Lead-free combined firework concentrated in emission and filled with gunpowder

A combination of fireworks and leadless technology, which is applied in pyrotechnics, offensive equipment, weapon types, etc., can solve the problems of small force in the inner cylinder of fireworks, large consumption of propellant, and dispersion of propellant, so as to avoid safety problems and shorten the production cycle , Improve the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

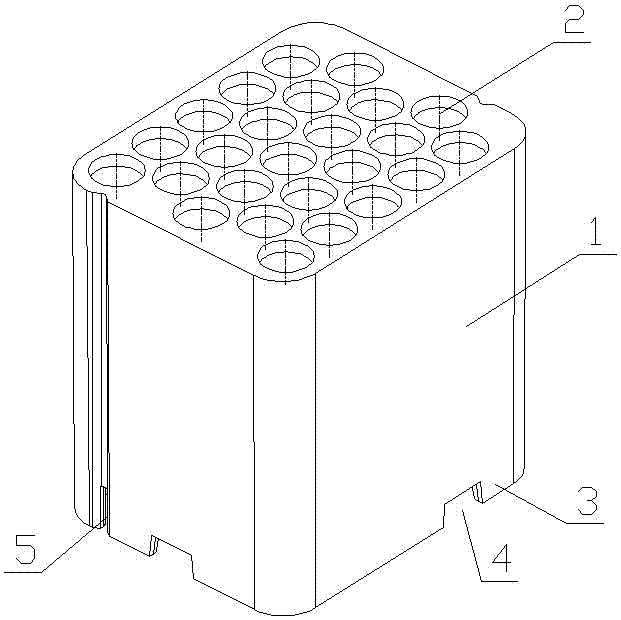

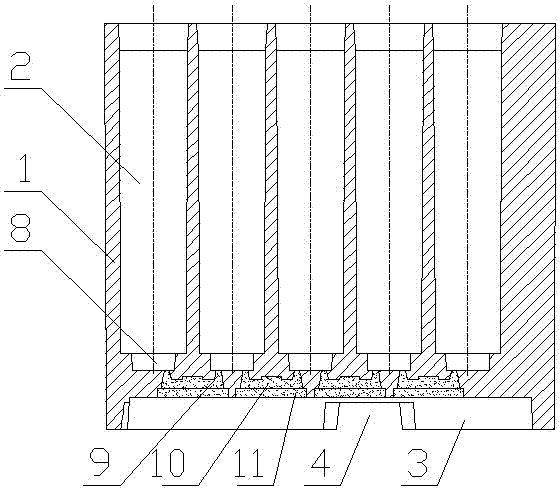

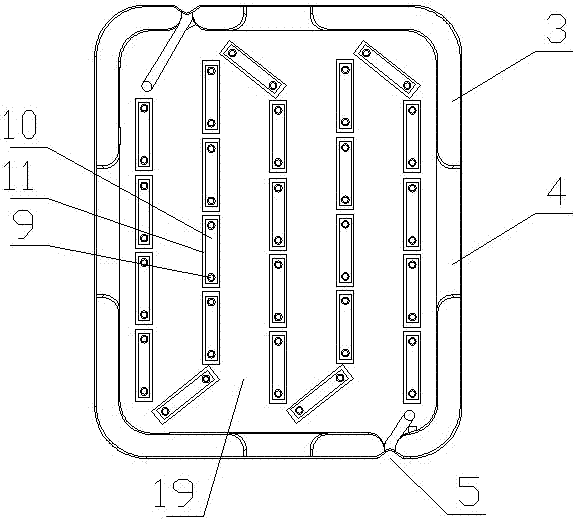

[0035] Such as figure 1 , figure 2 , image 3 As shown, this is a 25-shot combination firework, which is produced by a one-time compression molding process or plastic injection molding. The combined firework includes a main body, 25 tubular cavities uniformly distributed in parallel on the main body, the upper port of the tubular cavity is open, the lower port is closed, and the tubular cavity is equipped with a firework inner tube and gunpowder. A protruding frame is arranged around the bottom surface of the main body, and a plurality of pressure relief grooves are arranged on the frame. The side surface of the main body is provided with a side groove.

[0036] The bottom of each tubular cavity is provided with a medicine groove for improving the concentrated intensity of gunpowder emission, and the medicine groove is a conical groove, or a cylindrical groove, or an ellipsoidal groove, or a hemispherical groove, or Square grooves, or combined grooves composed of multiple groov...

Embodiment 2

[0046] Such as Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, this is a 100 leadless combination firework, which is produced by a one-time compression molding process or plastic injection molding. The combined firework includes a body, 100 tubular cavities uniformly distributed in parallel on the body, the upper port of the tubular cavity is open, the lower port is closed, and the tubular cavity has a built-in firework inner tube and gunpowder. A protruding frame is arranged around the bottom surface of the main body, and a plurality of pressure relief grooves are arranged on the frame. The side surface of the main body is provided with a side groove.

[0047] The bottom of each tubular cavity is provided with a medicine groove for improving the concentrated intensity of gunpowder emission, and the medicine groove is a conical groove, or a cylindrical groove, or an ellipsoidal groove, or a hemispherical groove, or Square grooves, or combined grooves composed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com