New energy tensioner and working method thereof

A new energy and tension machine technology, applied in the direction of mechanical equipment, emergency power arrangement, fluid pressure actuation device, etc., can solve the problems of energy waste, no energy conversion and utilization, etc., to reduce costs, improve power generation effect, and save energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

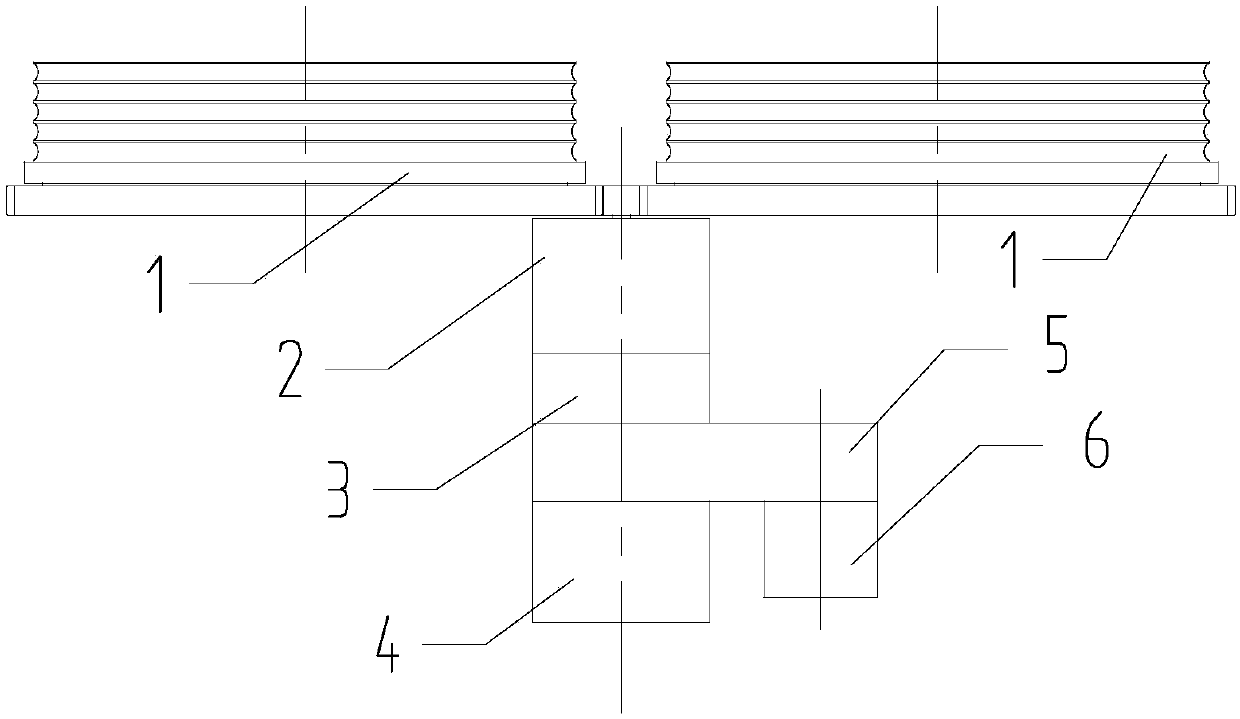

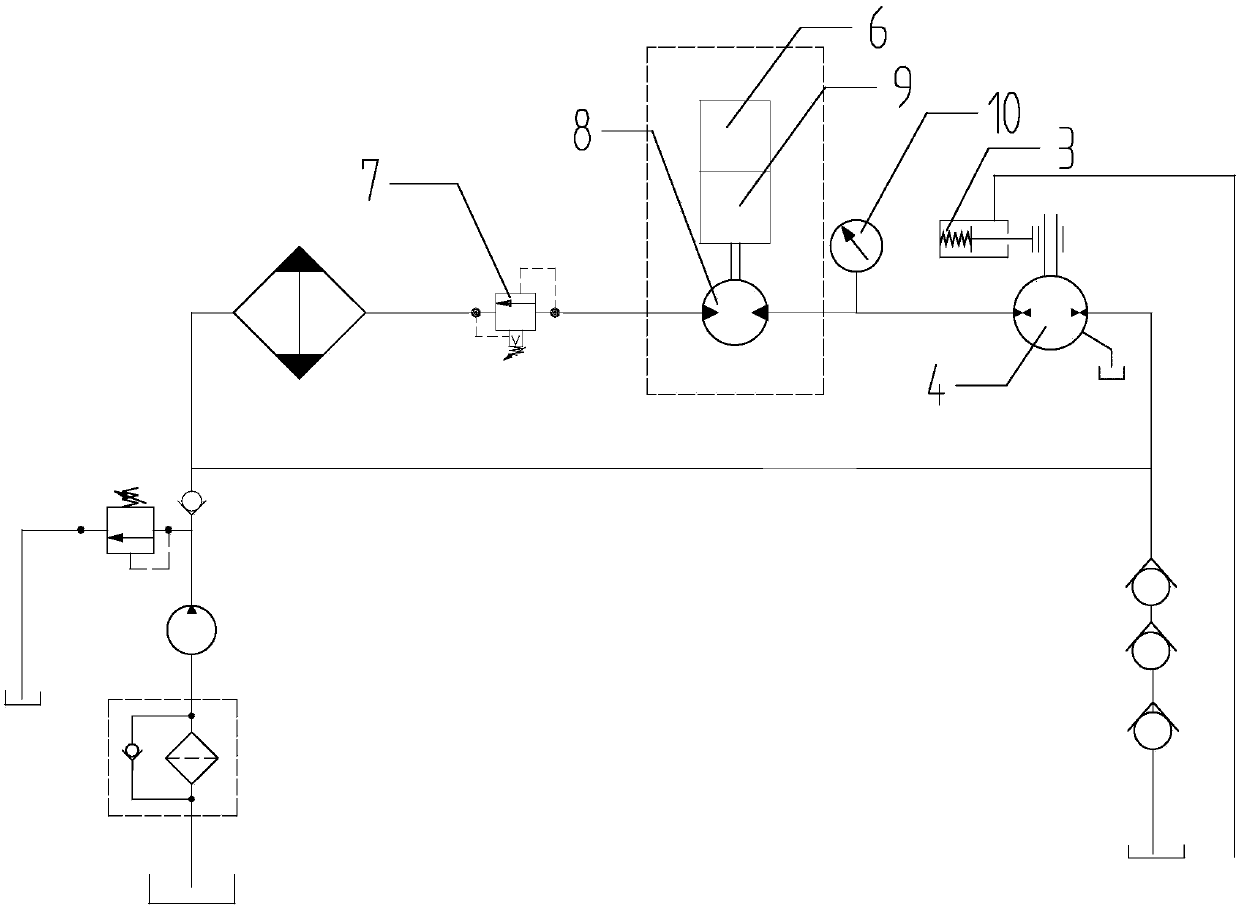

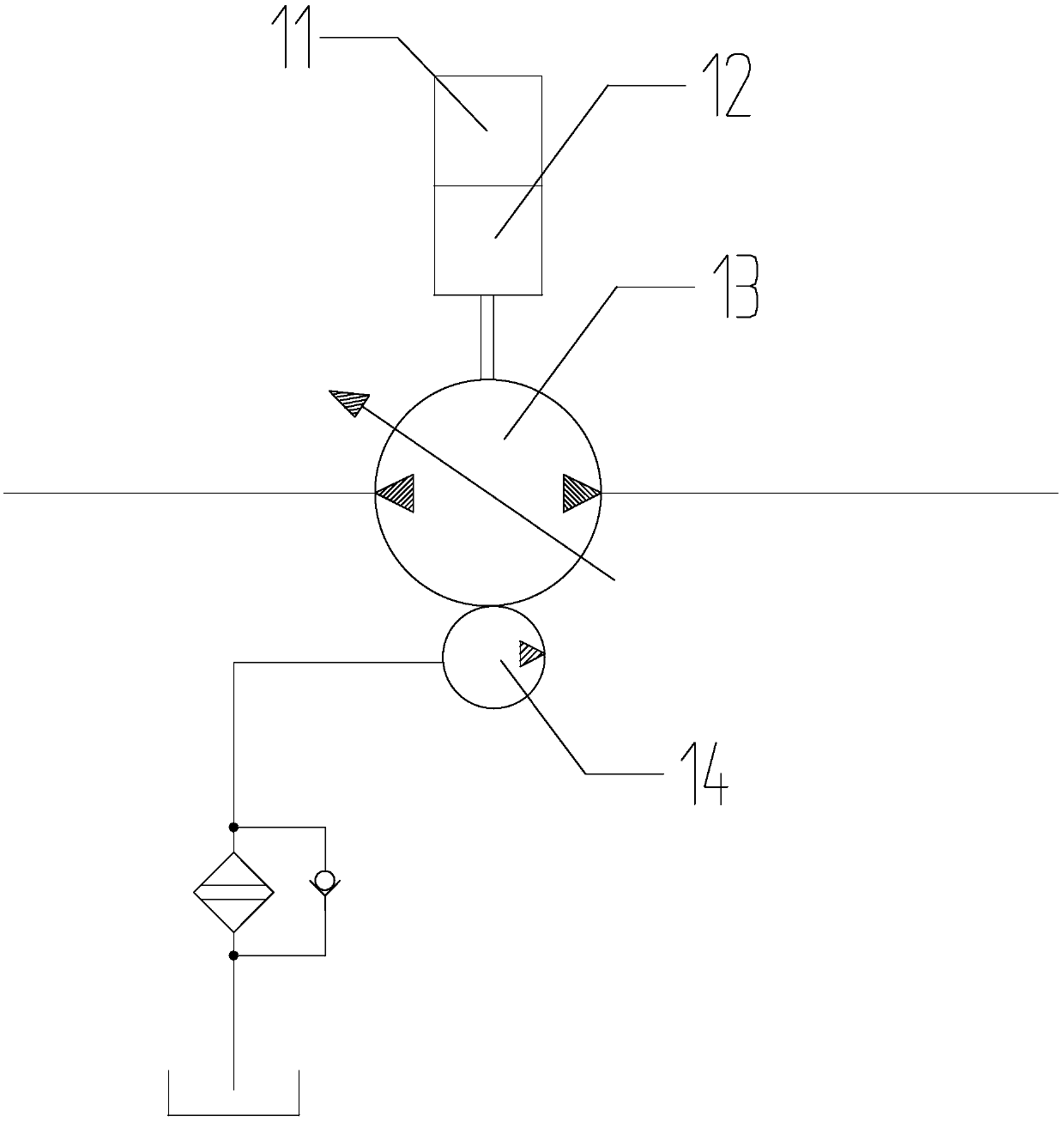

[0033] Such as figure 1 , 3 As shown in 4, a new energy tension machine includes a mechanical structure part, a hydraulic system part, a control system part and a power device part. The mechanical structure part includes a tension wheel 1, a first gear box 2 connected to the tension wheel 1, and The brake 3 connected to the first gear box 2, the transfer case 5 connected to the brake 3, and the generator 6 connected to the transfer case 5; the hydraulic system part includes a hydraulic circuit, a tension regulating valve 7 arranged on the hydraulic circuit, and tension Table 10, main hydraulic motor 4, main hydraulic pump 13, main hydraulic pump charge pump 14, fan pump 16, tail car pump 17, brake charge pump 18, brake 3 connected to main hydraulic motor 4, fan pump 16 and tail car pump 17 is connected, the tail car pump 17 is connected to the brake charge pump 18, the main hydraulic pump 13 is connected to the main hydraulic pump charge pump 14, and it also includes the part co...

example 2

[0046] The difference from the first example above is that the generator 6 is arranged in the mechanical structure part, and a speed increasing mechanism is arranged at the large gear of the tension wheel 1, and the generator 6 is connected to the speed increasing mechanism. The generator 6 is connected through the speed increasing mechanism, which can realize the acceleration on the generator 6 side and improve the power generation effect.

example 3

[0048] Such as figure 2 As shown, the difference from the above example 1 is that the generator 6 is installed in the hydraulic system, and the hydraulic circuit between the tension adjustment valve 7 and the tension meter 10 is equipped with a hydraulic drive motor 8 that drives the generator 6 to generate electricity. The machine 6 is connected to a hydraulic drive motor 8 through a second gear box 9. The generator 6 is connected to the hydraulic drive motor 8 through the second gear box 9 to achieve drive power generation under passive working conditions. The second gear box 9 can effectively increase the speed and improve the power generation effect.

[0049] the above Figure 1-4 The shown new energy tension machine and its working method are specific embodiments of the present invention, which have already embodied the essential features and progress of the present invention, and can be shaped according to actual needs and under the enlightenment of the present invention. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com