Combined expansion mandrel

An expanding mandrel, combined technology, applied in the direction of expanding mandrels, gear teeth, belts/chains/gears, etc., can solve the problems of low positioning accuracy, only tens of microns, and high processing cost of parts, and reduce the processing cost. Cost, ensure machining accuracy, and adjust the effect of multi-purpose of one axis in a wide range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to clearly illustrate the technical characteristics of the present solution, the present invention will be further elaborated below through specific implementation modes and in conjunction with the accompanying drawings.

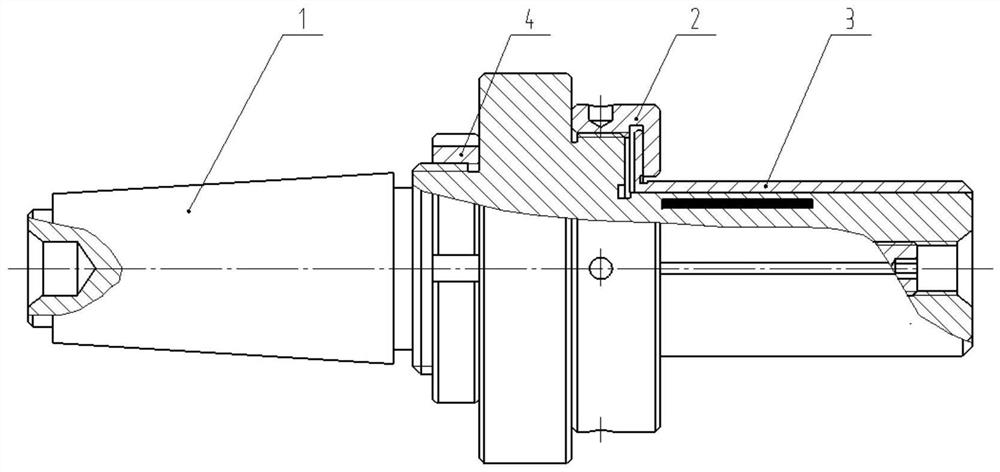

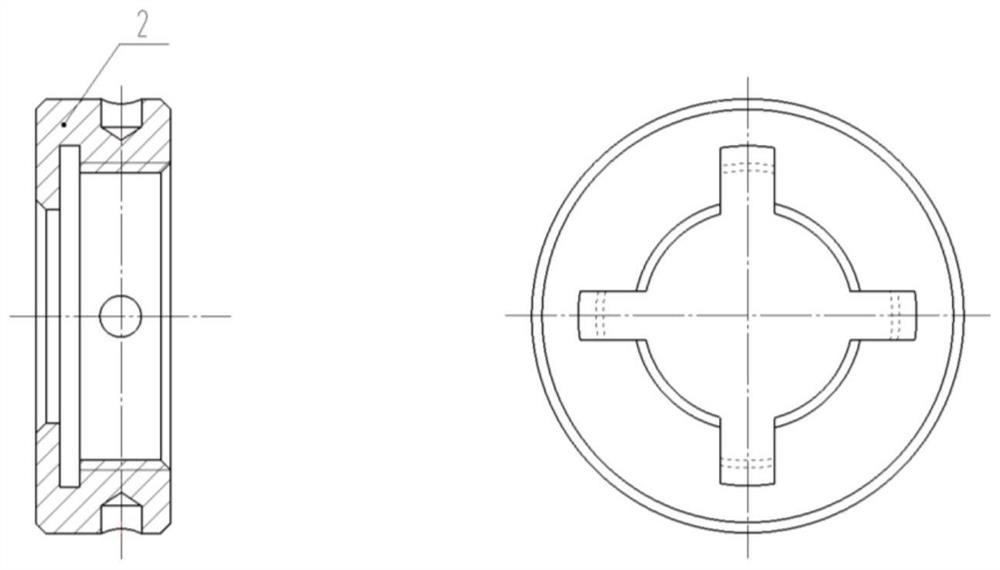

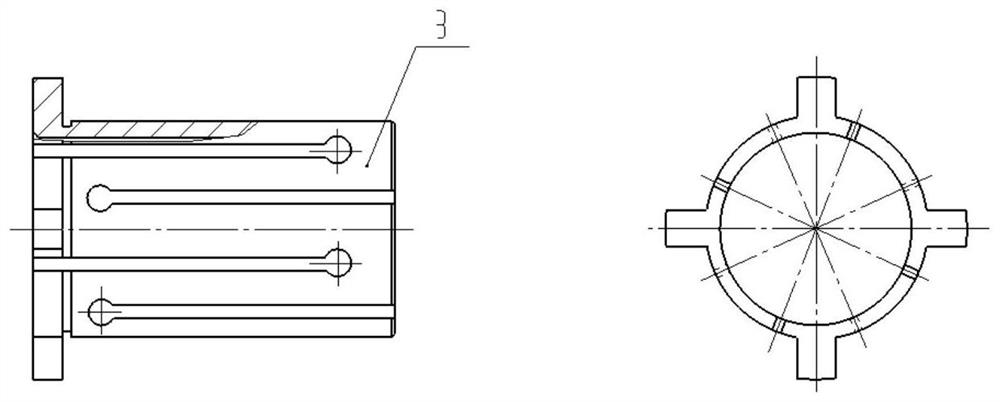

[0014] like figure 1 , figure 2 , image 3 , Figure 4 As shown, a combined expansion mandrel includes a hydraulic expansion mandrel assembly 1 , a lock nut 2 , a split spring collet 3 and a round nut 4 . The middle part of the hydraulic expansion mandrel assembly 1 is provided with a plurality of shaft shoulders, and the outer circumference of the shaft shoulders is provided with threads, which are threadedly connected with the round nut 4 and the lock nut 2 respectively. The shaft section is connected with the inner hole of the open spring collet 3 through transition fit, and the left and right end faces are provided with top holes. A plurality of radial light holes are provided on the outer circumference of the lock nut 2, an annular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com