Directly contacting distillation desalting hollow fiber membrane apparatus and method

A desalination device and fiber membrane technology, applied in the field of hollow fiber direct contact membrane distillation desalination device, can solve the problems of reduced membrane water flux, high conduction heat loss, and reduced membrane efficiency, and achieve good anti-pollution performance, water production The effect of high flux and increased salt production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

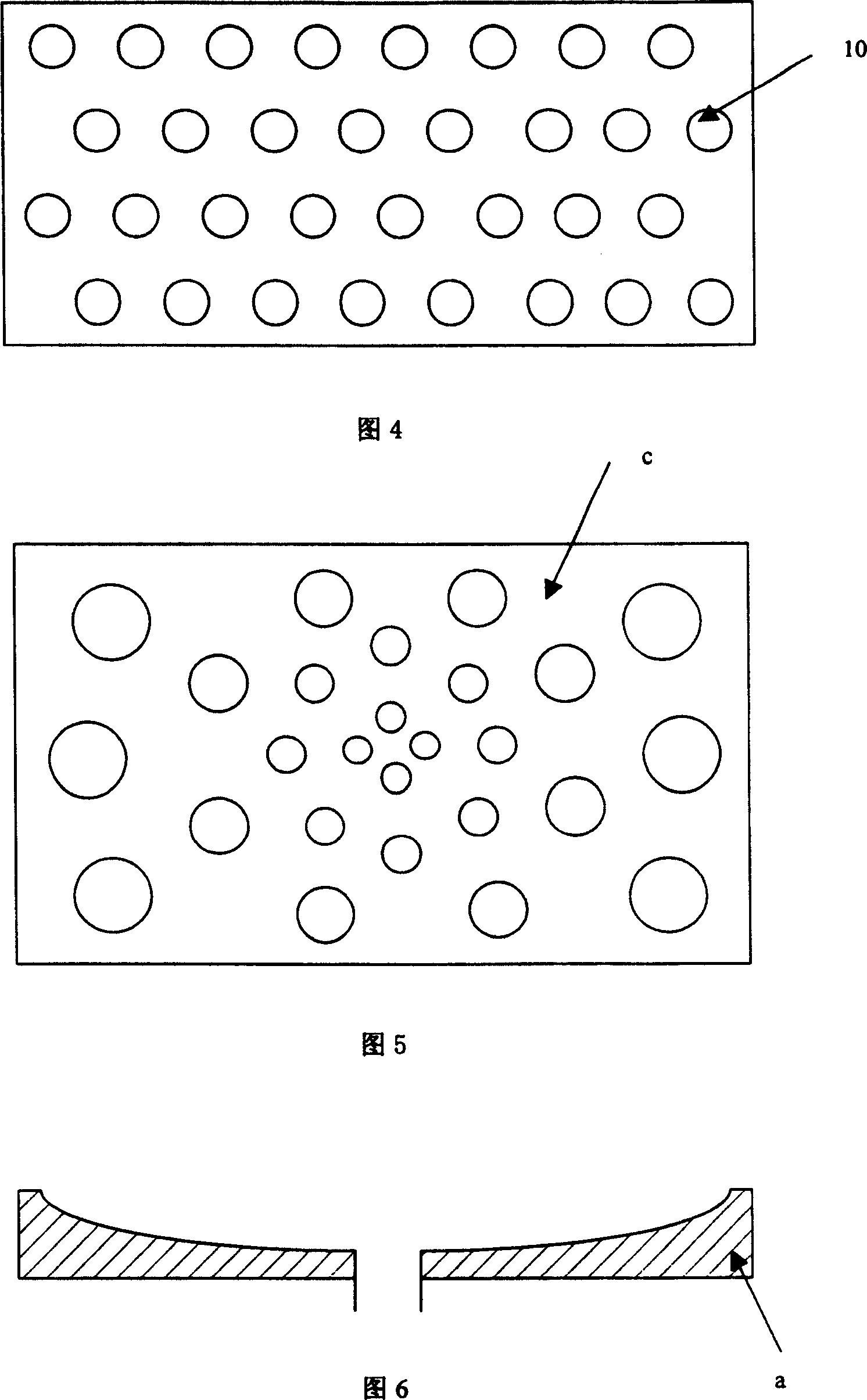

[0072] Membrane module: polyvinylidene fluoride porous non-polar hollow fiber membrane inner diameter: 1000 microns, membrane thickness 100 microns, membrane porosity 40%, pore diameter 0.1 microns; effective length 80 cm, total membrane thickness 30 cm, packing density 0.2 , the ends of the hollow fiber membranes are bonded together by a silicone adhesive;

[0073] The diameter of the hole in the center of the polyethylene porous plate is 0.10cm, and the holes are arranged in a ring, and the hole diameter increases to 2.0cm in turn;

[0074] The hollow plate is made of polyacrylic acid material;

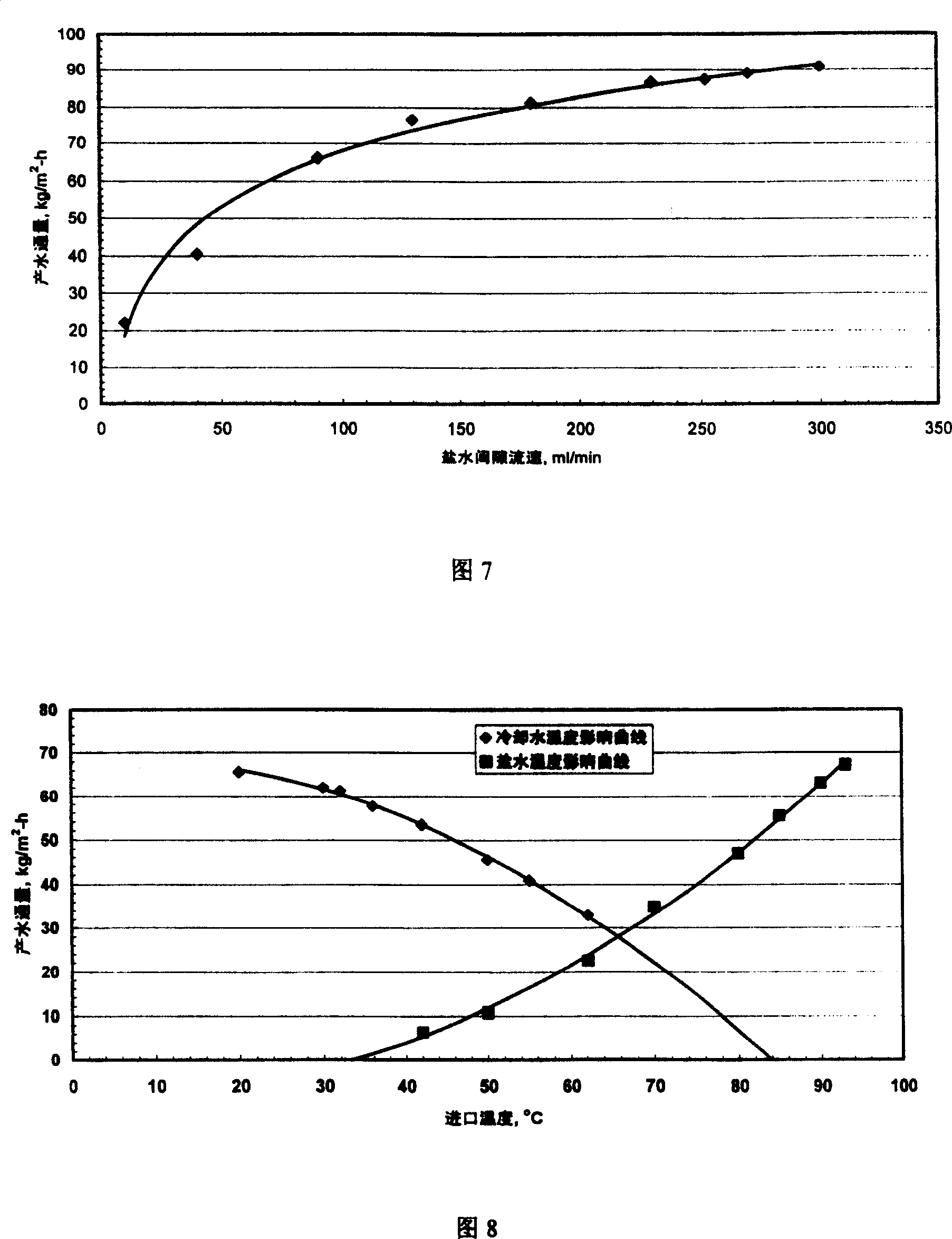

[0075] Inlet temperature of hot salt solution: 60°C, interstitial velocity: 300cm / min, concentration by weight: 3%;

[0076] Cooling water inlet temperature: 15°C, line speed: 1500cm / min.

[0077] The water flux of the membrane is 33kg / m 2 -h.

Embodiment 2

[0083] Membrane module: polytetrafluoroethylene (PTFE) porous non-polar hollow fiber membrane inner diameter: 350 microns, membrane thickness 300 microns, membrane porosity 60%, pore diameter 0.8 microns; effective length 50cm, total membrane thickness 150cm, packaged Density 0.4, the ends of hollow fiber membranes are bonded together by silicone adhesive;

[0084] The diameter of the hole in the center of the polypropylene porous plate is 0.2cm, and the holes are arranged in a ring, and the hole diameter increases to 2.0cm in turn;

[0085] The hollow plate is made of plexiglass material;

[0086] Hot salt solution inlet temperature: 90°C, interstitial velocity: 50cm / min, concentration by weight: 15%;

[0087] Cooling water inlet temperature: 30°C, line speed: 3000cm / min.

[0088] The water flux of the membrane is 109kg / m 2 -h.

Embodiment 3

[0094]Membrane module: perfluorodimethyldioxole-tetrafluoroethylene (PDD-TFE) porous non-polar hollow fiber membrane inner diameter: 1500 microns, membrane thickness 500 microns, membrane porosity 45%, pore diameter 0.5 microns; effective length 10cm, total membrane thickness 1cm, packing density 0.08, the hollow fiber membranes are bonded together at the ends by epoxy resin adhesives;

[0095] The diameter of the hole in the center of the polyacrylic acid porous plate is 0.08cm, and the holes are arranged in a ring, and the hole diameter increases to 0.8cm in turn;

[0096] The hollow plate is made of polyvinylidene fluoride;

[0097] Hot salt solution inlet temperature: 80°C, interstitial velocity: 500cm / min, weight percent concentration: 30%;

[0098] Cooling water inlet temperature: 50°C, line speed: 5000cm / min.

[0099] The water flux of the membrane is 72kg / m 2 -h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com