Detecting method for miniature roll balls

A detection method and miniature technology, which can be used in measurement devices, material analysis by optical means, instruments, etc., can solve the problems of easy loss of placement and transfer, and achieve the effect of accurate observation, saving work energy and improving detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention relates to a detection method of a miniature rolling ball.

[0019] First, make sure that the maximum diameter of the micro ball to be tested is set to D=3.969mm.

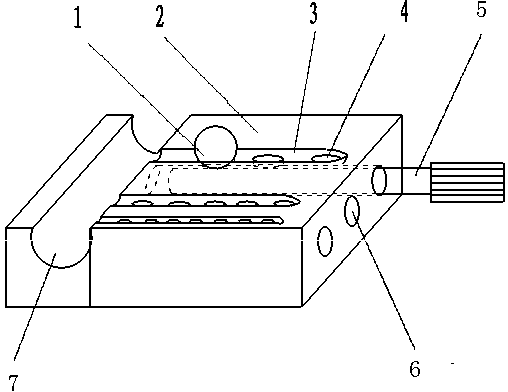

[0020] The detection method of the present invention realizes the detection of miniature rolling balls to be inspected with different sizes and specifications by means of a ball support plate and with the assistance of a microscope. Wherein, be provided with lower alleyway 3, put ball hole 4, turn ball hole 6 and ball delivery groove 7 on the ball holder board 2 that transparent material is made.

[0021] to combine figure 1 , the ball feeding groove 7 with an inclined angle is arranged on one end of the ball holder plate 2 and is a semicircular through groove, the maximum groove width of the semicircular through groove ≥ the maximum diameter Dmm=3.969mm of the miniature rolling ball to be checked, and Several parallel lower lanes 3 are arranged on the upper surface of the ball support plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com