Rolling mill gear box with high-low speed output

A gearbox and low-speed technology, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of occupying a large installation space and the volume of the gearbox, and achieve the effect of compact structure and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

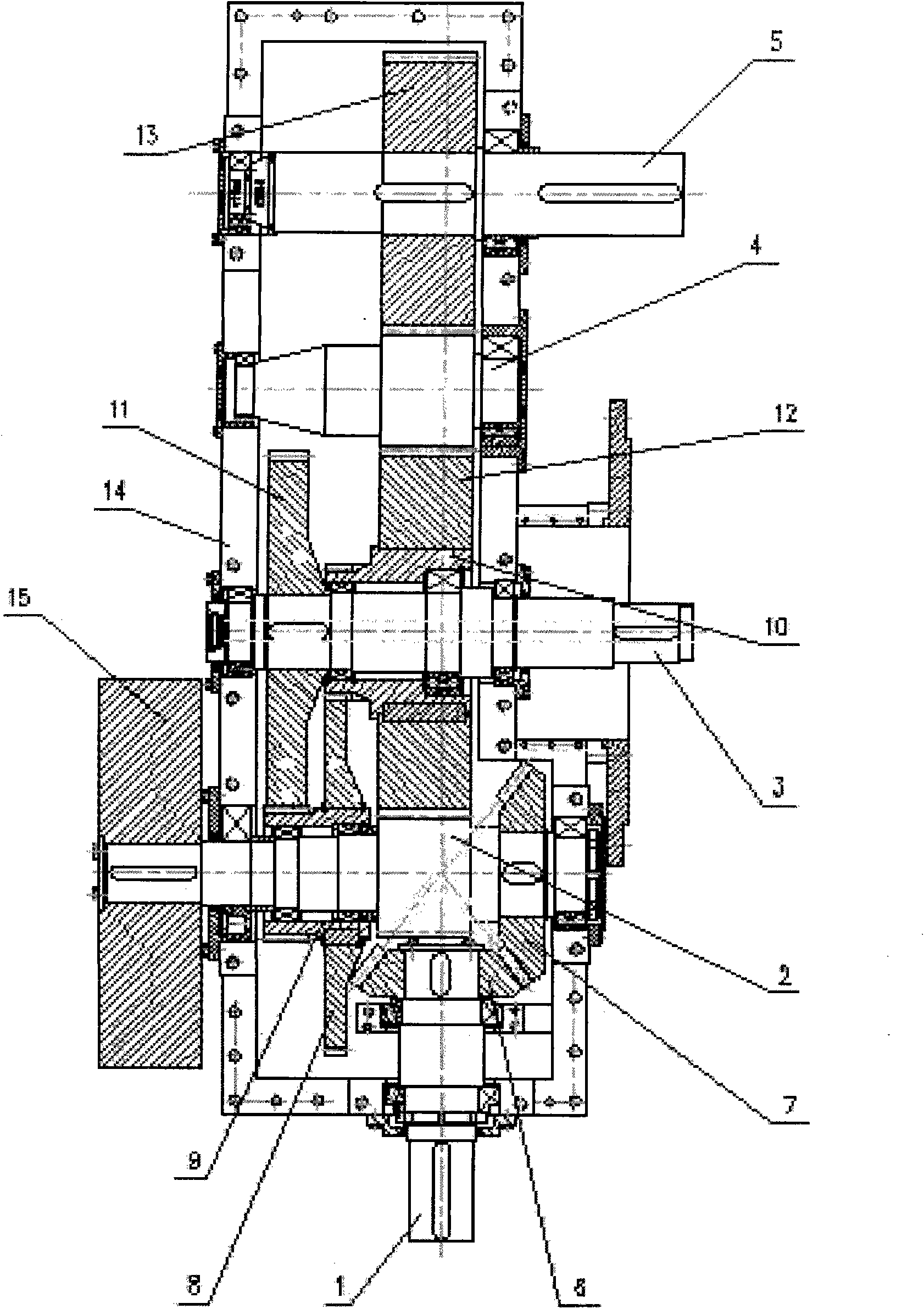

[0019] The accompanying drawings disclose the specific structures of the embodiments of the present invention without limitation, and the present invention will be further described below in conjunction with the accompanying drawings.

[0020] Depend on figure 1 It can be seen that the present invention contains the first gear shaft 2, the first output shaft 3, the second gear shaft 4, and the second output shaft 5, which are arranged in parallel and supported on the casing 14 by bearings; the input shaft 1 and the first gear shaft 2 Vertically set and supported on the box by bearings;

[0021] A large bevel gear 7 is fixedly arranged on the first gear shaft 2 by a key, and a first hollow gear shaft 9 is supported by a bearing. The large bevel gear 7 and the first hollow gear shaft 9 are respectively located in the first gear shaft 2 On both sides of the gear, the second transmission gear 8 is fixedly arranged on the first hollow gear shaft 9 through keys;

[0022] On the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com