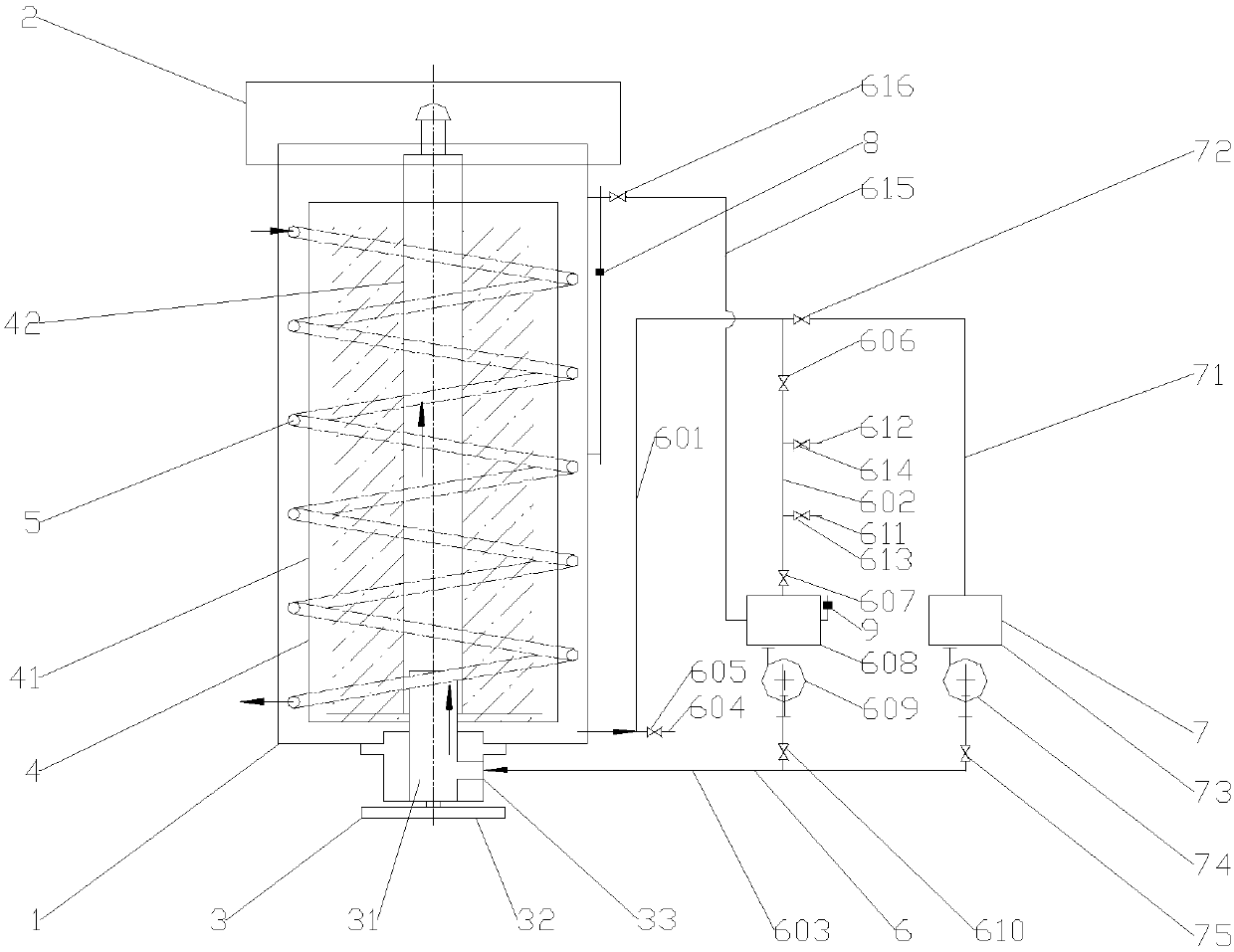

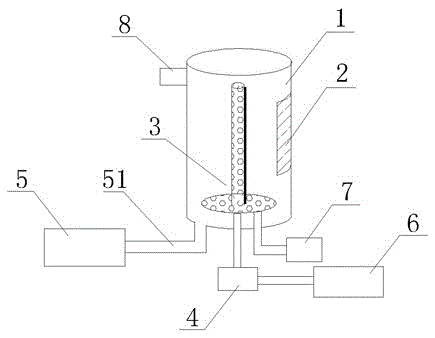

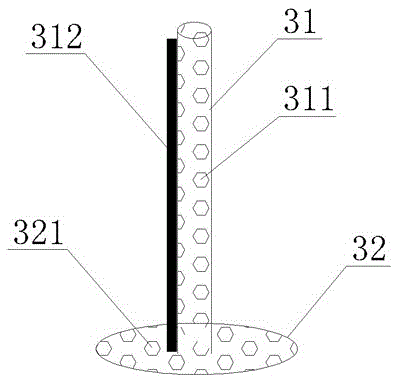

The invention relates to a total-tailings paste filling and stockpiling combined treatment method based on a deep-cone thickener. A combined treatment system is composed of a one-stage or multi-stage pump station, the deep-cone thickener and a two-segment horizontal stirring device. The deep-cone thickener is arranged near the multi-stage pump station. A continuous feeding and discharging mode is adopted for achieving the continuous concentration process, and the two functions of filling and tailings stockpiling are both taken into consideration. In the running process of a filling system, total tailings of a concentration plant are completely thrown into the deep-cone thickener through the one-stage or multi-stage pump station. When filling is needed, deep-cone bottom flow is pumped to the two-segment stirrer through a mortar pump and is mixed with cement, and qualified paste is prepared and flows to or is pumped to a stope. When filling is not needed, the bottom flow is pumped by a plunger pump to a tailings pond by means of the pump station, and stockpiling of paste is performed. The method can well solve the filling problem of a gob and the stockpiling problem of tailings at the same time, filling cost is greatly reduced, the strength of filling bodies is improved, discharge of the tailings is reduced to the maximum extent, and meanwhile tailings paste is discharged.

Owner:UNIV OF SCI & TECH BEIJING +1

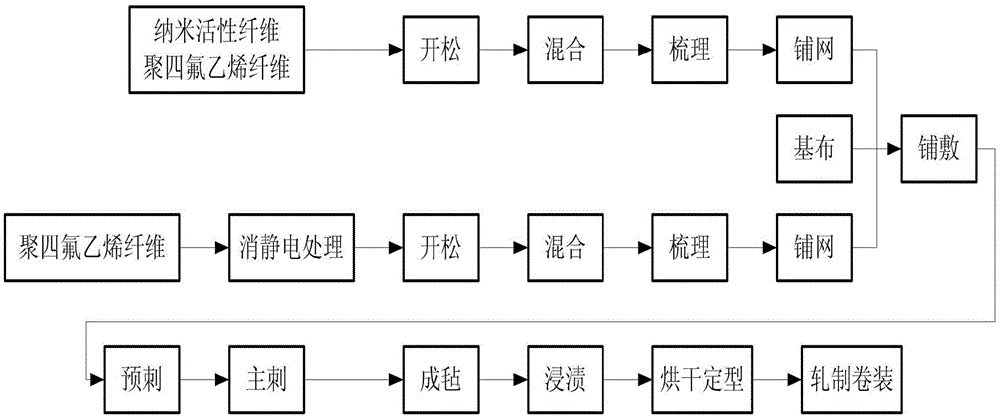

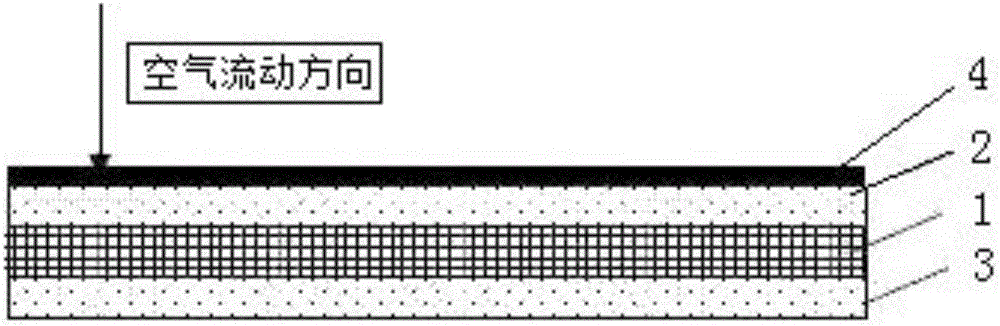

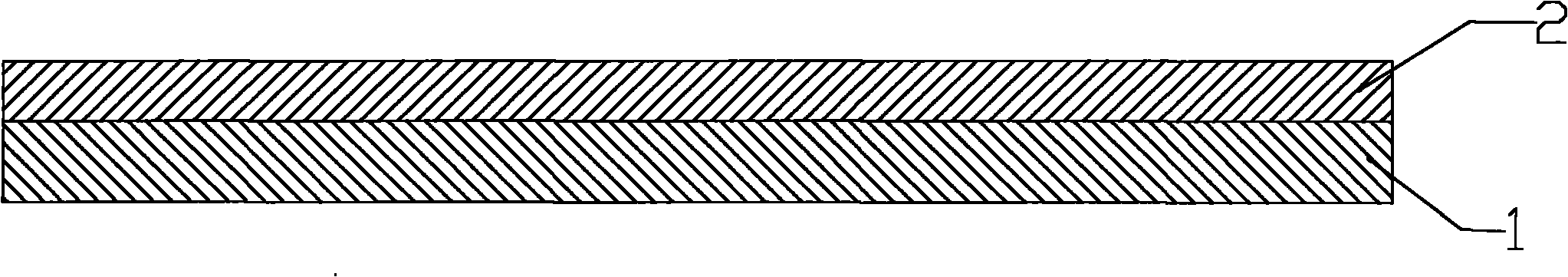

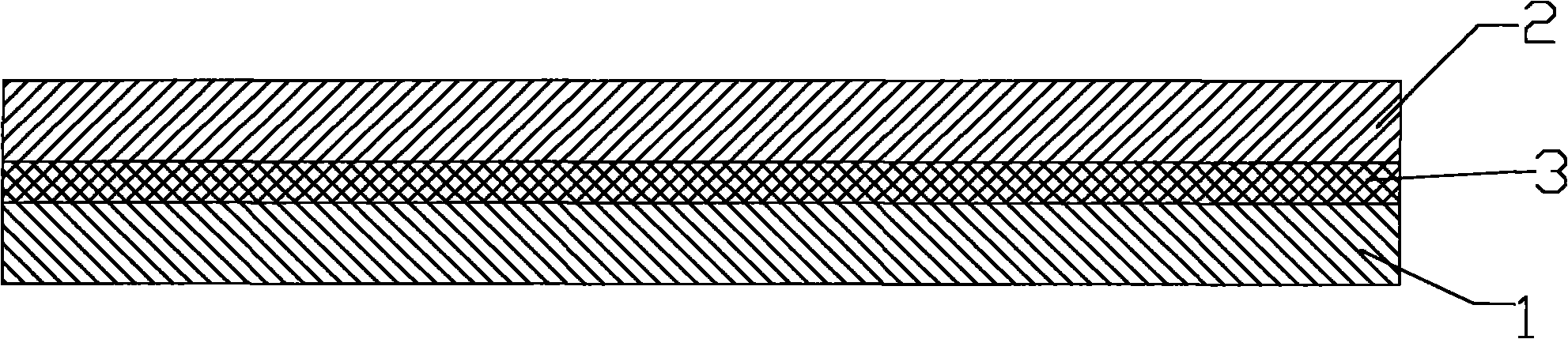

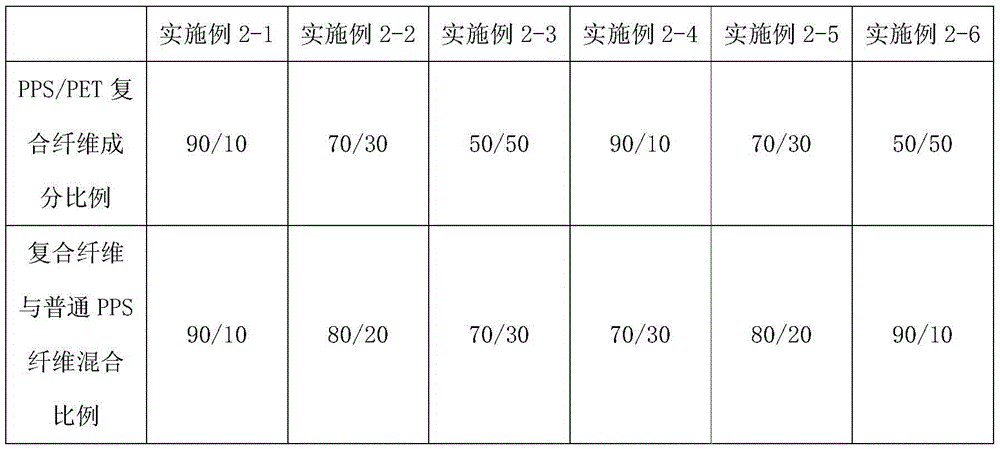

High-precision high temperature and corrosion resisting nanometer filter cloth with adsorption and decomposition functions and making method thereof

InactiveCN105597424AEmission reductionNarrow pore size distributionSynthetic resin layered productsLiquid repellent fibresActivated carbonFiber

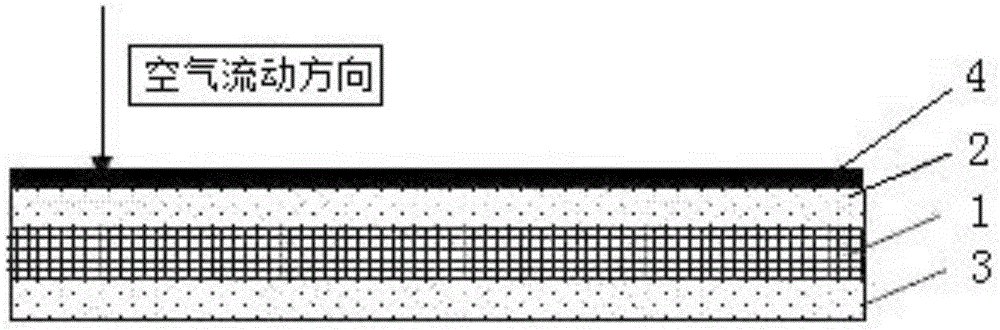

The invention discloses high-precision high temperature and corrosion resisting nanometer filter cloth with adsorption and decomposition functions and a making method thereof. The filter cloth comprises a middle base cloth layer, wherein a superfine fiber dust-facing surface layer is arranged on the upper surface of the base cloth layer, an air transmitting and purifying surface layer is arranged on the lower surface of the base cloth layer, the superfine fiber dust-facing surface layer is formed by laying nanometer activated carbon fibers and polytetrafluoroethylene superfine fibers into a net, the base cloth layer, the superfine fiber dust-facing surface layer and the air transmitting and purifying surface layer are needled into felt, and a PTFE emulsion dipping layer is arranged on the surface of the felt. The filter cloth has the advantages that the nanometer activated carbon fibers and a polytetrafluoroethylene base material are used for making the filter cloth, and the filter cloth has a microcellular structure, can adsorb and decompose harmful gases and is high in filtering precision; meanwhile, according to the making method, by means of the dipping treatment process, the surface of the filter cloth has certain hydrophobicity, and the resistance to acid, alkali and corrosion of the filter cloth is improved.

Owner:SUZHOU HUILONG PURIFYING FILTER

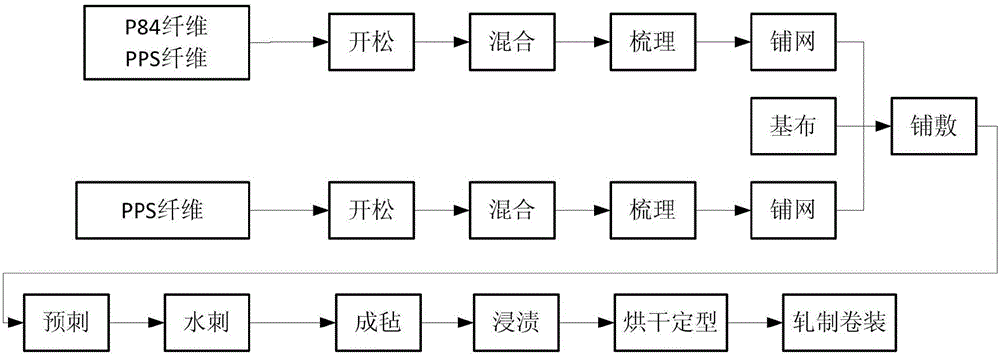

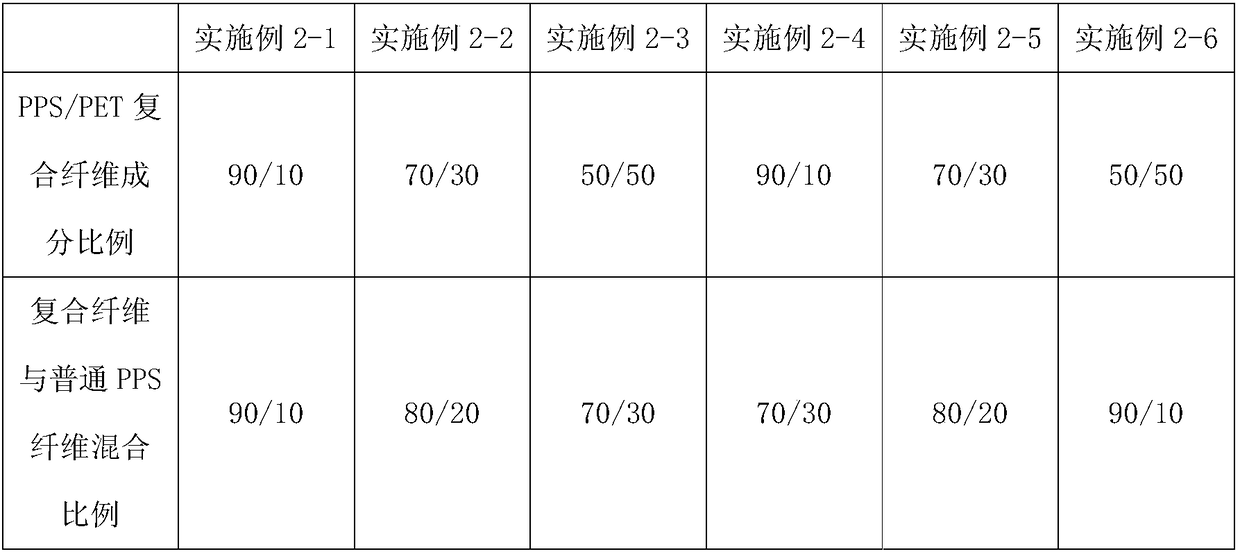

P84 fiber and PPS (Polyphenylene Sulfide) fiber composite high-temperature-resisting spunlaced felt and preparation method thereof

InactiveCN105688510AImprove filtration efficiencyUniform pore size distributionLamination ancillary operationsDispersed particle filtrationEmulsionSurface layer

The invention discloses a P84 fiber and PPS (Polyphenylene Sulfide) fiber composite high-temperature-resisting spunlaced felt and a preparation method thereof. The P84 fiber and PPS fiber composite high-temperature-resisting spunlaced felt comprises a base cloth layer in the middle, wherein the upper surface of the base cloth layer is provided with an ultrafine fiber dust accepting surface layer, and a ventilation and air purification surface layer is arranged on the lower surface of the base cloth layer; the base cloth layer, the ultrafine fiber dust accepting surface layer and the ventilation and air purification surface layer are needled to form the felt; the surface of the felt is provided with a PTFE (Polytetrafluoroethylene) emulsion impregnation layer. The ultrafine fiber dust accepting surface layer is composed of P84 fibers with a three-leaf-shaped structure and a PPS fiber spreading net with the size of 1D; an ultrahigh-pressure multi-path spunlacing process is used for replacing a traditional needling process; a spunlacing flexible entangling laminating technology and a splitting process are utilized, so that the P84 fibers are split and cracked into fibers with relatively fine fiber diameters, and irregular pores are formed; the distribution of pore diameters is more uniform, tight and intensive than a needed filtering material; the felt has extremely high filtering efficiency and the emission concentration is lower than 10mg / m<3>.

Owner:SUZHOU HUILONG PURIFYING FILTER

Recovery method for hydrogen chloride gas produced in production process for 3,5-dichloro-4-aminobenzotrifluoride

InactiveCN103521059AImprove absorption efficiencyCorrosion resistantChlorine/hydrogen-chlorideDispersed particle separationRecovery methodHigh concentration

The invention discloses a recovery method for hydrogen chloride gas produced in a production process for 3,5-dichloro-4-aminobenzotrifluoride. The method is characterized by comprising the following steps: pressurizing HCl gas produced in production of 3,5-dichloro-4-aminobenzotrifluoride by using a fan and introducing the pressurized HCl gas into a primary falling film absorber from the bottom of a tower; subjecting the HCl gas to absorption by a spray device and then to separation by a gas-liquid device; allowing separated gas to enter into a secondary falling film absorber for absorption; then allowing tail gas to enter into a two-stage alkali spray tower for absorption; and finally, carrying out evacuation by using a high exhaust pipe, cyclically using falling film absorption liquid and allowing the falling film absorption liquid to flow out from the bottom of the secondary falling film absorber when the concentration of the falling film absorption liquid reaches 30%, wherein the falling film absorption liquid is reused as hydrochloric acid with a mass concentration of 30%. The recovery method has the following advantages: the falling film absorbers have the advantages of high absorption efficiency, corrosion resistance, high absorption strength, high concentration of the product hydrochloric acid, a low outlet temperature, stable operation and convenience in controlling; discharge of HCl exhaust gas is substantially reduced while recovery of useful materials; and a good effect is obtained during multiple cycles of absorption of HCl gas with water.

Owner:NANTONG HAISHENG PHARMA

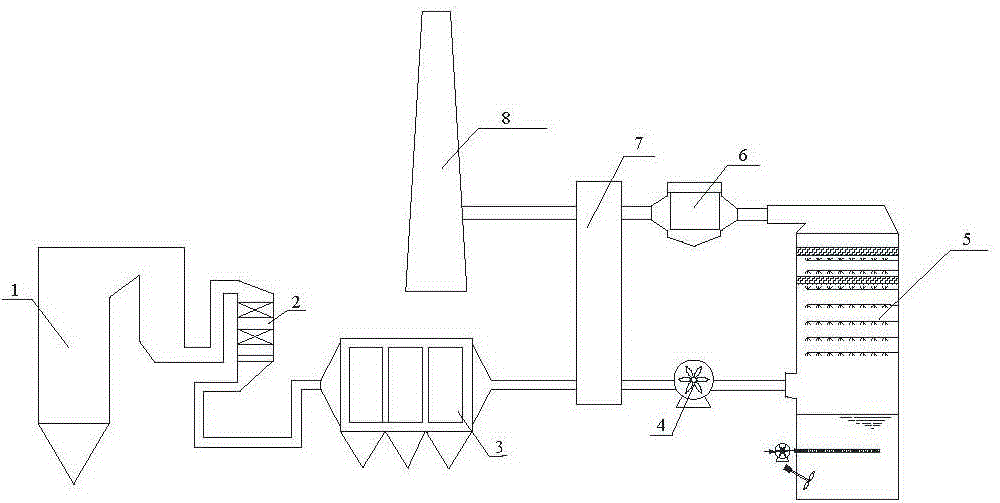

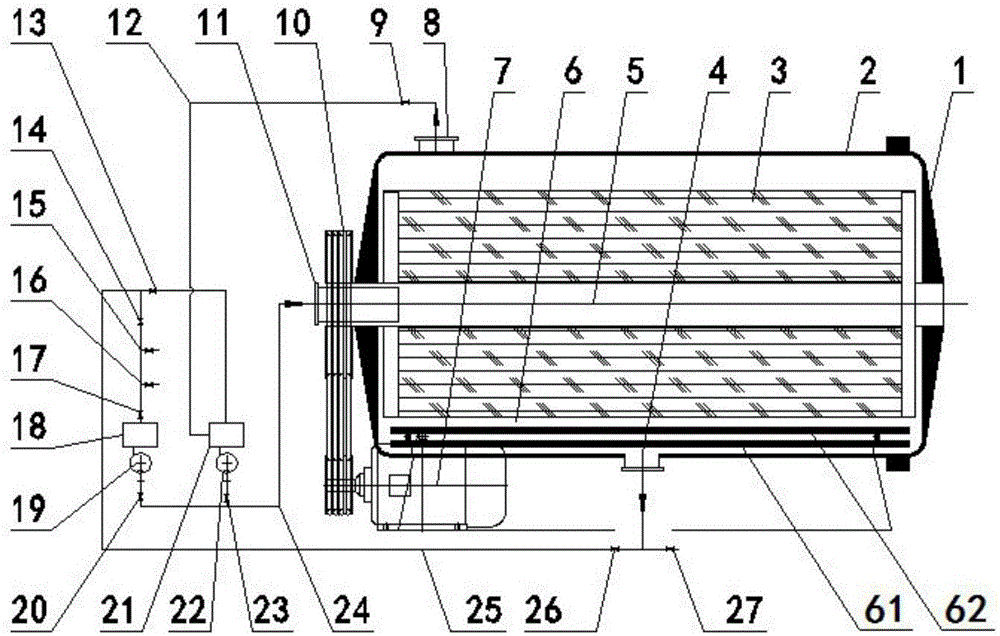

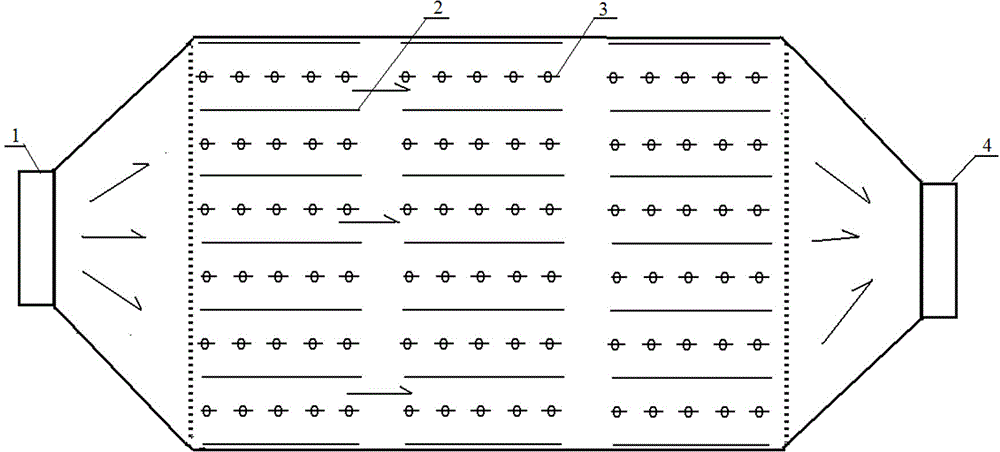

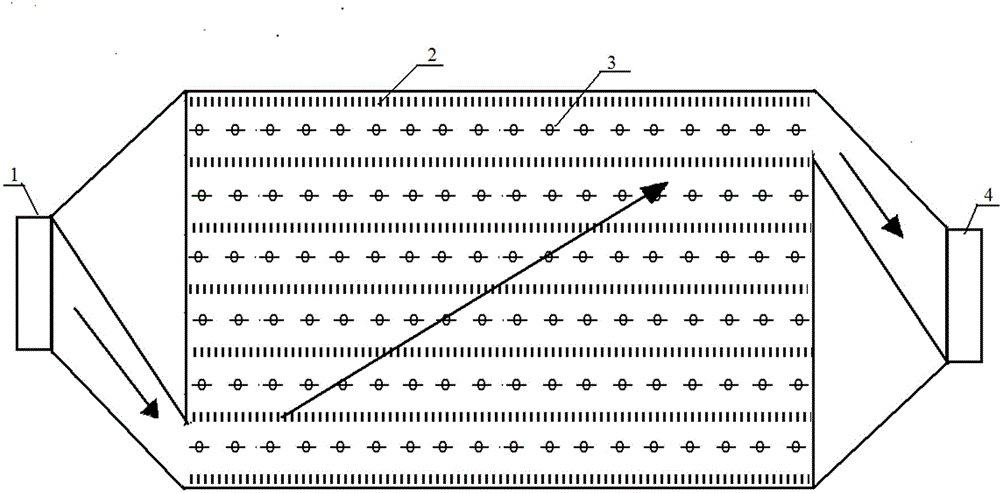

Coal-fired flue gas pollutant ultralow emission system with rotary type GGH

InactiveCN104791820AReduce dosageImprove desulfurization efficiencyLighting and heating apparatusDispersed particle separationFlue gasPollutant emissions

The invention relates to a coal-fired flue gas pollutant ultralow emission system with a rotary type GGH. The system comprises a denitrating reactor, an electrical dust precipitator, a booster fan, a desulfurizing tower, a wet-type electrostatic dust precipitator and a chimney which are connected in sequence, and the system further comprises the rotary type GGH. The rotary type GGH comprises a heat absorption segment of the rotary type GGH and a heat emission segment of the rotary type GGH, wherein the heat absorption segment of the rotary type GGH is arranged between the electrical dust precipitator and the booster fan, and the heat emission segment of the rotary type GGH is arranged between the wet-type electrostatic dust precipitator and the chimney. The heat absorption segment of the rotary type GGH is arranged in front of the booster fan, so that pressure in a purified flue gas side is negative, and by means of the GGH arrangement, the emission concentration of pollutant can be prevented from raising due to the fact that raw flue gas is leaked out to purified flue gas. By treating coal-fired flue gas, the emission concentration of NO[x] is lower than 50 mg / m<3>, the emission concentration of SO[2] is lower than 35 mg / m<3>, the emission concentration of dust is lower than 5 mg / m<3>, and the emission concentration of mercury is lower than 3 micrograms / m<3>.

Owner:ZHEJIANG UNIV

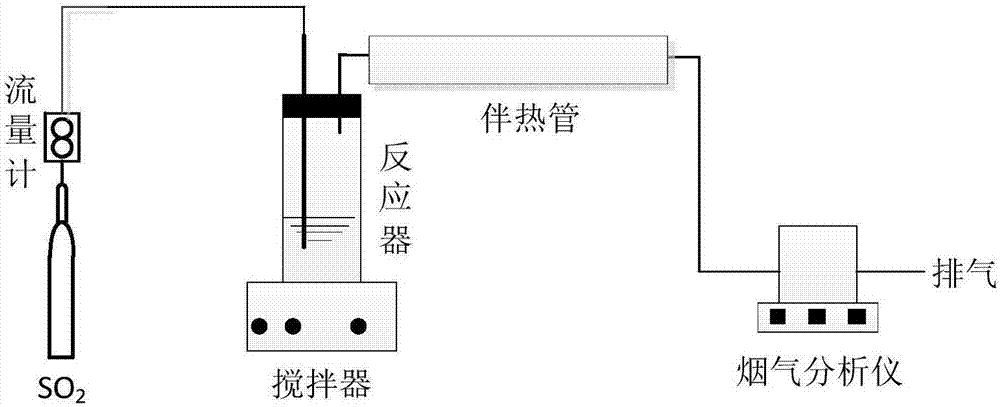

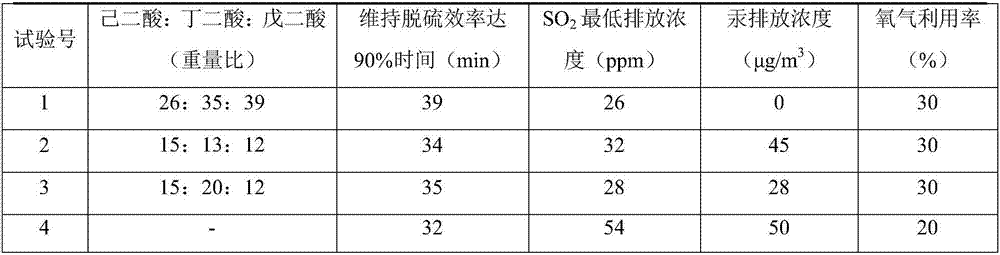

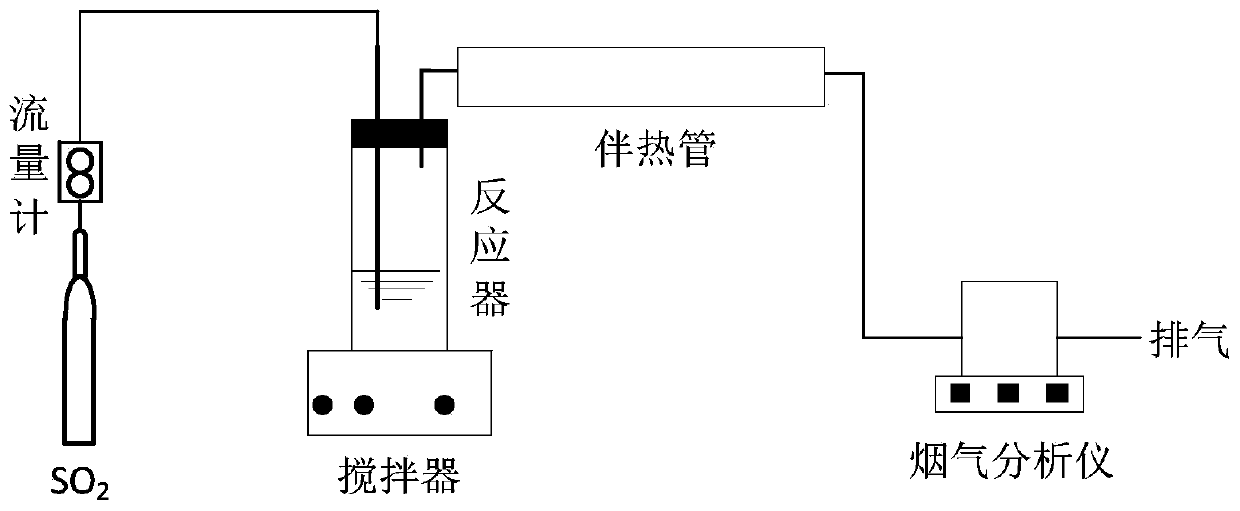

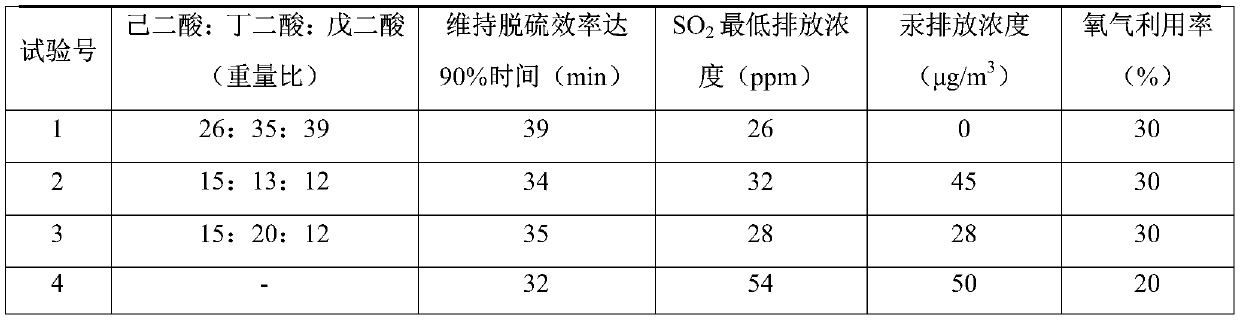

Desulfurization additive applicable to limestone-gypsum wet-method flue gas desulfurization technique

ActiveCN107349774AIncreased ability to neutralize acidsFacilitated DiffusionDispersed particle separationGypsumOrganic acid

The invention discloses a desulfurization additive applicable to a limestone-gypsum wet-method flue gas desulfurization technique. The desulfurization additive is prepared from the following raw materials in parts by weight: 60 to 70 parts of mixed organic acid, 10 to 20 parts of loss inhibitor, 0 to 1 part of mercury stabilizer, 20 to 30 parts of oxidation catalyst and 5 to 15 parts of antifoaming agent, wherein the mixed organic acid is a mixture of adipic acid, succinic acid and glutaric acid; the weight ratio of the adipic acid to the succinic acid to the glutaric acid is 26 to 35 to 39; the oxidation catalyst is a mixture of manganese sulfate and iron sulfate; the weight ratio of the manganese sulfate to the iron sulfate is 3 to 4. The desulfurization efficiency and the utilization rate of limestone can be improved through the use of the desulfurization additive; further, the loss of the desulfurization additive and the emission concentration of the mercury can be reduced. In the same condition, after the additive provided by the invention is added into a desulfurization system, the time of maintaining that the desulfurization efficiency reaches 90 percent is prolonged; improvement of the utilization rate of the limestone is shown.

Owner:CENT CHINA BRANCH OF CHINA DATANG CORP SCI & TECH RES INST CO LTD

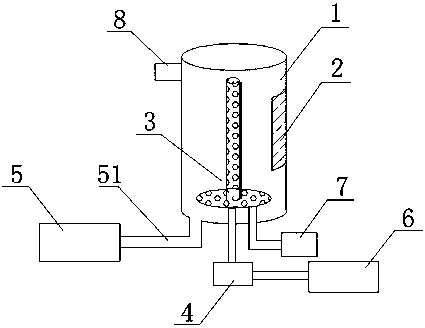

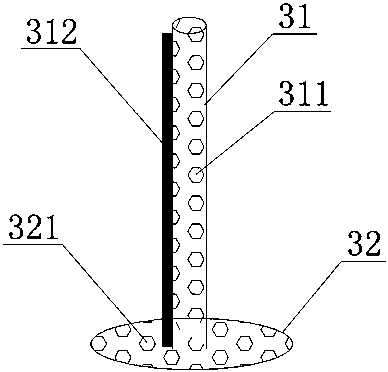

Novel cloth dyeing, dehydration, drying and forming device and integrated machine with same

InactiveCN106120210AHigh emission concentrationReduce energy consumptionLiquid/gas/vapor removalTextile treatment machine arrangementsColor differenceDyeing

The invention relates to a novel cloth dyeing, dehydration, drying and forming device which comprises a cylinder body, a cylinder cover, a hollow reel, a power device and a moving mechanism. The cylinder body is covered with the cylinder cover. The hollow reel is arranged in the cylinder body. The power device is arranged outside the cylinder body. An output shaft of the power device is connected with the hollow reel so as to drive the hollow reel to rotate. The moving mechanism is arranged at the bottom of the cylinder body. The hollow reel is in a cylindrical shape. The device has the advantages that cloth is reeled in a cylindrical shape and then is dyed, dehydrated and dried, and fabric dyeing, dehydration and drying operation is finished in one equipment; the cloth is dyed and dehydrated in a cylindrical shape, so that cloth is always in a cylindrical shape, tightening is avoided, and therefore the cloth deformation amount and dyeing color difference are greatly reduced.

Owner:王博敏

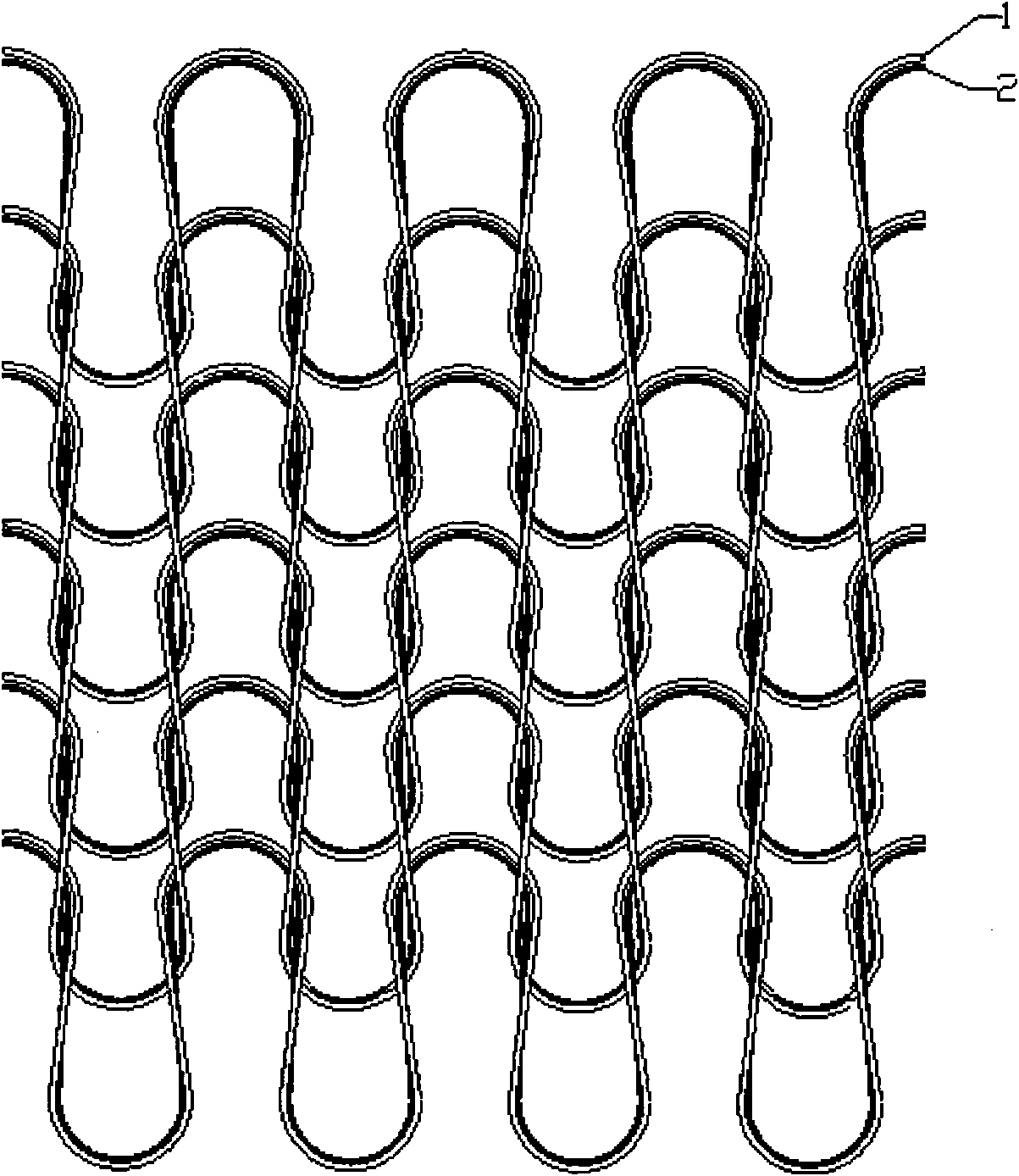

Composite wool knitted fabric

InactiveCN102092154ADehumidifyingHigh emissivitySynthetic resin layered productsCarbon fibersPhysical well being

The invention discloses a composite wool knitted fabric. The inner layer of the fabric is an antimicrobial and skin-kindly layer made of bamboo charcoal fibers, and the outer layer is a heat insulating layer made of wool fibers. The composite wool knitted fabric has the effects of dehumidifying and insulating heat as well as degerming and eliminating smell, is beneficial to the health of bodies and is suitable for being worn close to the skin.

Owner:WUJIANG YUANMING PRINTING FACTORY

Bamboo charcoal fiber yarn and application in home textile products

A bamboo charcoal fiber yarn adopts bamboo charcoal fiber with a fineness of 0.9dtex as a raw material and the bamboo charcoal fiber yarn with finenesses of 60 and 40 is spinned through the processes of blowing, combing, drawing, roving, spinning and decoloring; wherein, the weight percent X of the content of the bamboo charcoal in the bamboo charcoal fiber is not less than 20 and not more than 25. The bamboo charcoal fiber yarn can be used to prepare home textile products through the processes of beaming, sizing, spinning, and dyeing.

Owner:SHANGHAI SHUIXING HOME TEXTILE

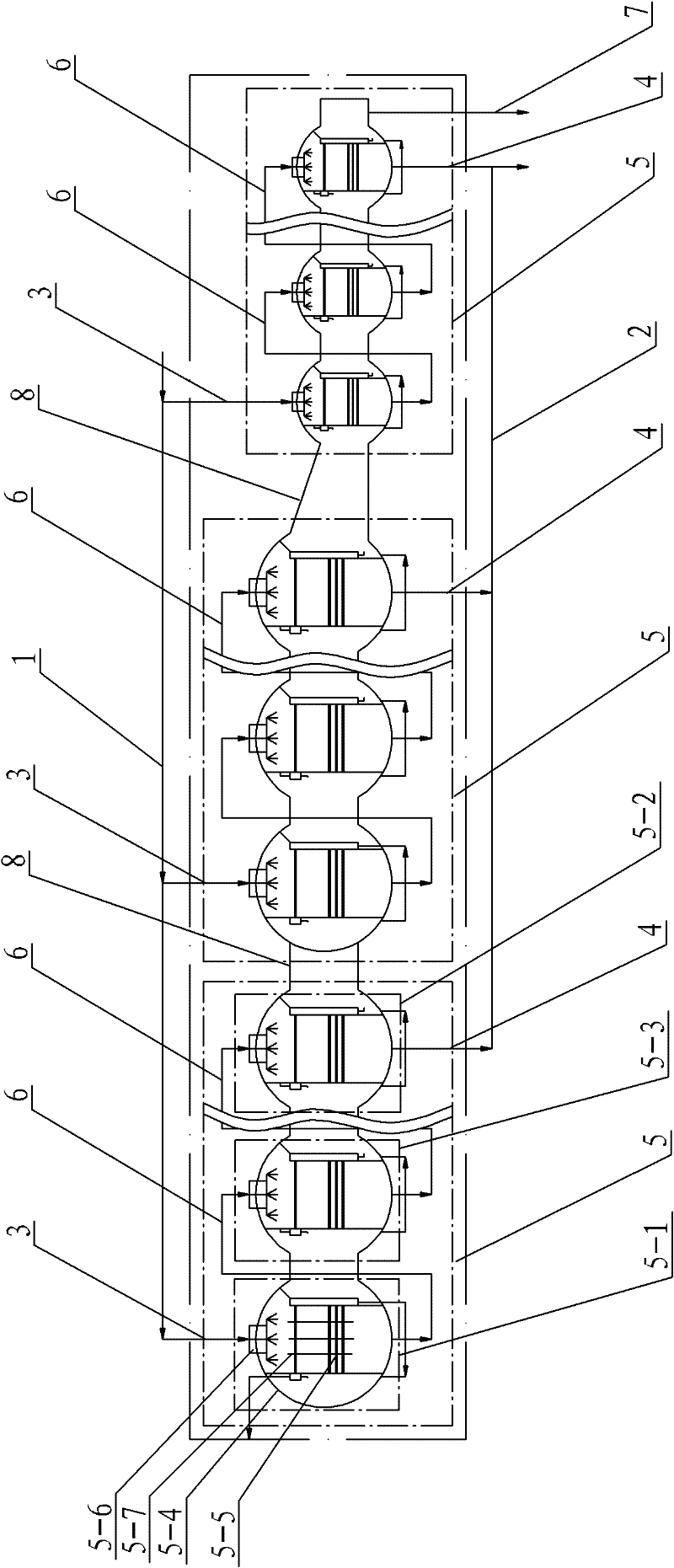

Main evaporator of low-temperature multi-effect sea water desalinization high-concentration factor combined system

InactiveCN102336495AHigh emission concentrationMeet the concentration ratio requirementsSeawater treatmentMultistage water/sewage treatmentSaline waterHigh concentration

The invention discloses a main evaporator of a low-temperature multi-effect sea water desalinization high-concentration factor combined system, which relates to a main evaporator of a combined system. The main evaporator provided by the invention solves the problem that the dense sea water desalinized by the existing low-temperature multi-effect sea water desalinization system cannot meet the requirements on the concentration factor of salt chemical industry of sea water desalinization downstream industry and results in waste of sea water. In the main evaporator, multi-effect sea water evaporators are orderly connected in series, multi-effect intermediate-effect evaporators are orderly connected in series, and first-effect evaporators, the multi-effect intermediate-effect evaporators and tail-effect evaporators are orderly connected in series, an evaporator feeding sea water female pipe is arranged above the multi-effect sea water evaporators, a plurality of sea water feeding connection pipes are horizontally arranged in parallel, the fed sea water is uniformly sprayed on each heat exchange tube of a heat exchange tube bundle through a shower pipe, water films are formed on each heat exchange tube, and an evaporator strong brine discharge female pipe is arranged under the plurality of sea water evaporators. The main evaporator provided by the invention is suitable for the multi-effect sea water desalinization high-concentration factor combined system.

Owner:HARBIN TURBINE AUX EQUIP ENG

Novel environment-friendly biological alcohol oil

The invention discloses novel environment-friendly biological alcohol oil which is composed of three raw materials of, by mass, 0.5% of a combustion improver, 89.5% of methyl alcohol and 10% of water. The three raw materials are stirred for 30 minutes in a container under normal pressure and temperature conditions. The combustion improver is composed of raw materials of, by mass, 5% of sodium hydroxide, 33% of water, 20% of methyl alcohol, 1% of magnesium oxide, 0.4% of ferrocene and 40.6% of oleic acid, and the raw materials are stirred for 10 minutes in a container under normal pressure and temperature conditions to obtain the combustion improver after the raw materials are dissolved. Compared with existing natural gases, liquefied gases and diesel, the novel environment-friendly biological alcohol oil has lower cost which is reduced by over 30%, and the dangerousness is greatly reduced under normal pressure. The burning temperature of existing oil doesn't exceed 1100 DEG C, and the burning temperature of the biological alcohol oil at furnace mouths can reach over 1200 DEG C. The soot emission concentration of the existing oil is high; however, the soot emission concentration of the biological alcohol oil is lower than 3.0 mg / m<3>. The emission concentration of sulfur dioxide of the existing oil is high; however, the emission concentration of the sulfur dioxide of the biological alcohol oil is lower than 3.0 mg / m<3>.

Owner:武汉中大农研生物技术有限公司

Non-woven filter cloth for air conditioner

InactiveCN106521947AHas antibacterial and antibacterial effectFast moisture absorption and heat dissipationBiochemical fibre treatmentFiltration separationPolyesterUltraviolet lights

The invention discloses a non-woven filter cloth for an air conditioner. The non-woven filter cloth is prepared from, by weight, 40-60 parts of tea polyphenol fiber, 30-60 parts of linen fiber, 20-40 parts of bamboo charcoal fiber, 5-12 parts of multifunctional polyester fiber, 10-20 parts of an antibacterial agent and 10-24 parts of a finishing agent. According to the non-woven filter cloth for the air conditioner, the antibacterial agent and the finishing agent are added, and by pasting the antibacterial agent and the finishing agent on the outer surface of the non-woven filter cloth, the non-woven filter cloth achieves antibacterial and bacteriostatic effects; the linen fiber and the bamboo charcoal fiber are adopted, the linen fiber is high in moisture absorption and heat dissipation speed, health care capability, anti-corrosion capability and bacteriostatic capability, resistant to fouling, static electricity and ultraviolet light and good in flame retardant effect, the bamboo charcoal fiber has the advantages of being superhigh in adsorption capacity, capable of emitting far-infrared rays and high in negative ion emission concentration, and therefore the non-woven filter cloth obtained through weaving achieves the antifouling, antistatic, anticorrosion and bacteriostatic effects; by adding the tea polyphenol fiber, the antibacterial performance of the non-woven filter cloth is effectively improved.

Owner:JIANGSU HAINA AIR CONDITIONER PURIFICATION EQUIP

Civil aviation jet fuel solid phase impurity removing device

ActiveCN104190119AControl nesting interval timeAutomatic nestingCentrifugal force sediment separationCycloneEngineering

The invention discloses a civil aviation jet fuel solid phase impurity removing device. The civil aviation jet fuel solid phase impurity removing device comprises a pressure sealing tank and a cyclone, and is characterized in that a separating plate is arranged at the middle-lower part of the pressure sealing tank, the periphery of the separating plate is welded with the inner wall of the pressure sealing tank in a sealing manner, a mounting hole is formed on the separating plate, a cone part of the cyclone is inserted into the mounting hole to be in sealing connection with the separating plate, the separating plate divides the pressure sealing tank into two independent sealing units, a feeding pipe of the cyclone penetrates through the wall of the pressure sealing tank to be in sealing connection with the wall of the pressure sealing tank, a high-level discharge pipe is arranged at the top of the pressure sealing tank, a lower-level blowdown pipe is arranged at the bottom of the pressure sealing tank, and a lower-level blowdown pipe is arranged on the wall of the pressure sealing tank above the separating plate. The civil aviation jet fuel solid phase impurity removing device can completely replace gravity settling impurity removal equipment in the civil aviation jet fuel impurity removal process, and can effectively improve the impurity removal efficiency and the equipment processing capacity, reduce the equipment investment and occupied area and prolong the service life of a filter screen in the lower level.

Owner:中国航油集团津京管道运输有限责任公司 +1

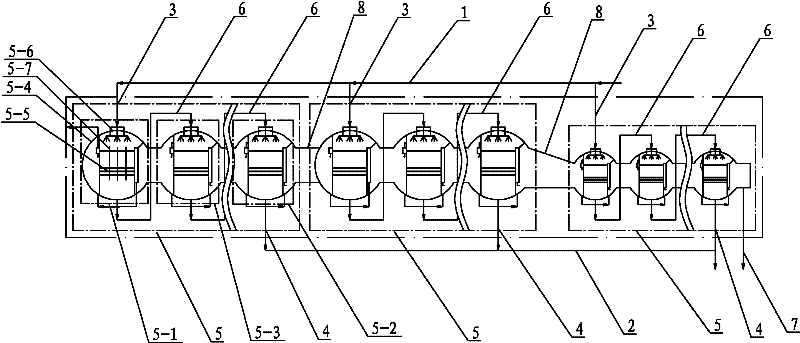

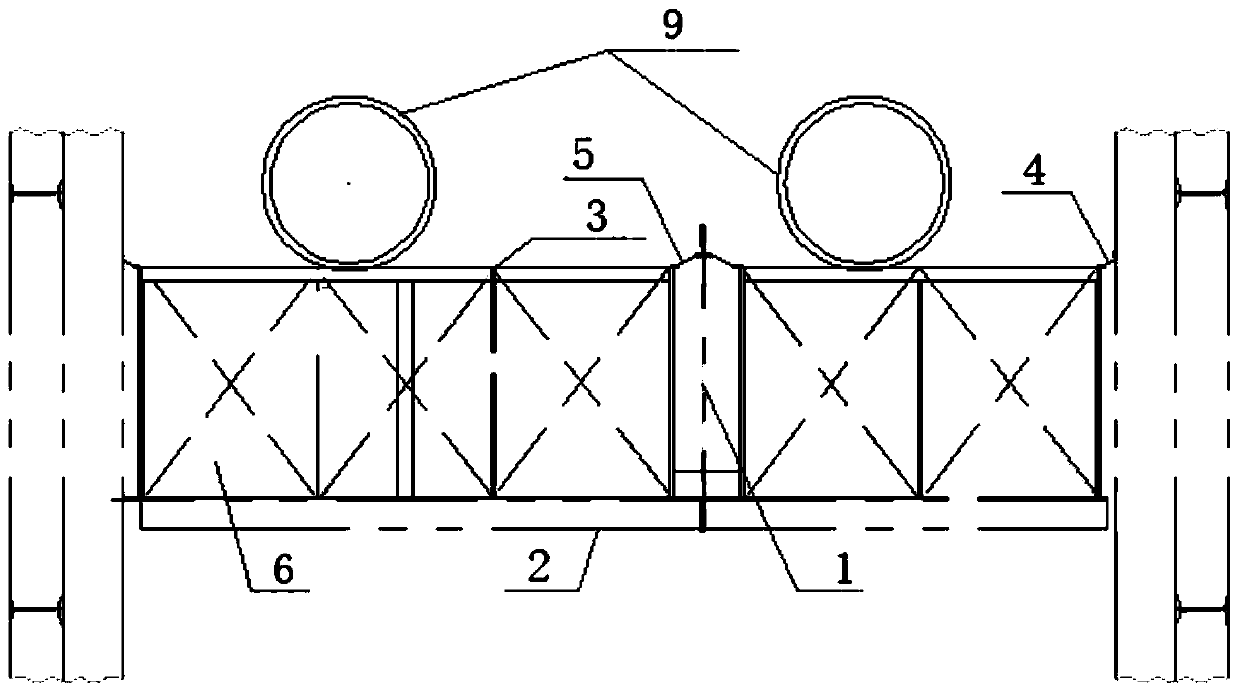

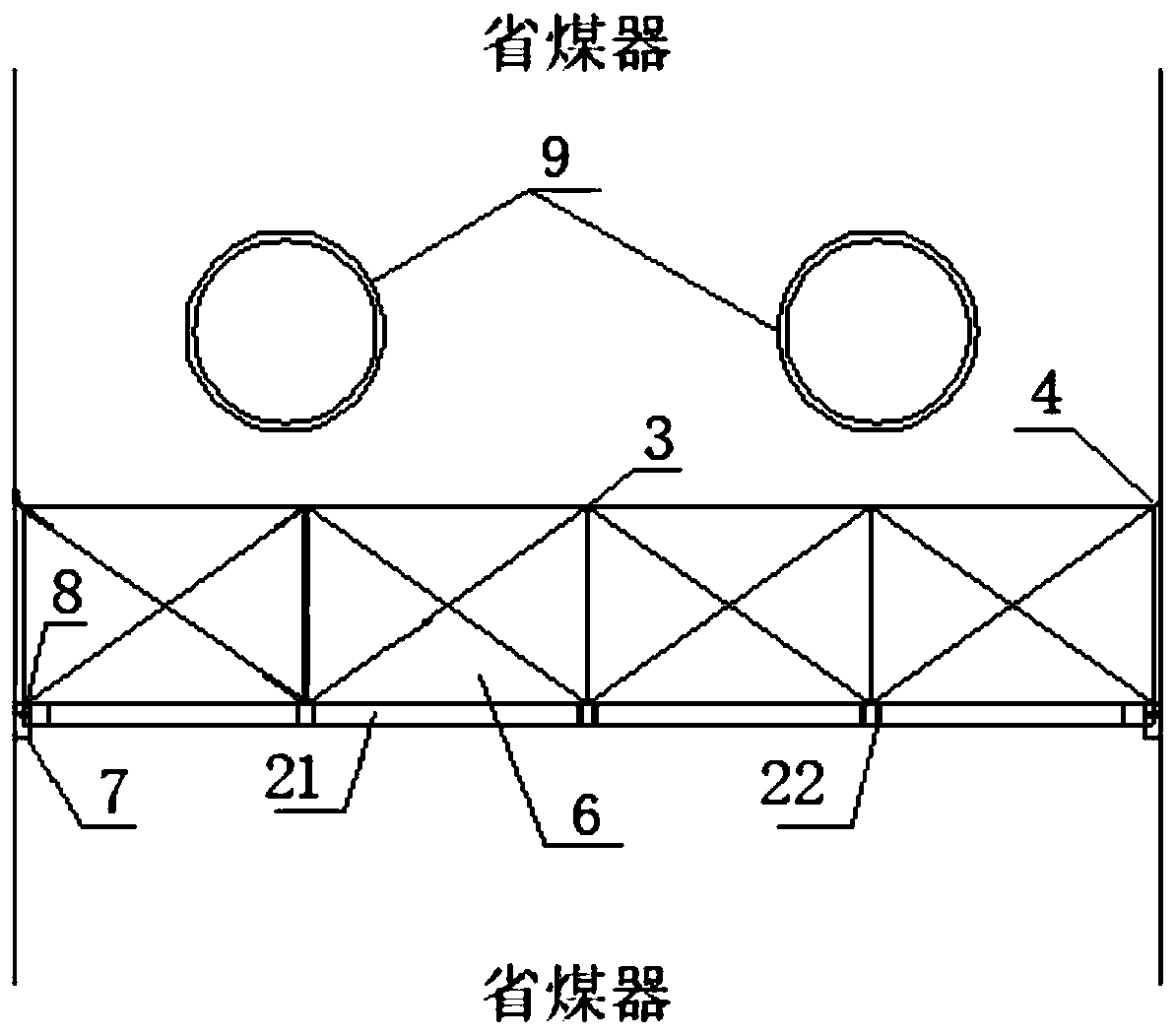

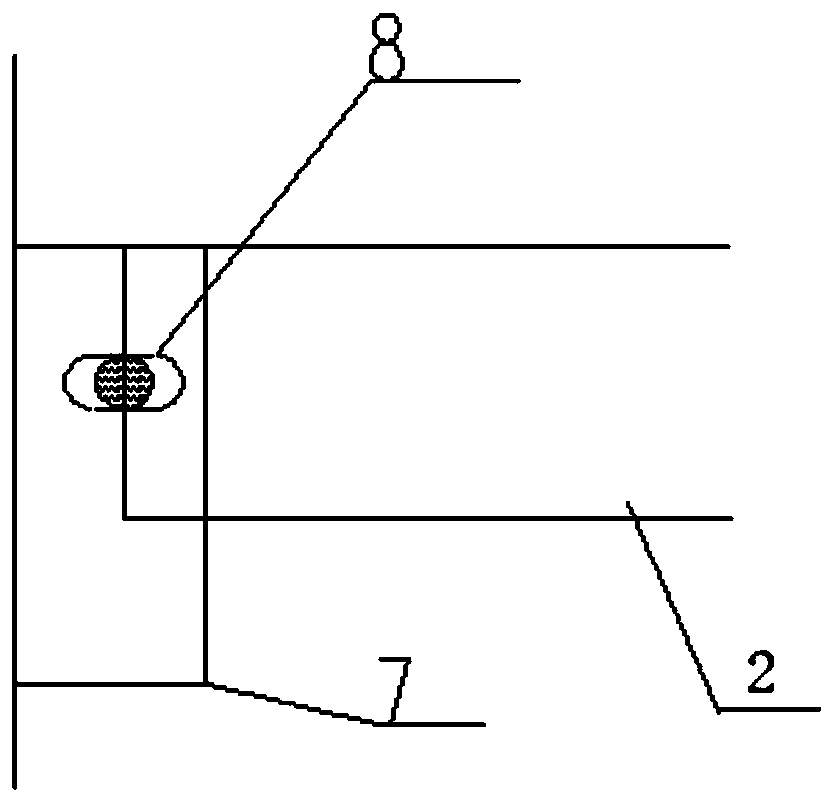

Normal-temperature SCR denitration device and process for improving denitration efficiency of boiler

PendingCN111151131AOvercoming the problem of low denitrification efficiencyHigh emission concentrationGas treatmentDispersed particle separationThermodynamicsPtru catalyst

The invention discloses a normal-temperature SCR denitration device and process for improving the denitration efficiency of a boiler. The device is arranged in an overhaul space of a boiler economizer. The device comprises non-standard catalyst units, a supporting structure and soot blowers. The non-standard catalyst units are arranged on the supporting structure, the end of the supporting structure is connected with the inner wall of a flue, the soot blowers are arranged at the top ends of the non-standard catalyst units, a sealing layer is arranged between every two adjacent non-standard catalyst units, and sealing pieces are arranged between the non-standard catalyst units on the edge and the flue. A sliding structure is arranged between the supporting structure and the flue. The maintenance space between the flue heating surfaces is fully utilized, SCR catalyst arrangement is realized by adopting a non-standard catalyst with relatively low height, the tail and the heating surface of a boiler do not need to be modified, and a reactor shell does not need to be additionally arranged. After an existing boiler with ultra-low NOx emission concentration distance and small emission standard line deviation adopts the device, the denitration efficiency of the boiler can be effectively improved by 10%-20%, and therefore the NOx emission concentration reaches the standard.

Owner:HUANENG CLEAN ENERGY RES INST

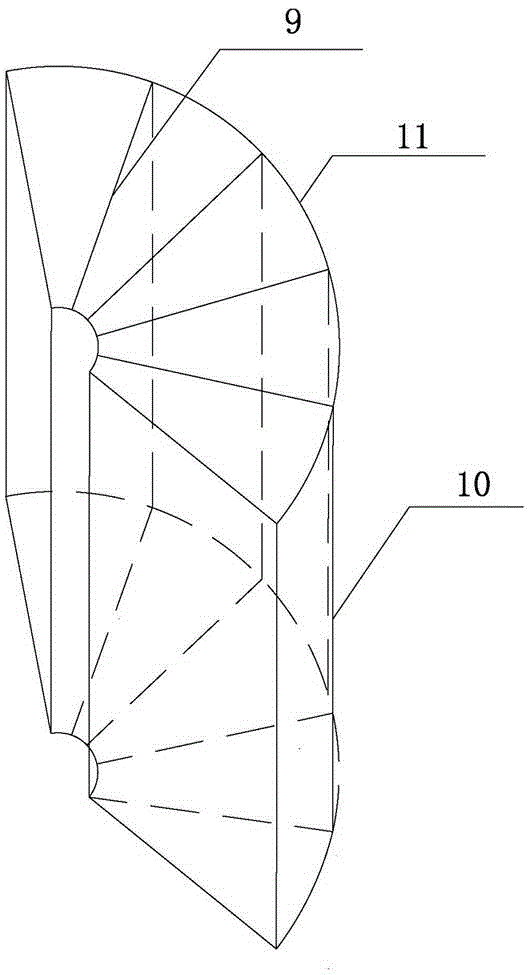

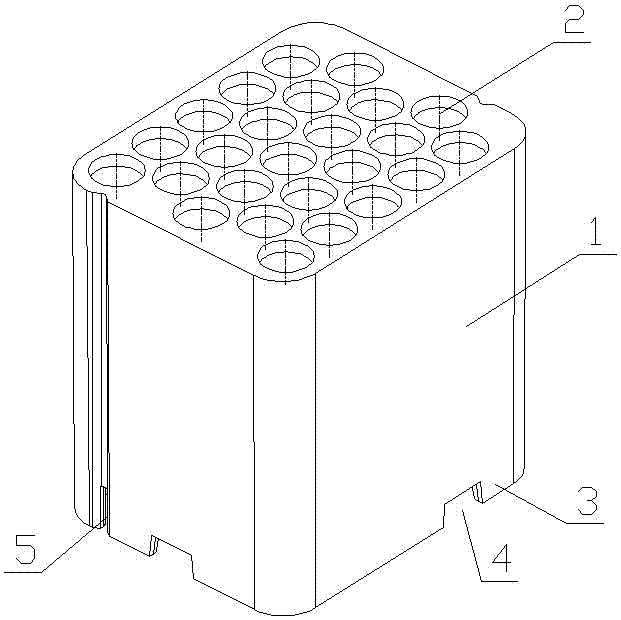

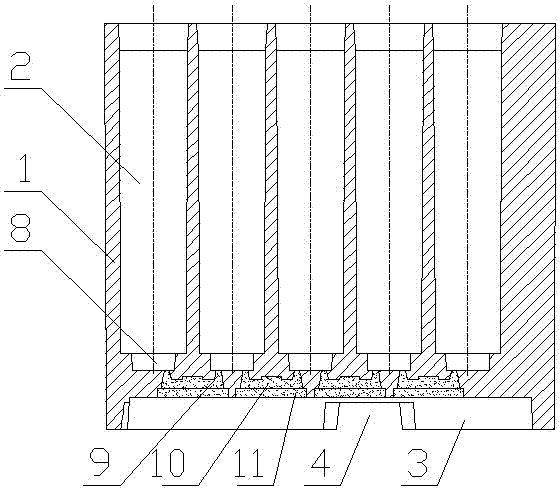

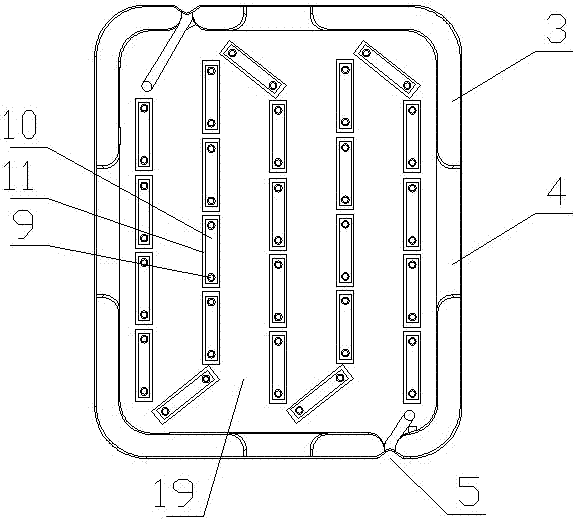

Lead-free combined firework concentrated in emission and filled with gunpowder

InactiveCN107328313AHigh bonding strengthSavingsFireworksStructural engineeringMechanical engineering

The invention relates to a lead-free combined firework concentrated in emission and filled with gunpowder. The bottom of each tubular body is provided with an explosive groove used for improving the concentration strength of gunpowder emission; the bottom face of each gunpowder groove is provided with a fire leading hole which is a through hole; the bottom face of a firework body is provided with a fire leading groove; the fire leading holes are communicated with the fire leading groove in the bottom face of the firework body; and the fire leading holes and the fire leading groove are filled with slip casting gunpowder. The lead-free combined firework concentrated in emission and filled with the gunpowder solves the problem that a lead, a glue lead, a cutting lead and an inserting lead need to be made for a combined firework, the work procedures are reduced, cost is reduced, safety is improved, and the problems that in the firework set-off process, rolling movement happens, the emission force is not concentrated, and direction is not stable are also solved.

Owner:浏阳世纪红烟花制造销售有限公司

Special non-woven filter cloth for air conditioner and metallized treatment process of special non-woven filter cloth

InactiveCN106544785APrecise thickness controlImprove uniformityCarbon fibresArtificial filaments from viscosePolyesterFar infrared

The invention discloses a special non-woven filter cloth for an air conditioner and a metallized treatment process of the special non-woven filter cloth. The special non-woven filter cloth for the air conditioner consists of tea polyphenol fibers, flax fibers, bamboo charcoal fibers, pearl fibers and multifunctional polyester fibers, wherein the tea polyphenol fibers account for 10-15% of the total mass of the non-woven filter cloth; the flax fibers account for 30-60% of the total mass of the non-woven filter cloth; the bamboo charcoal fibers account for 5-15% of the total mass of the non-woven filter cloth; the pearl fibers account for 10-20% of the total mass of the non-woven filter cloth; and the multifunctional polyester fibers account for 15-20% of the total mass of the non-woven filter cloth. The flax fibers and the bamboo charcoal fibers are adopted; the flax fibers absorb moisture and dissipate heat quickly, are high in health-care, anti-corrosion and bacteriostatic abilities, are stain-resistant, anti-static and ultraviolet-proof, and are good in flame-retardant effect; and the bamboo charcoal fibers have the characteristics of ultra-high adsorption capacity, capability of transmitting far infrared rays and high anion emission concentration, so that the non-woven filter cloth obtained by weaving also has effects of stain resistance, static electricity resistance, corrosion resistance and bacteria resistance.

Owner:JIANGSU HAINA AIR CONDITIONER PURIFICATION EQUIP

A joint disposal method of full tail paste filling and stockpiling based on deep cone thickener

ActiveCN104929683BHigh emission concentrationImprove security levelMaterial fill-upMining engineeringCombined treatment

The invention relates to a total-tailings paste filling and stockpiling combined treatment method based on a deep-cone thickener. A combined treatment system is composed of a one-stage or multi-stage pump station, the deep-cone thickener and a two-segment horizontal stirring device. The deep-cone thickener is arranged near the multi-stage pump station. A continuous feeding and discharging mode is adopted for achieving the continuous concentration process, and the two functions of filling and tailings stockpiling are both taken into consideration. In the running process of a filling system, total tailings of a concentration plant are completely thrown into the deep-cone thickener through the one-stage or multi-stage pump station. When filling is needed, deep-cone bottom flow is pumped to the two-segment stirrer through a mortar pump and is mixed with cement, and qualified paste is prepared and flows to or is pumped to a stope. When filling is not needed, the bottom flow is pumped by a plunger pump to a tailings pond by means of the pump station, and stockpiling of paste is performed. The method can well solve the filling problem of a gob and the stockpiling problem of tailings at the same time, filling cost is greatly reduced, the strength of filling bodies is improved, discharge of the tailings is reduced to the maximum extent, and meanwhile tailings paste is discharged.

Owner:UNIV OF SCI & TECH BEIJING +1

Cheese dyeing and dehydrating device, equipment using same and method of use thereof

InactiveCN106012386BHigh emission concentrationReduce processing energy consumptionSucessive textile treatmentsTextile treatment containersPulp and paper industryRotating drum

The invention discloses a cheese dyeing and dewatering device. The cheese dyeing and dewatering device comprises a cylinder body, a cylinder cover, a driving device, a centrifugal separation device, a heating circulating pipe, a liquid supply device and a drying device; the cylinder body is covered with the cylinder cover, the driving device is arranged at the bottom of the cylinder body, and the output end of the driving device extends into the cylinder body; the centrifugal separation device comprises a rotating drum and a cheese stringing tube used for installing cheese, the rotating drum is arranged on the cheese stringing tube in a sleeving mode, and the rotating drum and the cheese stringing tube are both fixedly connected with the output end of the driving device and each provided with holes allowing liquid and hot air to pass through; the heating circulating pipe is arranged in the cylinder body and located between the rotating drum and the inner wall of the cylinder body, the liquid supply device is arranged outside the cylinder body and connected with the cylinder body and the driving device respectively, and the drying device and the liquid supply device are arranged in parallel. The cheese dyeing and dewatering device has the advantages that cheese dyeing, dewatering and drying operations are completed on same equipment, centrifugal dewatering of the dyed cheese can be conducted in a dyeing machine, energy consumption and water consumption are reduced, and the space is saved.

Owner:王博敏

String wind type dust remover

InactiveCN106311479ALong distance across the electric fieldIncrease distanceElectrode constructionsEngineeringAerosol

The invention relates to a dust removing device used for collecting industrial smoke, in particular to a string wind type dust remover. The string wind type dust remover is suitable for upgrading of an old electric precipitator technology, and after an old electric precipitator is upgraded, under the condition that original technical parameters of the old electric precipitator are not changed, pm 2.5 micron-grade aerosol smoke particles can also be efficiently gathered.

Owner:袁野

A desulfurization additive suitable for limestone-gypsum wet flue gas desulfurization technology

ActiveCN107349774BImprove desulfurization efficiencyIncrease profitDispersed particle separationIron sulfateGlutaric acid

The invention discloses a desulfurization additive applicable to a limestone-gypsum wet-method flue gas desulfurization technique. The desulfurization additive is prepared from the following raw materials in parts by weight: 60 to 70 parts of mixed organic acid, 10 to 20 parts of loss inhibitor, 0 to 1 part of mercury stabilizer, 20 to 30 parts of oxidation catalyst and 5 to 15 parts of antifoaming agent, wherein the mixed organic acid is a mixture of adipic acid, succinic acid and glutaric acid; the weight ratio of the adipic acid to the succinic acid to the glutaric acid is 26 to 35 to 39; the oxidation catalyst is a mixture of manganese sulfate and iron sulfate; the weight ratio of the manganese sulfate to the iron sulfate is 3 to 4. The desulfurization efficiency and the utilization rate of limestone can be improved through the use of the desulfurization additive; further, the loss of the desulfurization additive and the emission concentration of the mercury can be reduced. In the same condition, after the additive provided by the invention is added into a desulfurization system, the time of maintaining that the desulfurization efficiency reaches 90 percent is prolonged; improvement of the utilization rate of the limestone is shown.

Owner:CENT CHINA BRANCH OF CHINA DATANG CORP SCI & TECH RES INST CO LTD

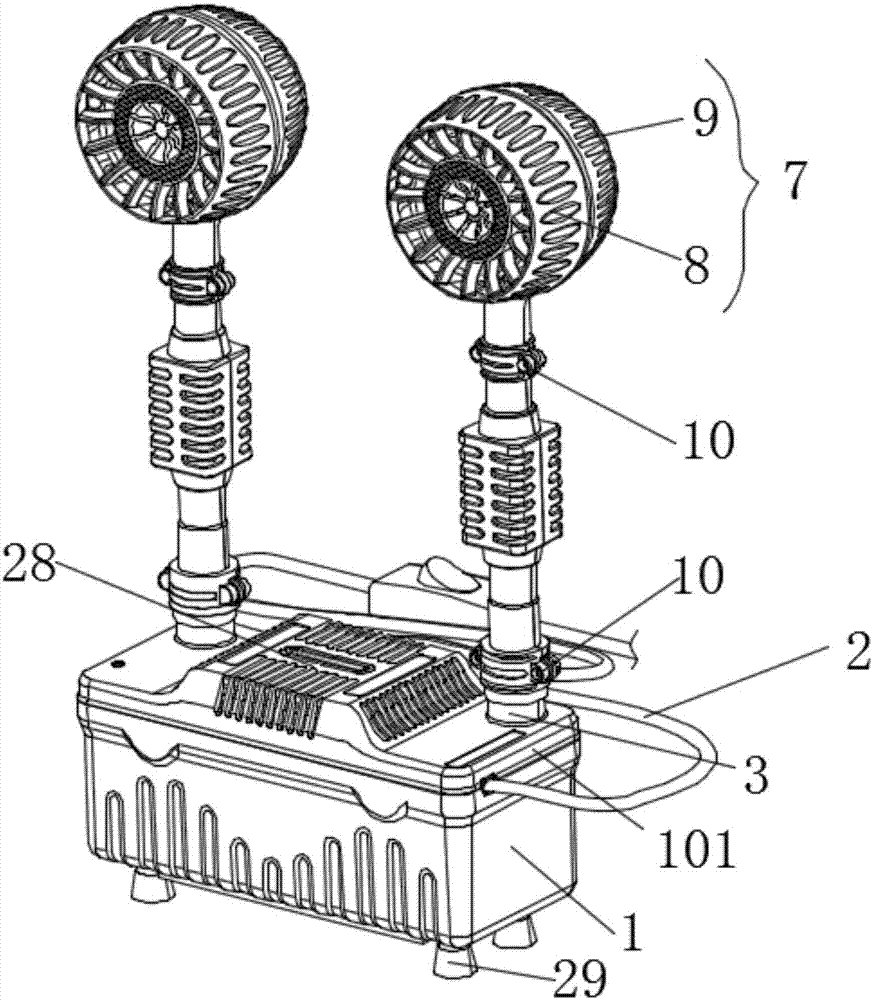

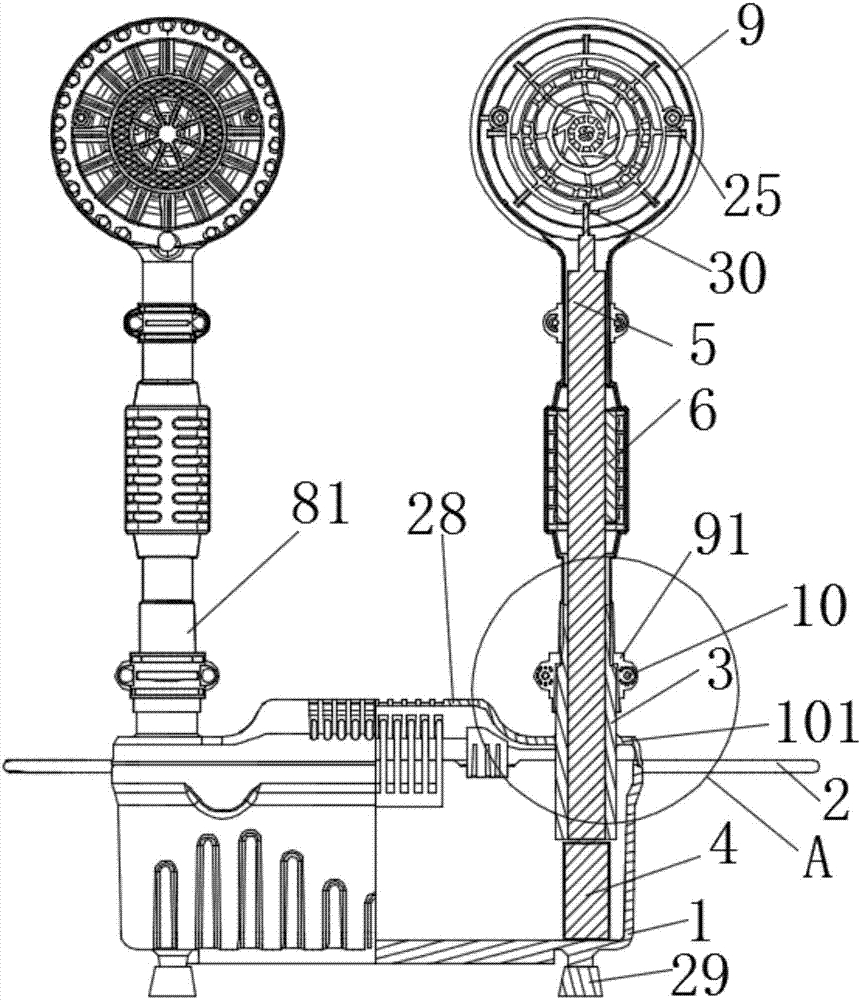

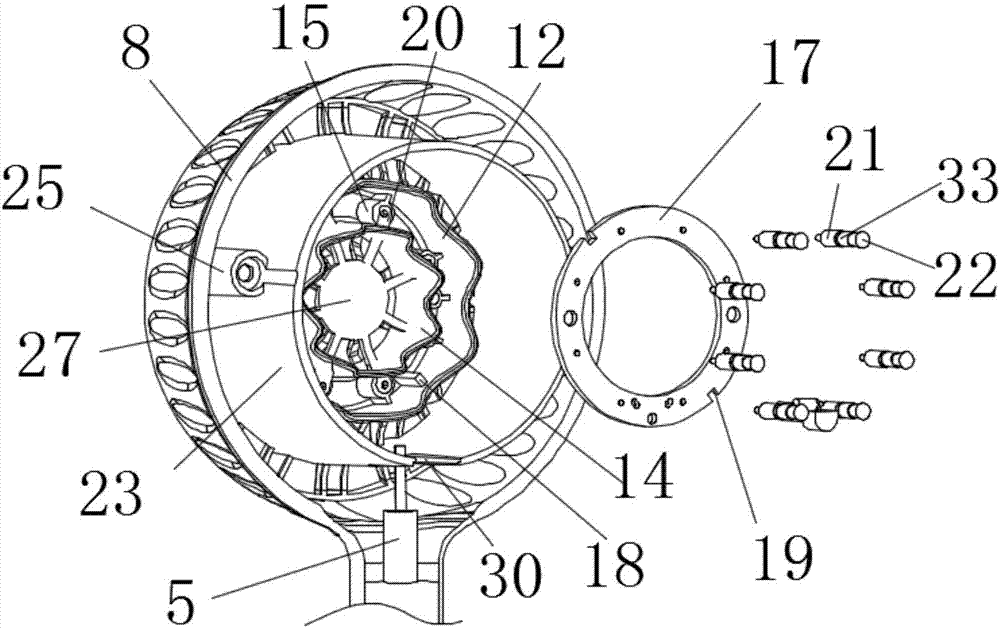

Particle-conductive air negative ion generator

PendingCN107482482AImprove production efficiencyIncrease teleportation distanceElectrical apparatusFront coverIon

The invention discloses a particle-conductive air negative ion generator. The generator comprises a main body, the upper portion of the main body is covered by a main body upper cover, a power line is arranged on one side of the main body, fixing cylinders are connected with the two sides of the main body upper cover in a penetrating mode, conversion devices are fixedly connected with the positions, corresponding to the fixing cylinders, of the bottom surface of the main body, the conversion devices are fixedly connected to negative ion output lines, and the negative ion output lines penetrate the fixing cylinders and magnetic conductors in sequence and extend into releaser emission assemblies, wherein each releaser emission assembly comprises a releaser dustproof rear cover and a releaser dustproof front cover. According to the particle-conductive air negative ion generator, a releaser dispersion plate is adopted, not only are installation and replacing more convenient, but also bilateral multipoint releasing heads are added, so that the transmitting area is expanded; anti-static-residue devices are arranged, so that the safety is improved; meanwhile, by means of a permeability design adopted by the releaser assemblies, discharging and transmission of negative ions are more promoted, and the limitation of the traditional closed ventilation single-channel performance is broken.

Owner:上海氧咖健康科技有限公司

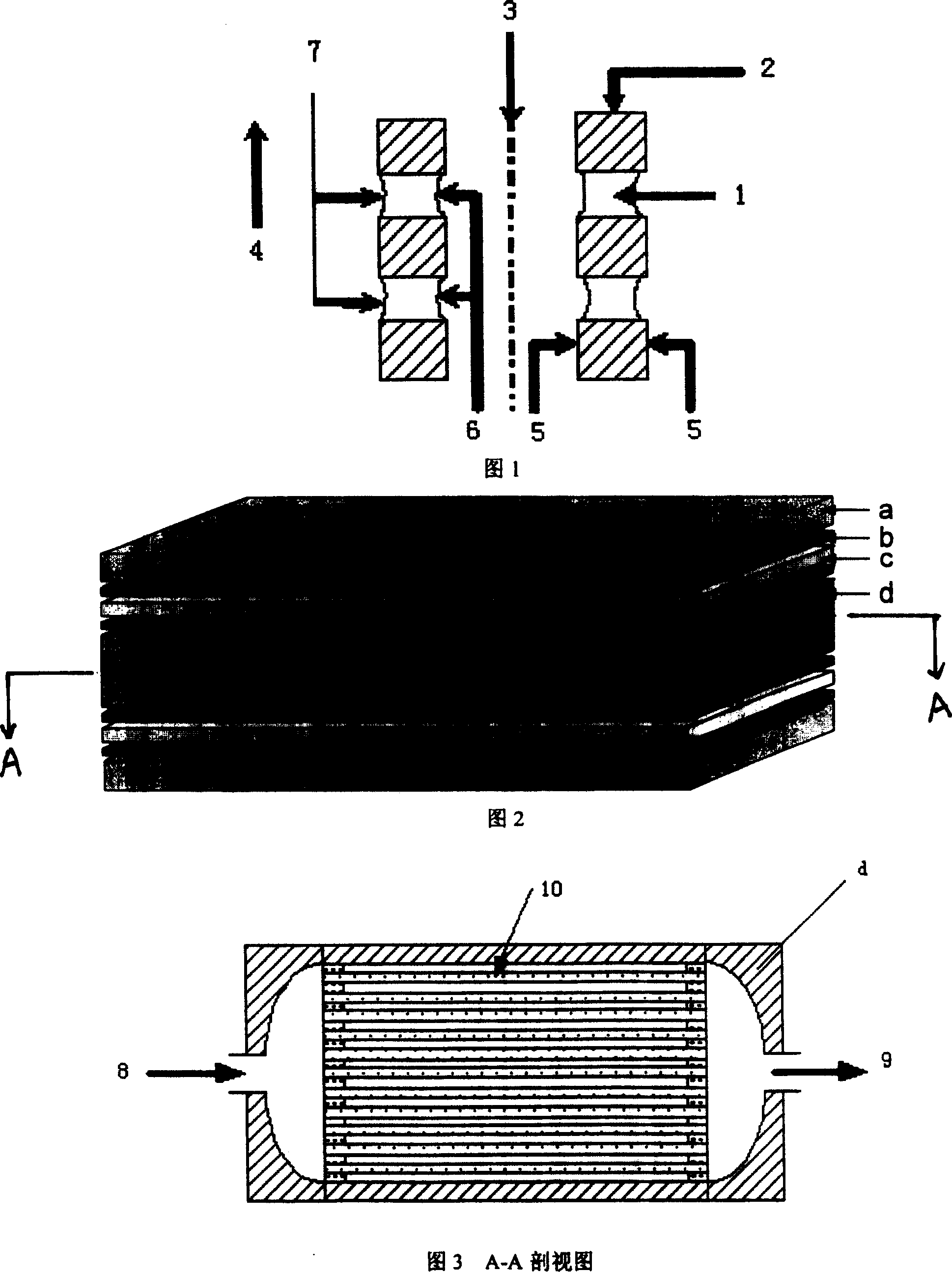

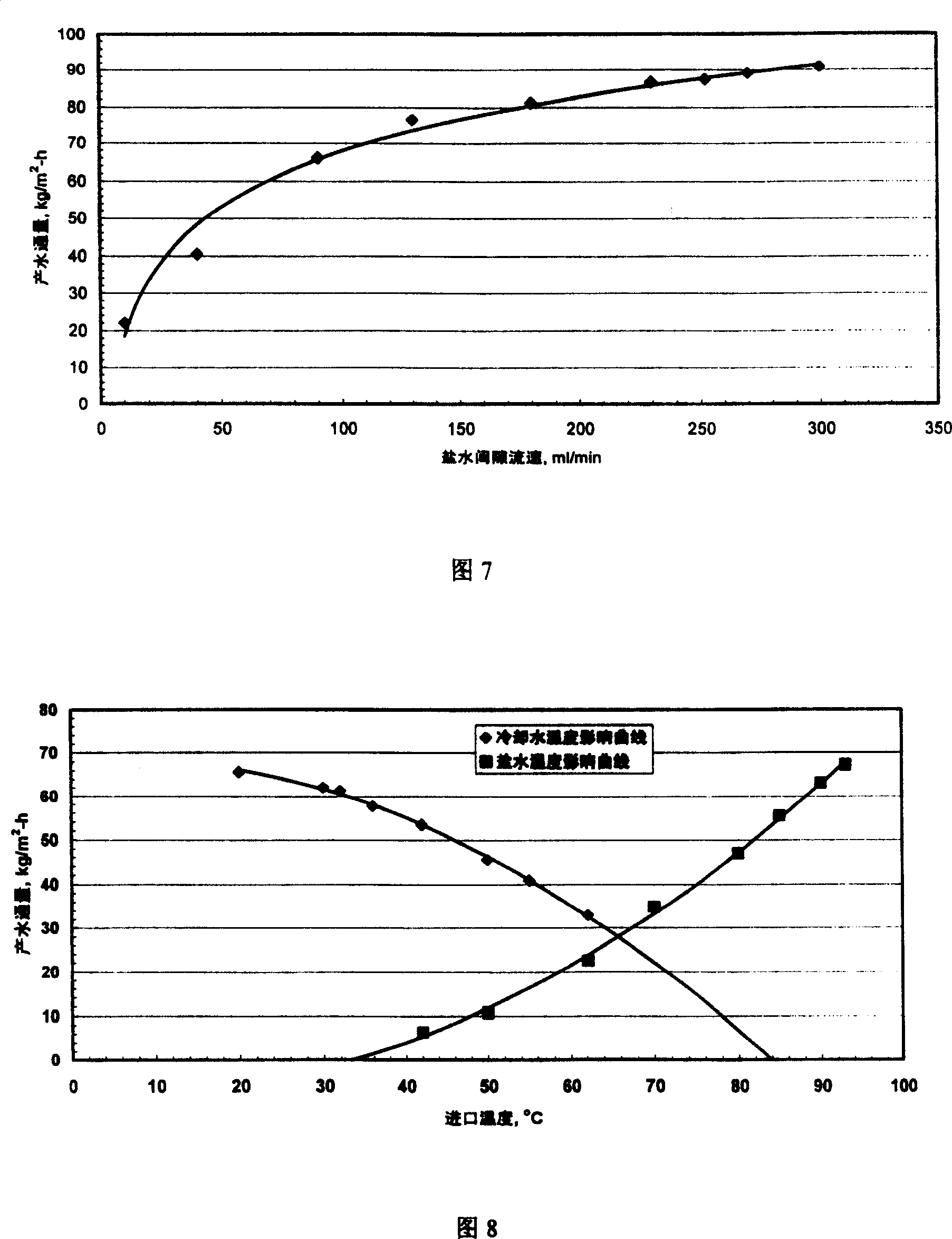

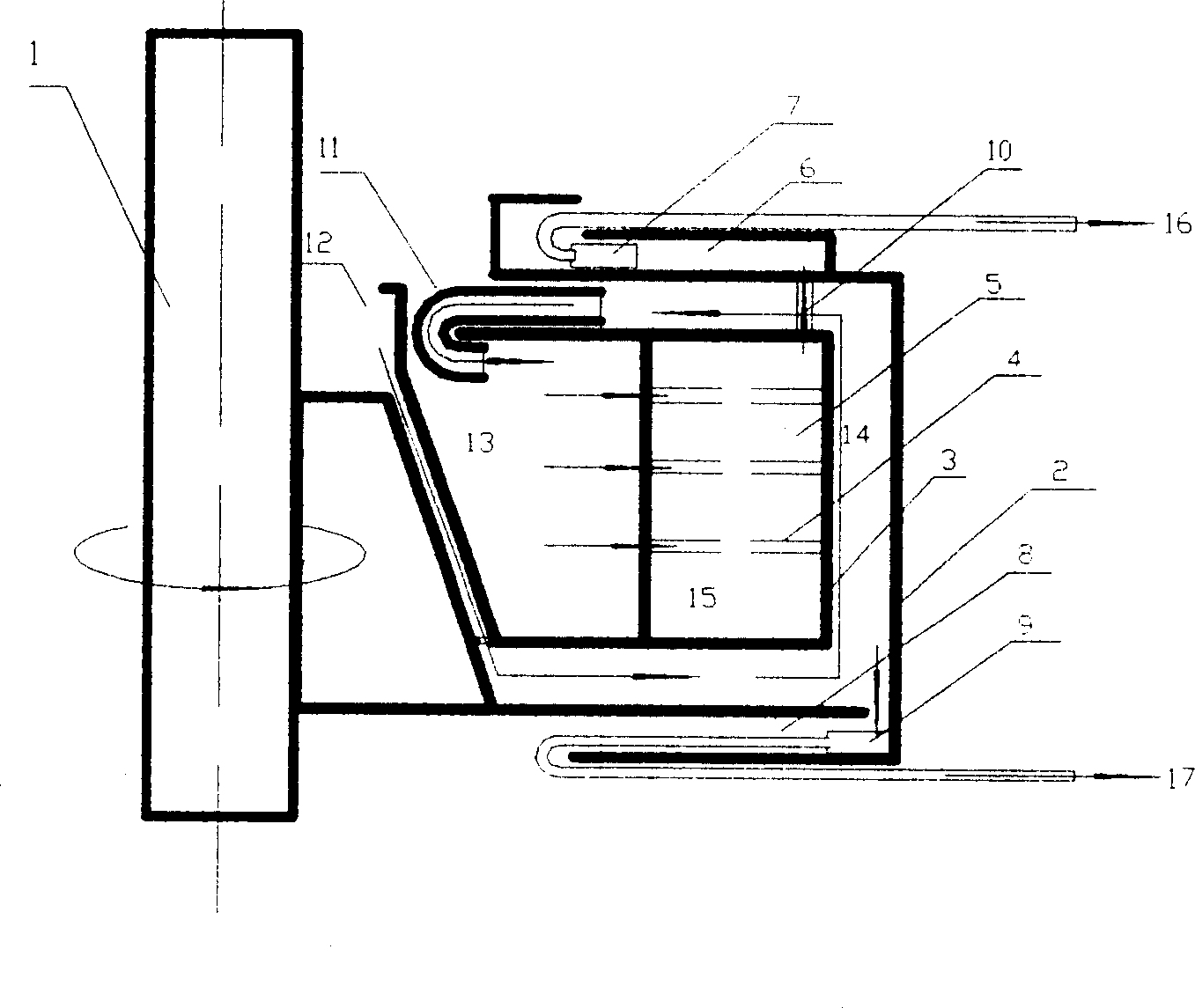

Directly contacting distillation desalting hollow fiber membrane apparatus and method

ActiveCN100348504CHigh recovery rateHigh emission concentrationGeneral water supply conservationSeawater treatmentHollow fibreRubber ring

The directly contacting membrane desalting apparatus with hollow fiber includes membrane tank, porous non-polar hollow fiber membrane arranged inside the membrane tank, porous plates and arc core cover plates. Two porous plates are set separately on two sides of the membrane tank; two arc core cover plates are set separately on the outer sides of the porous plates; the membrane tank, the porous plates and the core cover plates are arranged in parallel; and sealing rubber rings are set between the membrane tank and the porous plates and between the porous plates and the core cover plates. The desalting apparatus of the present invention has high water producing capacity, low water producing cost, high sea water recovering rate, simple operation and wide application range.

Owner:TIANJIN HYDROKING SCI & TECH

Application method for membrane

InactiveCN100351005CStable permeation pressureHigh emission concentrationSemi-permeable membranesMembrane surfacePressure difference

The present invention discloses an application method of membrane. In the high-speed rotary membrane equipment it utilizes the pressure difference formed by different liquid levels in the centrifugal field and does not external pump, and can form permeable pressure of membrane and flowing force of filtrate, and under the action of centrifugal force it can make membrane surface retain clean, and can raise discharge concentration of trapped liquor.

Owner:杨时英

A device for removing solid impurities in civil aviation jet fuel

ActiveCN104190119BRealize centrifugal separationEasy to handleCentrifugal force sediment separationCycloneEngineering

The invention discloses a civil aviation jet fuel solid phase impurity removing device. The civil aviation jet fuel solid phase impurity removing device comprises a pressure sealing tank and a cyclone, and is characterized in that a separating plate is arranged at the middle-lower part of the pressure sealing tank, the periphery of the separating plate is welded with the inner wall of the pressure sealing tank in a sealing manner, a mounting hole is formed on the separating plate, a cone part of the cyclone is inserted into the mounting hole to be in sealing connection with the separating plate, the separating plate divides the pressure sealing tank into two independent sealing units, a feeding pipe of the cyclone penetrates through the wall of the pressure sealing tank to be in sealing connection with the wall of the pressure sealing tank, a high-level discharge pipe is arranged at the top of the pressure sealing tank, a lower-level blowdown pipe is arranged at the bottom of the pressure sealing tank, and a lower-level blowdown pipe is arranged on the wall of the pressure sealing tank above the separating plate. The civil aviation jet fuel solid phase impurity removing device can completely replace gravity settling impurity removal equipment in the civil aviation jet fuel impurity removal process, and can effectively improve the impurity removal efficiency and the equipment processing capacity, reduce the equipment investment and occupied area and prolong the service life of a filter screen in the lower level.

Owner:中国航油集团津京管道运输有限责任公司 +1

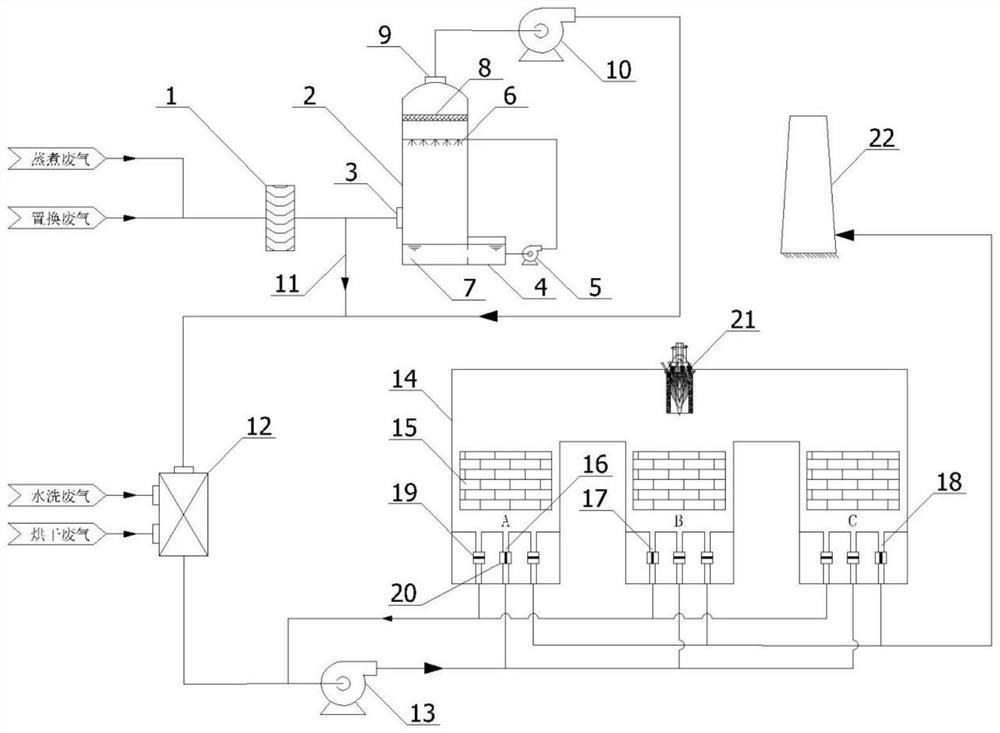

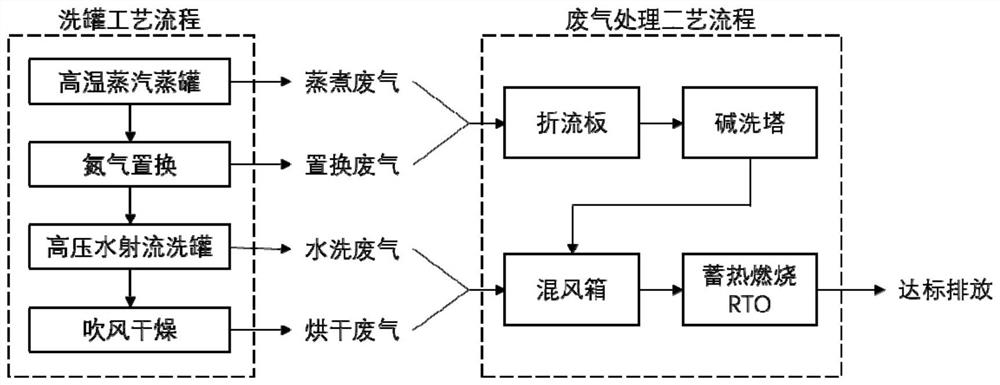

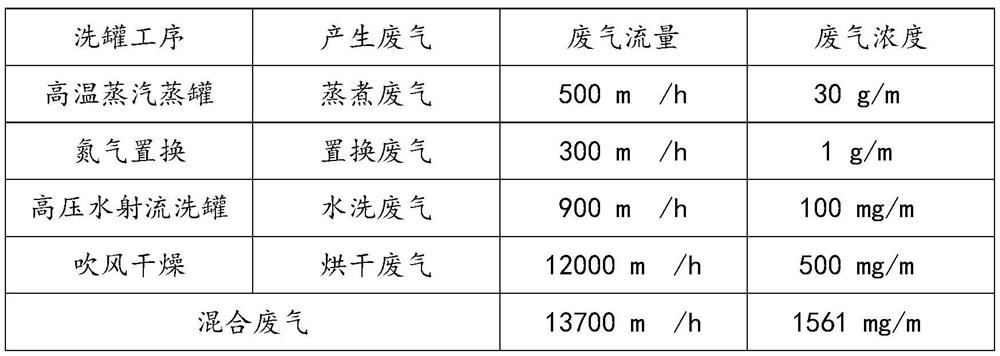

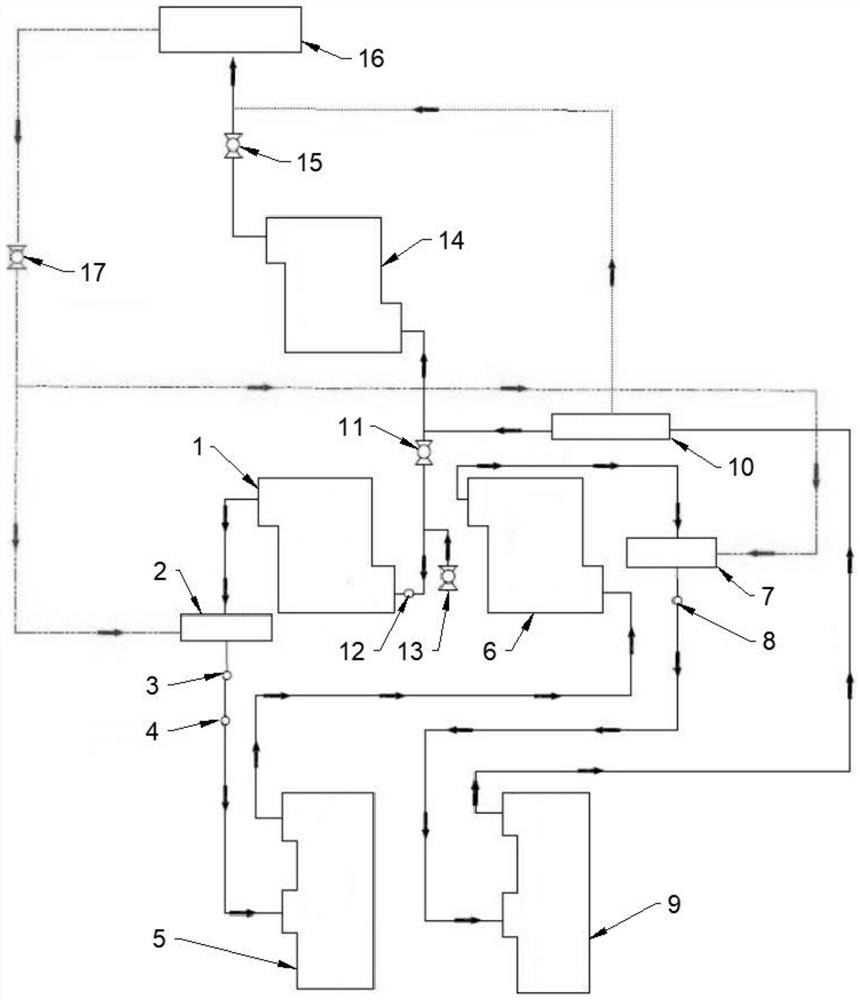

VOCs waste gas treatment system and method in railway oil tank truck cleaning process

The invention provides a VOCs waste gas treatment system and method in a railway oil tank truck cleaning process. The system comprises a high-concentration waste gas pretreatment device and a high-temperature oxidation treatment device, wherein the output end of the high-concentration waste gas pretreatment device is communicated with the input end of the high-temperature oxidation treatment device, the high-concentration waste gas pretreatment device is used for carrying out sedimentation alkali washing pretreatment on high-concentration waste gas generated by cooking and replacement, the input end of the high-temperature oxidation treatment device is further communicated with an exhaust end of low-concentration waste gas generated by water washing and drying, and the high-temperature oxidation treatment device is used for carrying out high-temperature oxidation treatment on the mixed high-concentration waste gas and low-concentration waste gas. According to the invention, high treatment efficiency and stable and up-to-standard emission concentration can be ensured, so that the purposes of environmental protection, emission reduction and improvement of the working environment of workers and the air quality of the ambient environment are achieved.

Owner:中车环境科技有限公司

A production process and special device for non-woven filter material without base cloth

ActiveCN105586713BMeet performance index requirementsHas industrial practical applicabilityMembrane filtersFiltration separationPerformance indexNational standard

The invention discloses a production process of a non-base-cloth non-woven filter material and a special device thereof. The production process is characterized by including the steps of lapping, pre-needling, splitting and spunlace. The special device for splitting pre-needled felt is designed. The technical problem that non-base-cloth pre-needled felt is prone to deformation under small external force is effectively solved through the device, by optimizing the splitting and spunlace process, the prepared non-base-cloth non-woven filter material meets the performance index requirements for warp and weft strong force of the filter material in the national standard, the emission concentration and total filter efficiency both meet the national standard requirement, dimensional stability is better, the procedures of the production process are simpler, production time is shorter and controllable, and industrial large-scale production is facilitated.

Owner:中国纺织科学研究院江南分院 +1

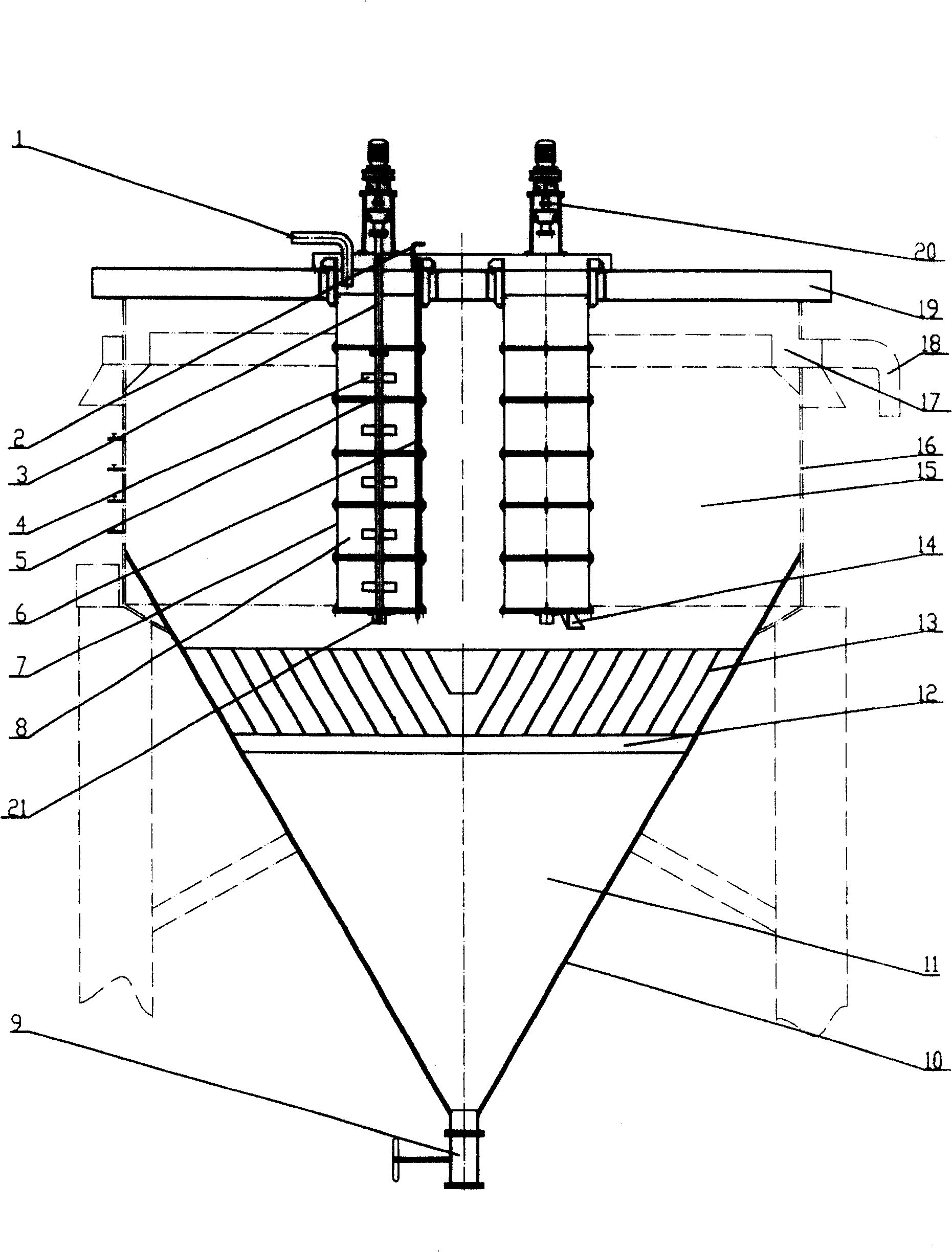

Highly effective reaction deep-cone settling method and apparatus

InactiveCN100443139CSimple process flowSmall footprintSedimentation settling tanksHigh densityEngineering

The highly effective reaction deep cone settling comprises coagulation reaction by mixing the mixer and sewage into the coagulation device, with the density of the sewage 1-60g / l, mechanical blending speed 200-400r / m, forming floc suspension which goes through is generated into secondary flow, and forms on the slanting plate big grain aggregates, sliding to the deep cone density chamber through the conical slanting plate center in sedimentation reaction, and with the big grain aggregates crushed and condensed in the density chamber and exhausted with further dehydration in deep cone condensation. It combines the deep cone sedimentation, coagulation and condensation. It is mainly used for the treatment of high density fine grain sewage with mud.

Owner:HUNAN UNIV OF TECH

Production process of non-base-cloth non-woven filter material and special device thereof

ActiveCN105586713AReduce external forceReduce moistureMembrane filtersFiltration separationNational standardPerformance index

The invention discloses a production process of a non-base-cloth non-woven filter material and a special device thereof. The production process is characterized by including the steps of lapping, pre-needling, splitting and spunlace. The special device for splitting pre-needled felt is designed. The technical problem that non-base-cloth pre-needled felt is prone to deformation under small external force is effectively solved through the device, by optimizing the splitting and spunlace process, the prepared non-base-cloth non-woven filter material meets the performance index requirements for warp and weft strong force of the filter material in the national standard, the emission concentration and total filter efficiency both meet the national standard requirement, dimensional stability is better, the procedures of the production process are simpler, production time is shorter and controllable, and industrial large-scale production is facilitated.

Owner:中国纺织科学研究院江南分院 +1

RST circulating thickening and emission reduction heat treatment equipment and system

PendingCN114440238AHigh emission concentrationEmission reductionIncinerator apparatusPrinting press partsEnvironmental engineeringLaboratory oven

The invention provides RST circulation thickening and emission reduction heat treatment equipment and system, relates to the technical field of organic waste gas treatment, and solves the problem that thickening and emission reduction cannot be truly achieved in the prior art. The RST circulation thickening and emission reduction heat treatment equipment comprises a first fan, a first color cell heat oven, a second fan, a second color cell heat oven and a second valve which are sequentially connected through pipelines; the air inlet end of the first valve communicates with the external environment, and the air outlet end of the first valve is connected into a pipeline from the air outlet end of the second valve to the air inlet of the first fan. An air inlet of the third fan is connected into a pipeline from an air outlet of the second color cell heat oven to the air inlet end of the second valve through a pipeline; the air inlet end and the air outlet end of the third valve are respectively connected with an air outlet of the third fan and waste gas treatment equipment through pipelines. Compared with the prior art, thickening and emission reduction of VOCs organic waste gas of the hot drying oven of the printing machine can be truly achieved, the efficiency of waste gas treatment equipment is better improved, and energy conservation and consumption reduction are achieved.

Owner:广东和炫环保智能科技有限公司

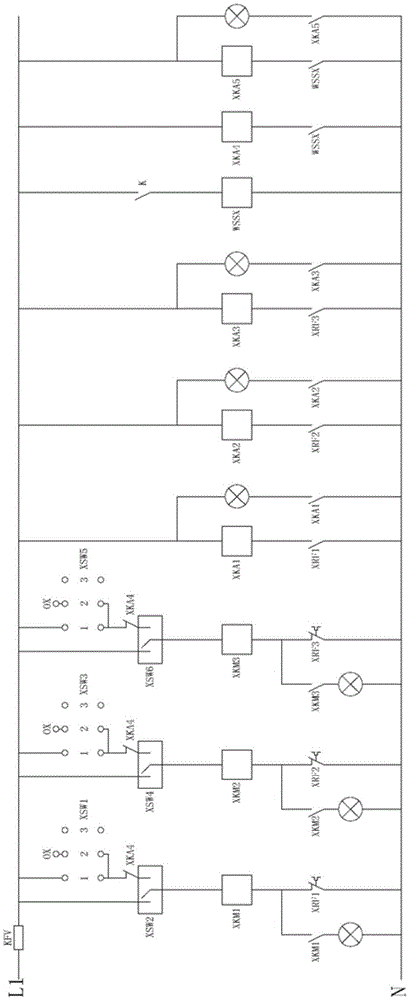

motor control circuit

InactiveCN104501612BImprove work efficiencyEasy to make and installControl devices for furnacesAutomatic controlEngineering

The invention discloses a motor control circuit. The motor control circuit comprises a selection switch, a contactor, a thermal relay and a display lamp, wherein the selection switch is configured to be connected to a positive electrode of a power supply and used for switching a manual control mode and an automatic control mode; one end of the contactor is connected to the selection switch, the contactor is electrified to control the closing of a contactor switch and powered off to control the opening of the contactor switch; one end of the thermal relay is connected to the contactor, the other end of the thermal relay is connected to a negative electrode of the power supply through the motor, the temperature of the thermal relay exceeds a preset value, the thermal relay is disconnected, a thermal relay switch is controlled to open, when the temperature of the thermal relay is lower than or equal to the preset value, the thermal relay is closed, and the thermal relay switch is controlled to close; one end of the display lamp is arranged between the contactor and the thermal relay through the contactor switch, and the other end of the display lamp is connected to the negative electrode of the power supply. The motor control circuit is simple to produce and install and convenient and safe to operate; the working efficiency of the motor is higher.

Owner:WUHU XINXING DUCTILE IRON PIPES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com