Desulfurization additive applicable to limestone-gypsum wet-method flue gas desulfurization technique

A technology of wet flue gas desulfurization and additives, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems that the devices cannot meet the emission standards, and achieve increased oxidation reaction rate, enhanced diffusion, and improved neutralization. The effect of the ability of acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

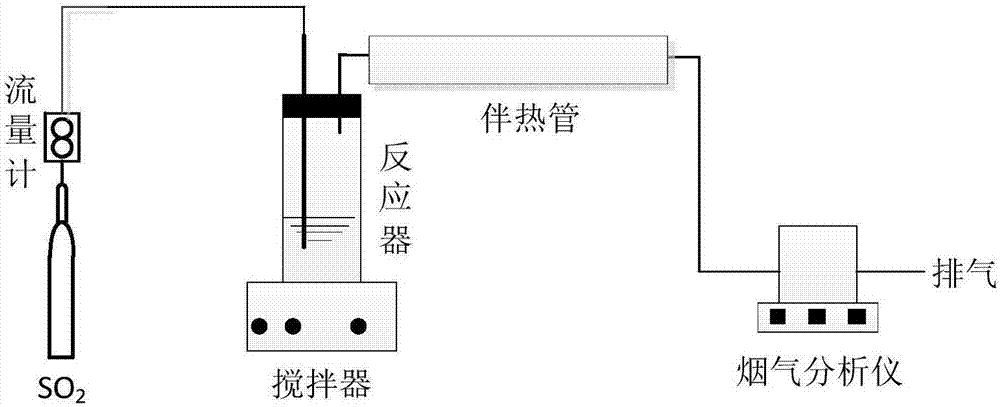

Method used

Image

Examples

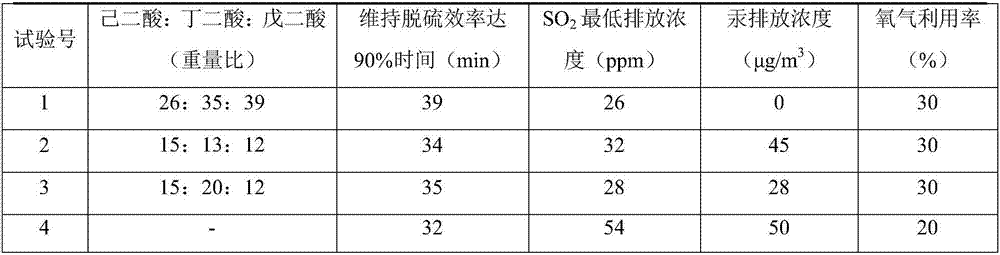

Embodiment 1

[0023] A desulfurization additive suitable for limestone-gypsum wet flue gas desulfurization technology, the weight ratio of each raw material in the desulfurization additive is: mixed organic acid 60: manganese sulfate 10: 2,4,6-trimercapto-s-triazine Trisodium salt 0.5: oxidation catalyst 20: polyoxyethylene ether 5.

[0024] The mixed organic acid is a mixture of adipic acid, succinic acid and glutaric acid, and the weight ratio of adipic acid, succinic acid and glutaric acid is 26:35:39.

[0025] The oxidation catalyst is a mixture of manganese sulfate and iron sulfate, and the weight ratio of manganese sulfate and iron sulfate is 3:4.

Embodiment 2

[0027] A desulfurization additive suitable for limestone-gypsum wet flue gas desulfurization technology, the weight ratio of each raw material in the desulfurization additive is: mixed organic acid 65: manganese sulfate 15: 2,4,6-trimercapto-s-triazine Trisodium salt 0.0037: oxidation catalyst 25: polyoxyethylene ether 10.

[0028] The mixed organic acid is a mixture of adipic acid, succinic acid and glutaric acid, and the weight ratio of adipic acid, succinic acid and glutaric acid is 26:35:39.

[0029] The oxidation catalyst is a mixture of manganese sulfate and iron sulfate, and the weight ratio of manganese sulfate and iron sulfate is 3:4.

Embodiment 3

[0031] A desulfurization additive suitable for limestone-gypsum wet flue gas desulfurization technology, the weight ratio of each raw material in the desulfurization additive is: mixed organic acid 70: manganese sulfate 20: 2,4,6-trimercapto-s-triazine Trisodium salt 1: oxidation catalyst 30: polyoxyethylene ether 15.

[0032] The mixed organic acid is a mixture of adipic acid, succinic acid and glutaric acid, and the weight ratio of adipic acid, succinic acid and glutaric acid is 26:35:39.

[0033] The oxidation catalyst is a mixture of manganese sulfate and iron sulfate, and the weight ratio of manganese sulfate and iron sulfate is 3:4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com