Application method for membrane

A technology of high-speed rotation and membrane device, which is applied in the field of membrane application, and can solve the problems of separation of unremovable sediment and concentrated liquid, limiting the concentration of discharged liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

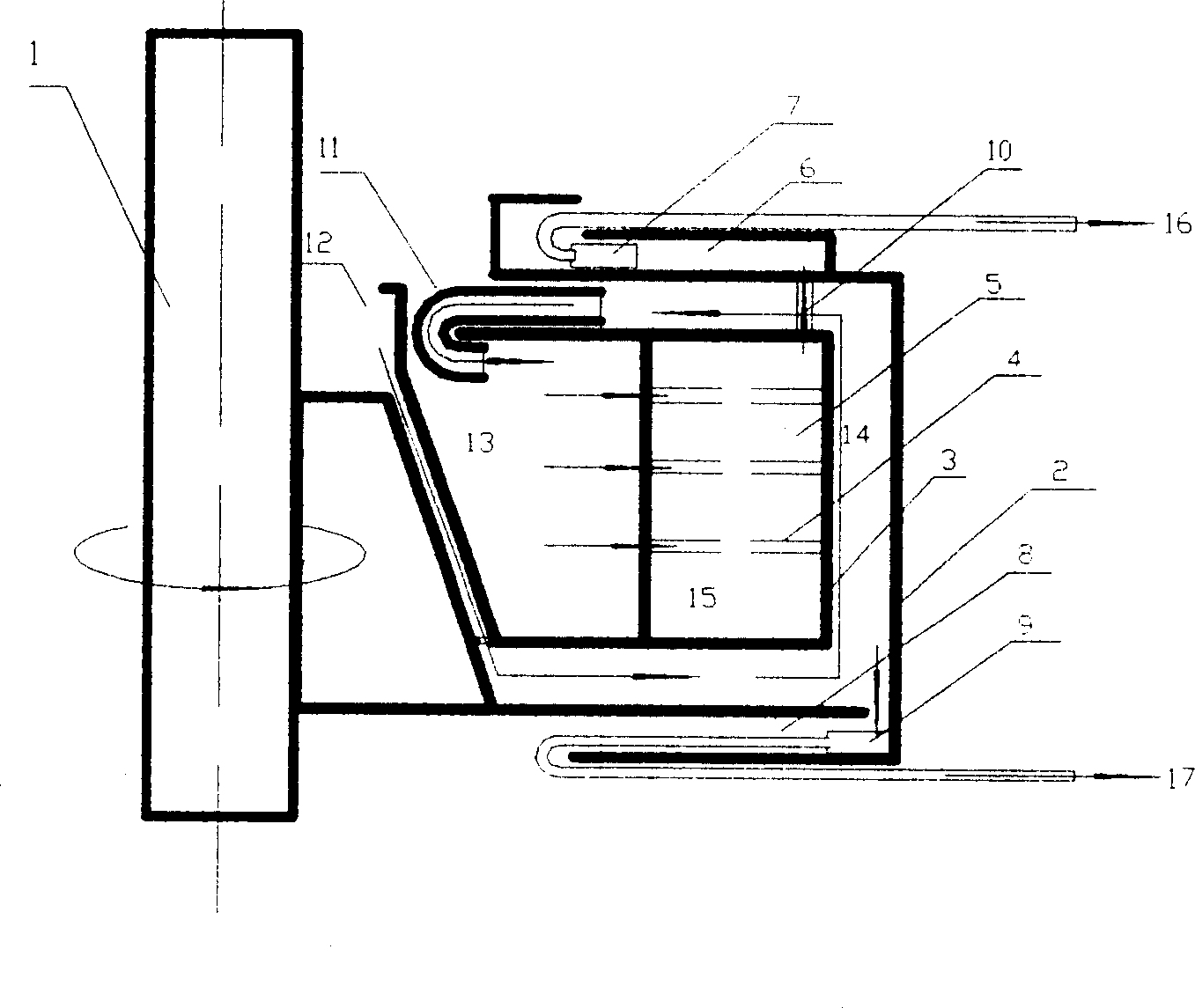

[0008] The high-speed rotating membrane device drives the filtrate to rotate at high speed to form a centrifugal force field, and the suspension enters the high-speed rotating membrane device from 12 suspension inlets.

[0009] The filtrate first enters the retentate part 14, and after settling and separating the filtrate at a relatively clear small radius, it is introduced into the filtrate part 13 through the deflector 11, and then passes through the membrane element 4. Pushed by the pressure formed by the difference, permeation is formed on the membrane surface of the membrane element 4, and the clear liquid that permeates the membrane surface is collected at the clear liquid part 15 in the membrane module 3, and is transported to the clear liquid tank 6 by the connecting pipe 10, Then the clear liquid suction pump 7 is sucked out and discharged through the clear liquid pipe 16. The position of the clear liquid suction pump 7 and the pressure in the clear liquid pipe 16 cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com