P84 fiber and PPS (Polyphenylene Sulfide) fiber composite high-temperature-resisting spunlaced felt and preparation method thereof

A fiber composite, high temperature resistant technology, applied in separation methods, chemical instruments and methods, synthetic resin layered products, etc., can solve the problem of general use effect and life, the emission concentration of PPS fiber needle felt is not up to standard, and the oxidation resistance is general. and other problems, to achieve the effect of protecting acid and alkali corrosion resistance, improving emission concentration and service life, and dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

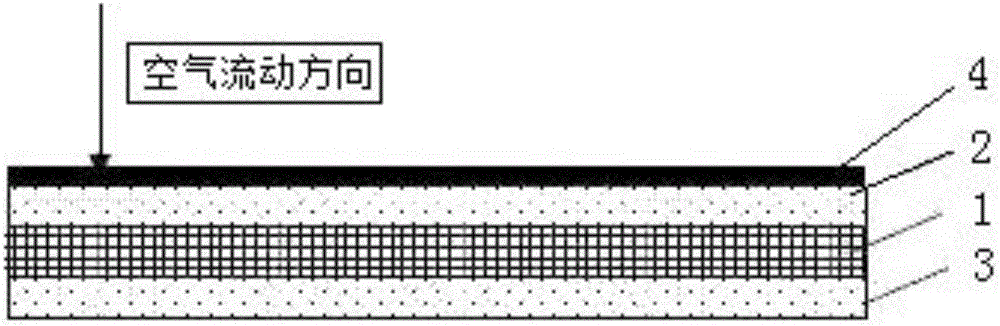

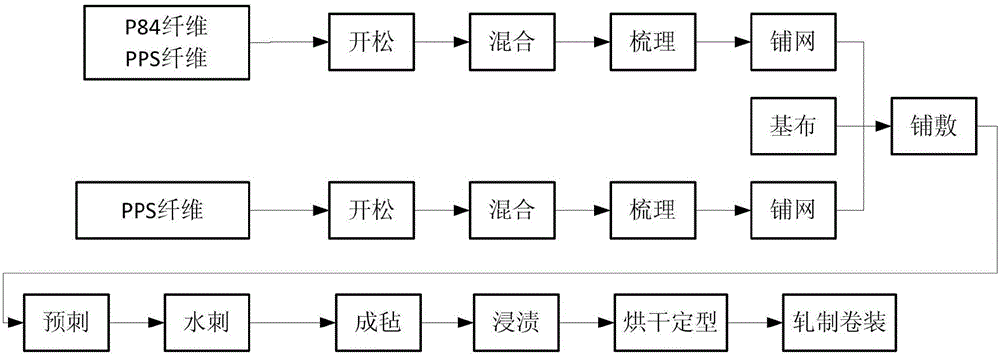

[0027] A kind of P84 fiber and PPS fiber composite high temperature resistant spunlace felt of this embodiment, comprises the middle base cloth layer 1 that is made of 100% PTFE reinforced base cloth, and the upper surface of base cloth layer 1 is provided with microfiber dust-repellent The surface layer 2, the lower surface of the base fabric layer 1 is provided with a high-efficiency air-permeable air-purifying surface 3, the base fabric layer 1, the microfiber dust-repelling surface layer 2 and the air-permeable air-cleaning surface layer 3 are spun into felt, and the surface of the felt has PTFE emulsion Dipping layer 4.

[0028] Wherein the superfine fiber dust-facing surface layer 2 is composed of P84 fibers of trilobal structure and 1D PPS fibers, wherein the component content of P84 fibers of trilobal structure is preferably 15%. The trilobal P84 fiber has high inter-fiber cohesion, and can be well compounded with 1D PPS fiber to provide high strength.

[0029] The ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com